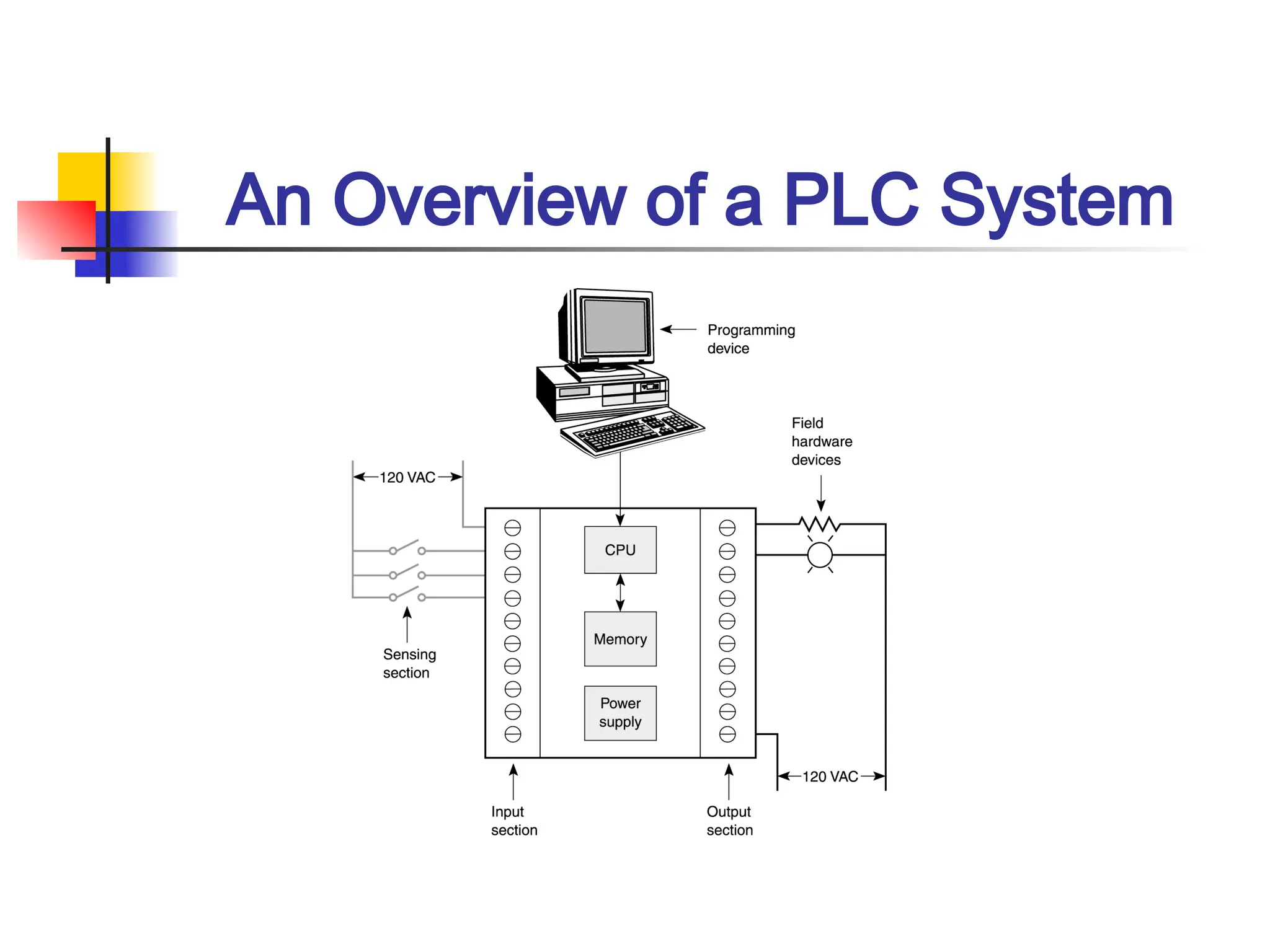

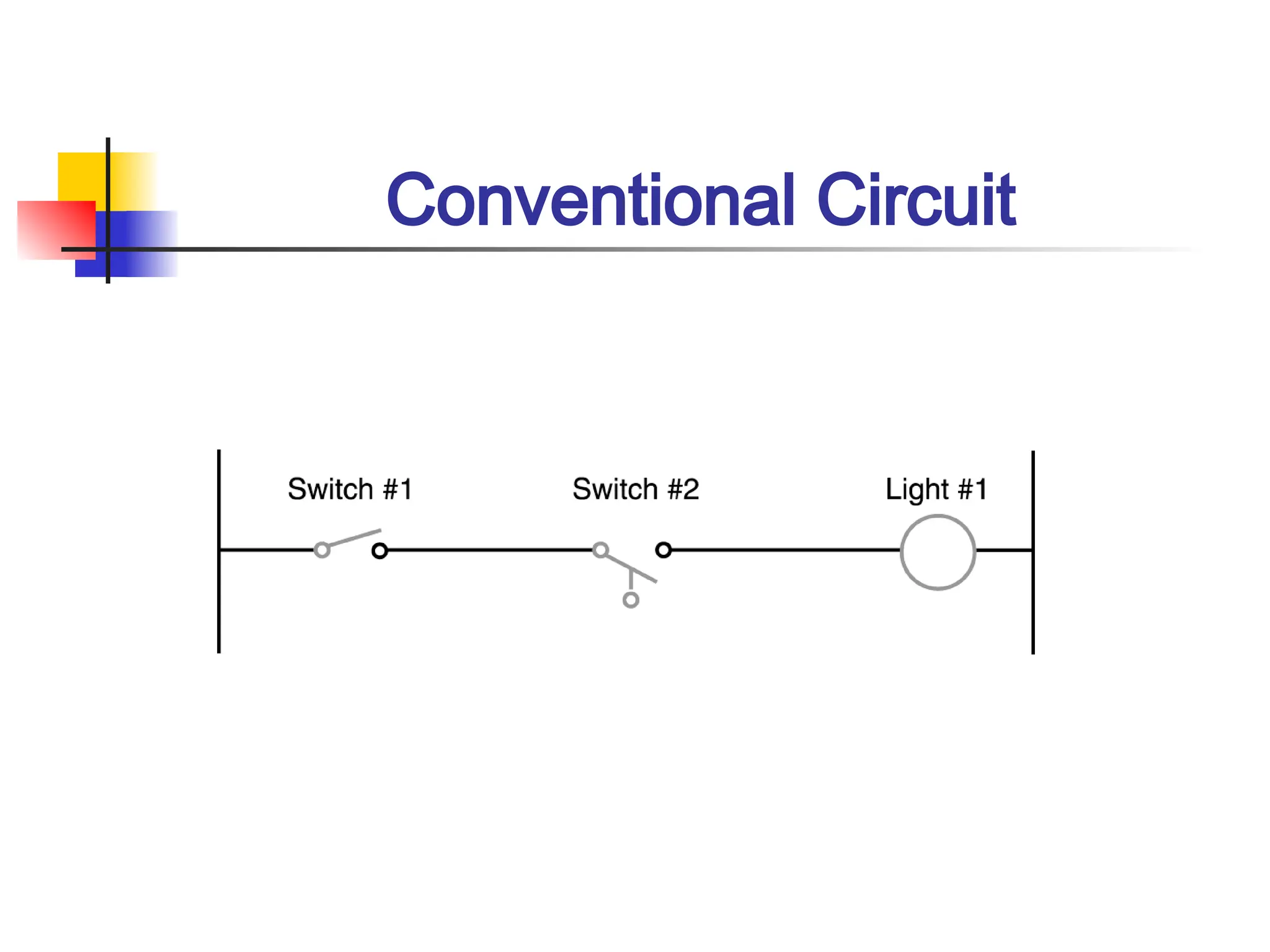

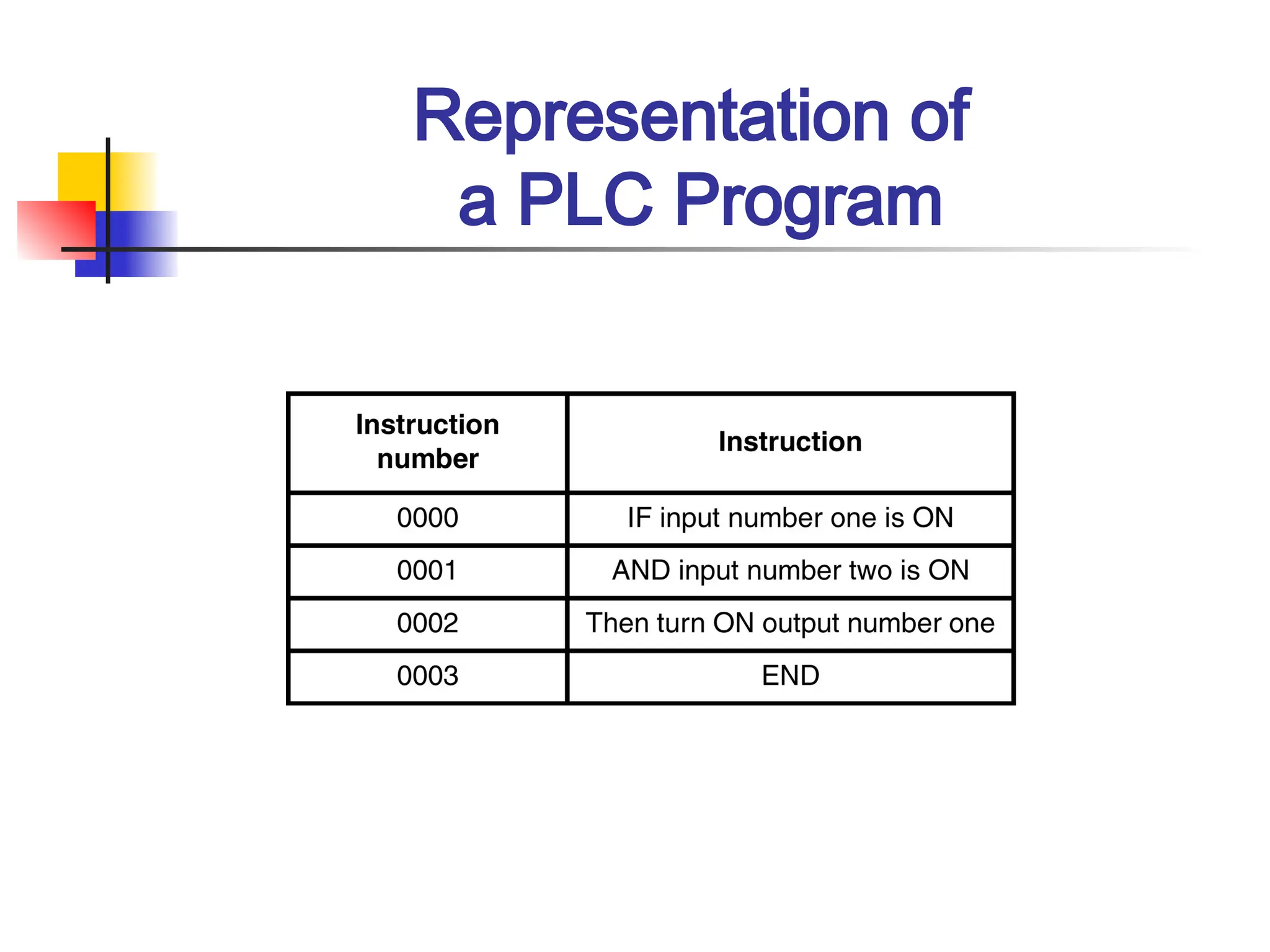

