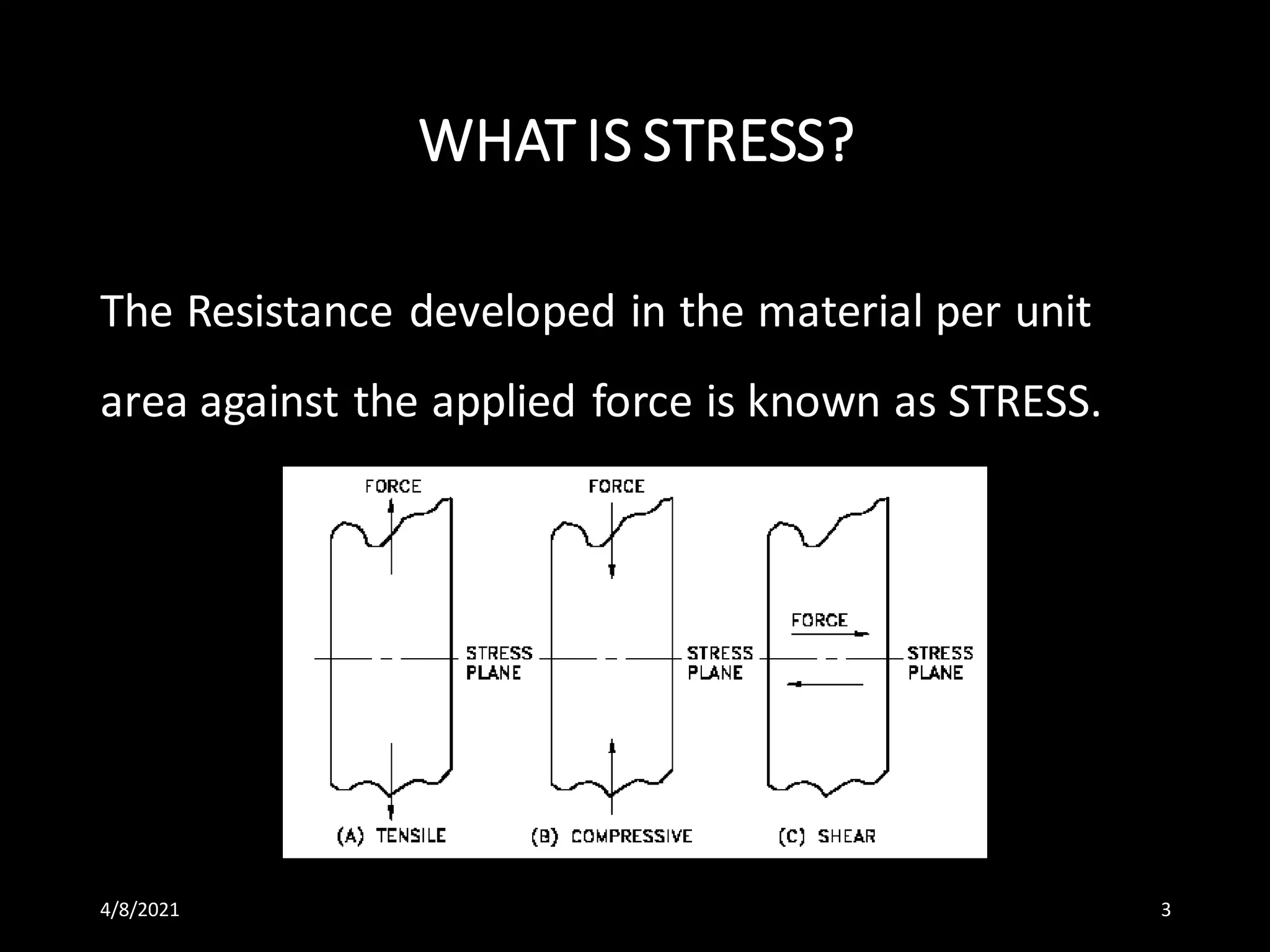

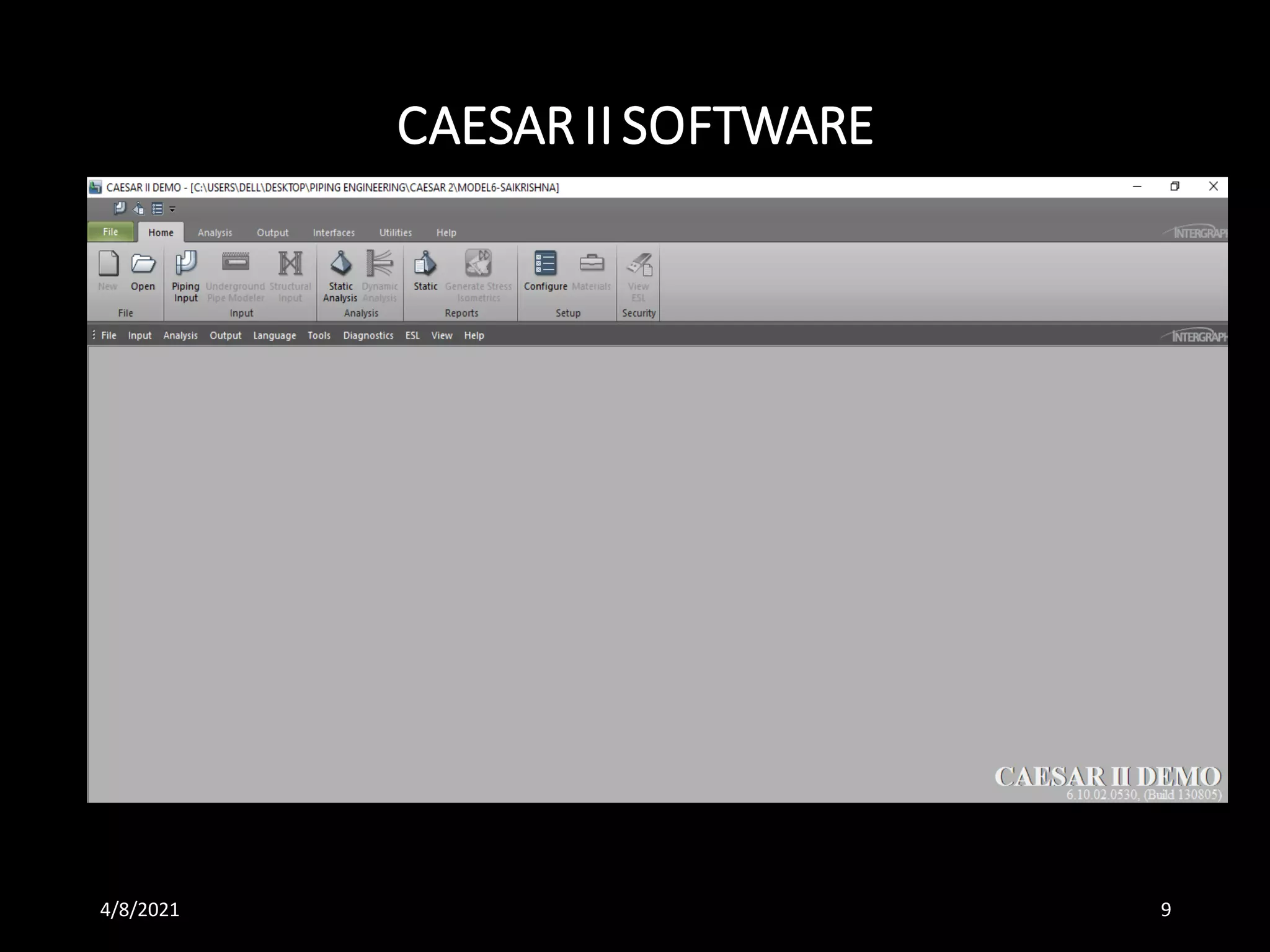

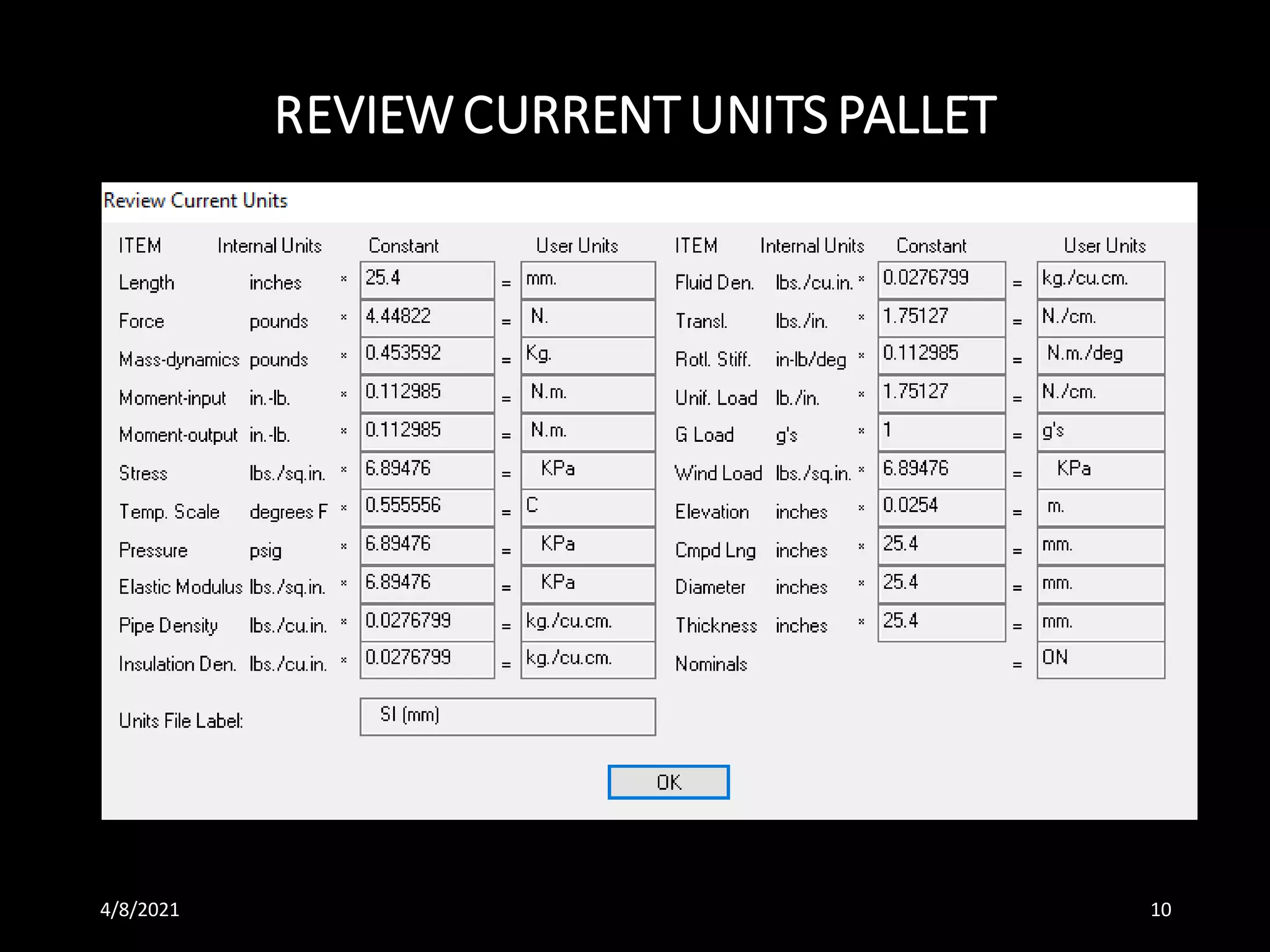

