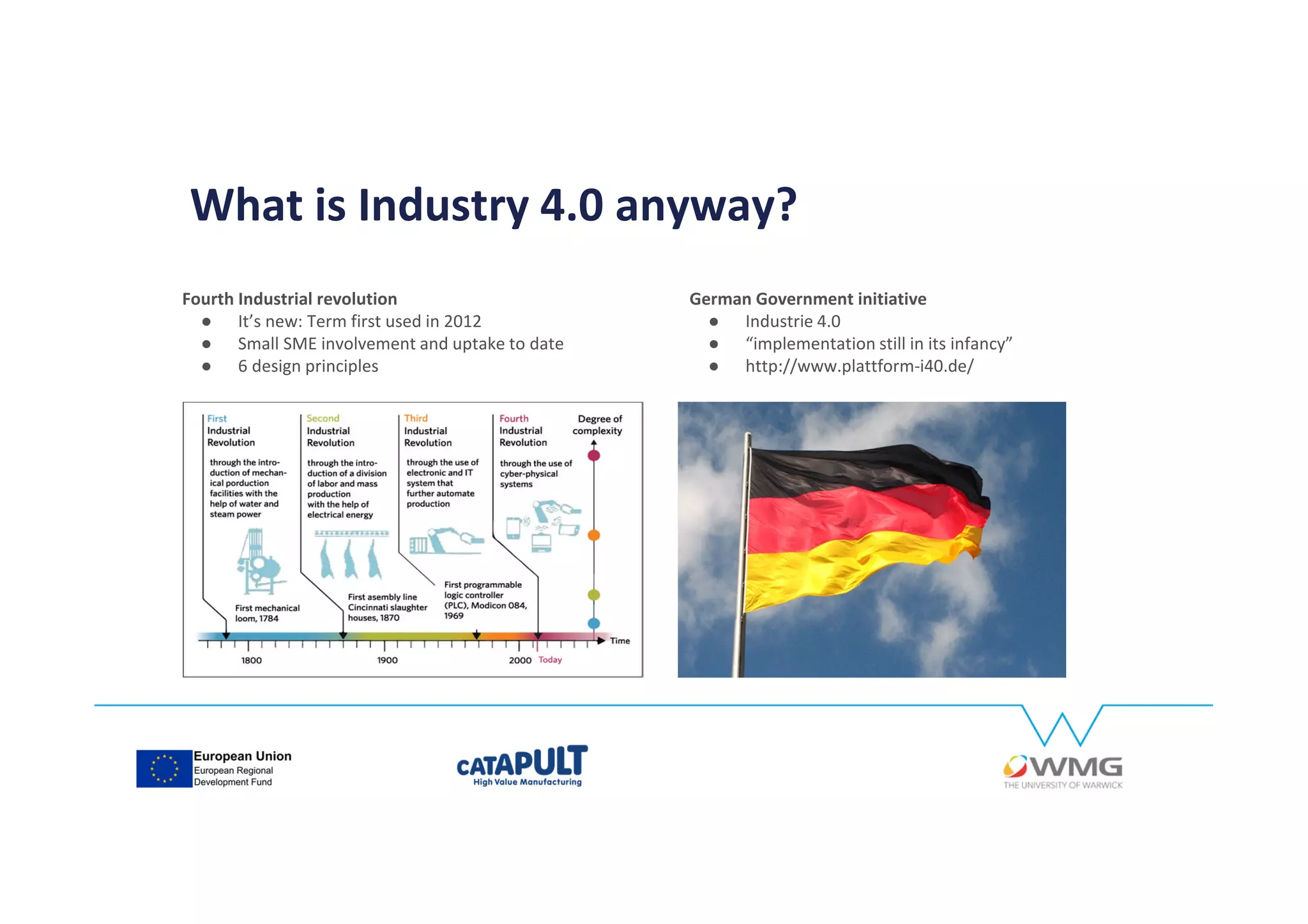

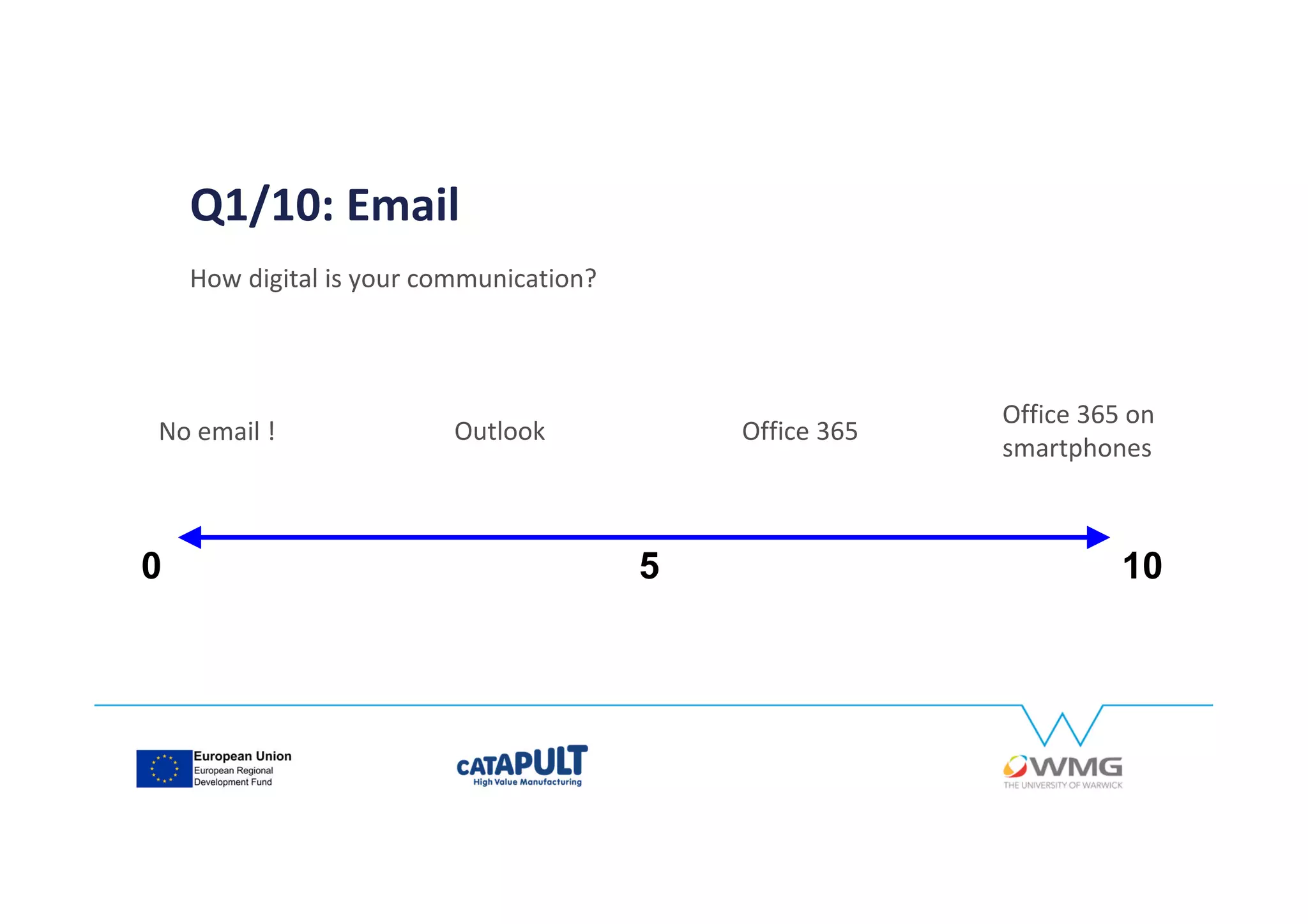

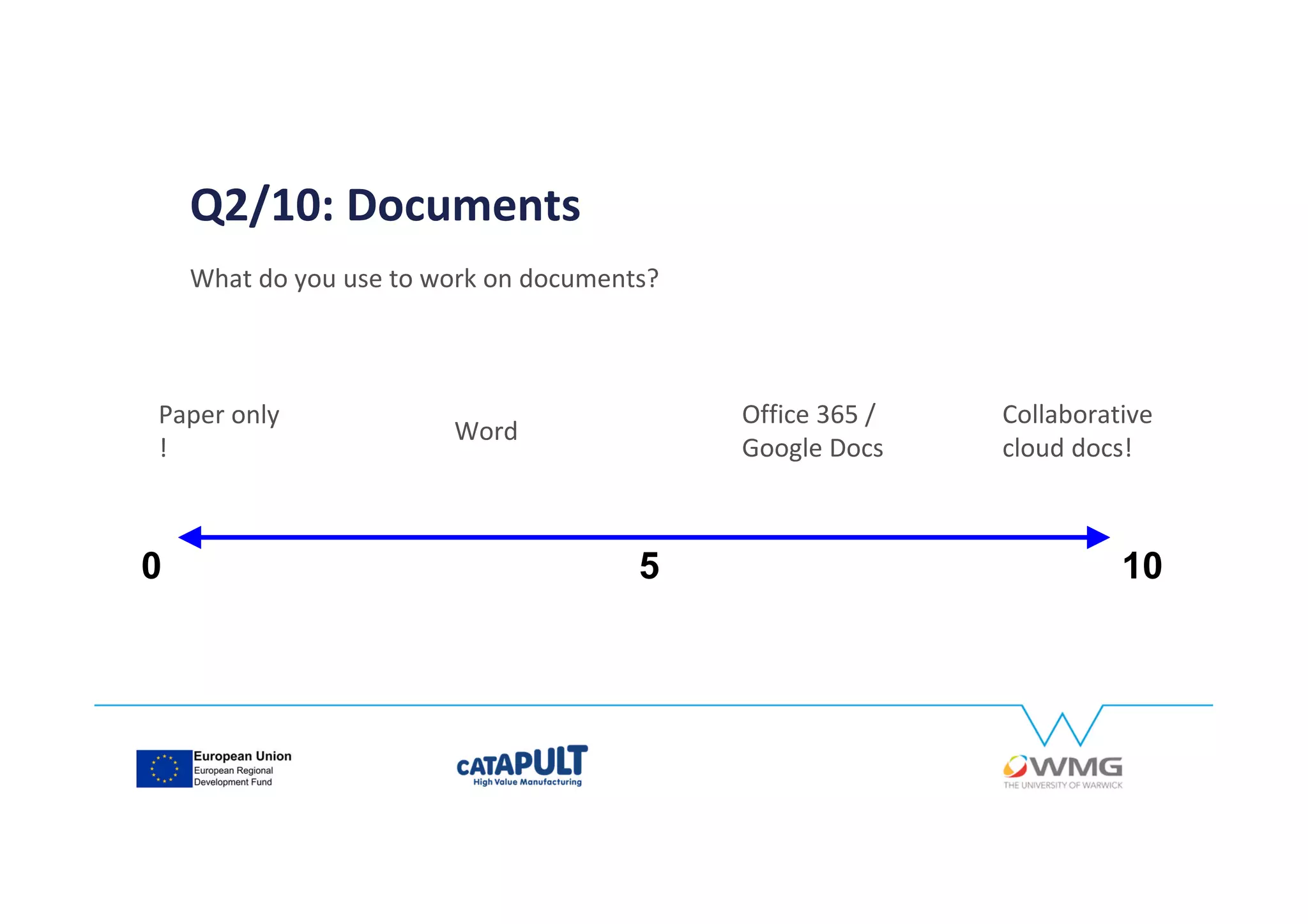

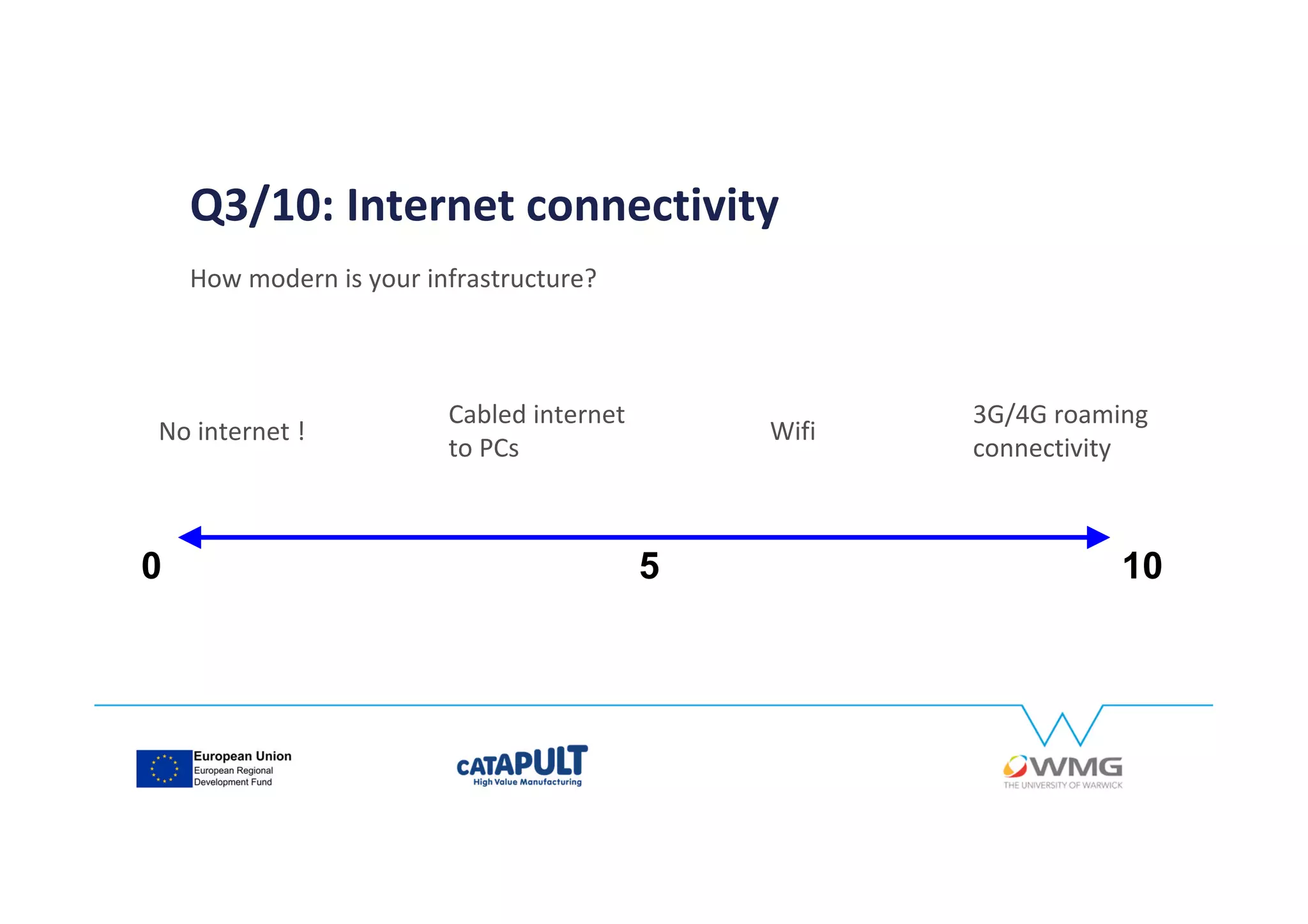