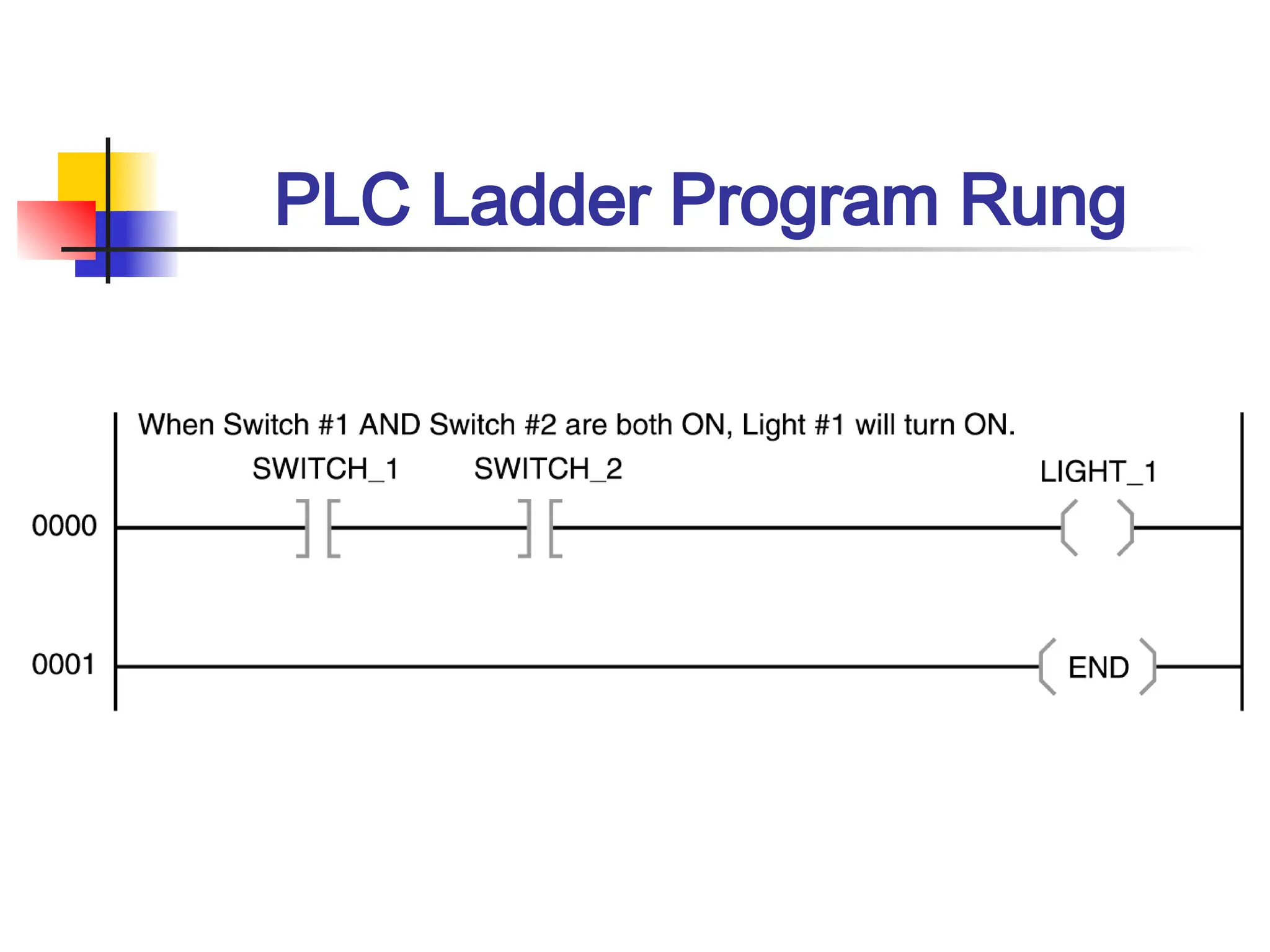

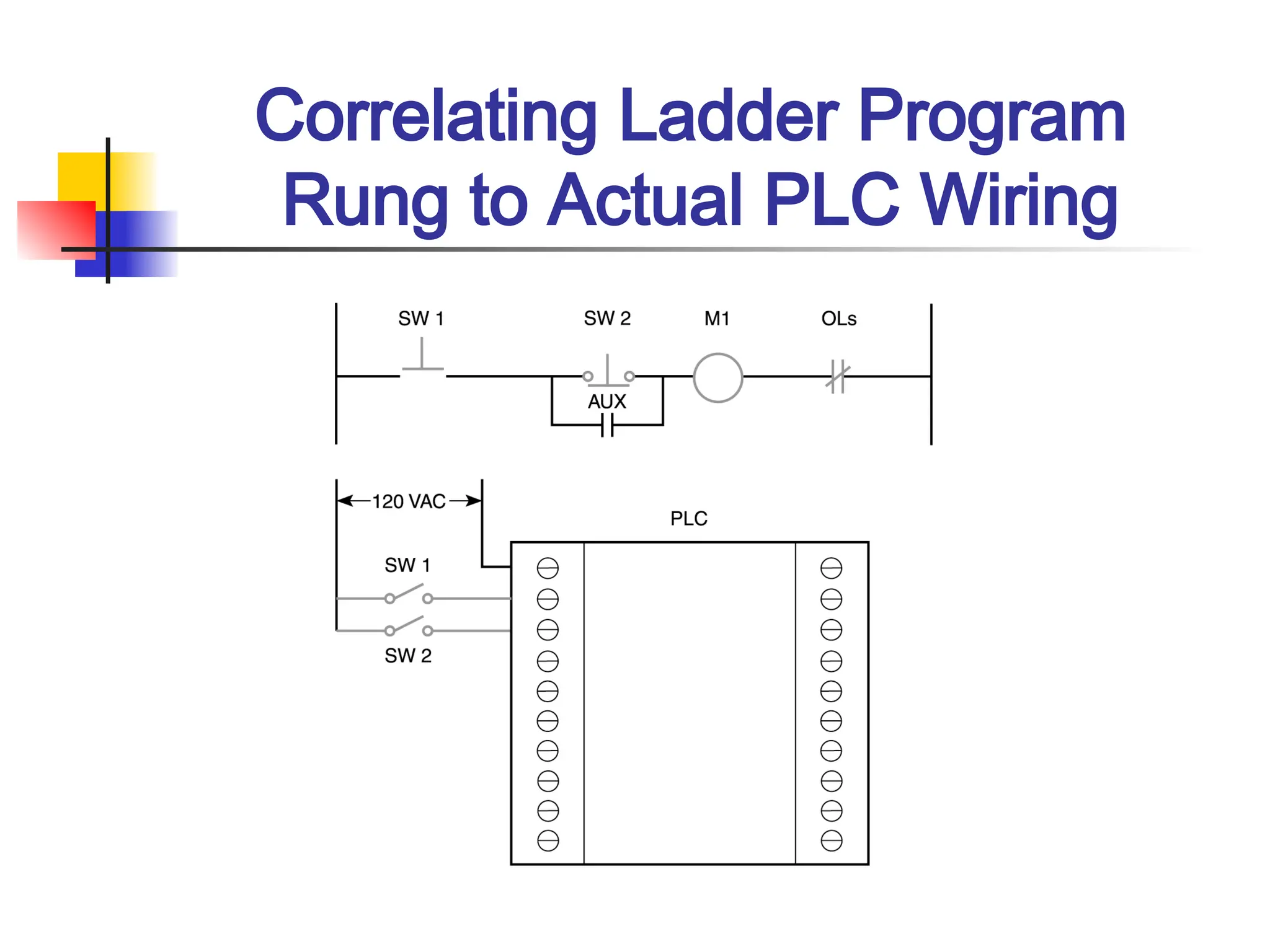

