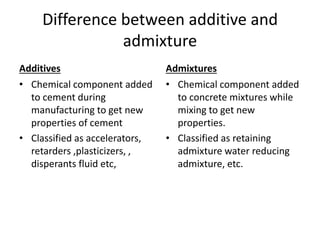

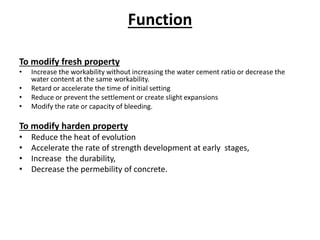

Admixtures are ingredients added to concrete to modify its properties. They are classified as chemical or mineral admixtures. Common chemical admixtures include accelerators, retarders, air-entraining, water-reducing, and superplasticizing admixtures. Mineral admixtures include fly ash, silica fume, ground granulated blast furnace slag, and rice husk ash which have pozzolanic properties. Admixtures are used to improve workability, strength, and durability among other properties of fresh and hardened concrete.