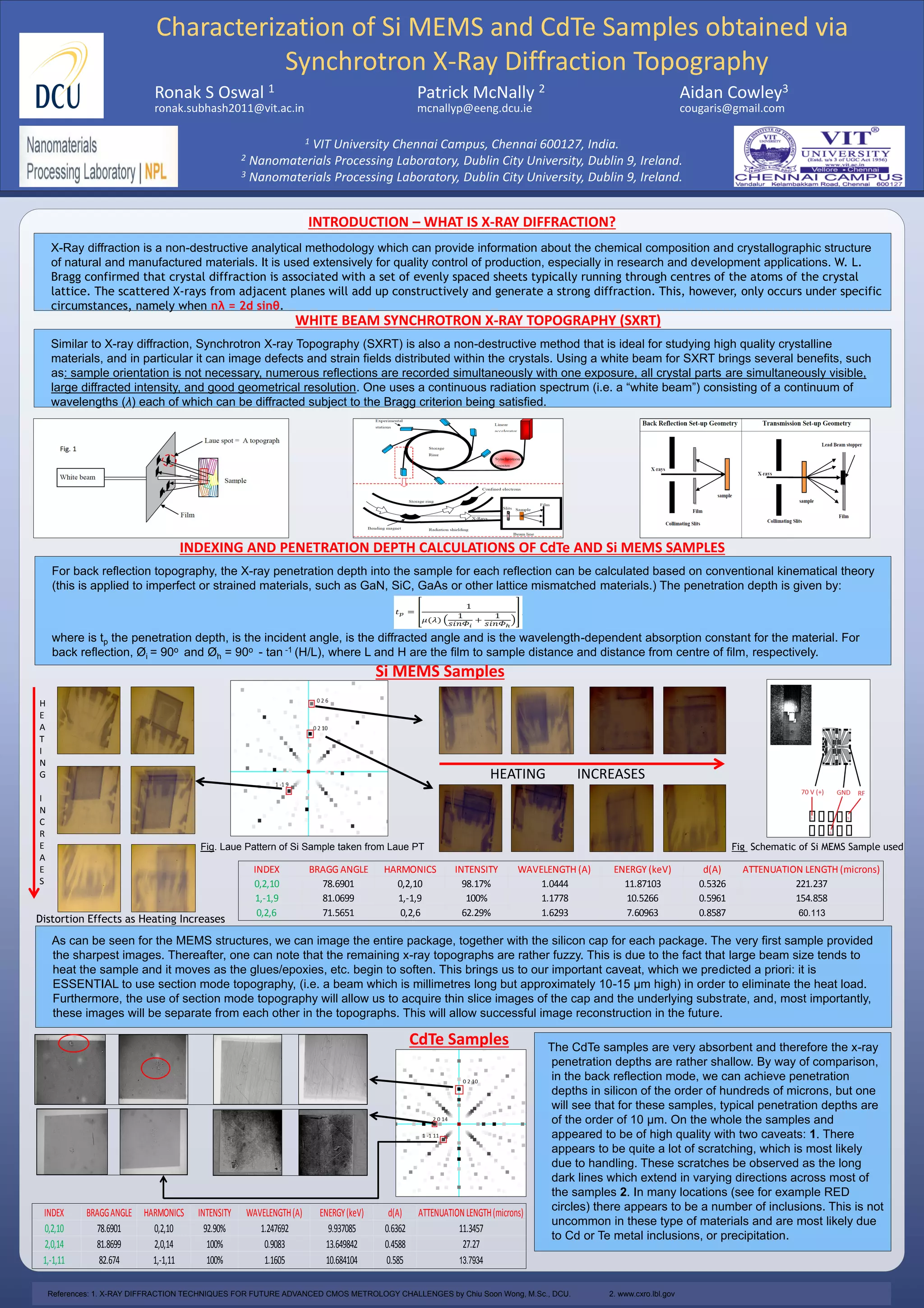

Synchrotron X-ray topography (SXRT) is a non-destructive method for studying crystalline materials like defects and strain fields within crystals. Using a white beam for SXRT provides benefits such as not requiring sample orientation, recording multiple reflections simultaneously, visualizing all crystal parts at once with good resolution. X-ray diffraction is also non-destructive and provides information on chemical composition and crystal structure of materials through Bragg's law relating wavelength and diffraction angle. Section mode SXRT imaging is essential to avoid sample heating from large beams and allow separation of cap and substrate images for future reconstruction of MEMS structures. CdTe samples showed high quality with some scratches and inclusions observed.