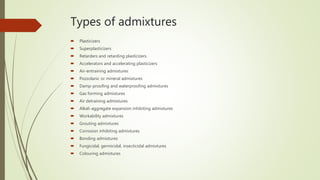

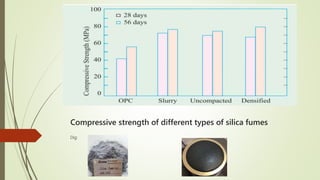

This document discusses various types of admixtures that are added to concrete to modify its properties. It describes 15 types of admixtures classified according to their function, including plasticizers, superplasticizers, retarders, accelerators, air-entraining agents, and pozzolanic materials. Common chemical admixtures are discussed in more detail, along with their effects on properties of fresh and hardened concrete. Mineral admixtures like fly ash, blast furnace slag, rice husk ash, and silica fume are also summarized in terms of their composition and impact on improving concrete quality and durability.