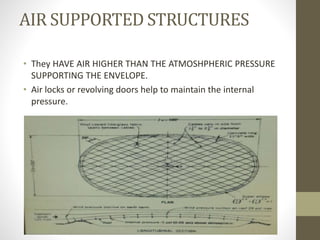

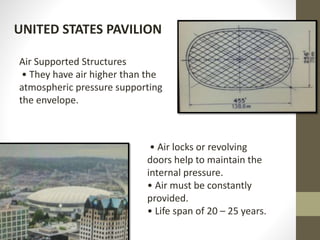

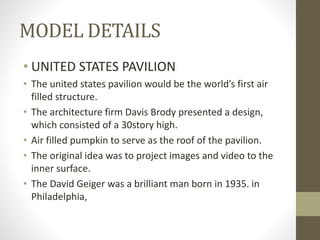

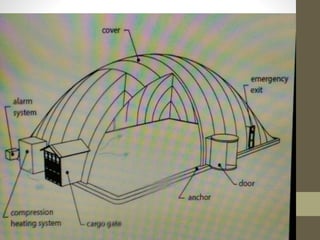

The document discusses pneumatic structures, which are buildings stabilized by compressed air pressure rather than rigid frames. It describes three main types - air supported, air inflated, and hybrid structures. It provides details on air supported structures, which have air pressure higher than atmospheric pressure to support the envelope. An example is given of the United States Pavilion at Expo 67, which had a 30-story high air-filled "pumpkin" serving as the roof. The document outlines some history of pneumatic structures and discusses construction materials, advantages like lower costs, and disadvantages like needing continuous fan operation.

![Advantages:

• Can be engineered to attach to a pre-existing structure[5]

• Considerably lower initial cost than conventional buildings

• Lower operating costs due to simplicity of design (wholly air-

supported structures only)

• Easy and quick to set up, dismantle, and relocate (wholly air-

supported structures only)[6]

• Unobstructed open interior space, since there is no need for

columns

• Able to cover almost any project

• Custom fabric colors and sizes, including translucent fabric, allowing

natural sunlight in](https://image.slidesharecdn.com/pneumaticstructures1-180830084219/85/Pneumatic-structures-1-10-320.jpg)