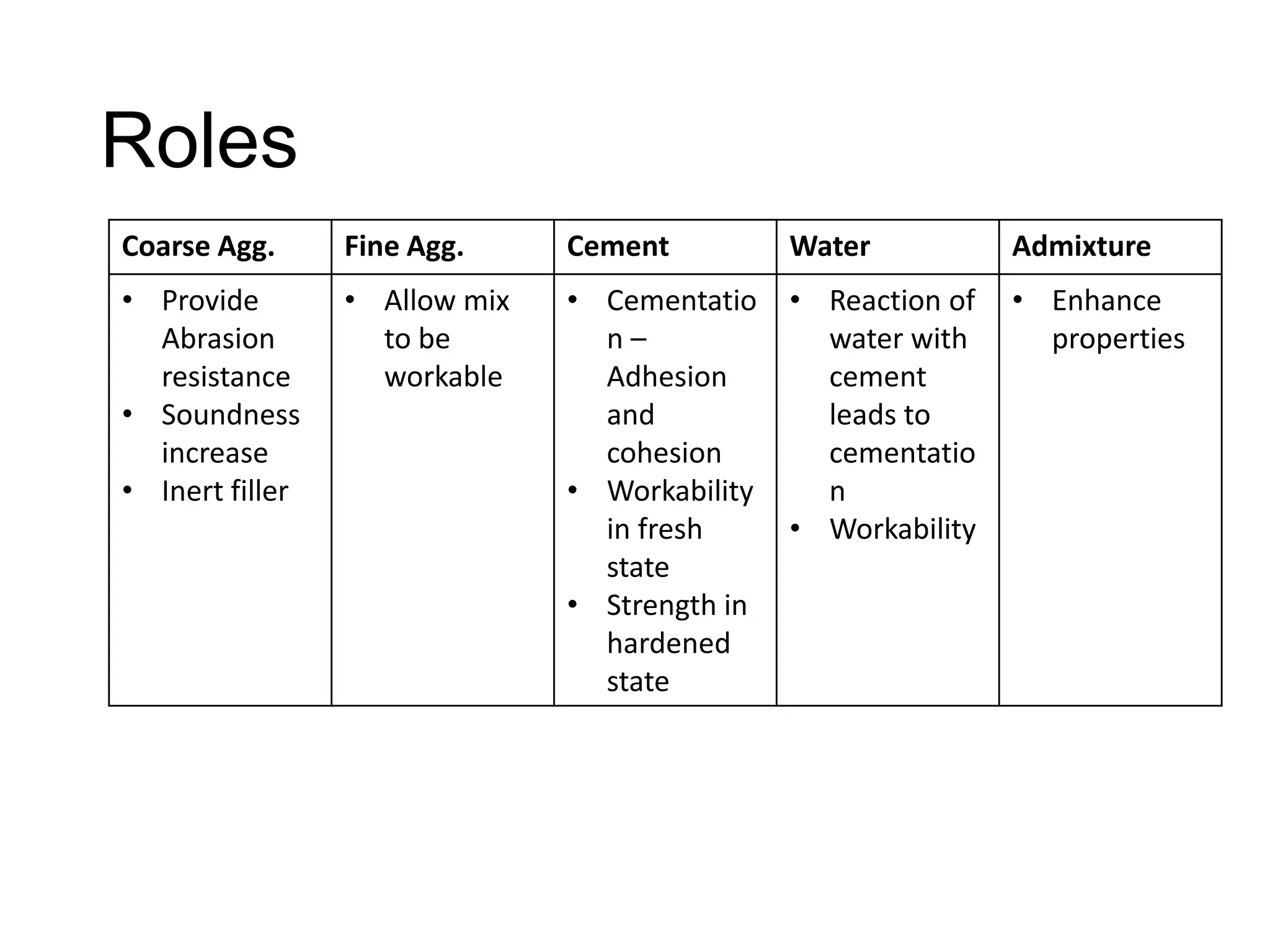

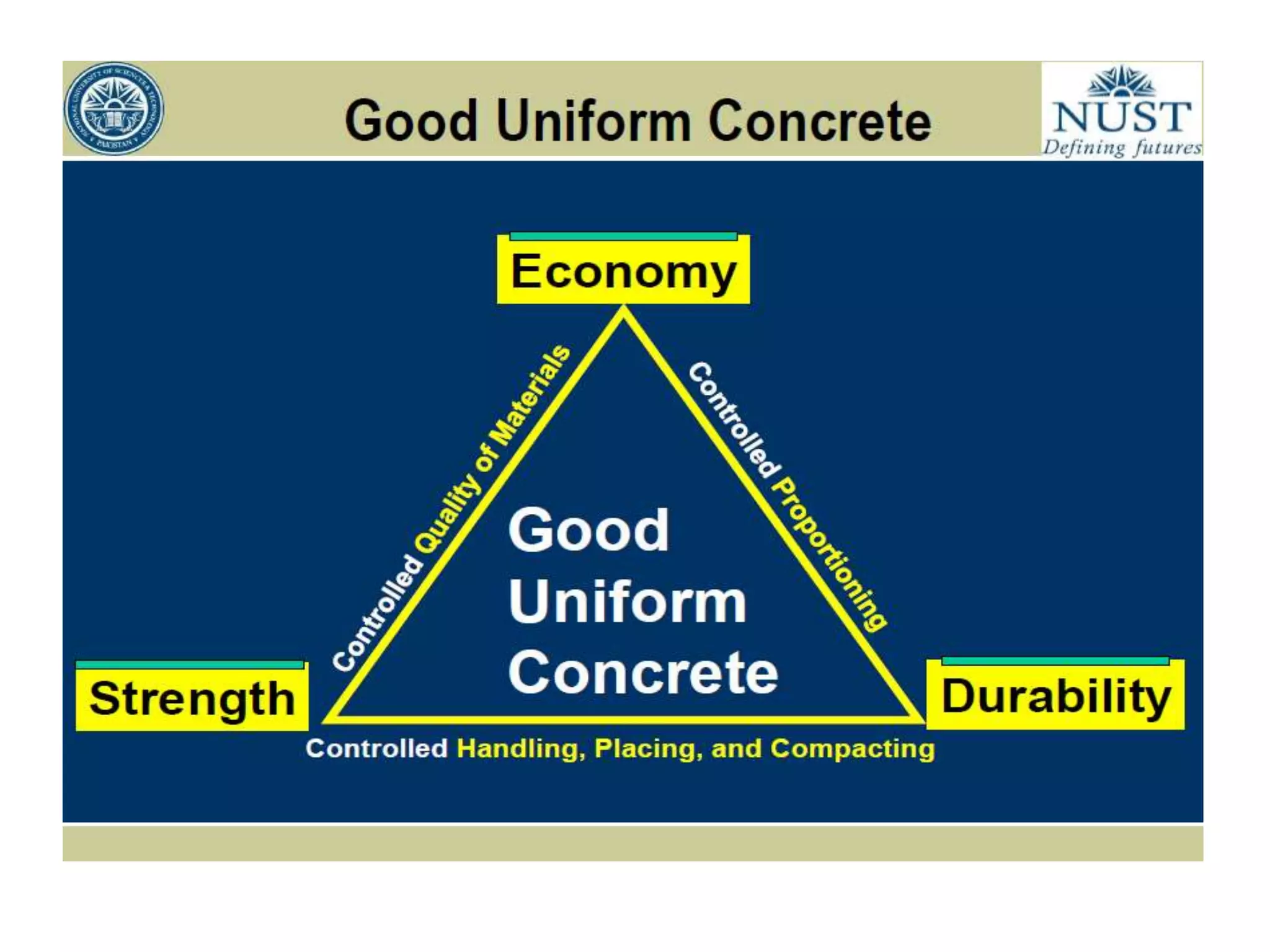

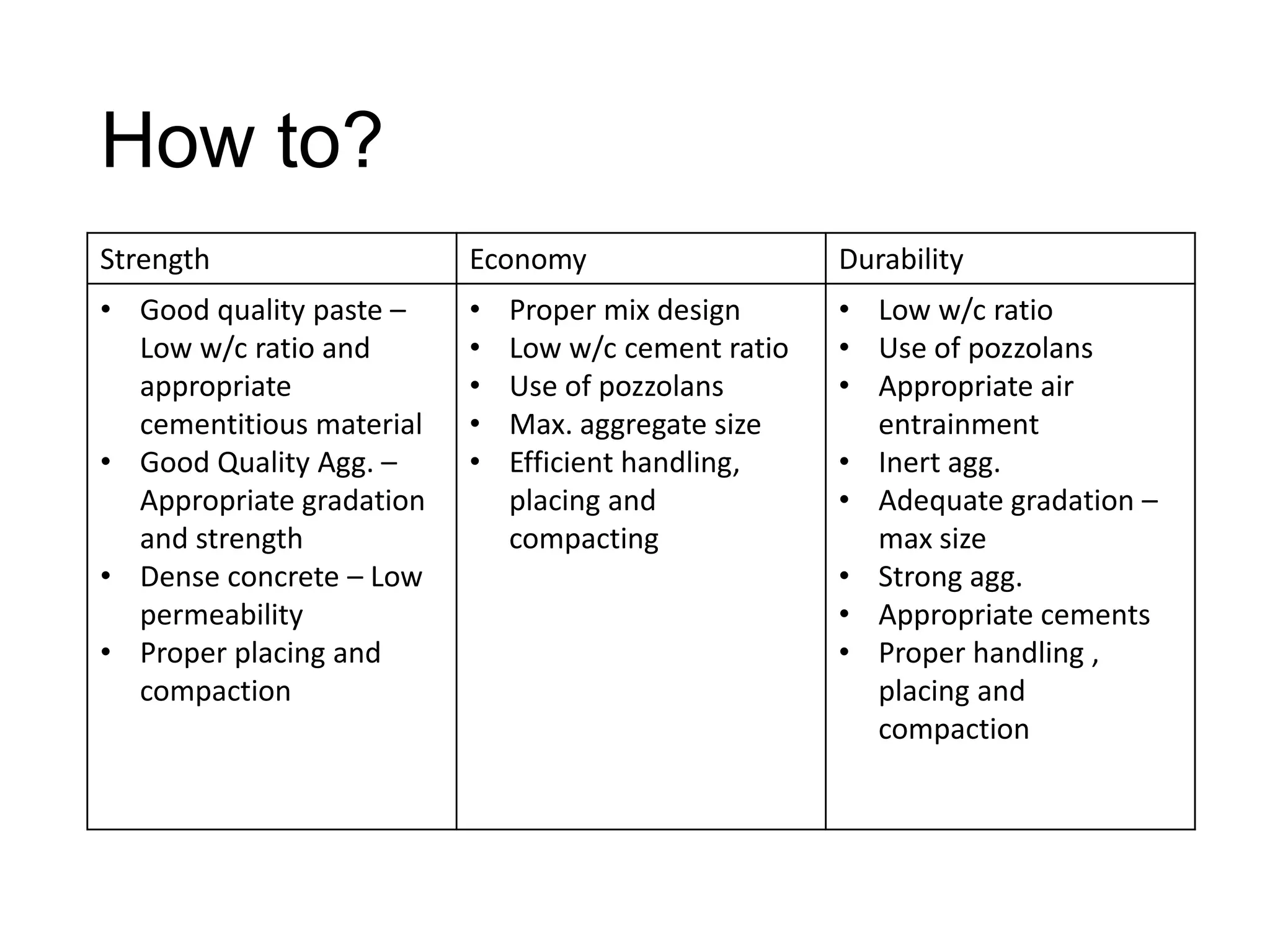

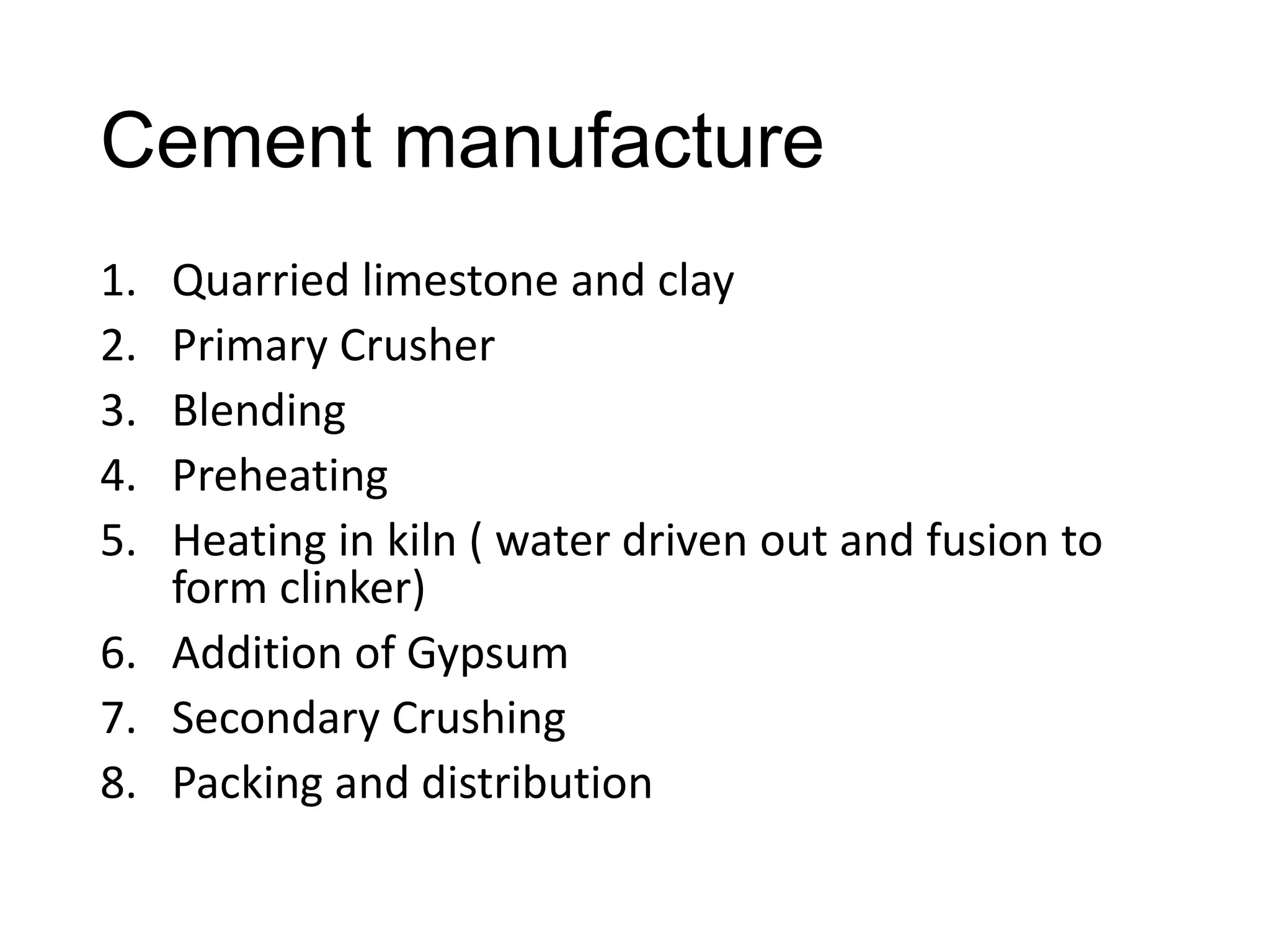