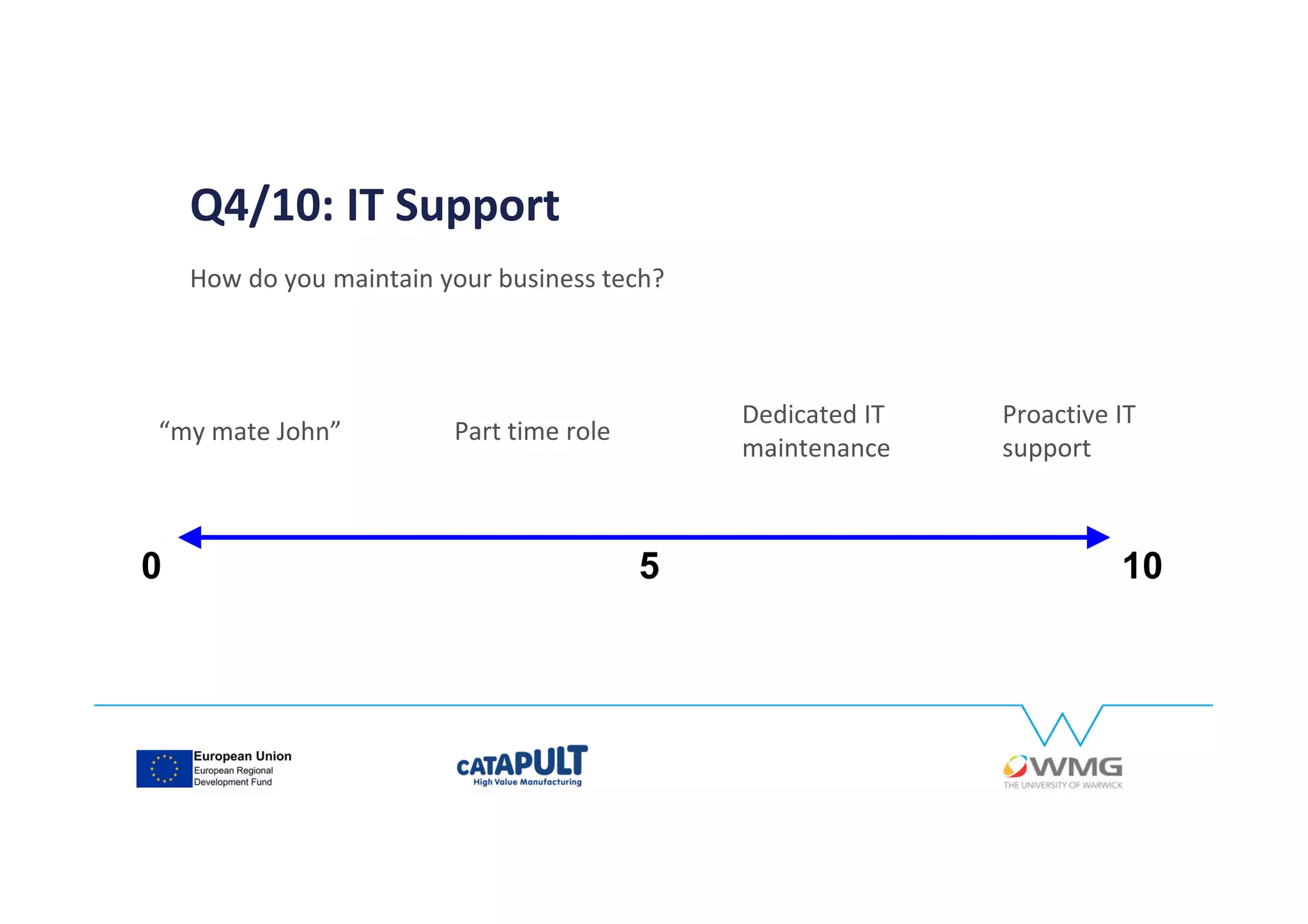

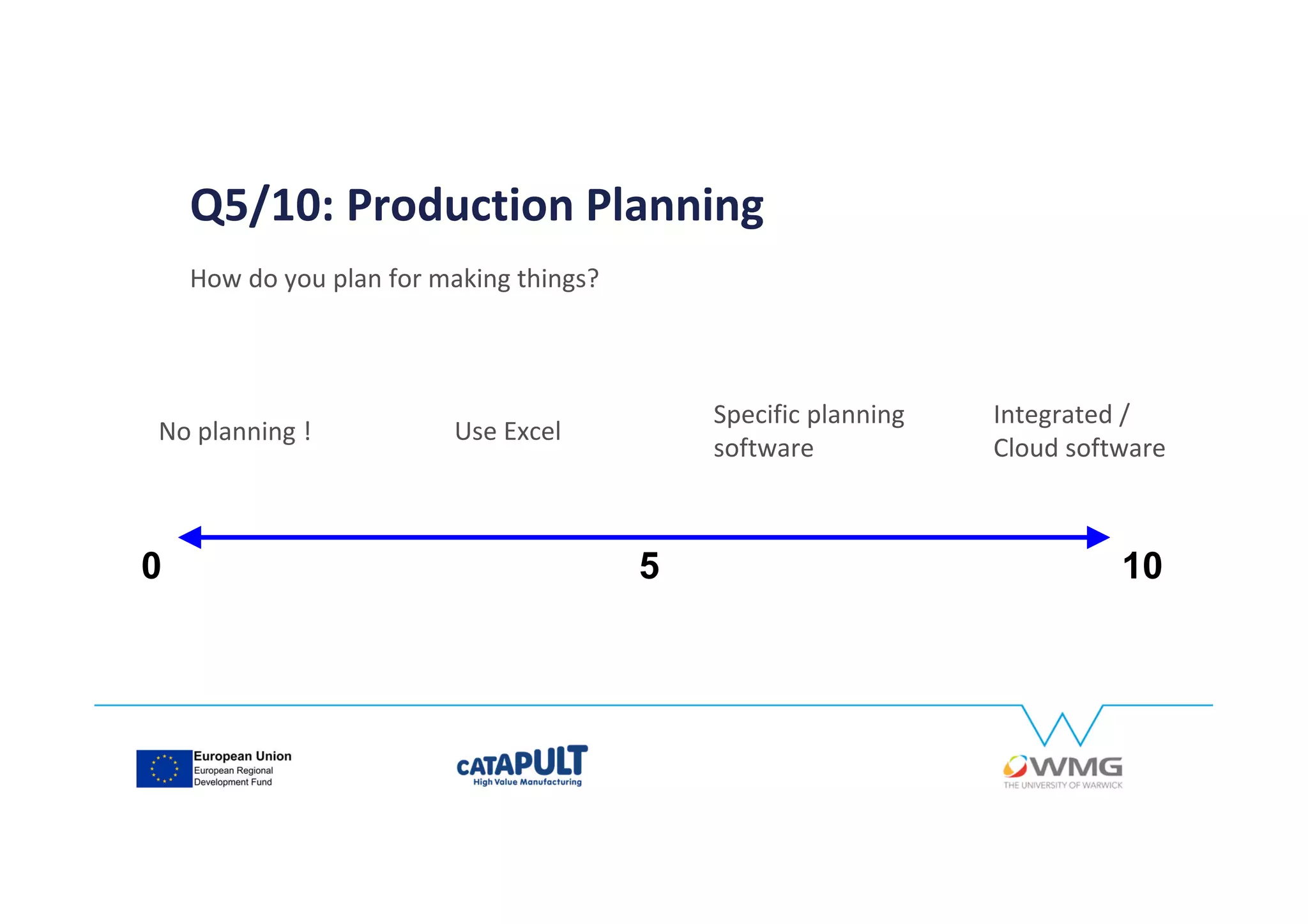

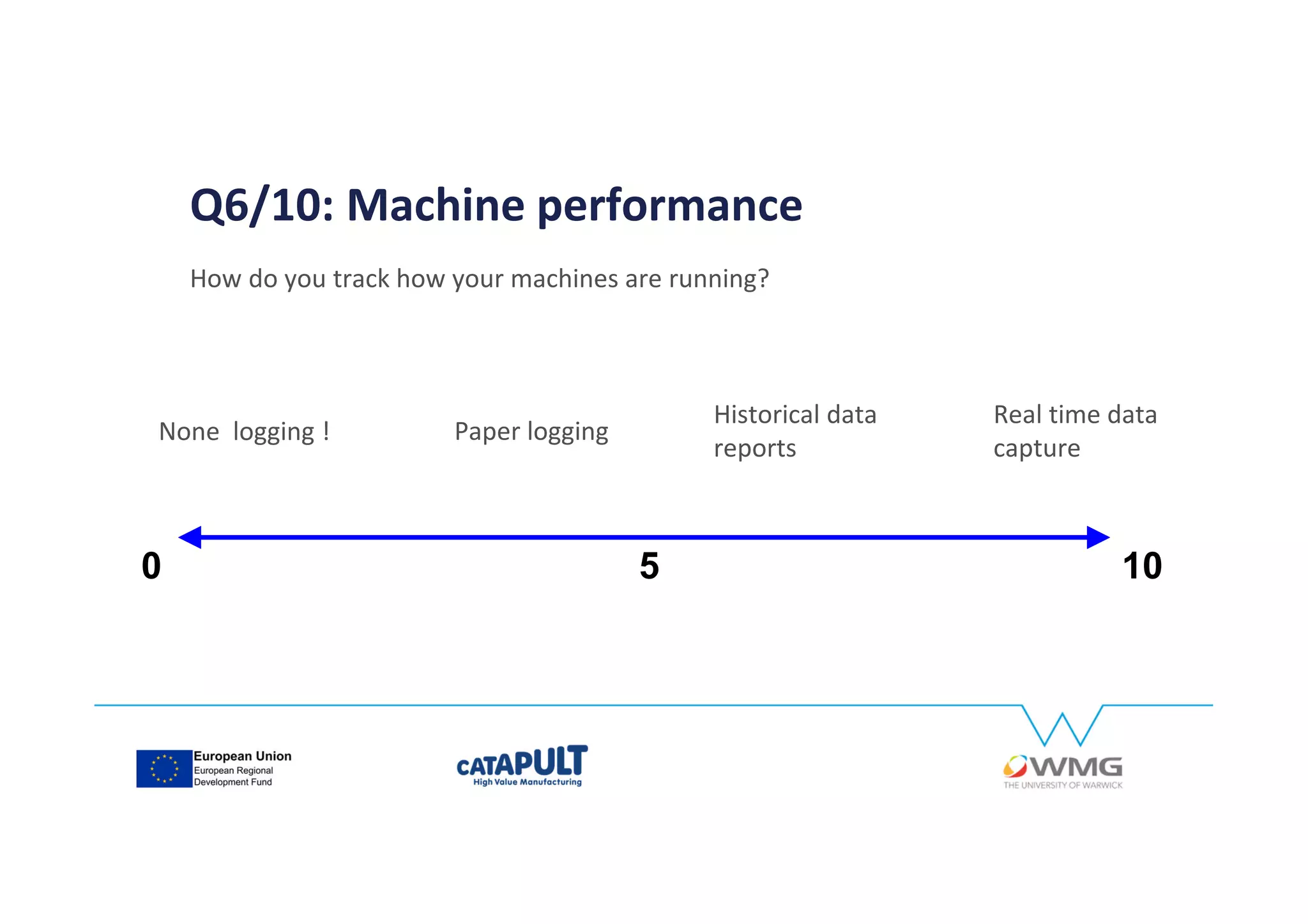