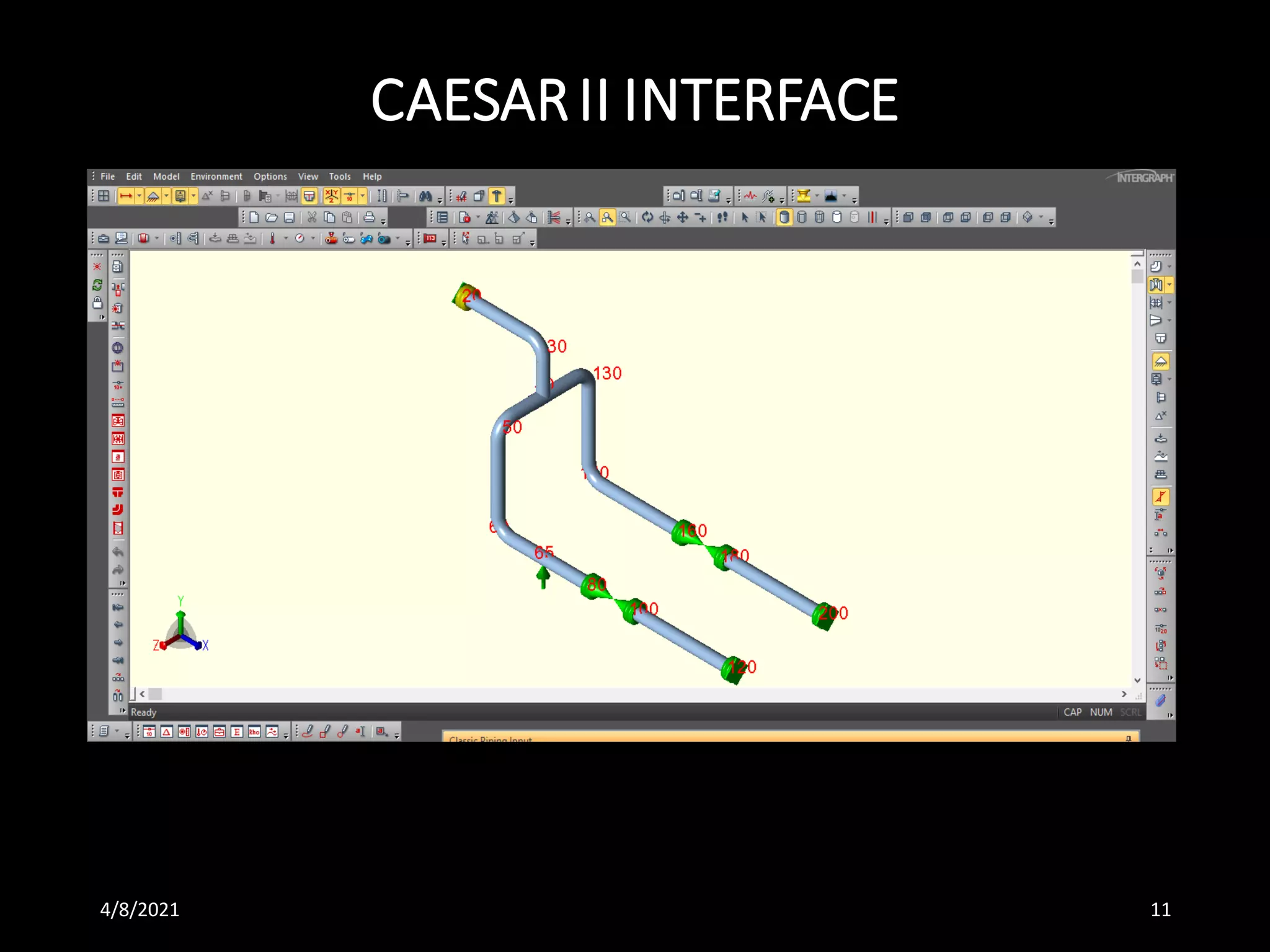

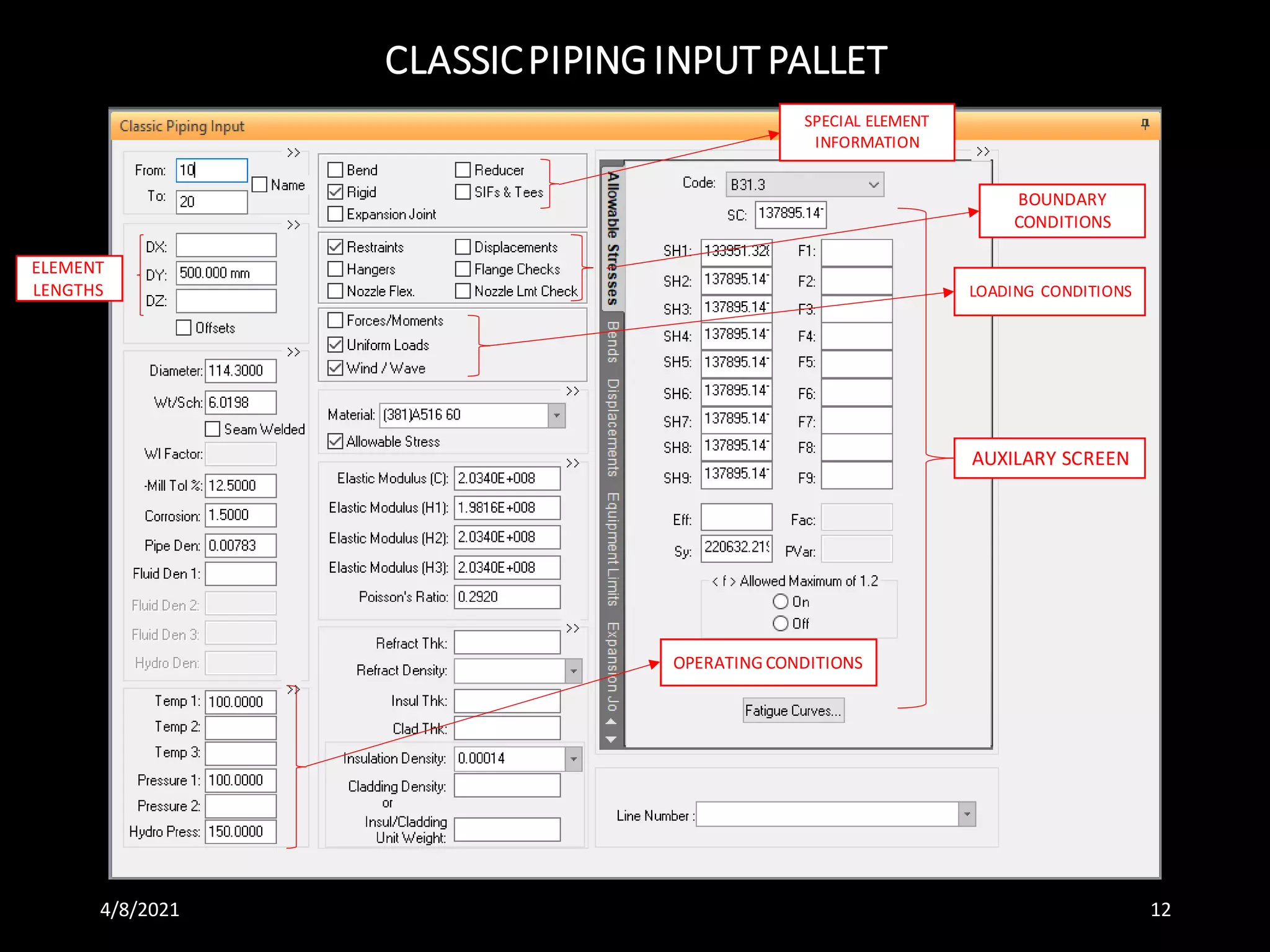

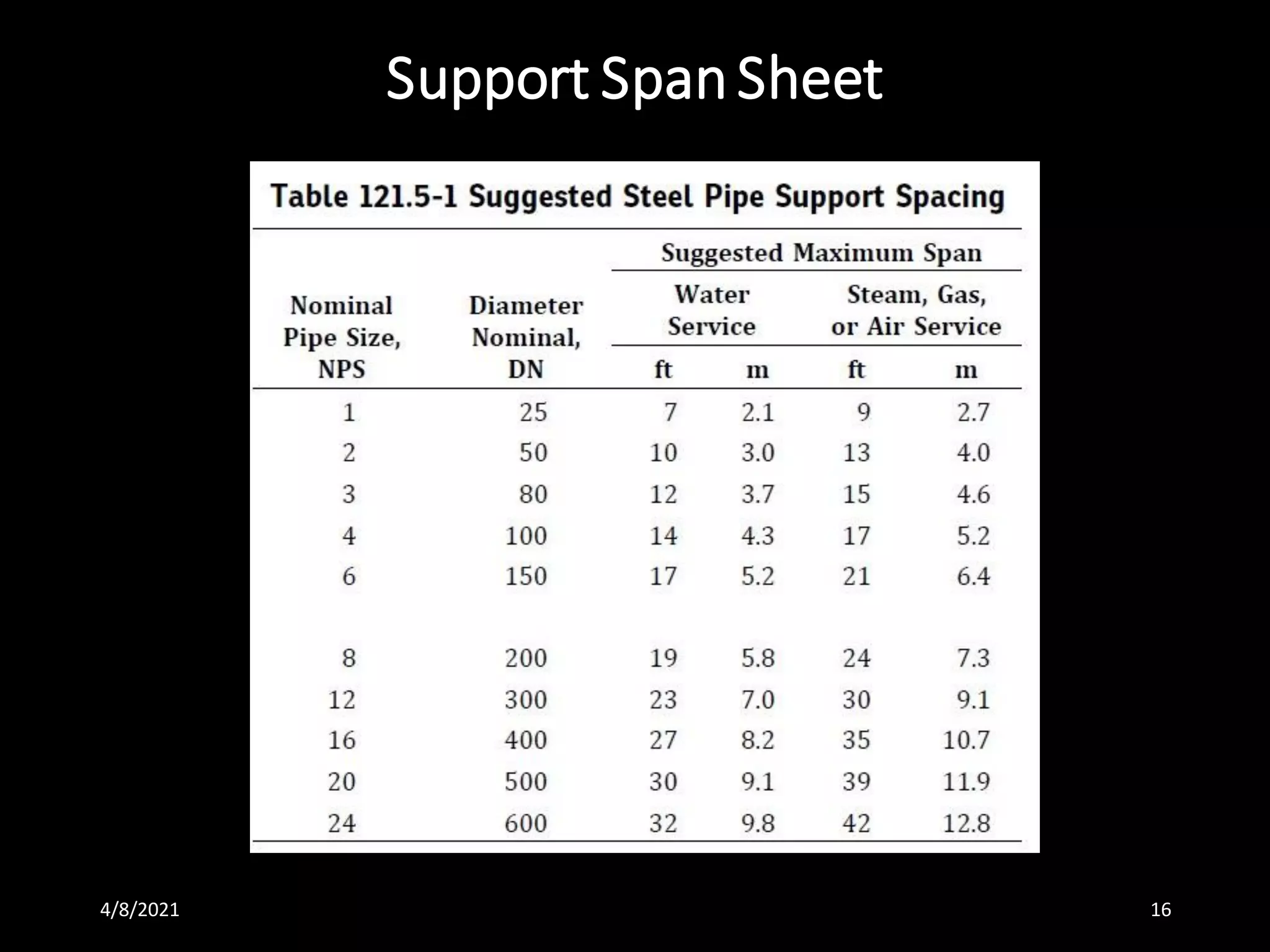