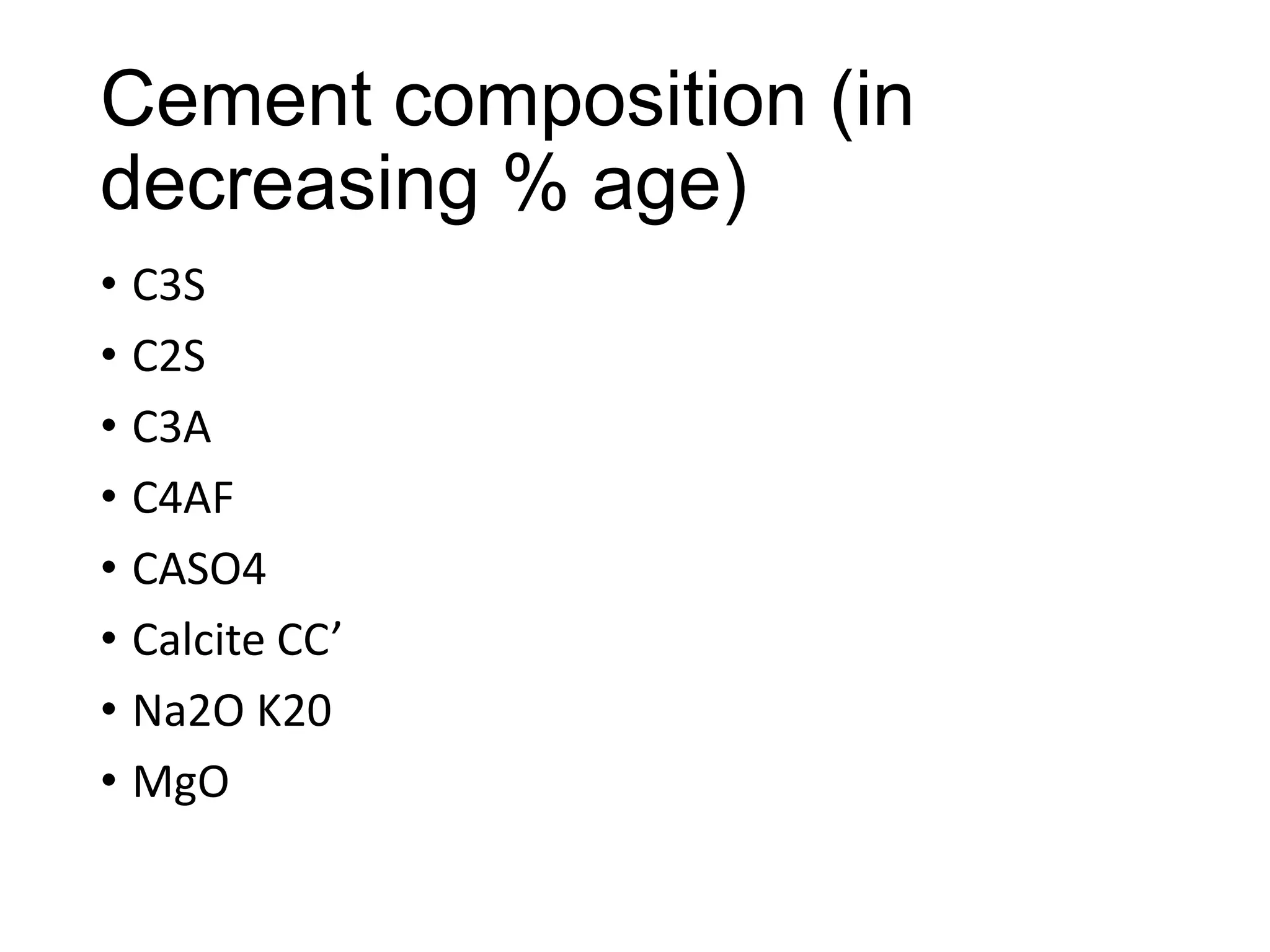

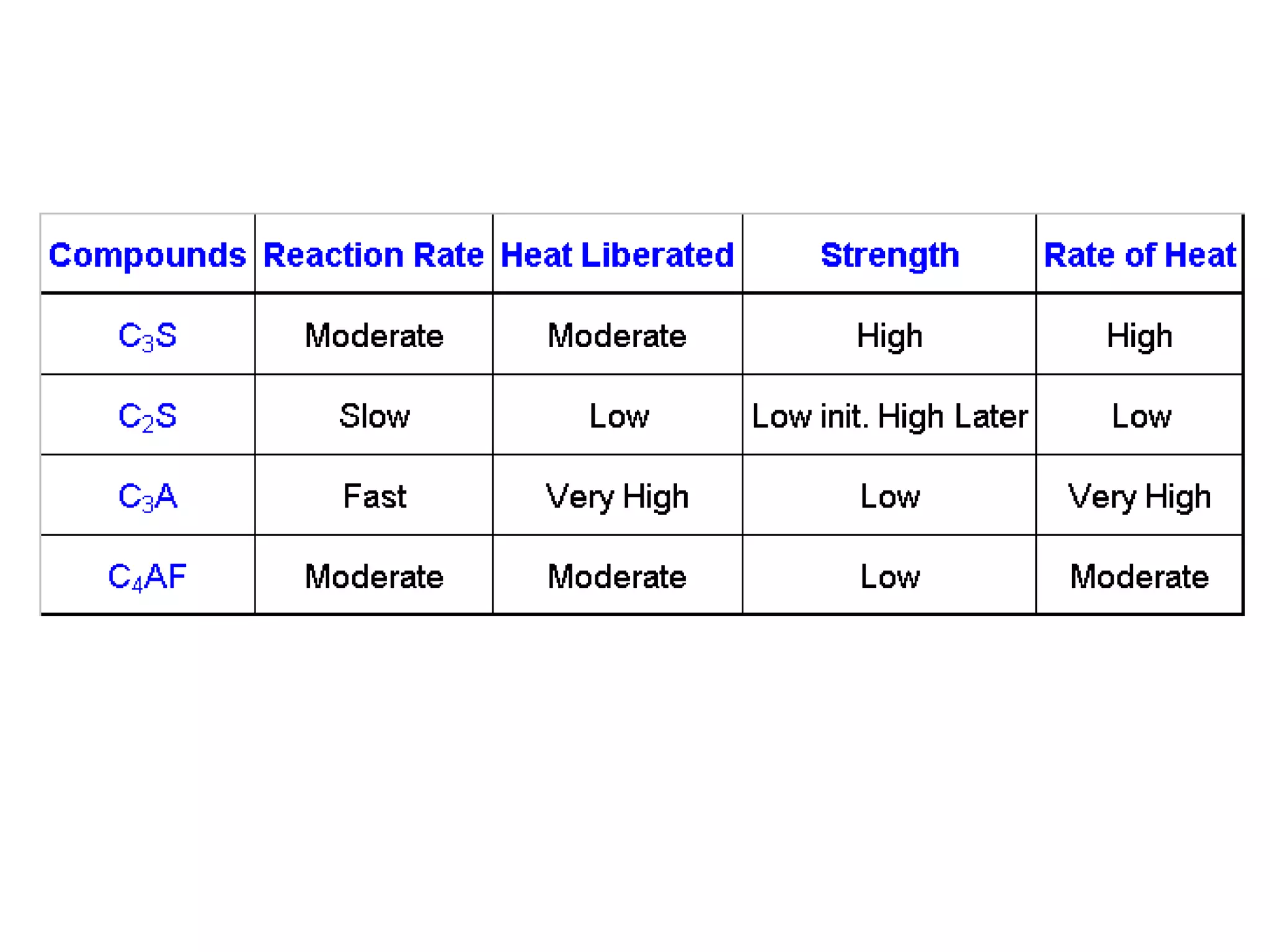

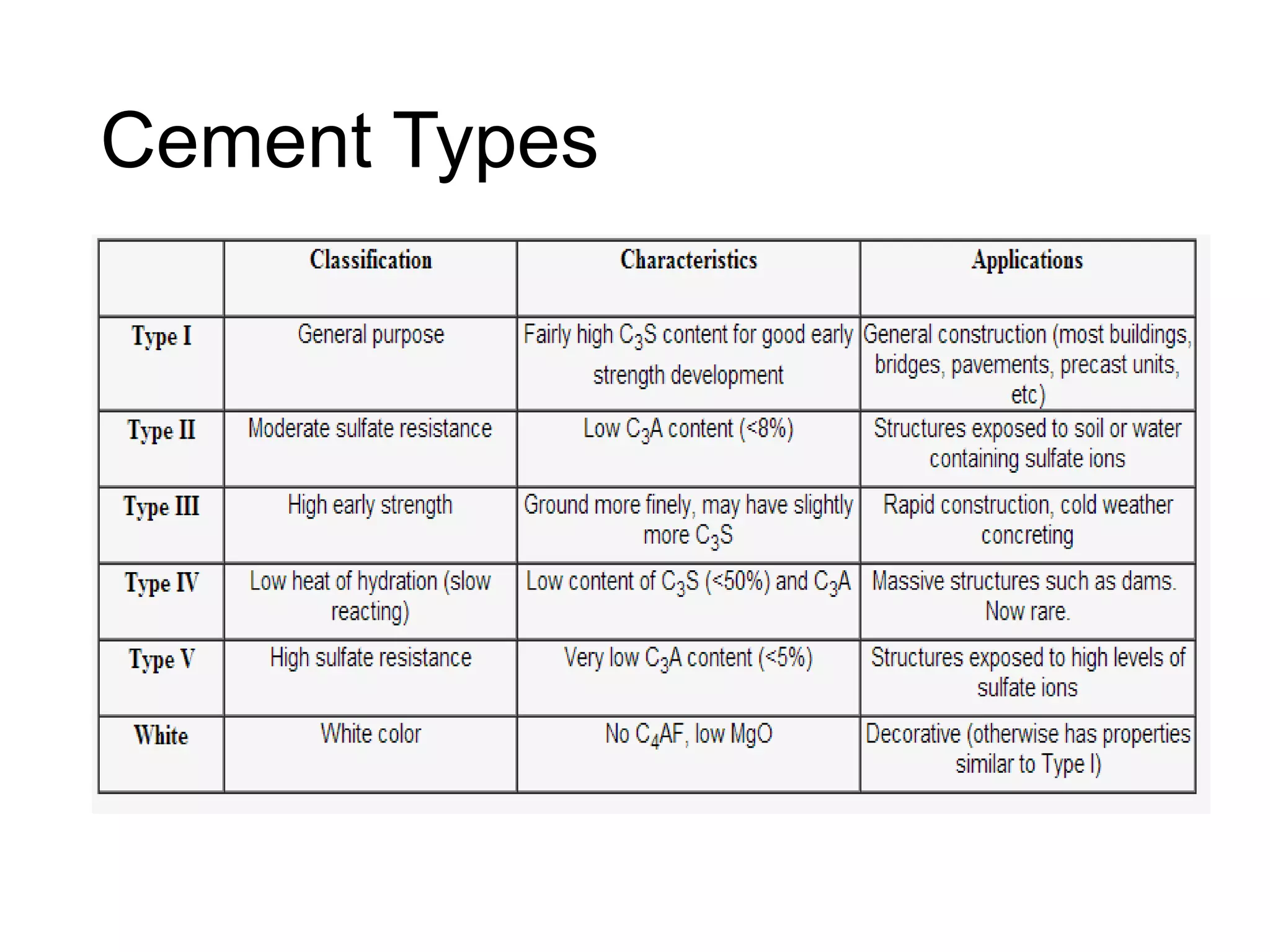

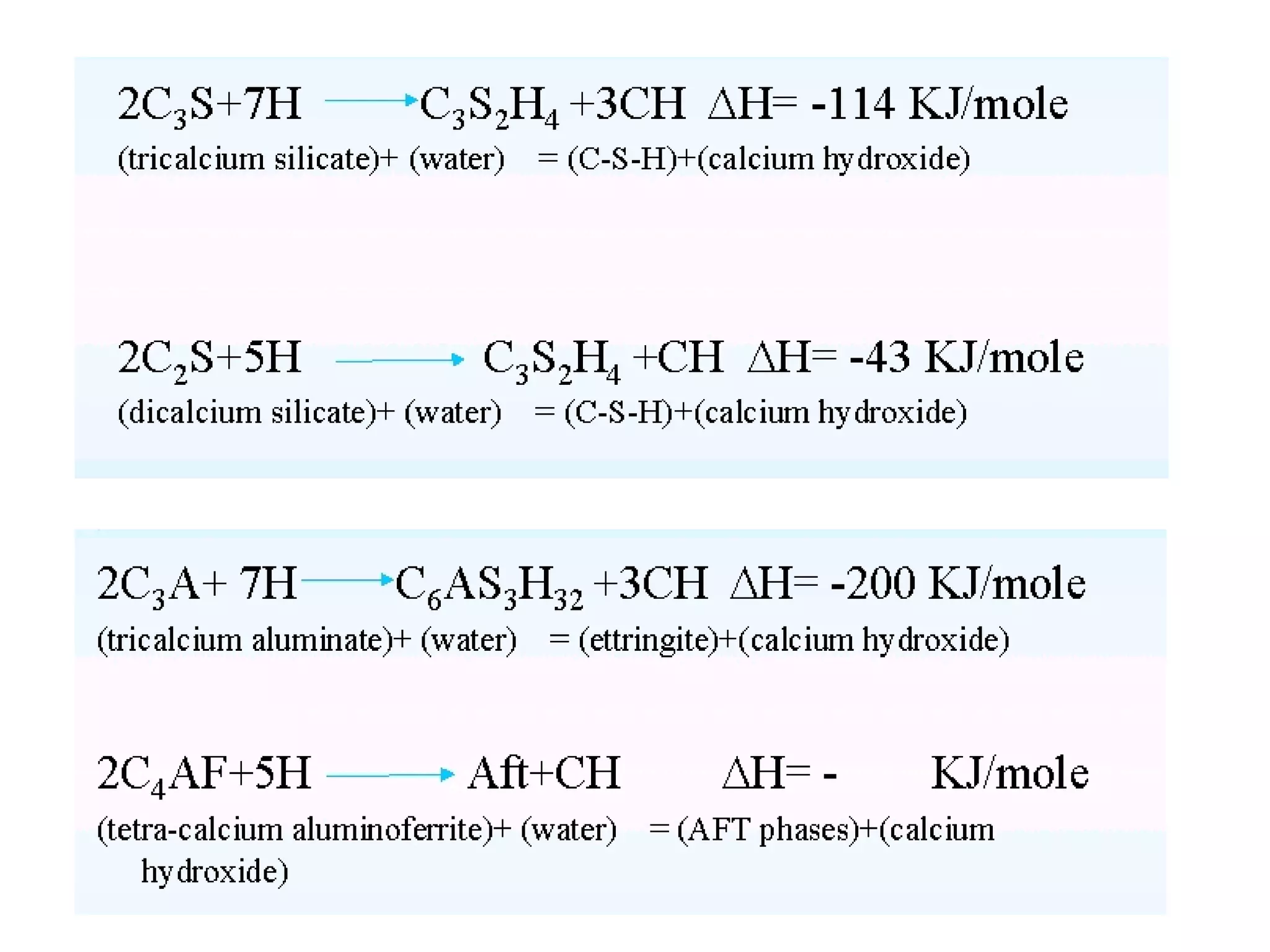

