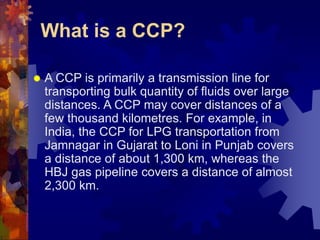

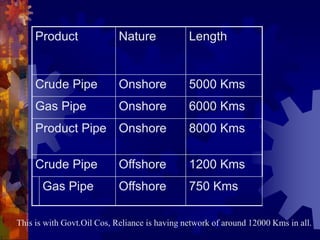

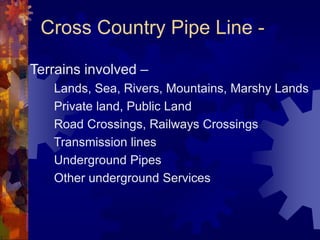

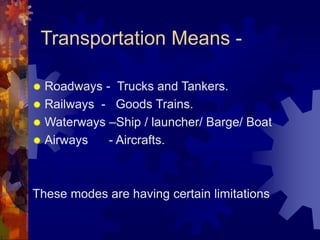

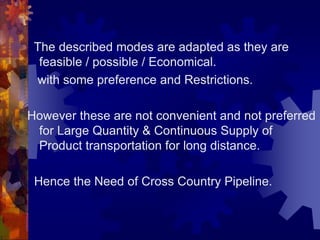

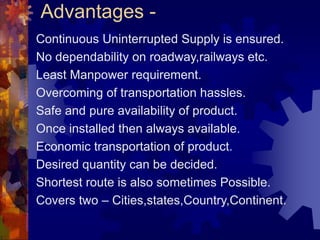

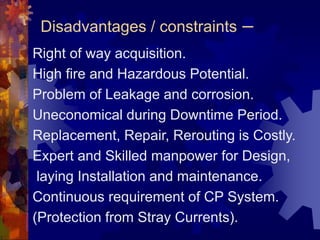

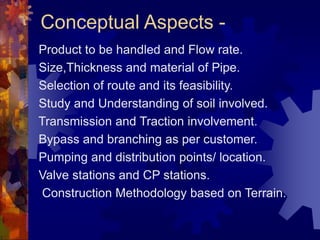

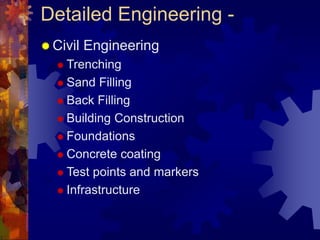

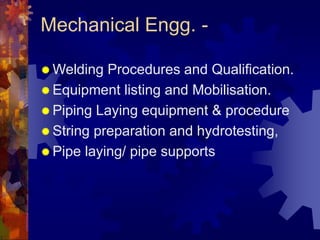

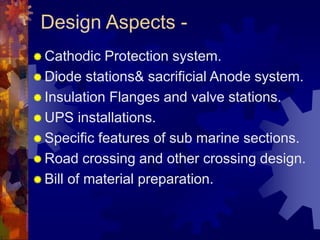

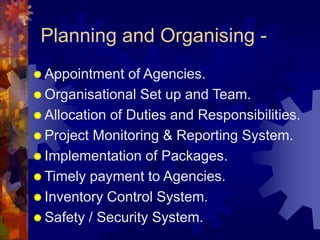

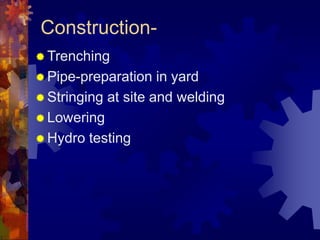

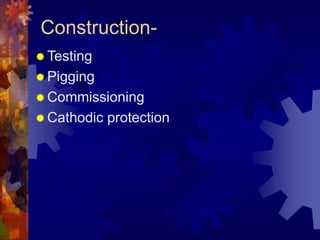

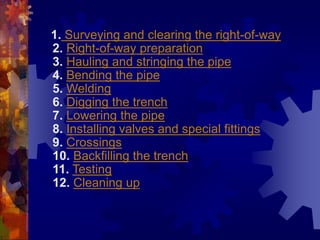

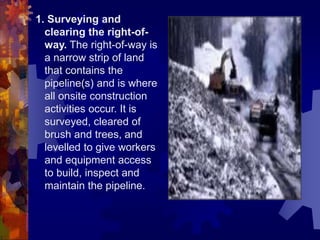

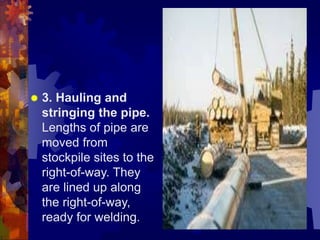

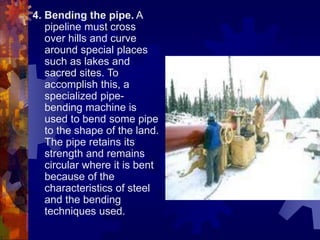

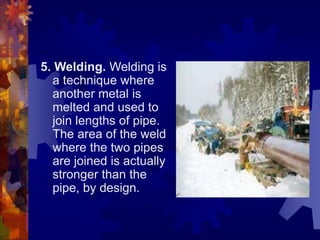

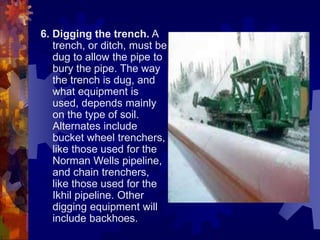

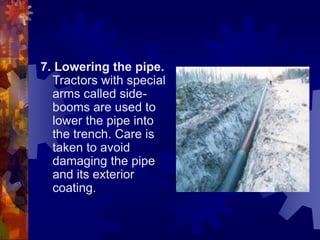

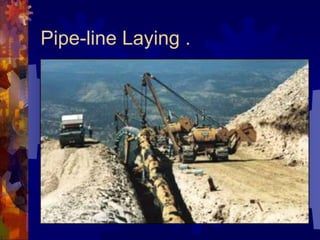

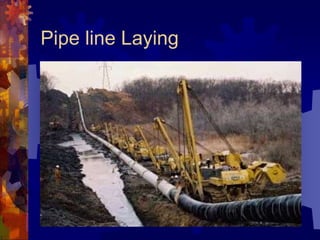