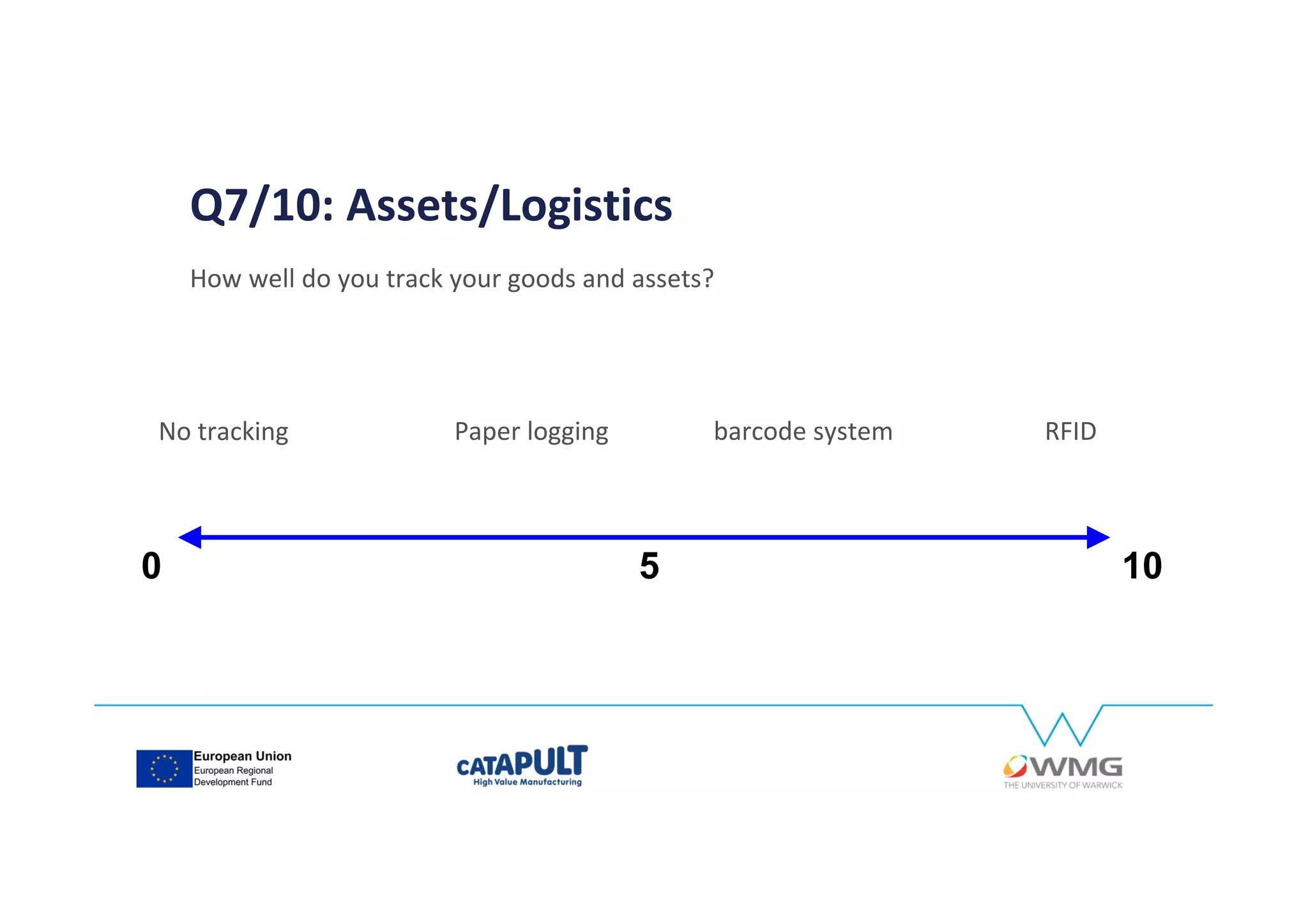

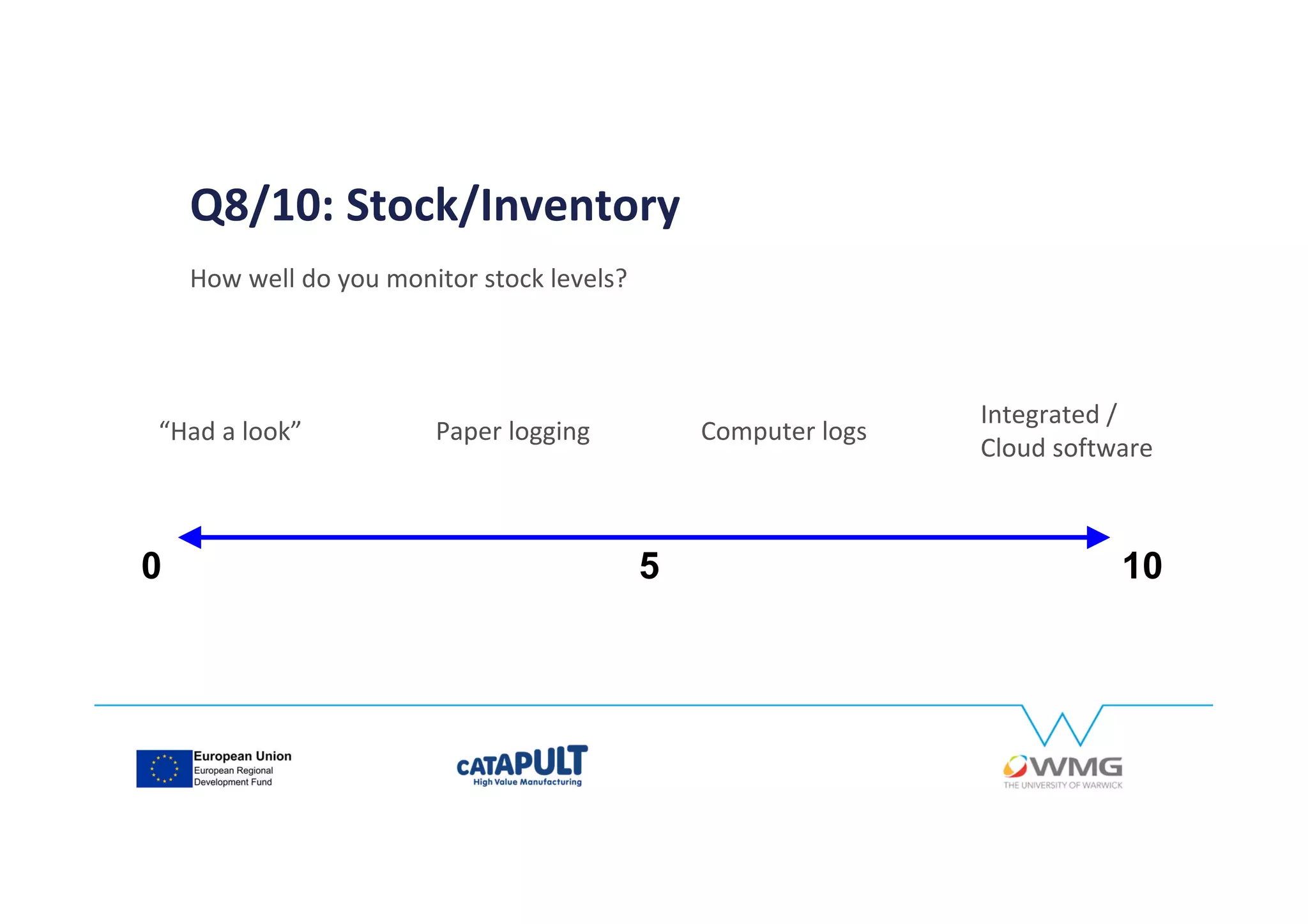

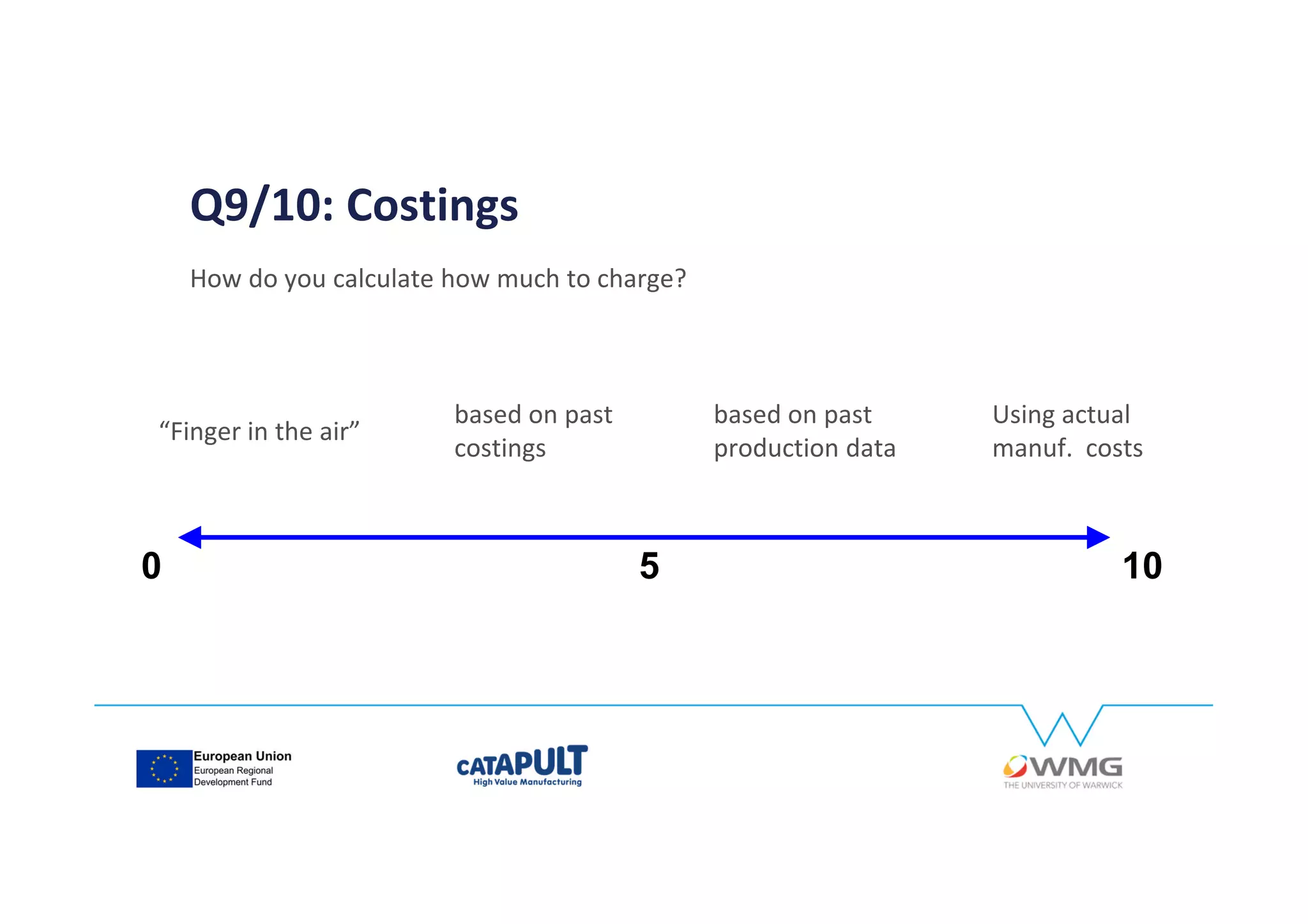

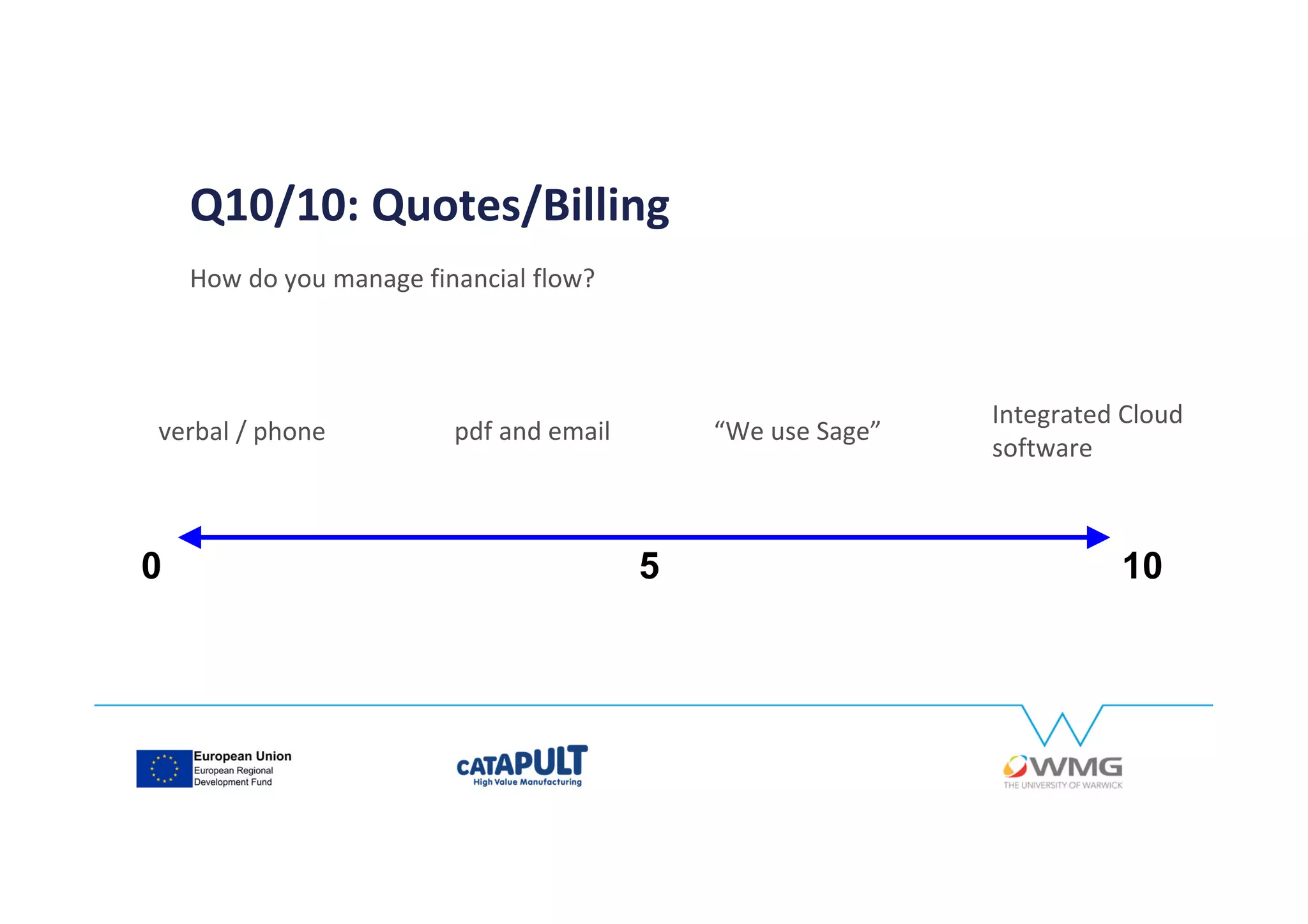