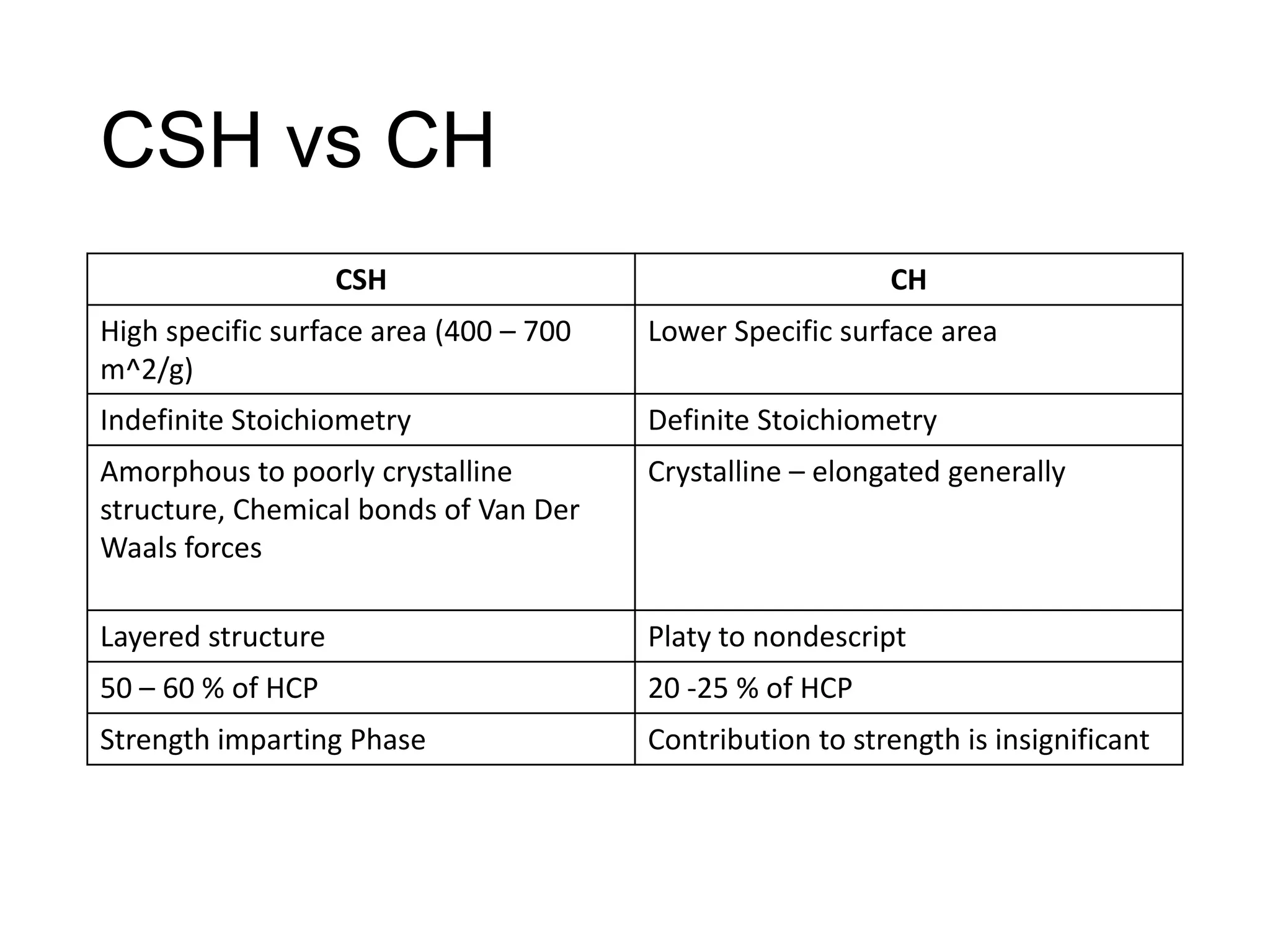

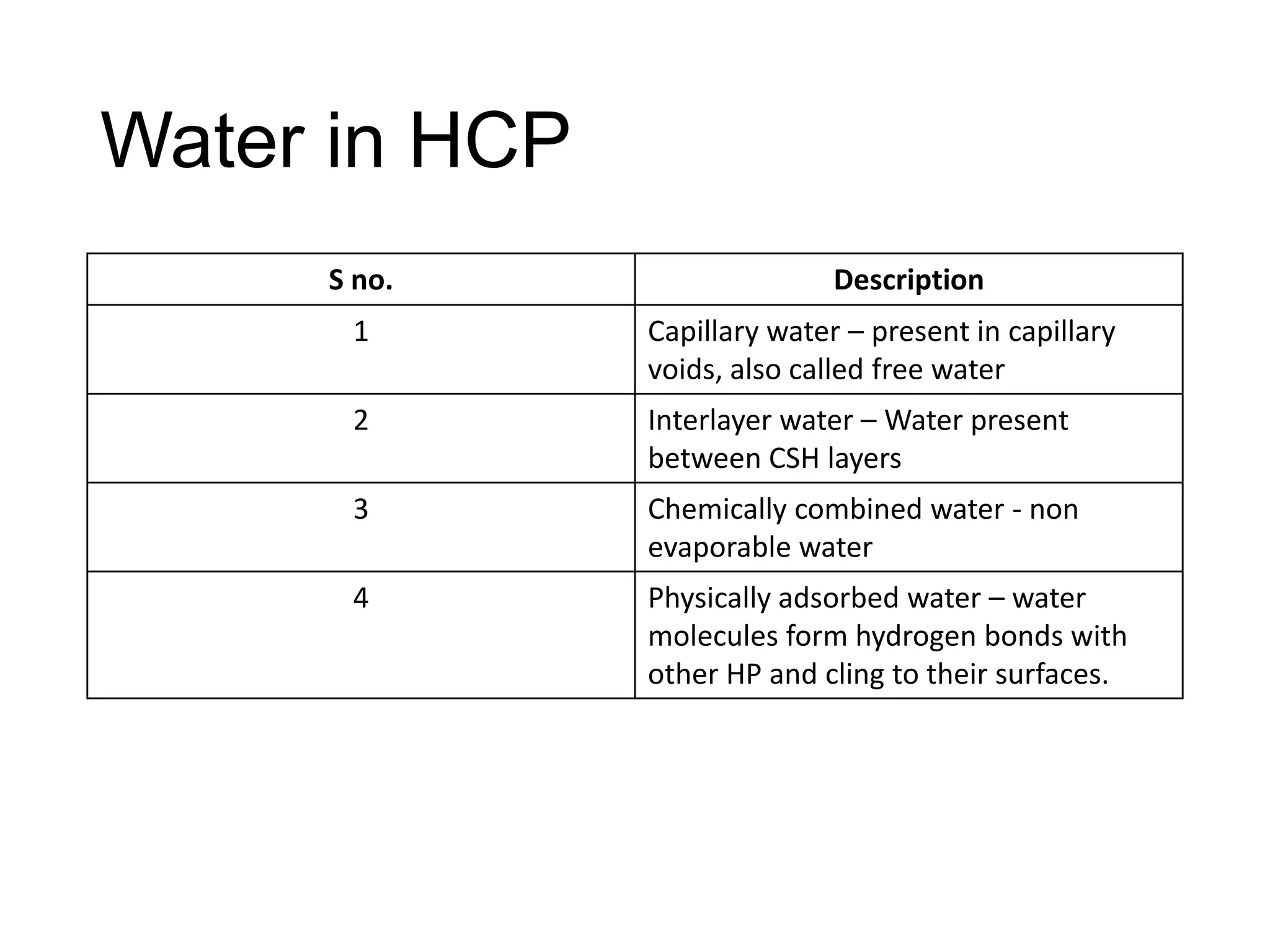

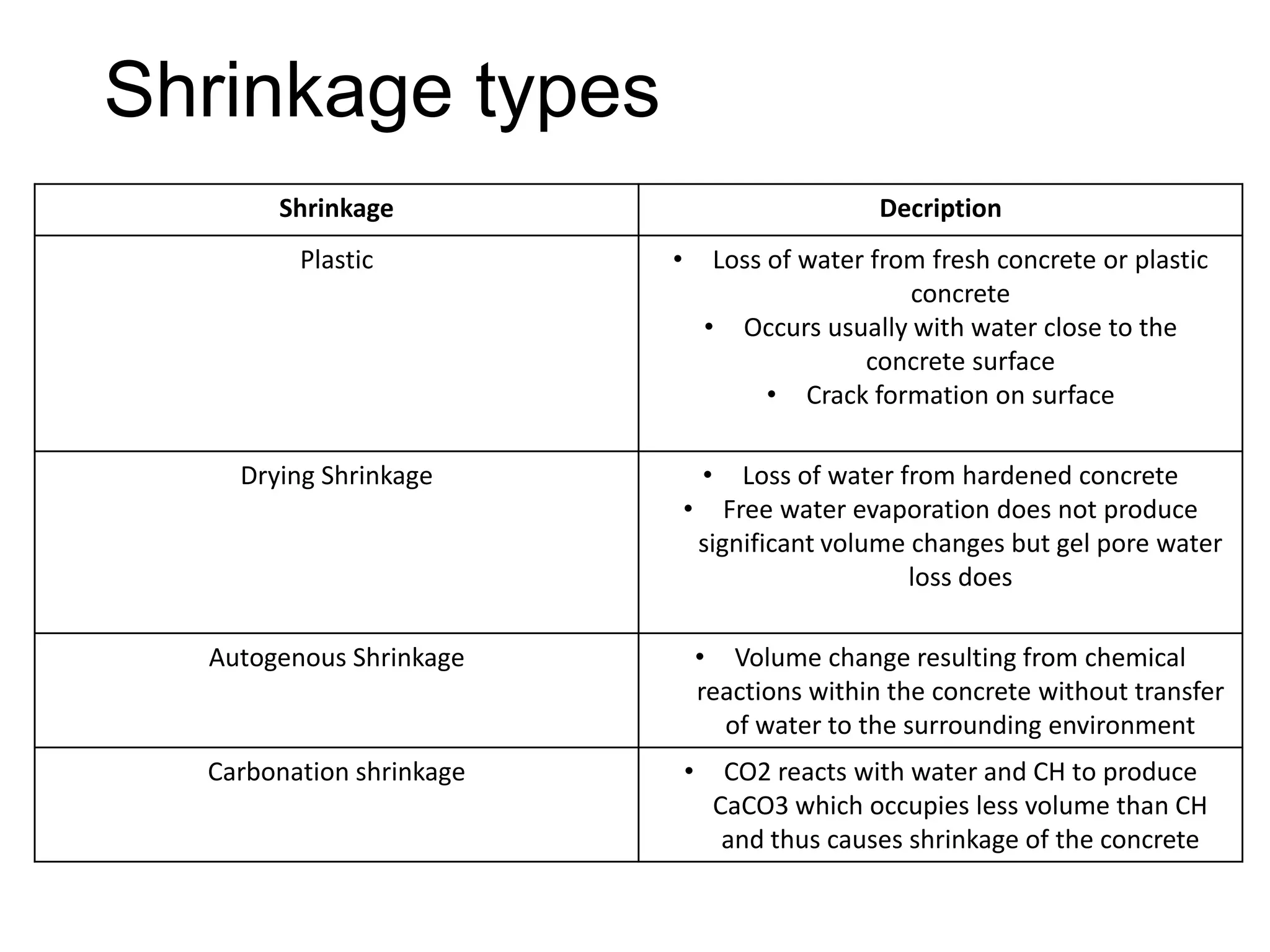

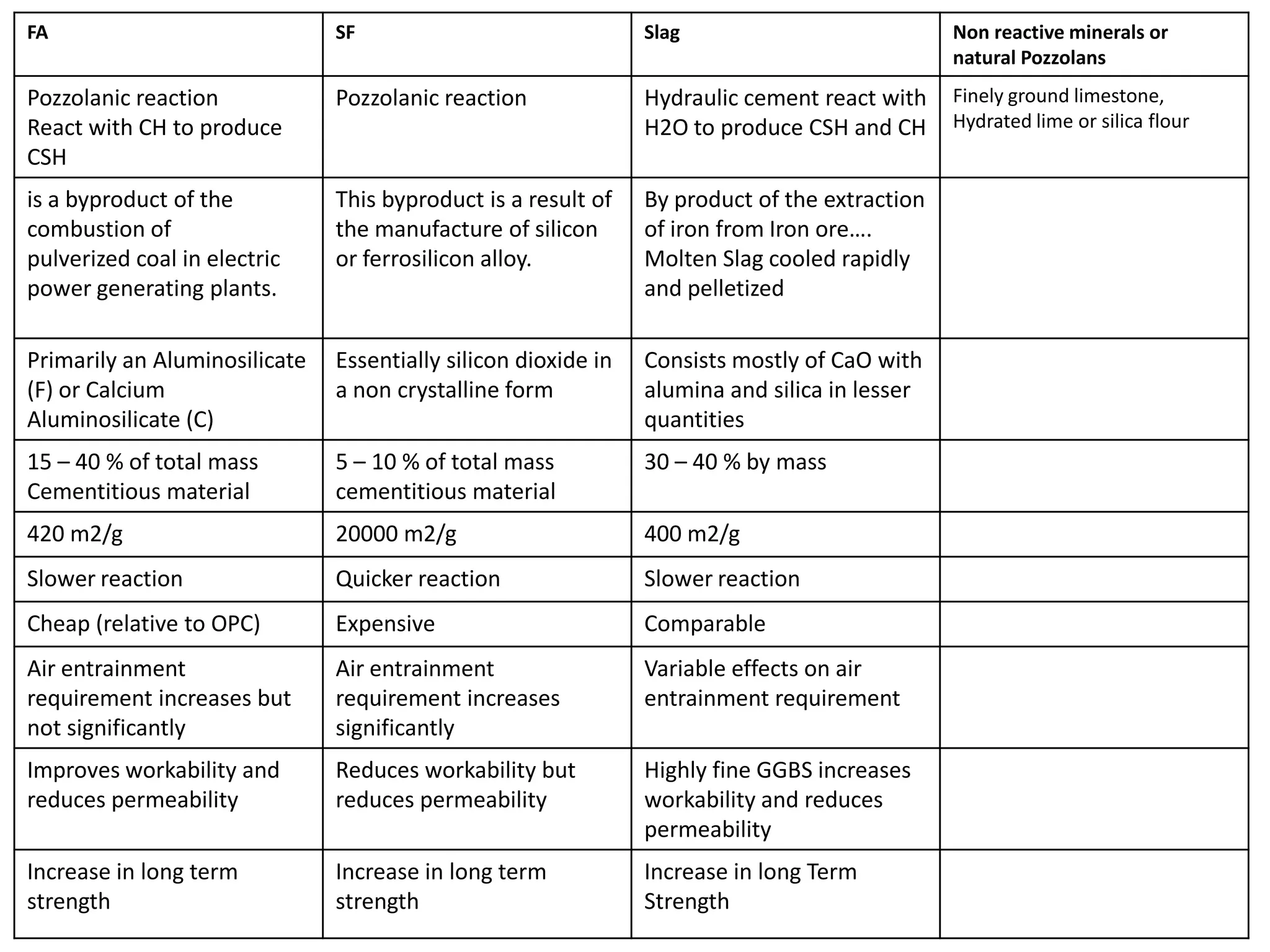

