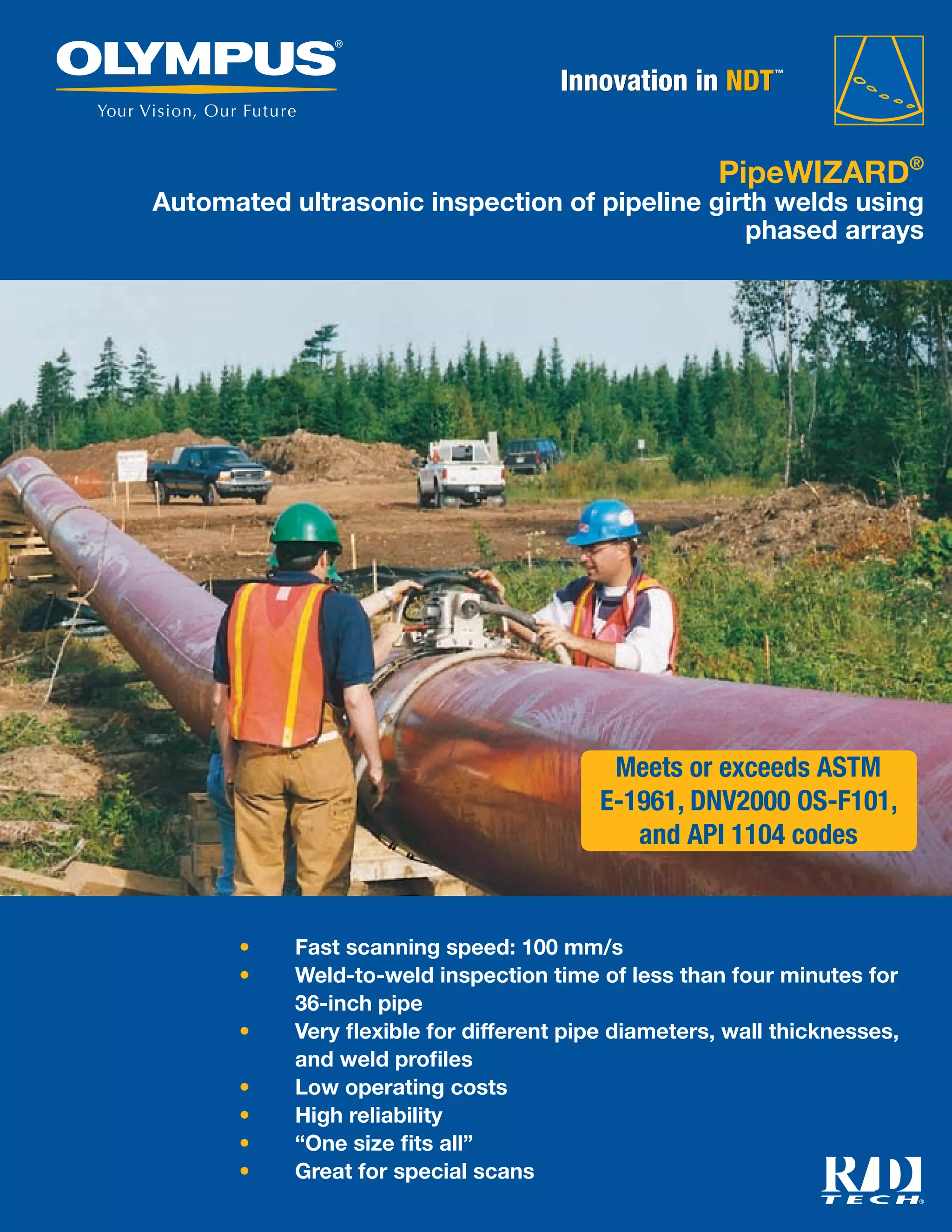

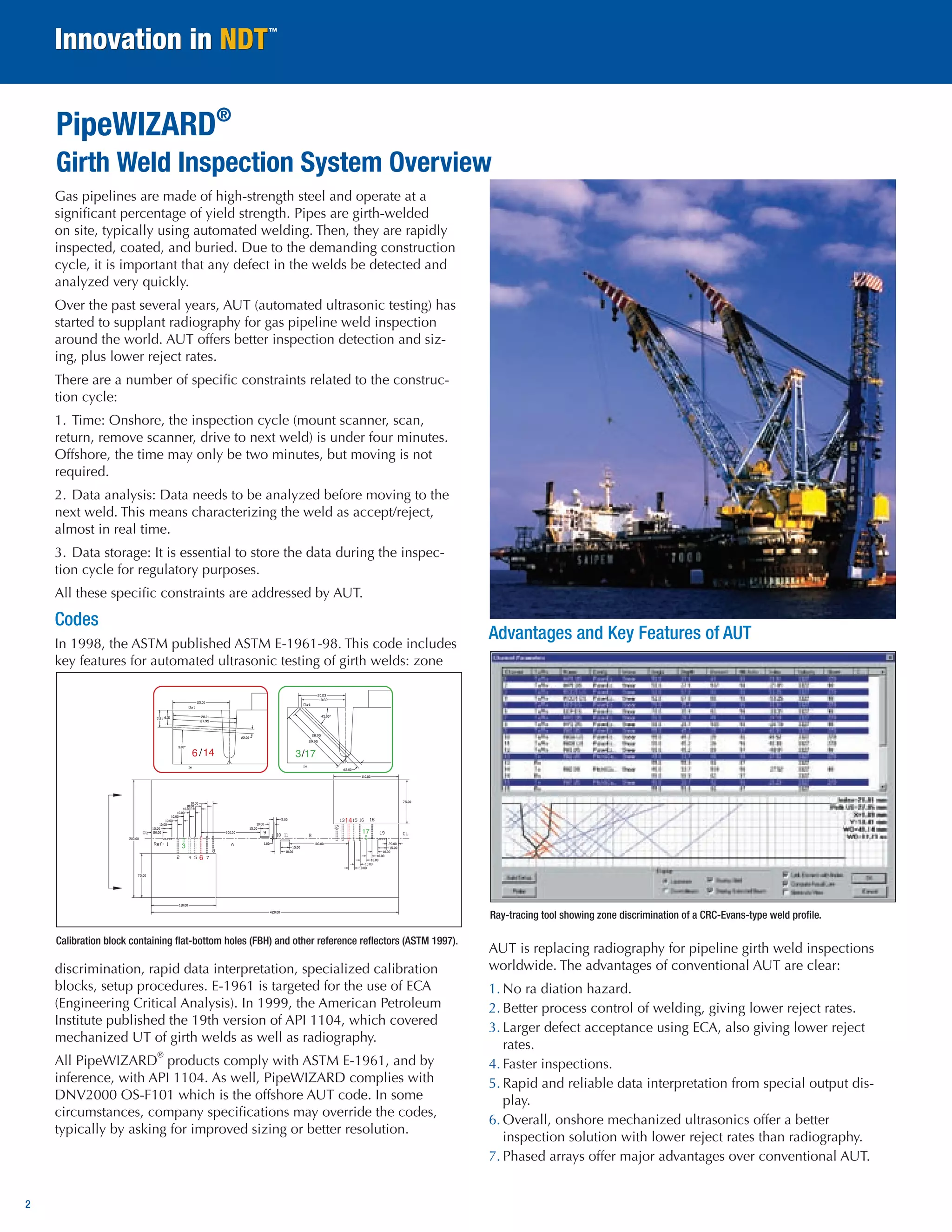

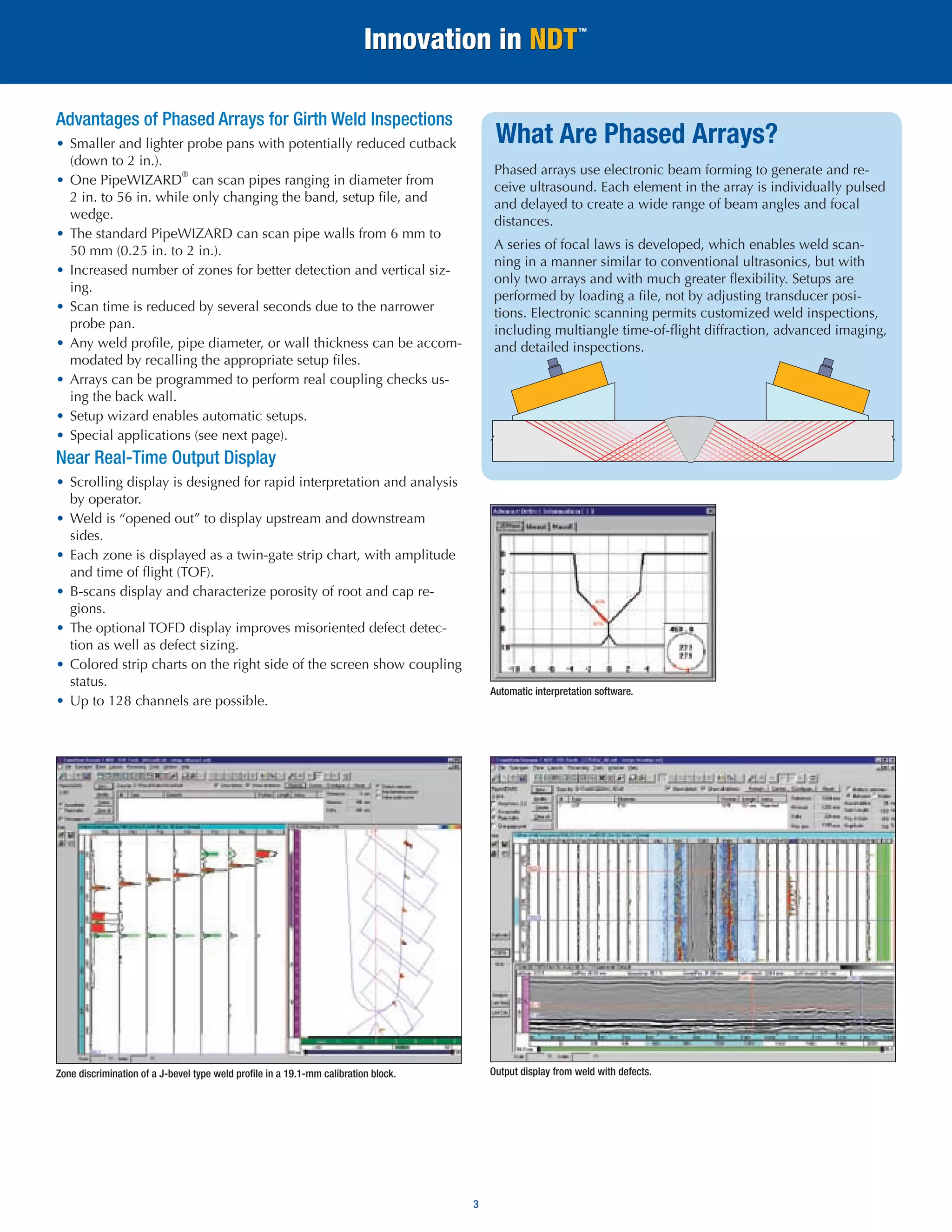

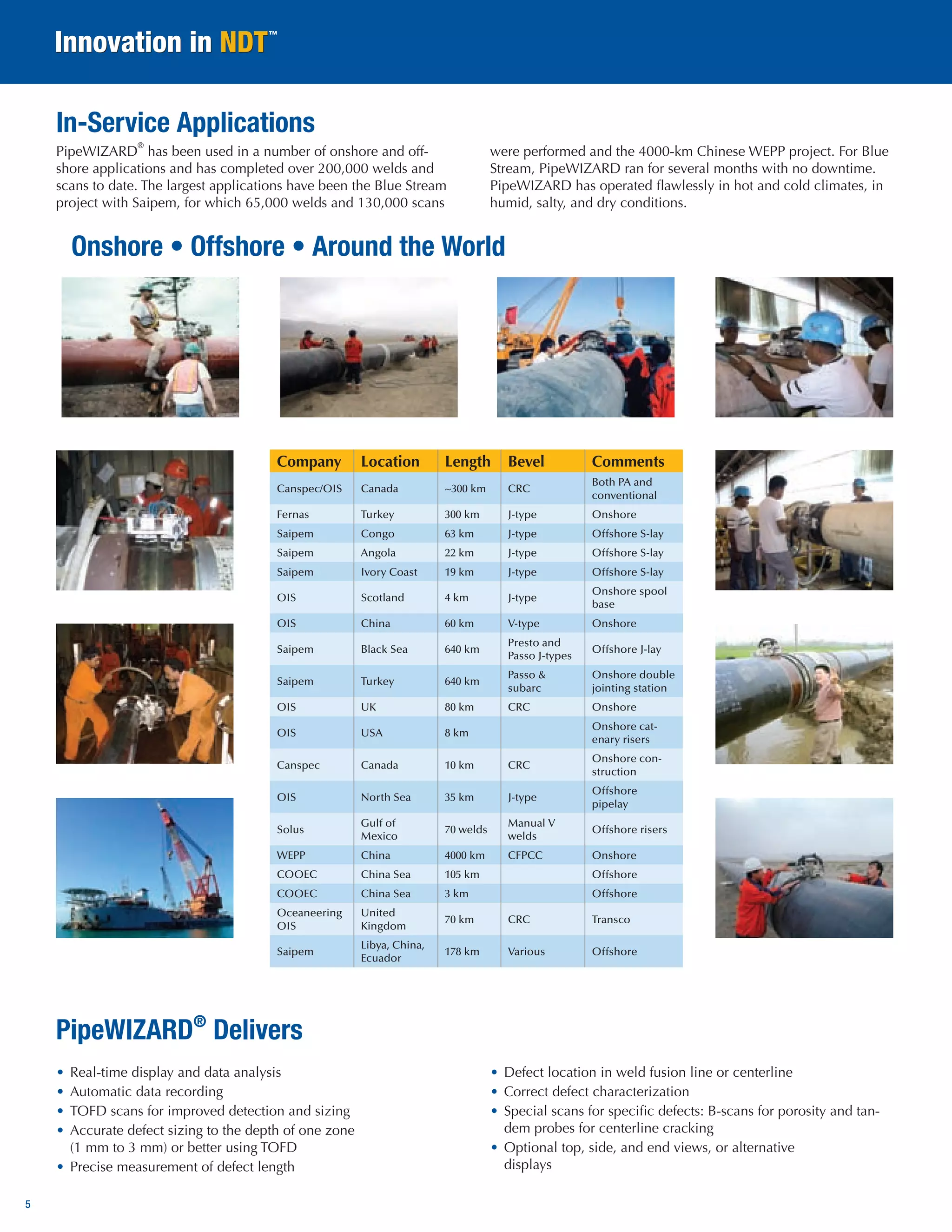