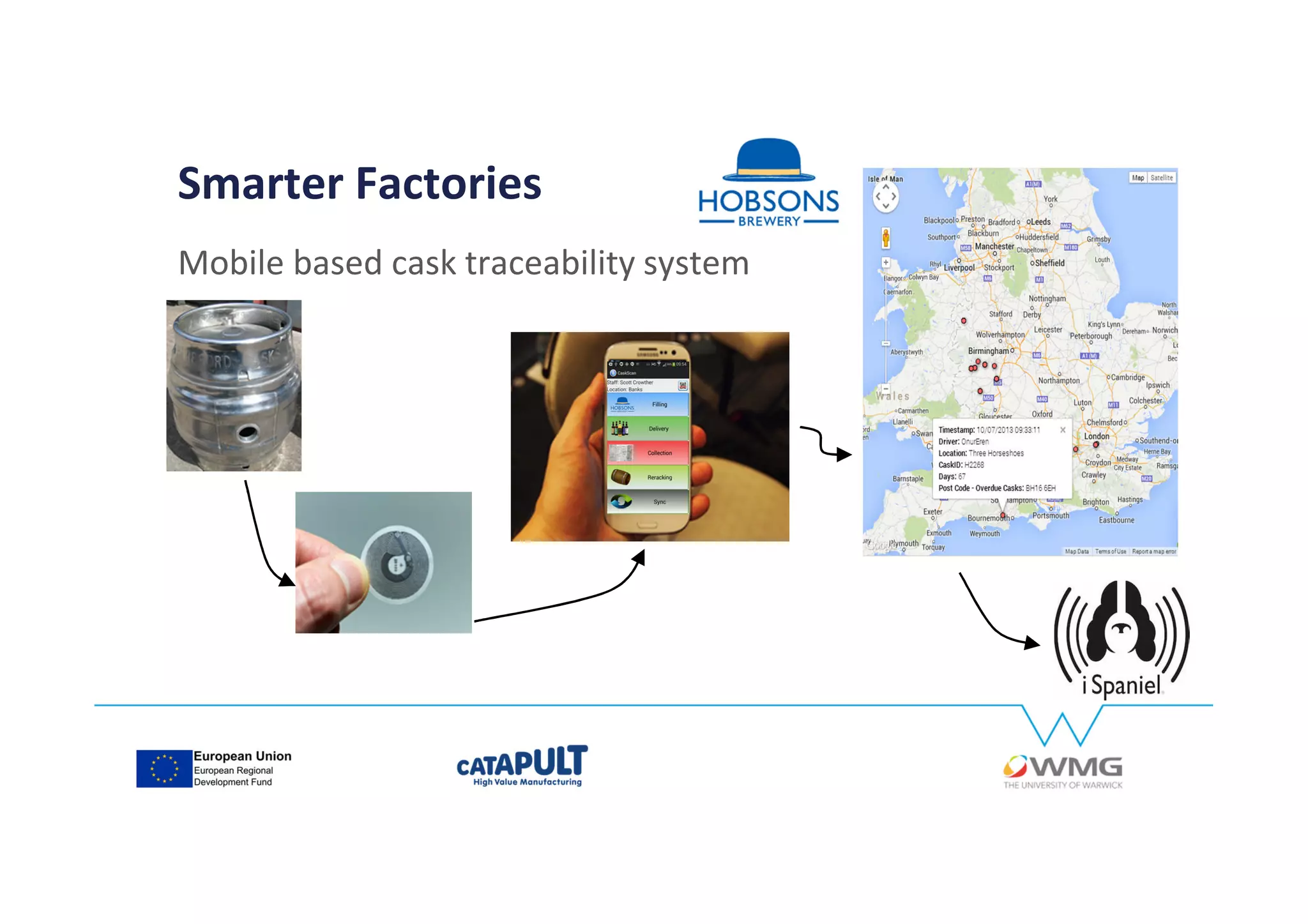

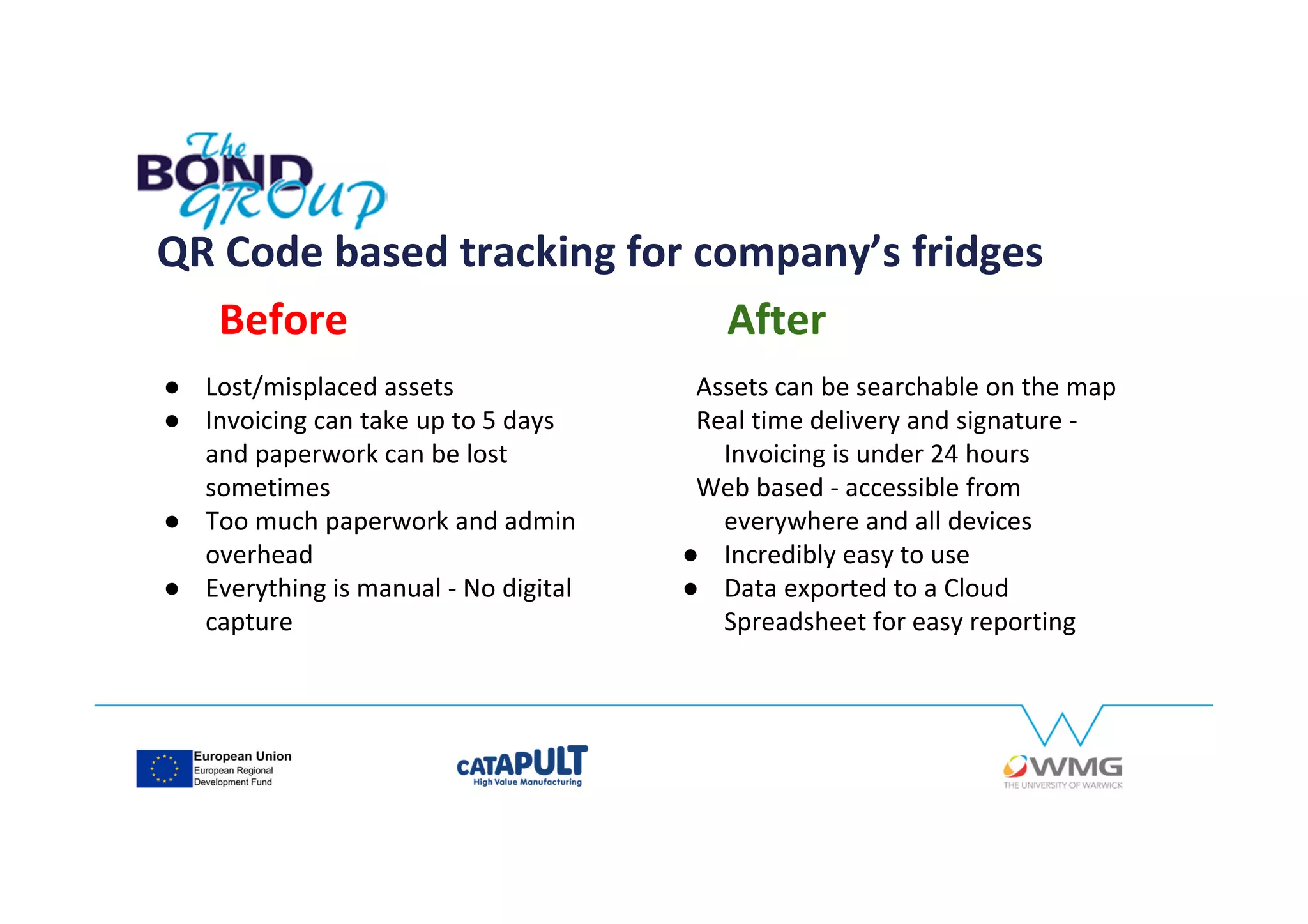

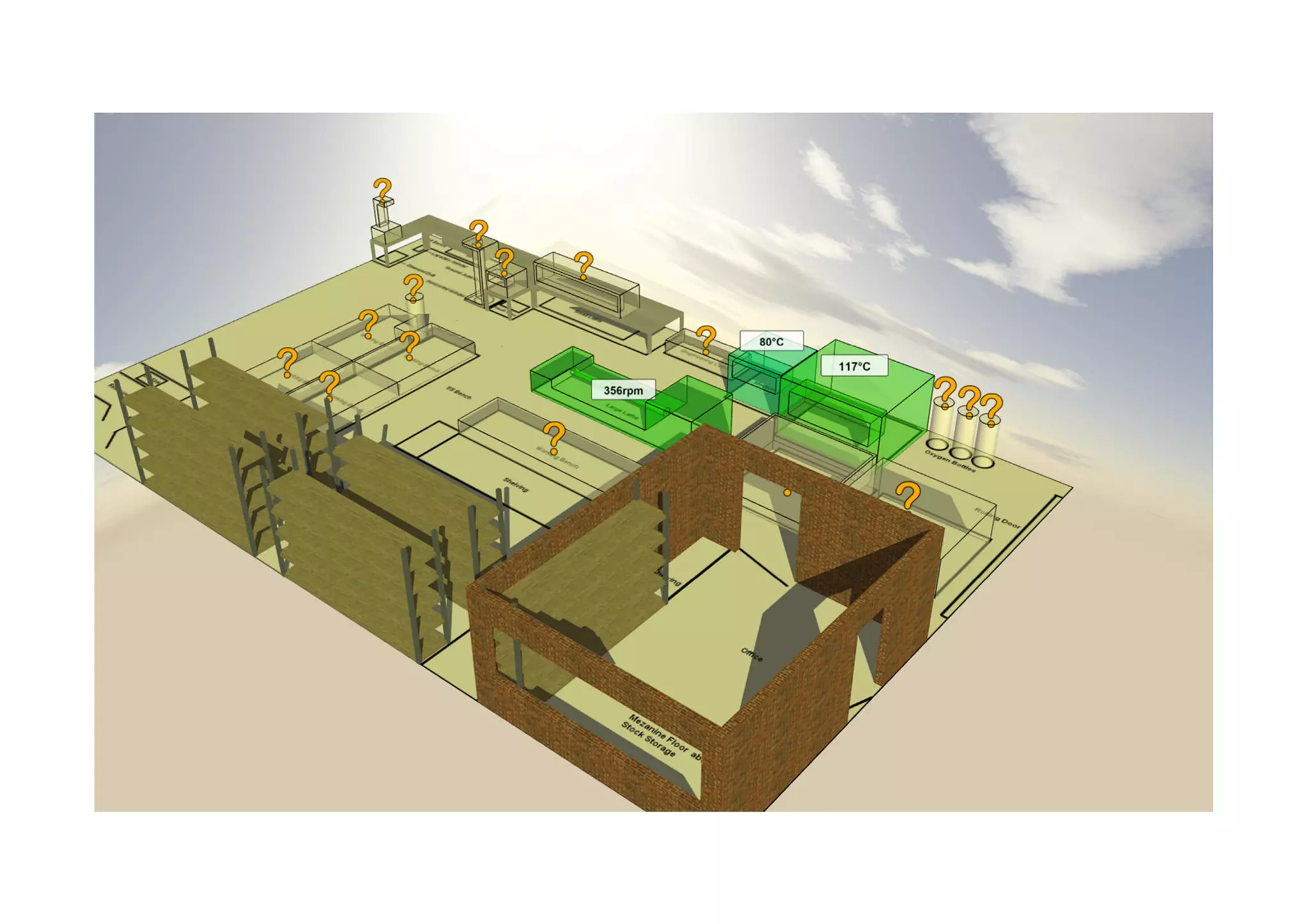