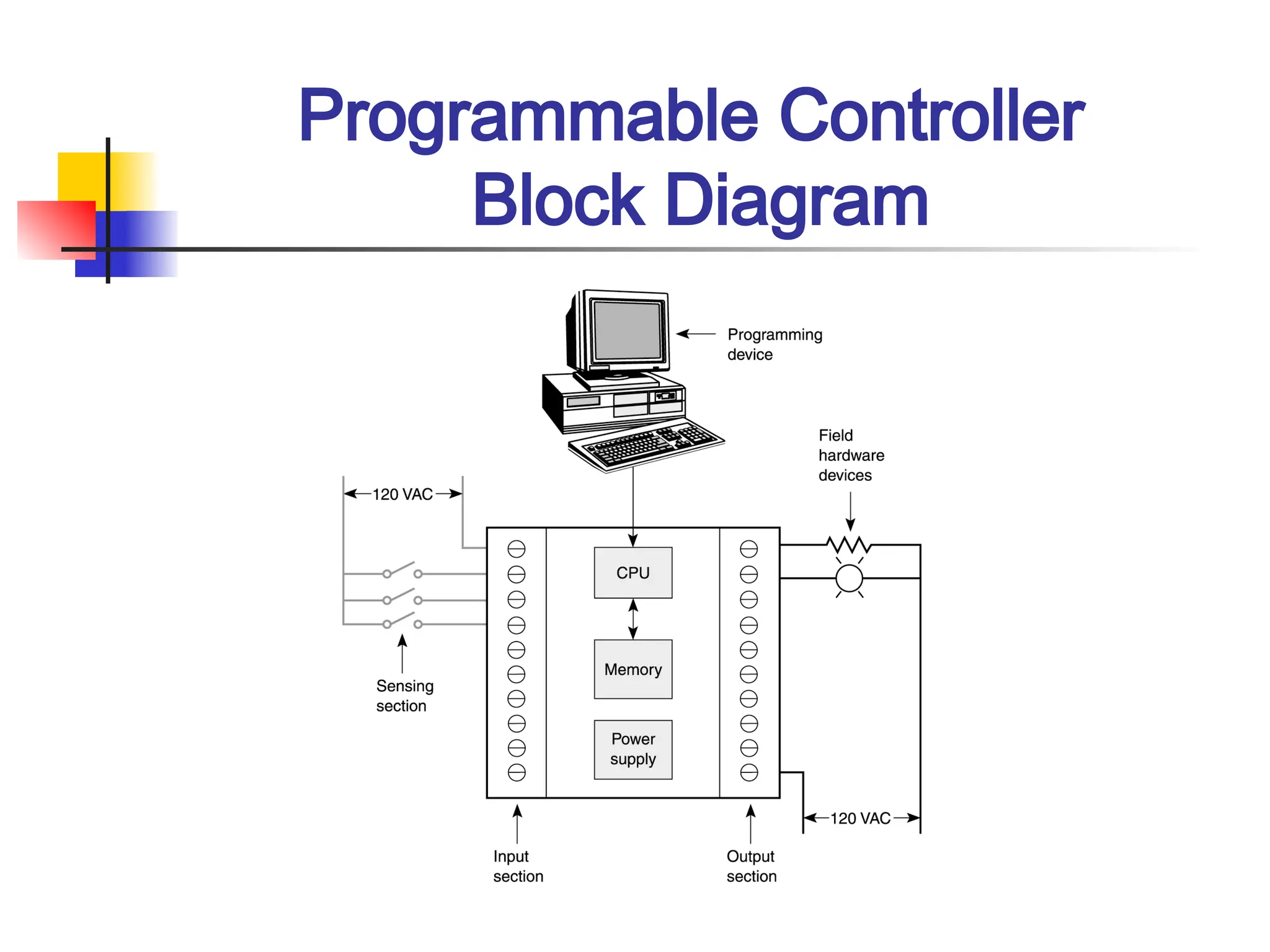

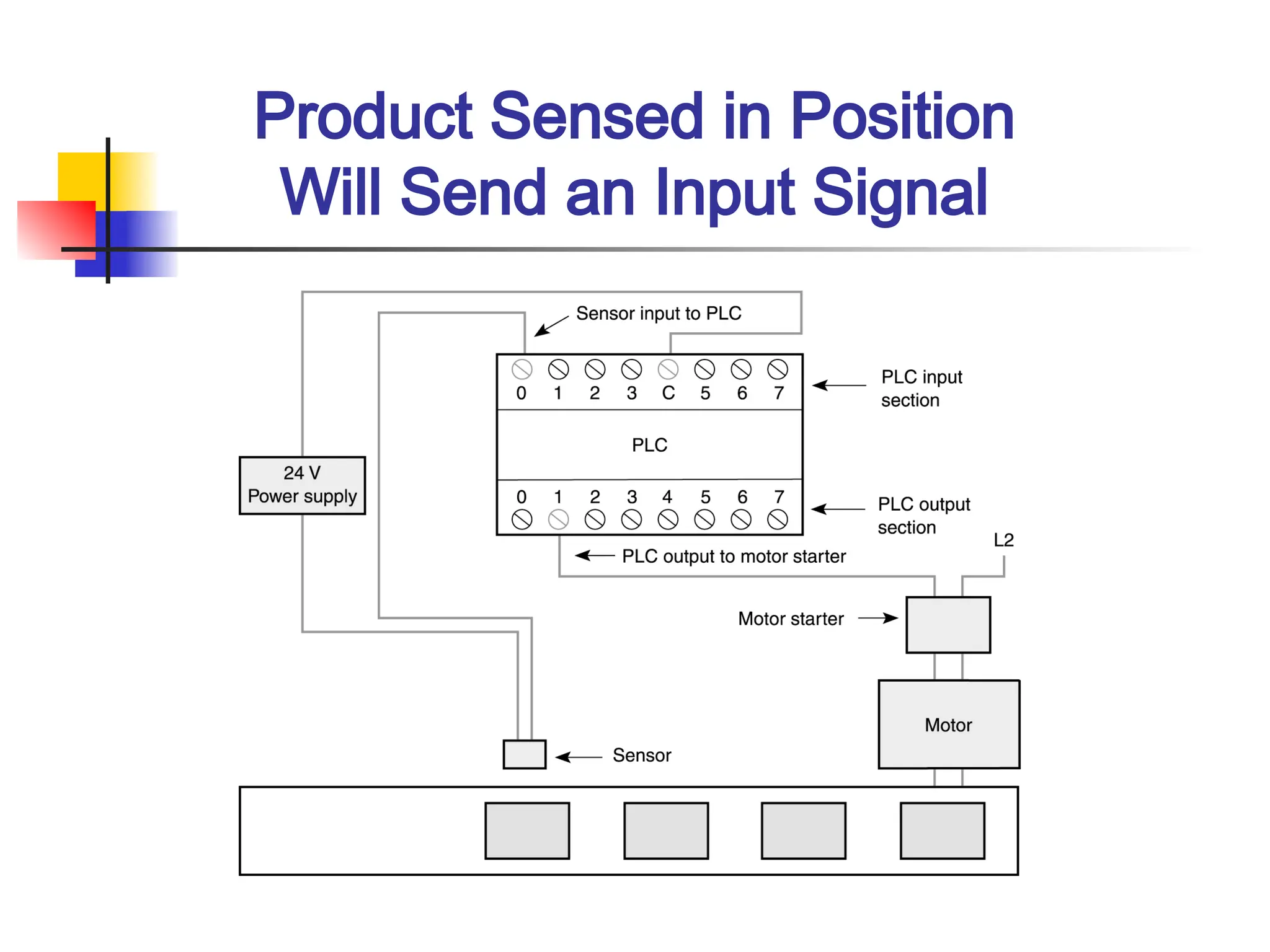

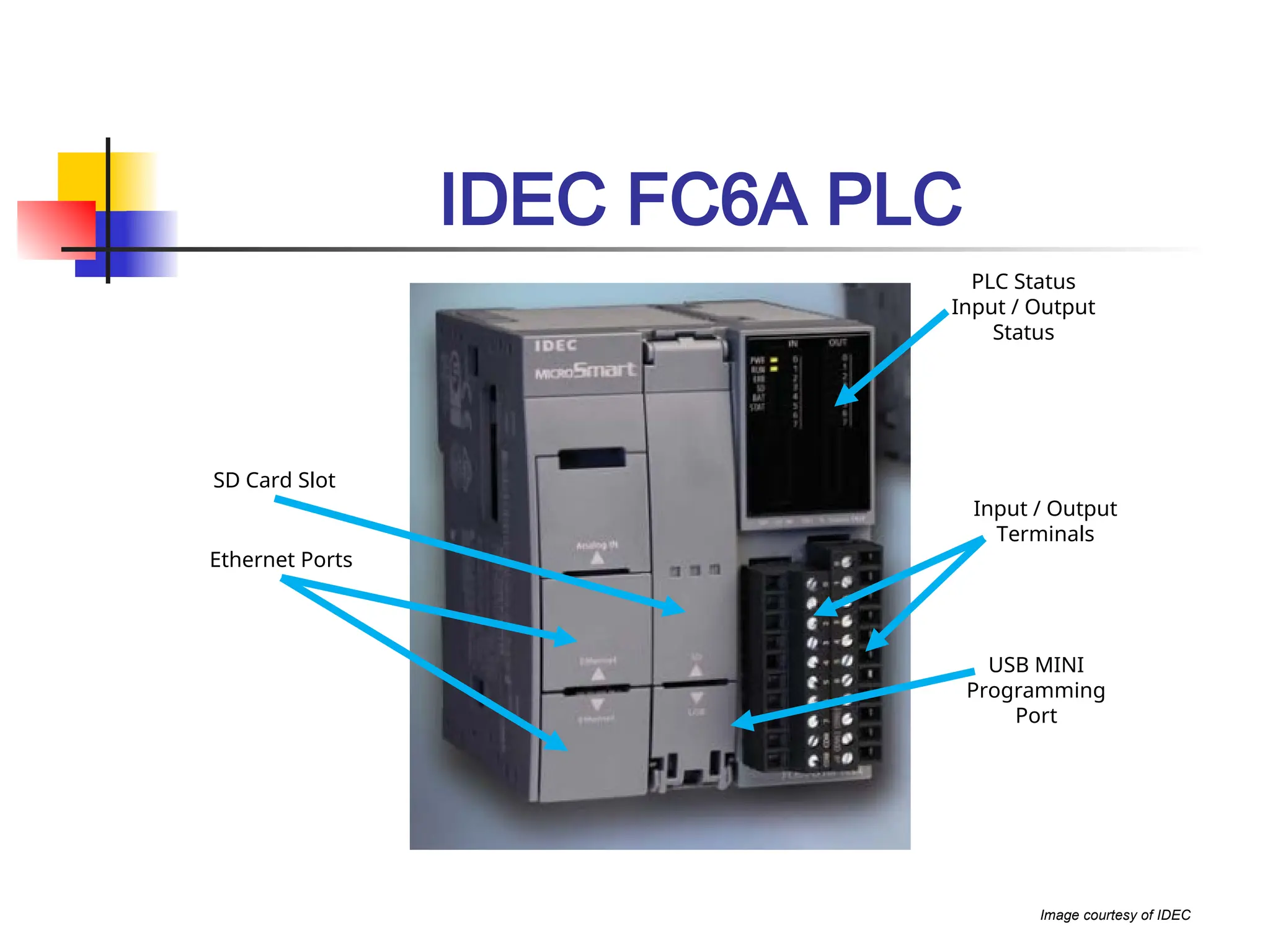