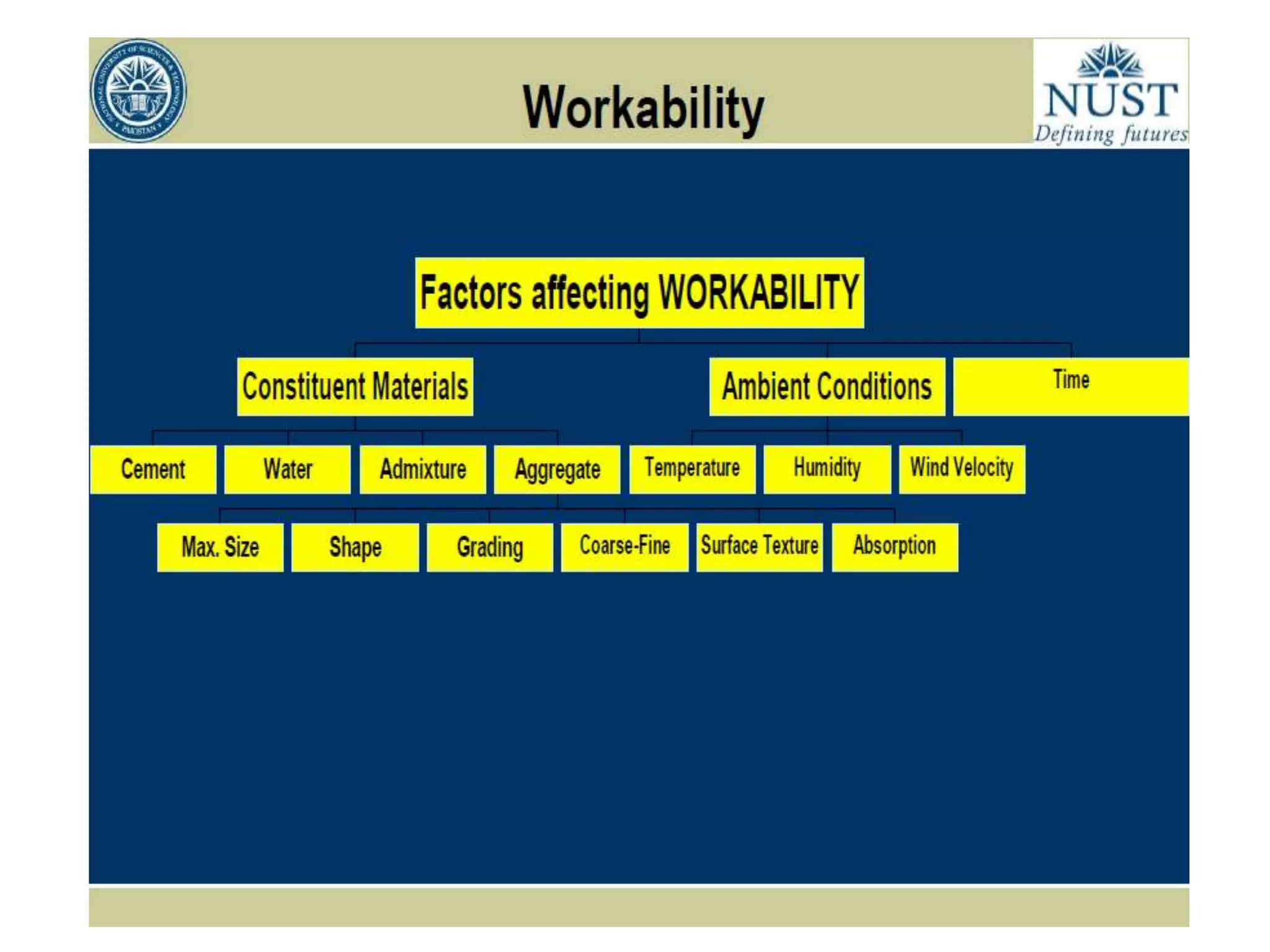

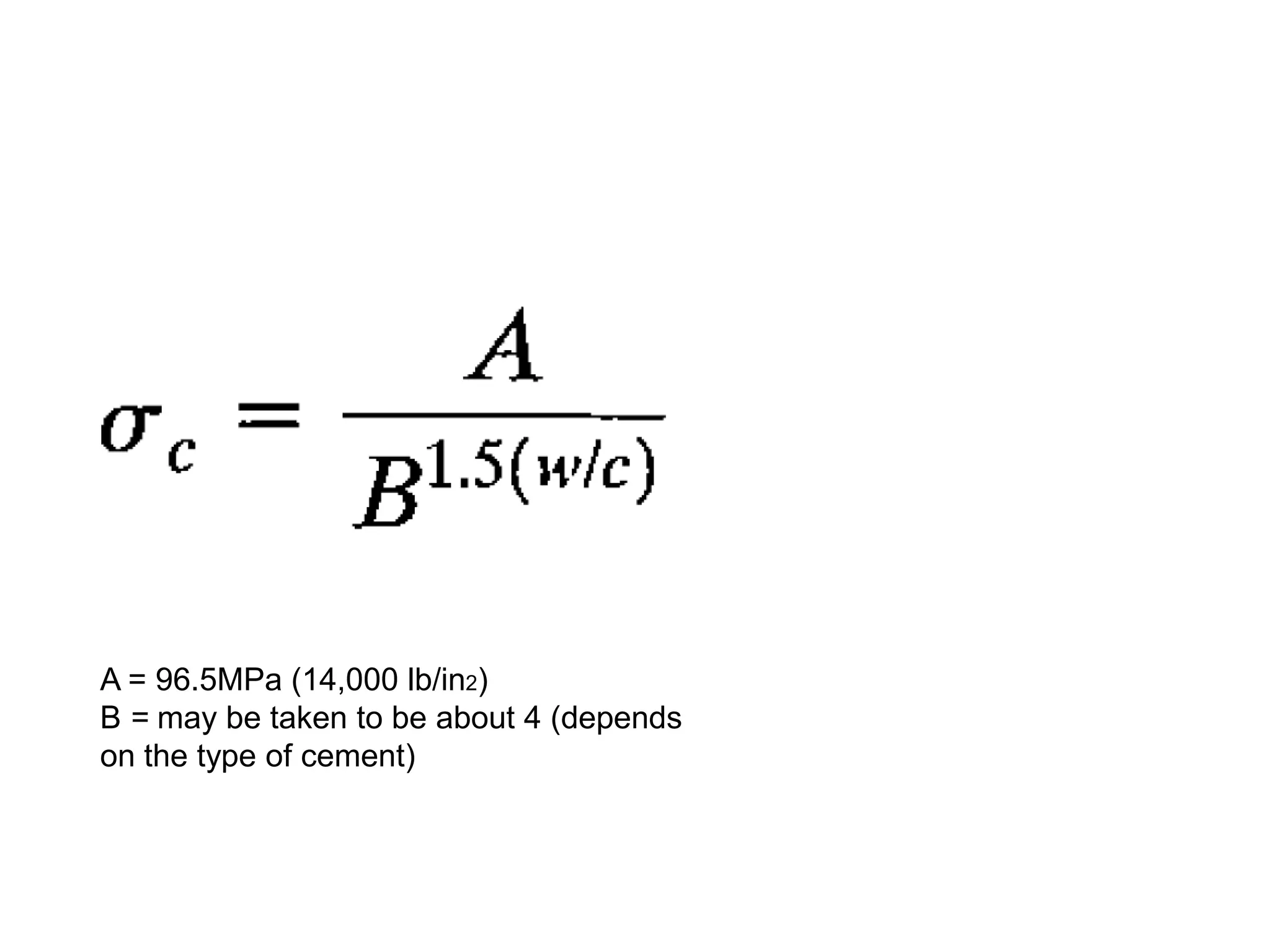

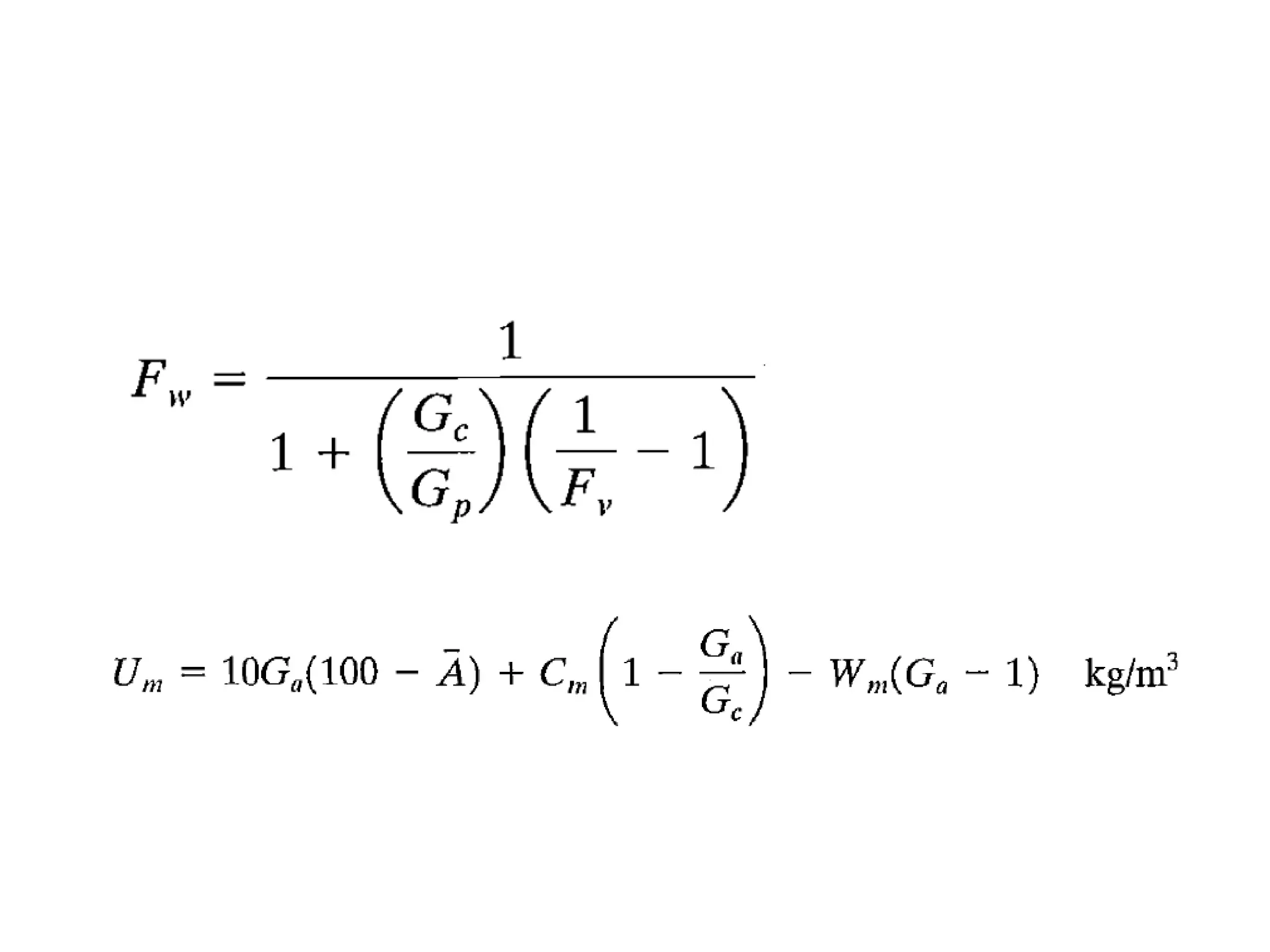

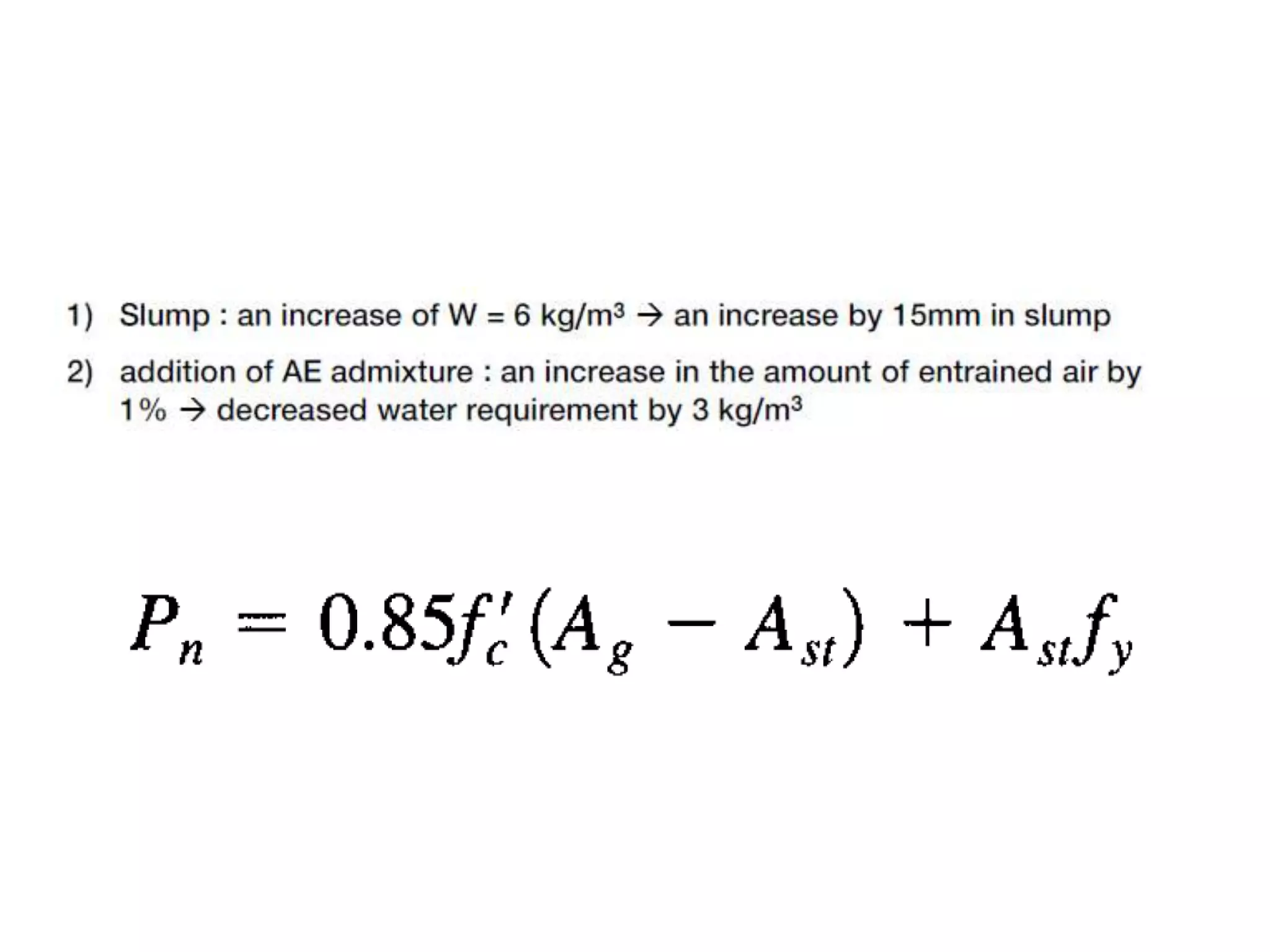