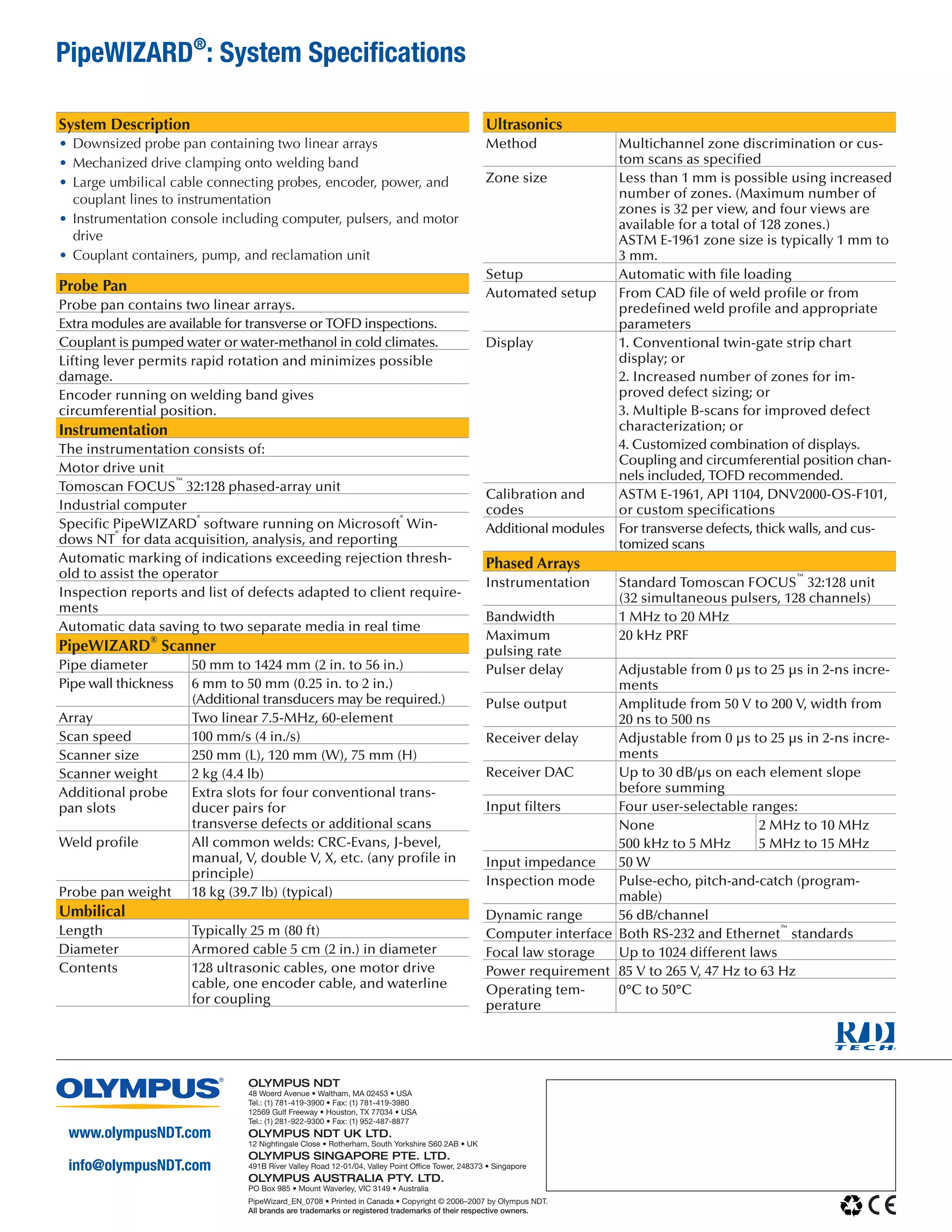

The document describes PipeWIZARD, an automated ultrasonic inspection system for pipeline girth welds using phased array technology. It can inspect welds fast, in under 4 minutes, and complies with industry codes. Phased arrays allow electronic beam forming for flexible inspection of different pipe diameters and wall thicknesses. The system provides zone discrimination for accurate defect sizing and detection of flaws in welds. It has been used to inspect over 200,000 welds on various pipeline projects worldwide.