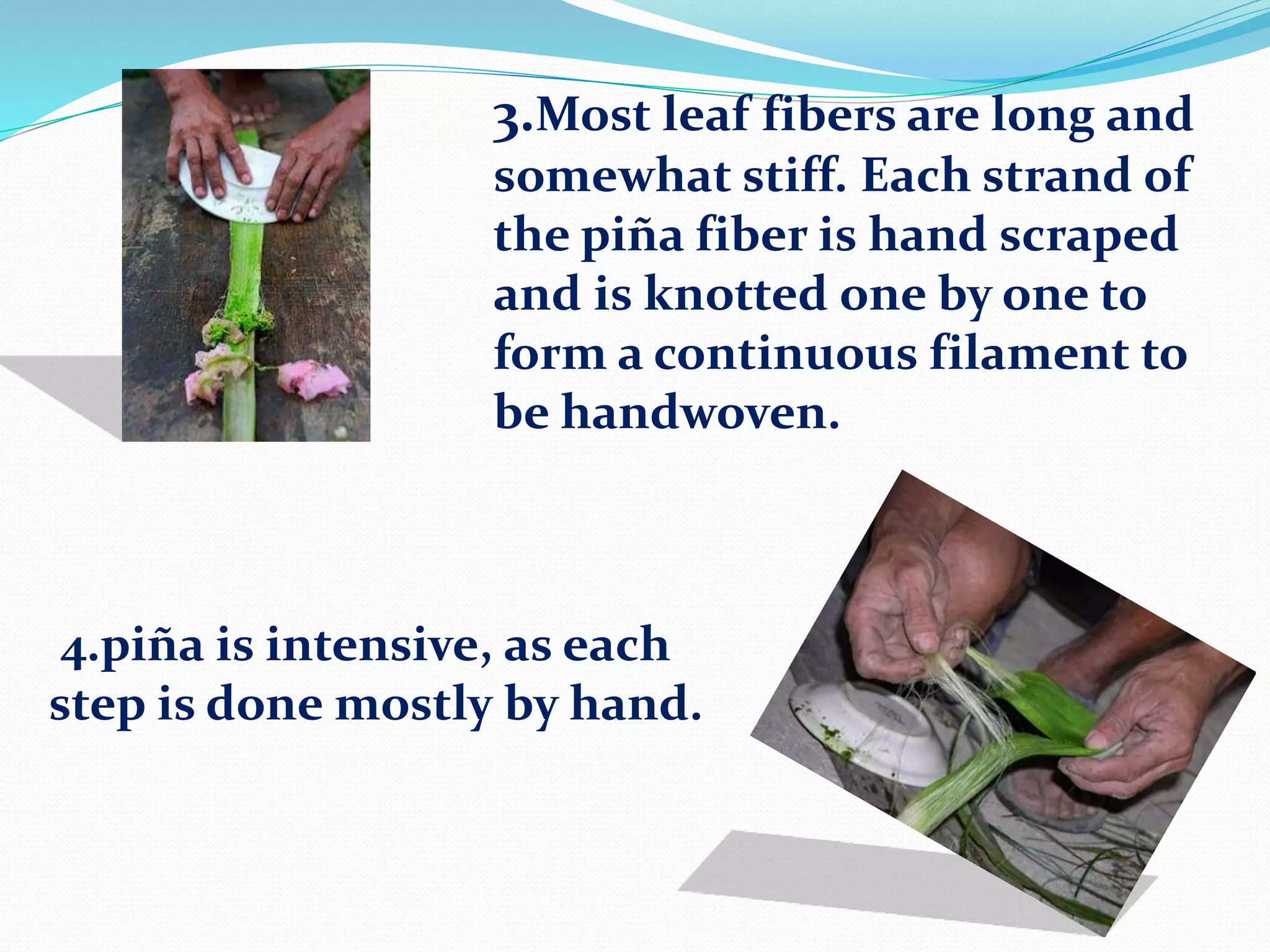

Pina fiber is obtained from the leaves of pineapple plants. It is made through a labor intensive process of cutting leaves, separating fibers, and hand scraping and knotting them. Pina fiber is lustrous and durable with physical and chemical properties that make it resistant to wear and require no harsh chemicals for care. While pina fabric was once globally in demand, cheaper cotton replaced it until recent revival efforts that have restored its status as a symbol of Philippine culture and elite fashion. Pina weaving survives as an important cultural heritage craft.