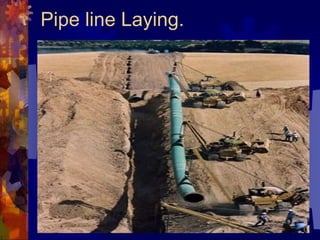

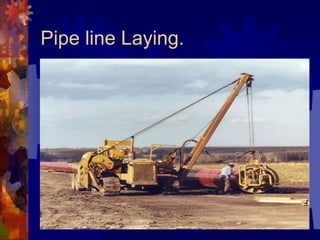

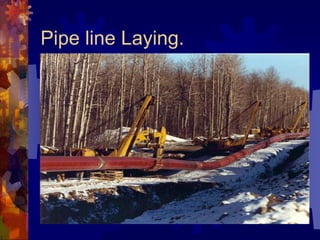

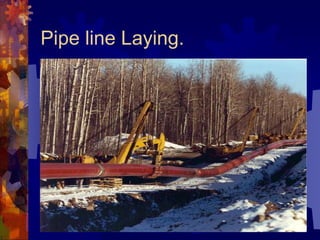

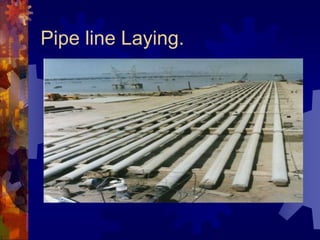

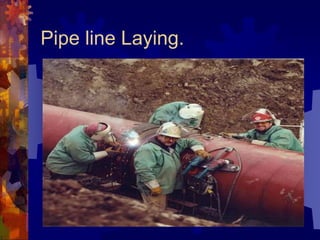

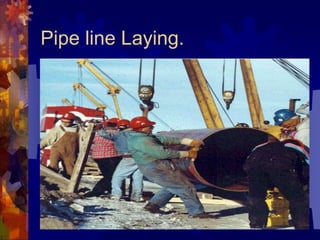

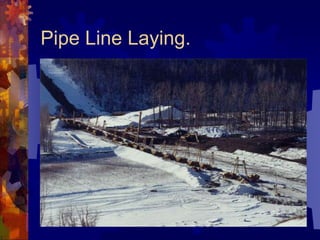

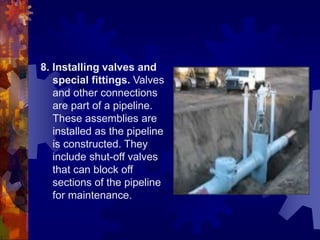

The document provides information on the key aspects of planning and constructing a cross-country pipeline project. It discusses surveying the route, acquiring rights-of-way, assembling and welding pipe sections, lowering the pipe into the ground, installing valves and crossing structures, backfilling trenches, testing the pipeline integrity, and implementing cathodic protection. The overall process involves detailed engineering design, procurement, and managing construction to safely deliver bulk fluids across long distances via an underground pipeline system.