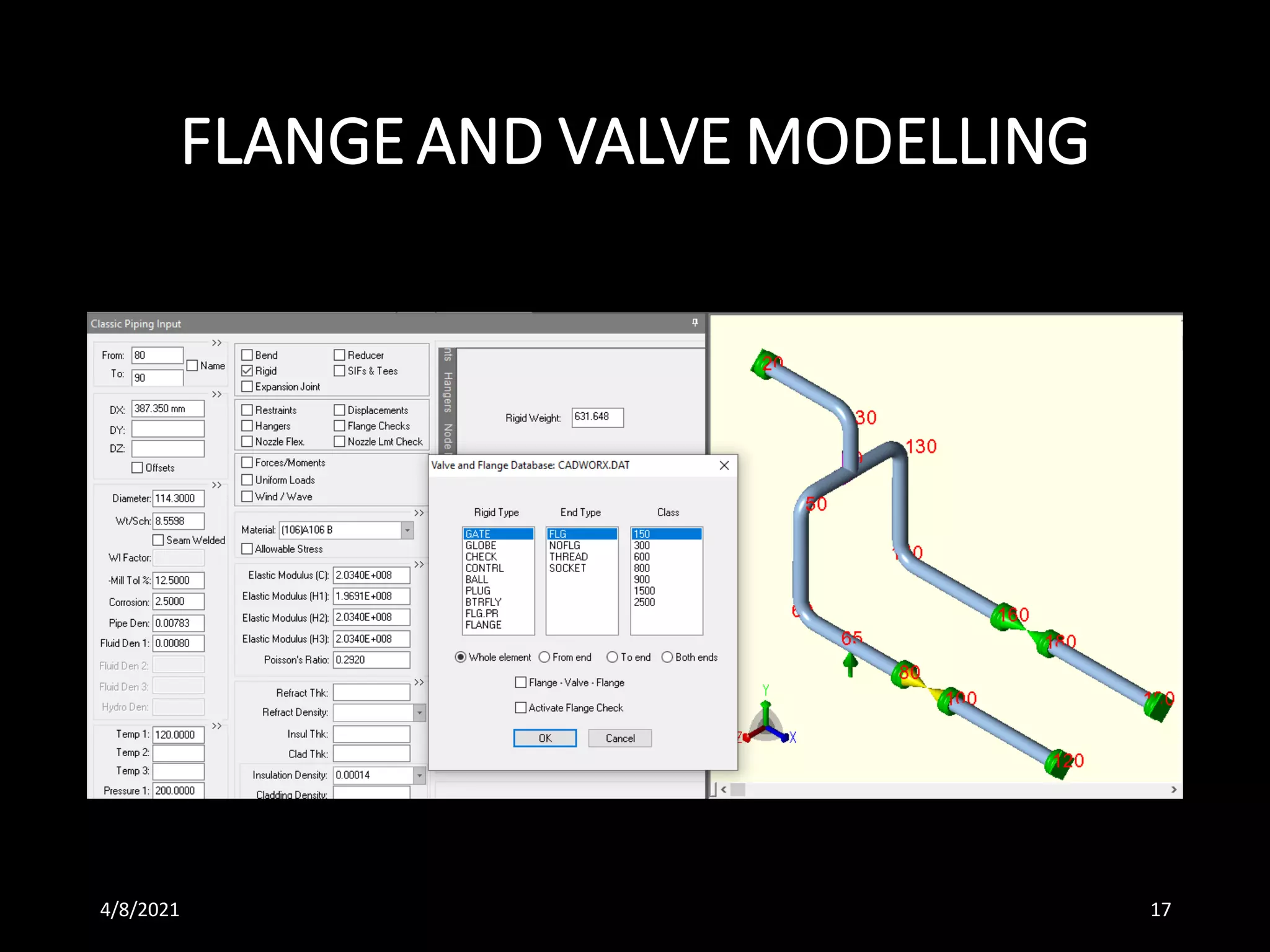

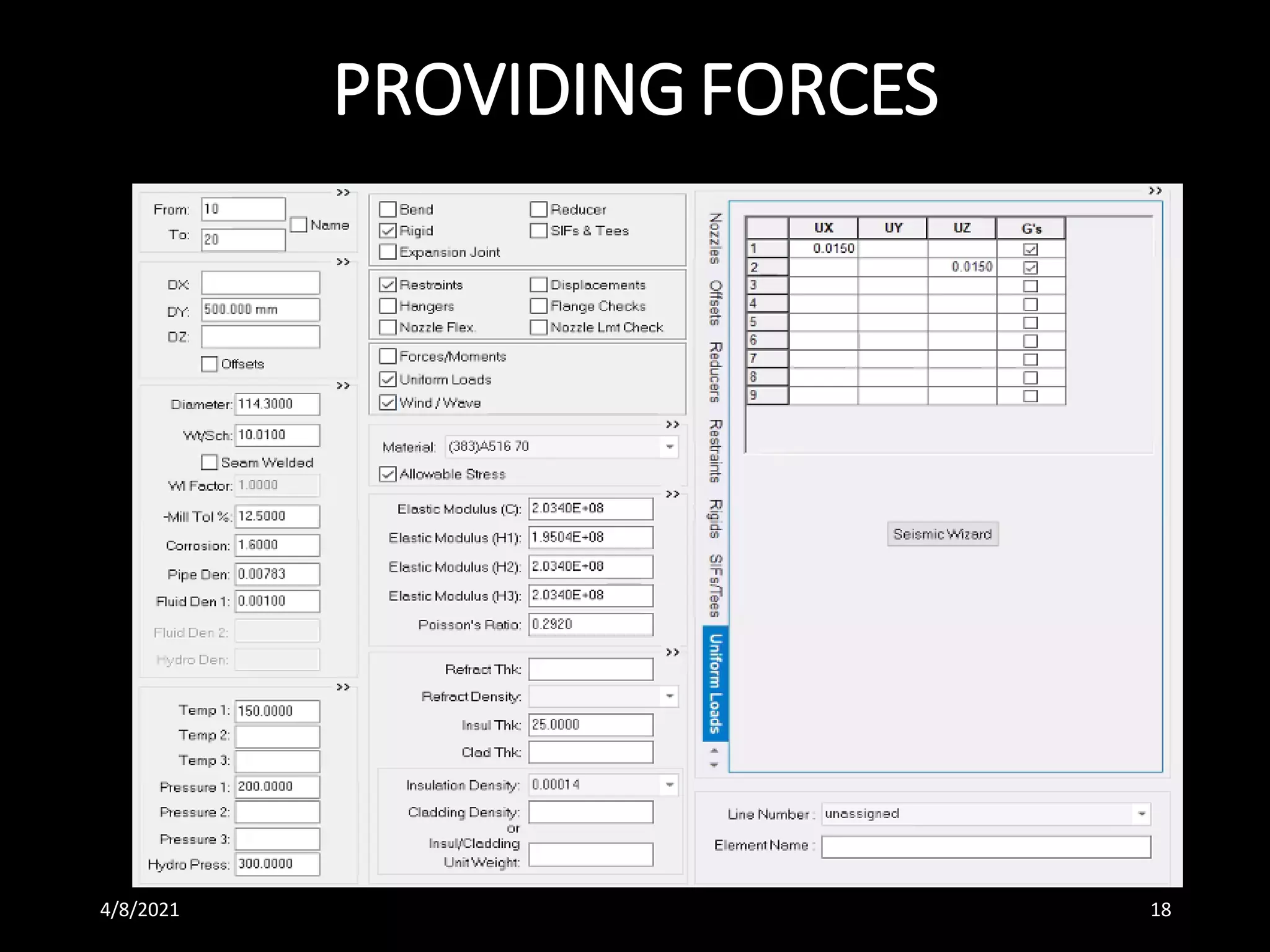

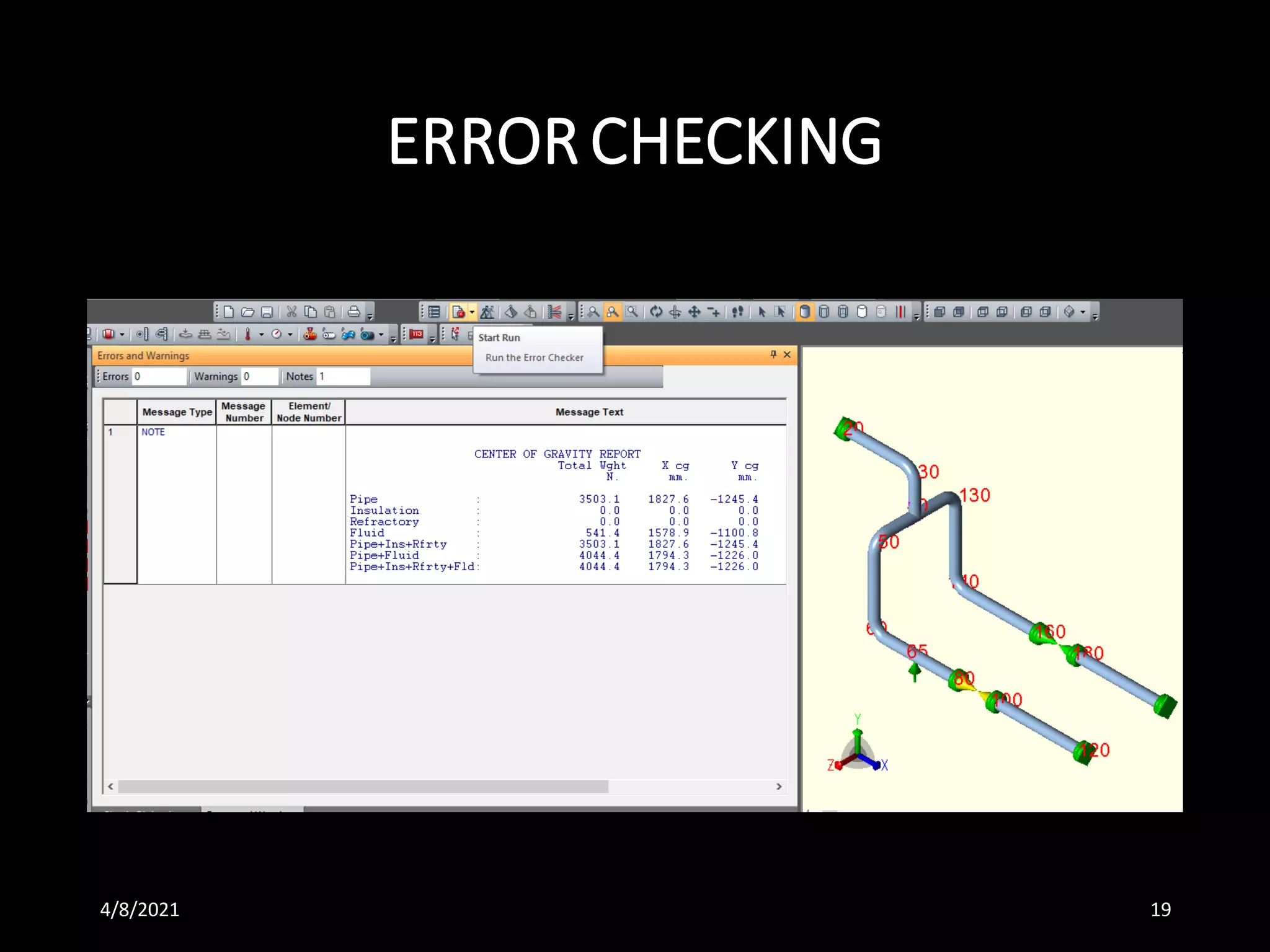