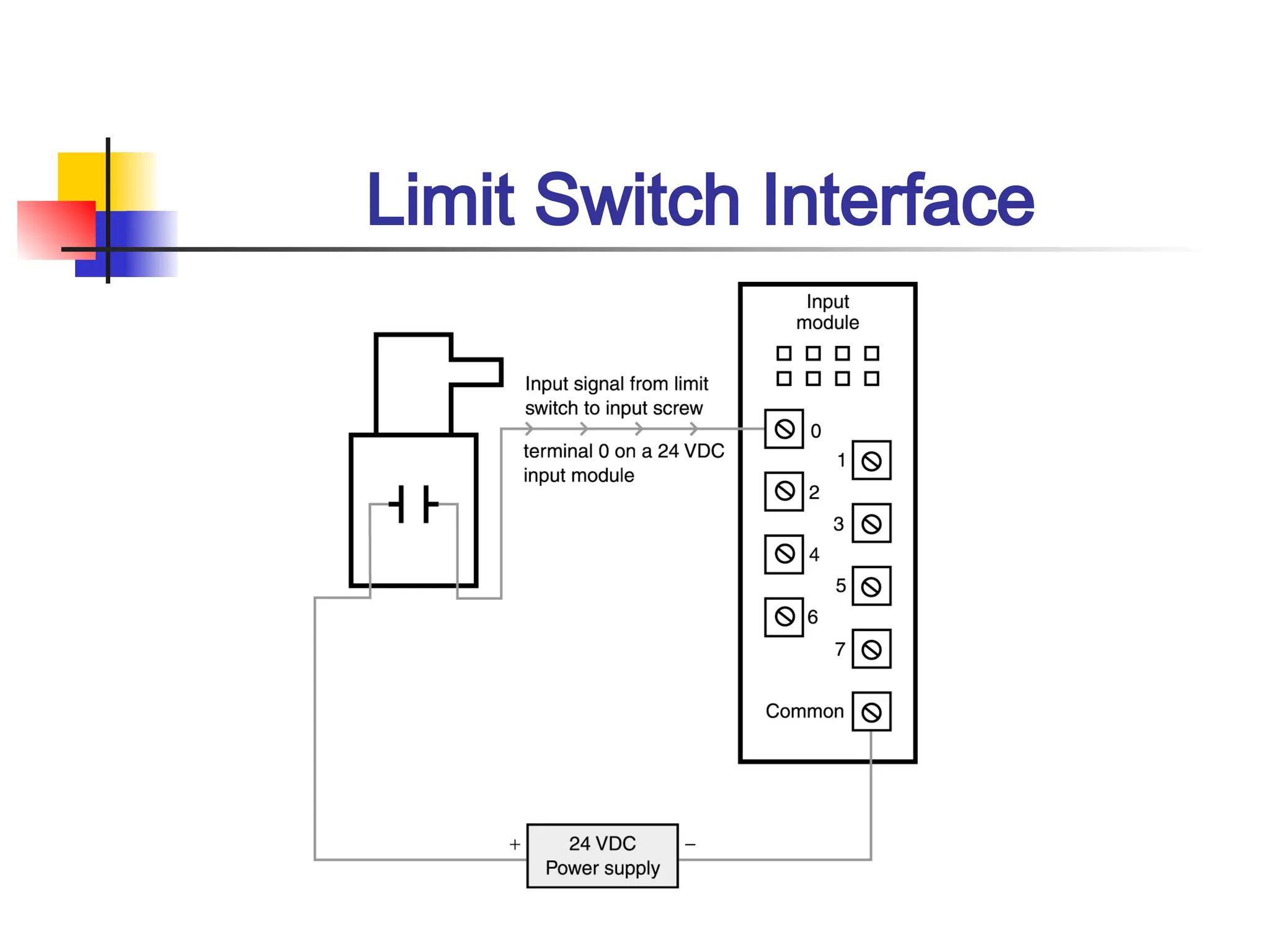

This document provides an introduction to programmable logic controllers (PLCs), outlining their definition, origin, and benefits, including ease of programming, reliability, and cost-effectiveness in automation. It details the transition from traditional electromechanical devices to PLCs in the 1960s, highlighting their significance in improving manufacturing processes and productivity. The document also explains how PLCs work, the role of microprocessors, and the types of inputs used in PLC systems.