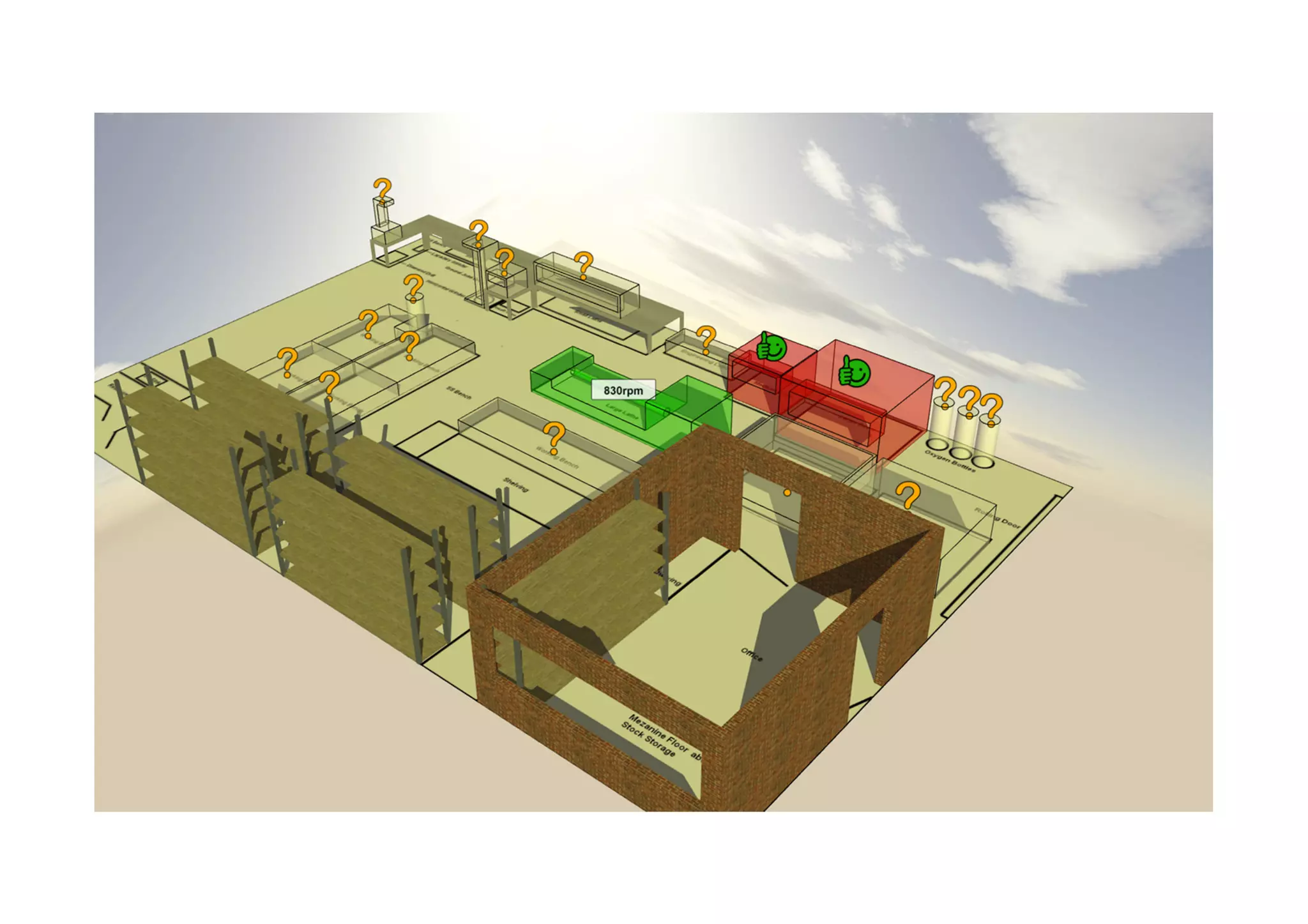

The document summarizes key points about smart manufacturing and moving to Industry 4.0. Part 1 discusses the value of data collection from machines and processes, and provides case studies on using sensors to monitor machine efficiency and oven temperature. Part 2 defines Industry 4.0 as the fourth industrial revolution, outlines its 6 design principles, and notes benefits for small businesses including faster response, improved productivity and flexibility. It concludes with an interactive quiz to self-assess a company's readiness for Industry 4.0.