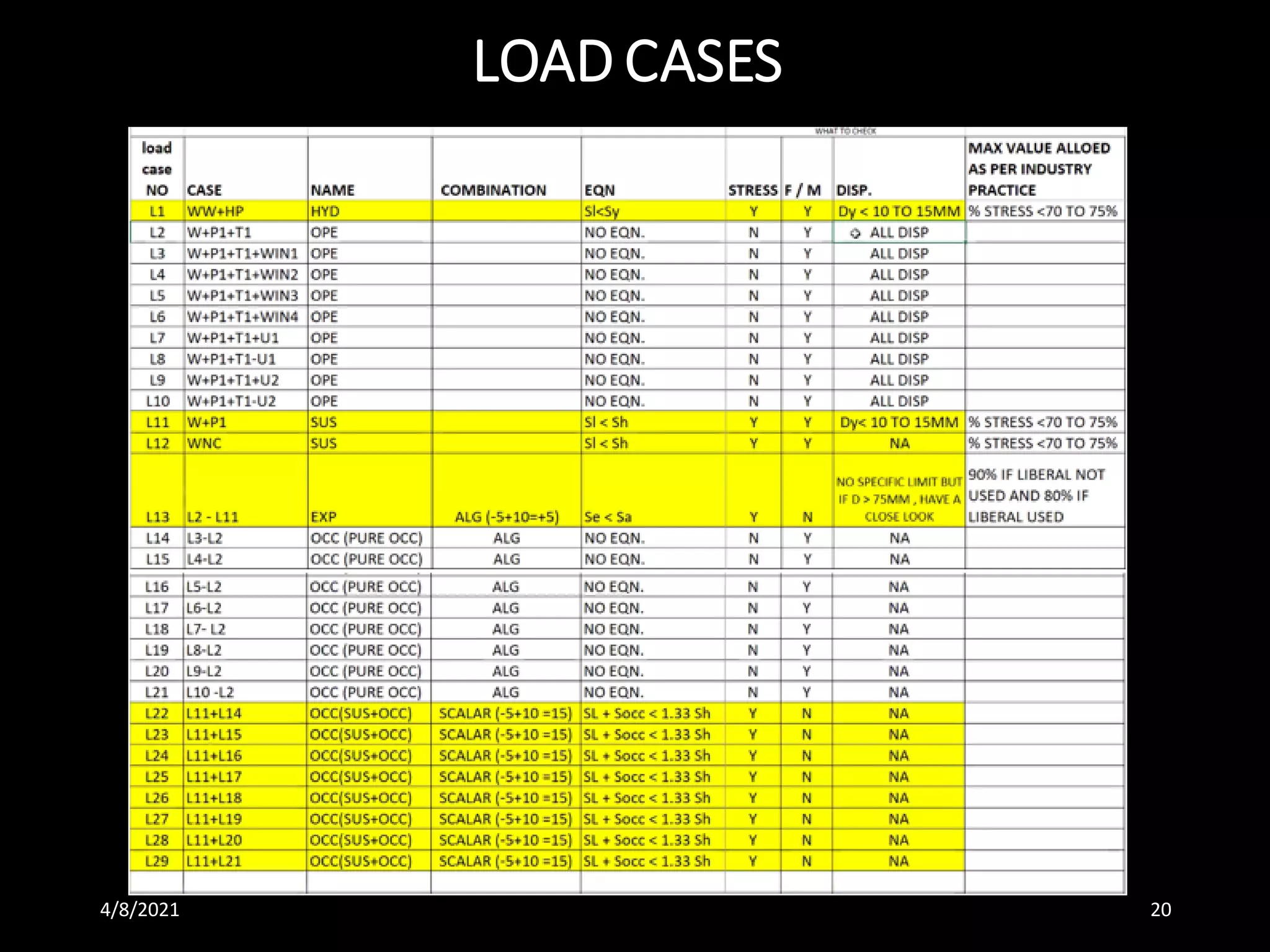

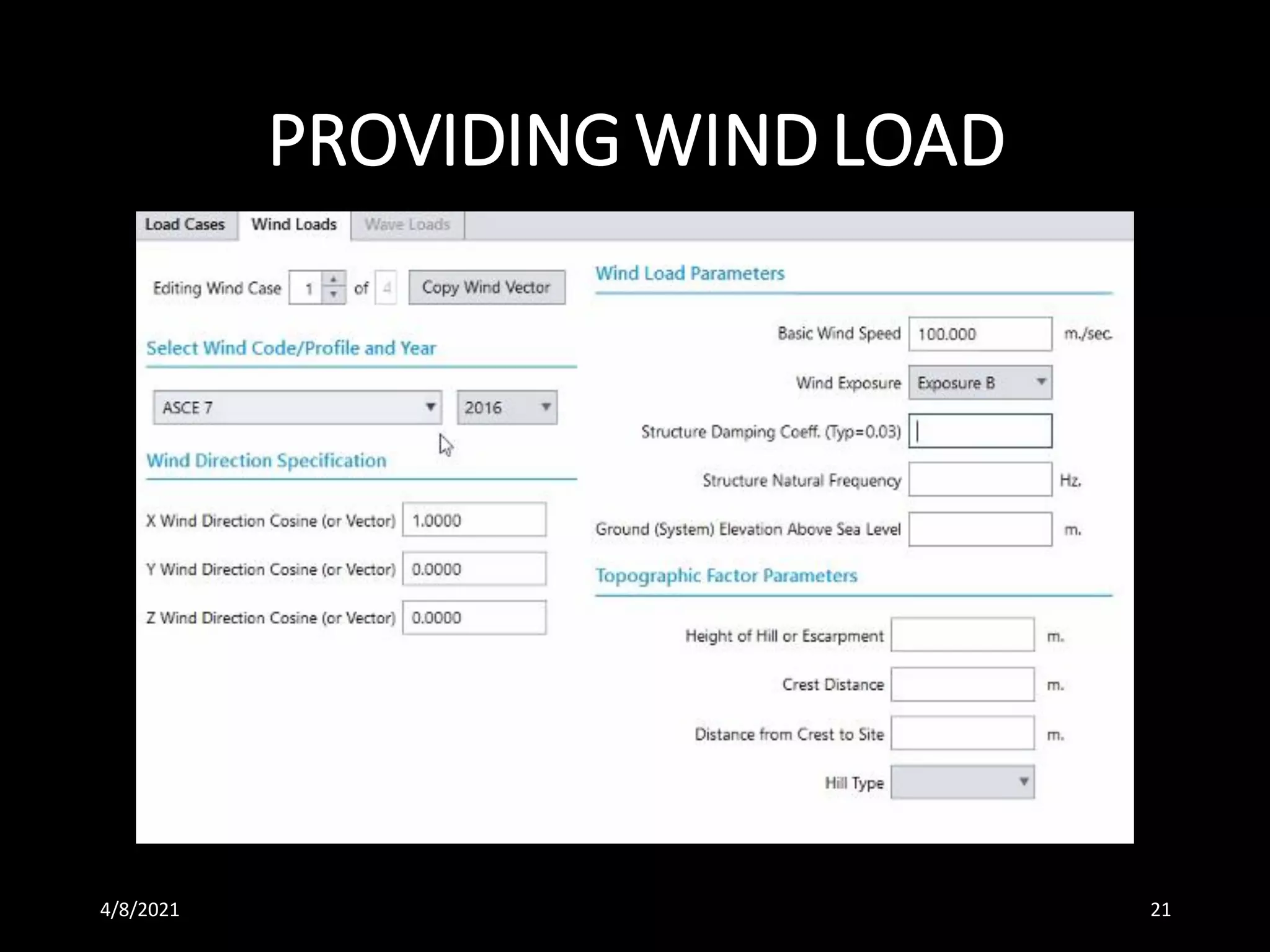

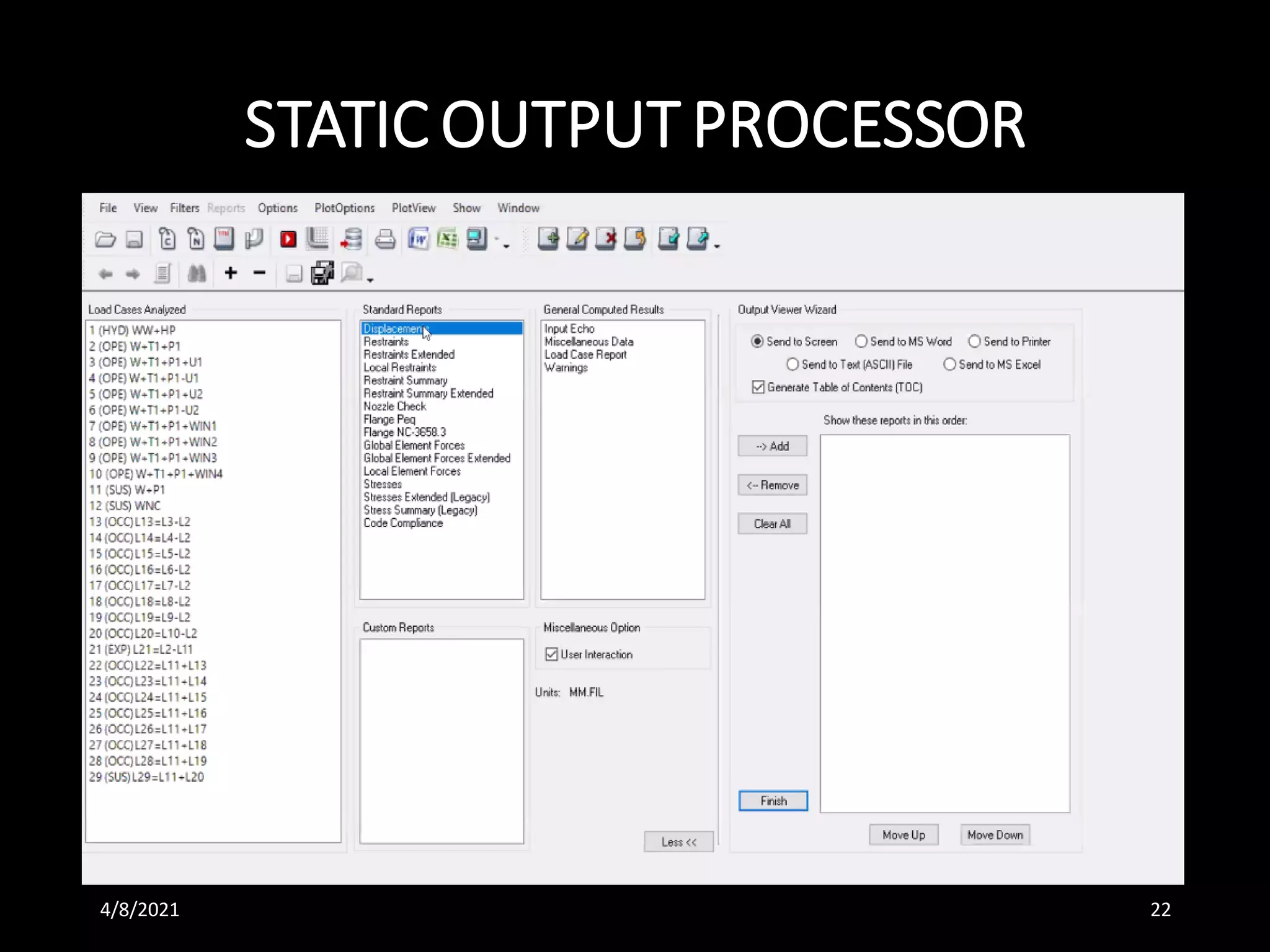