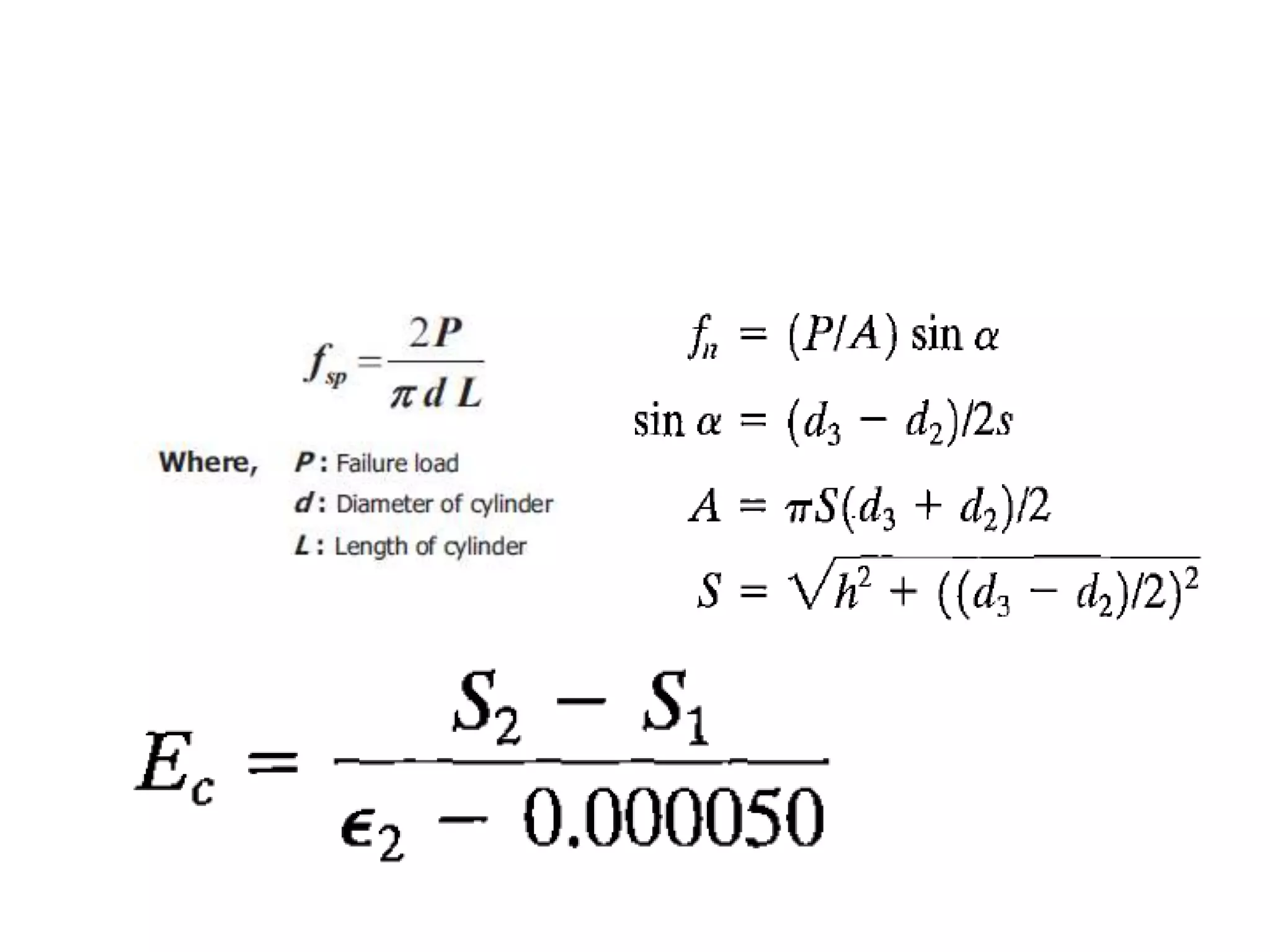

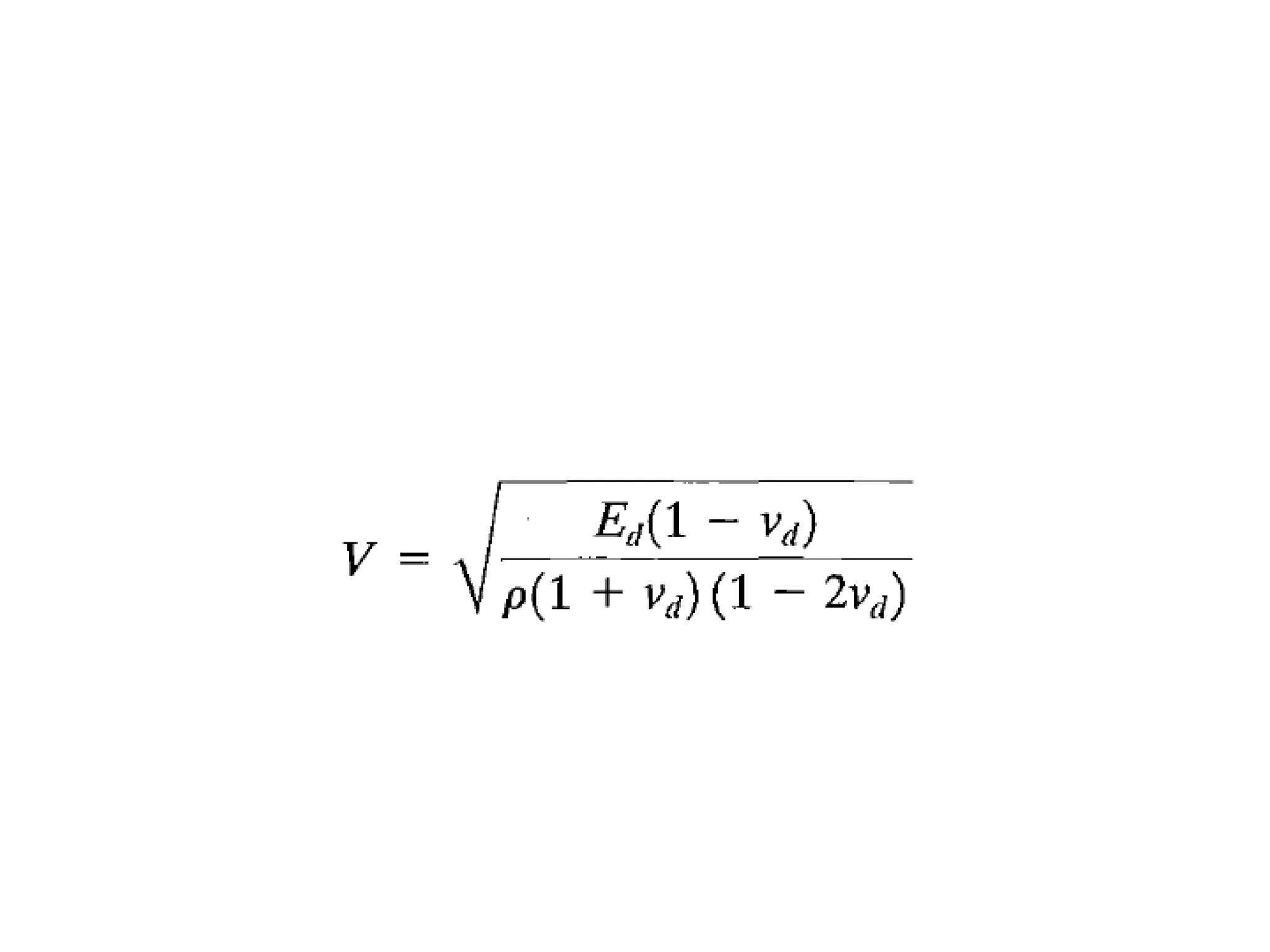

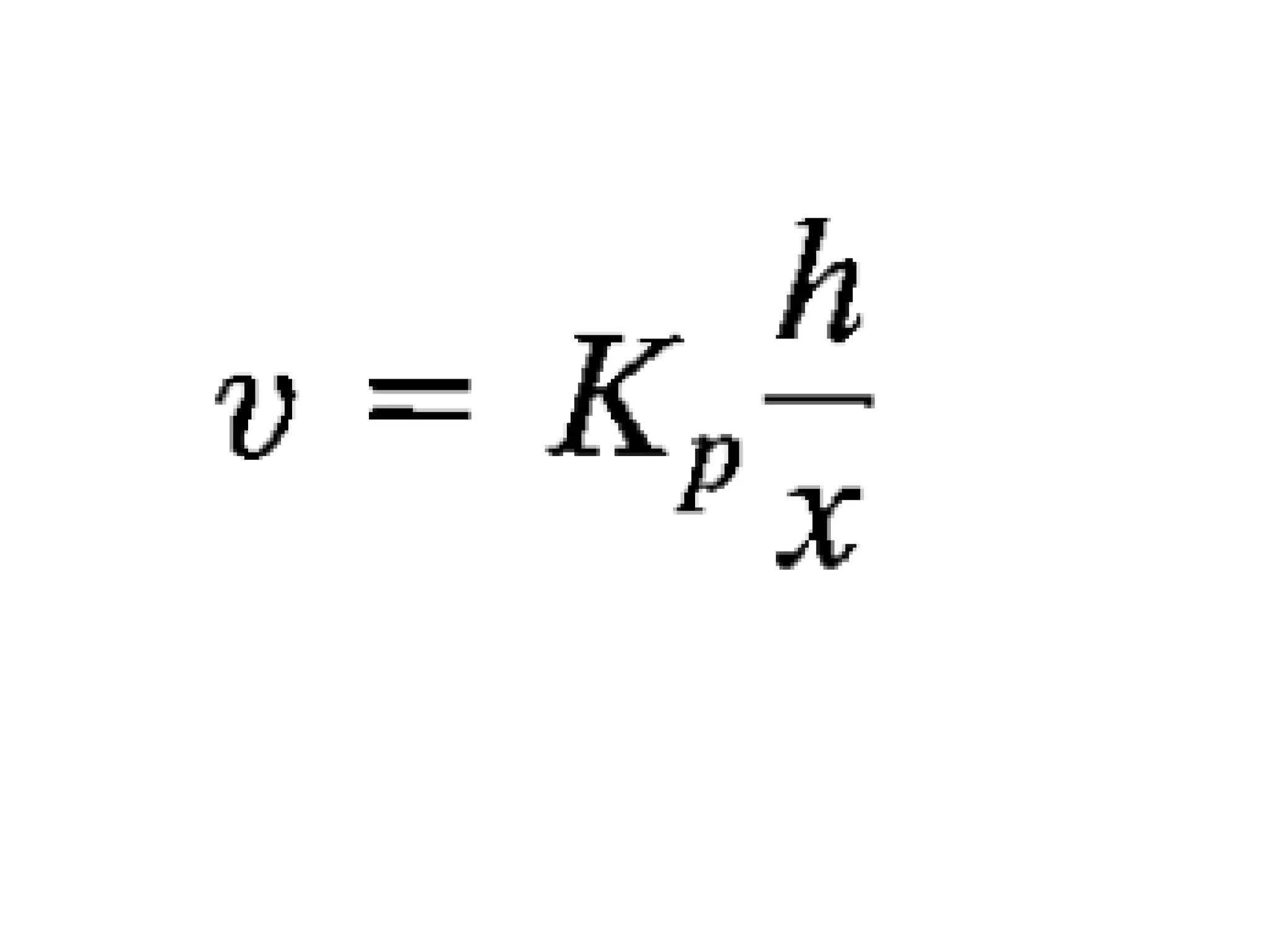

The document provides comprehensive details on the formulation of concrete, emphasizing factors influencing its durability, workability, and strength, such as water-to-cement ratio, aggregate types, and the use of various admixtures. It discusses the manufacturing process of cement, shrinkage types in concrete, and the role of chemical and mineral admixtures in enhancing properties while outlining challenges like segregation and alkali-silica reaction. Additionally, it covers the importance of aggregate properties and proper mix design to achieve optimal concrete performance.