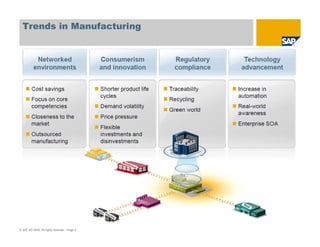

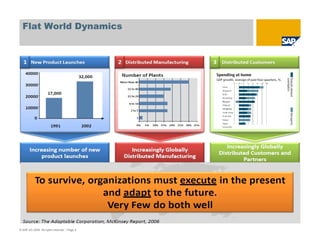

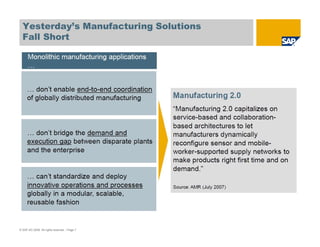

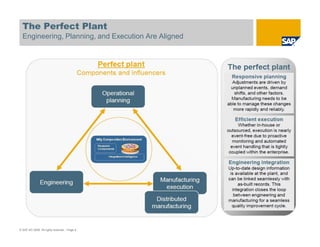

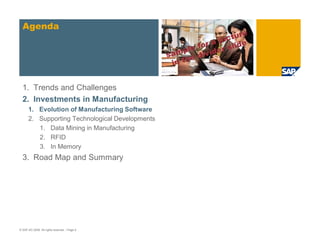

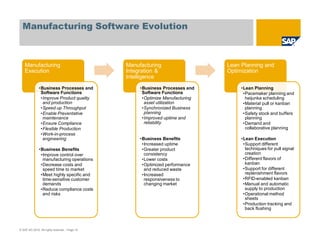

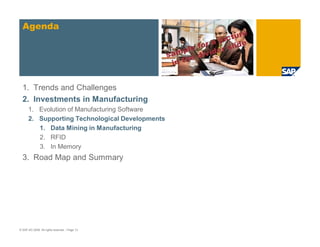

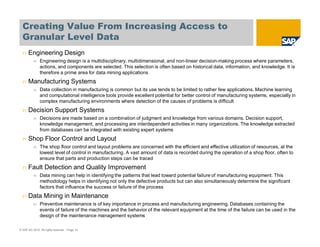

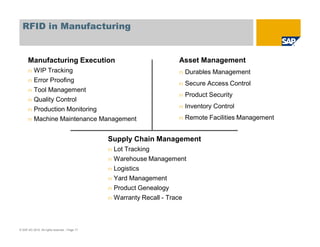

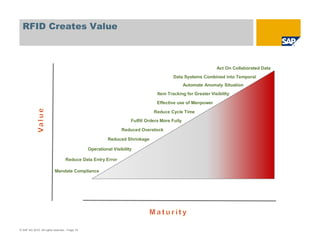

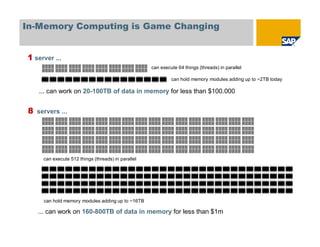

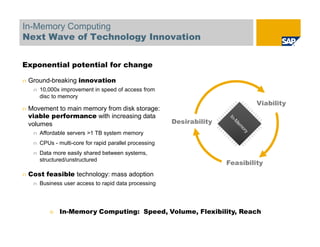

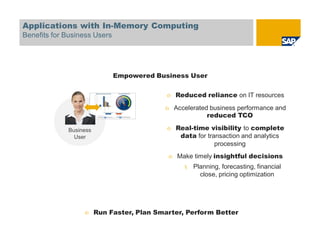

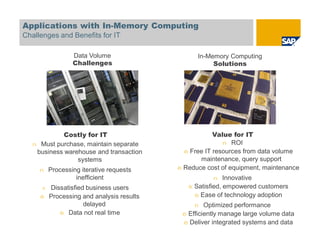

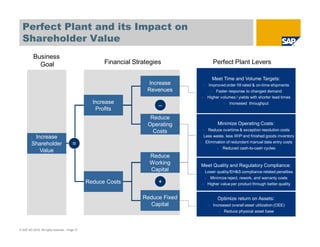

This document summarizes the latest trends in ERP software from a manufacturing perspective. It discusses how ERP software is evolving to better support manufacturing processes through improved manufacturing execution, integration, intelligence and lean planning. It also explores how technologies like data mining, RFID and in-memory computing can provide additional benefits when integrated with ERP systems, such as improved visibility, quality and maintenance in manufacturing. The document concludes by stating that in-memory computing represents a game-changing development by allowing vast amounts of transactional manufacturing data to be accessed with zero response time to support analytical queries.