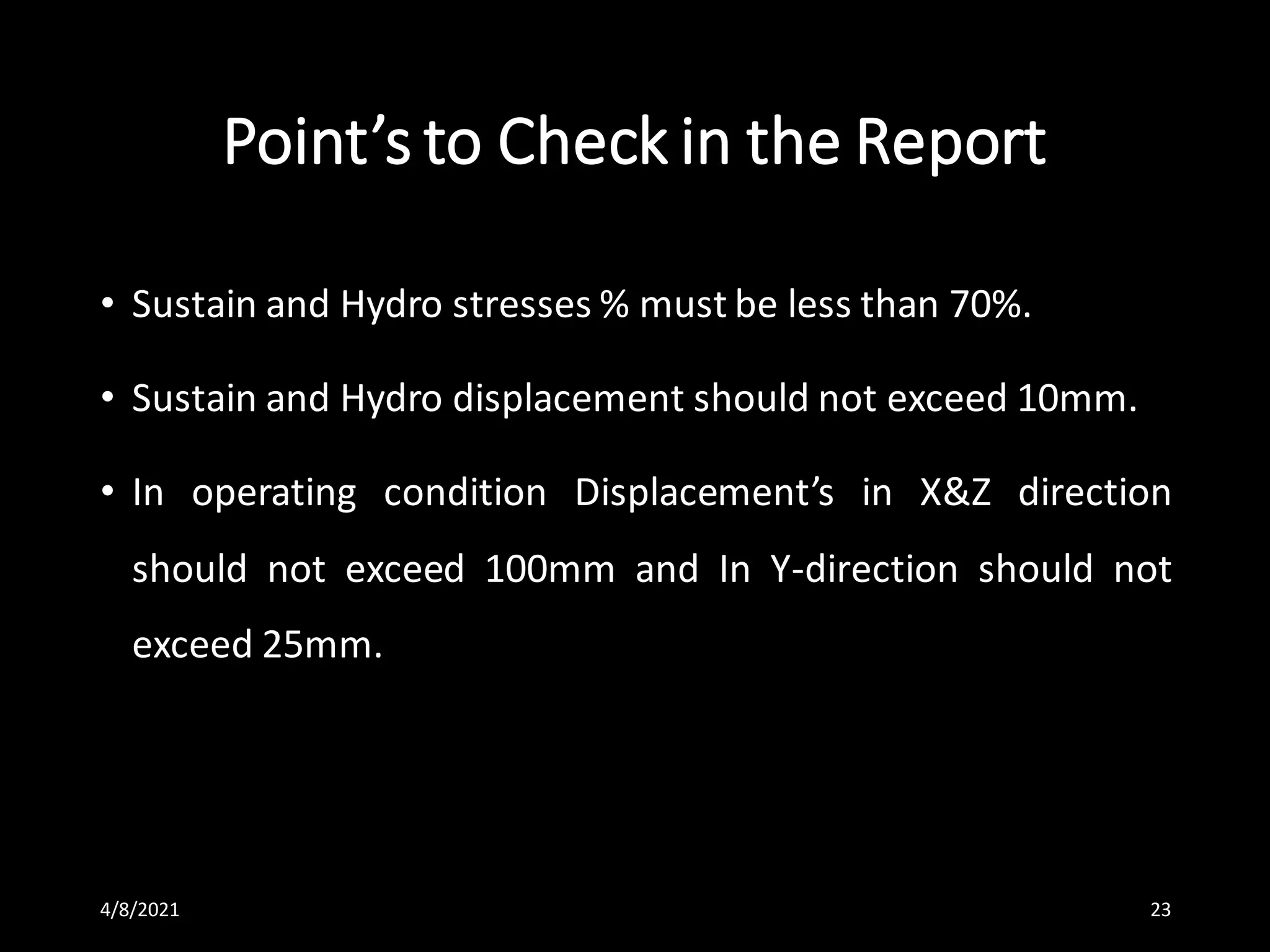

The document discusses pipe stress analysis, which evaluates the impact of loads, forces, and stresses on piping systems caused by factors such as temperature and pressure. It highlights the importance of performing stress analysis to prevent issues like excessive displacements and equipment failures, and introduces the CAESAR II software as a tool for conducting these analyses. Key properties related to stress analysis and guidelines for acceptable stress limits are also described.