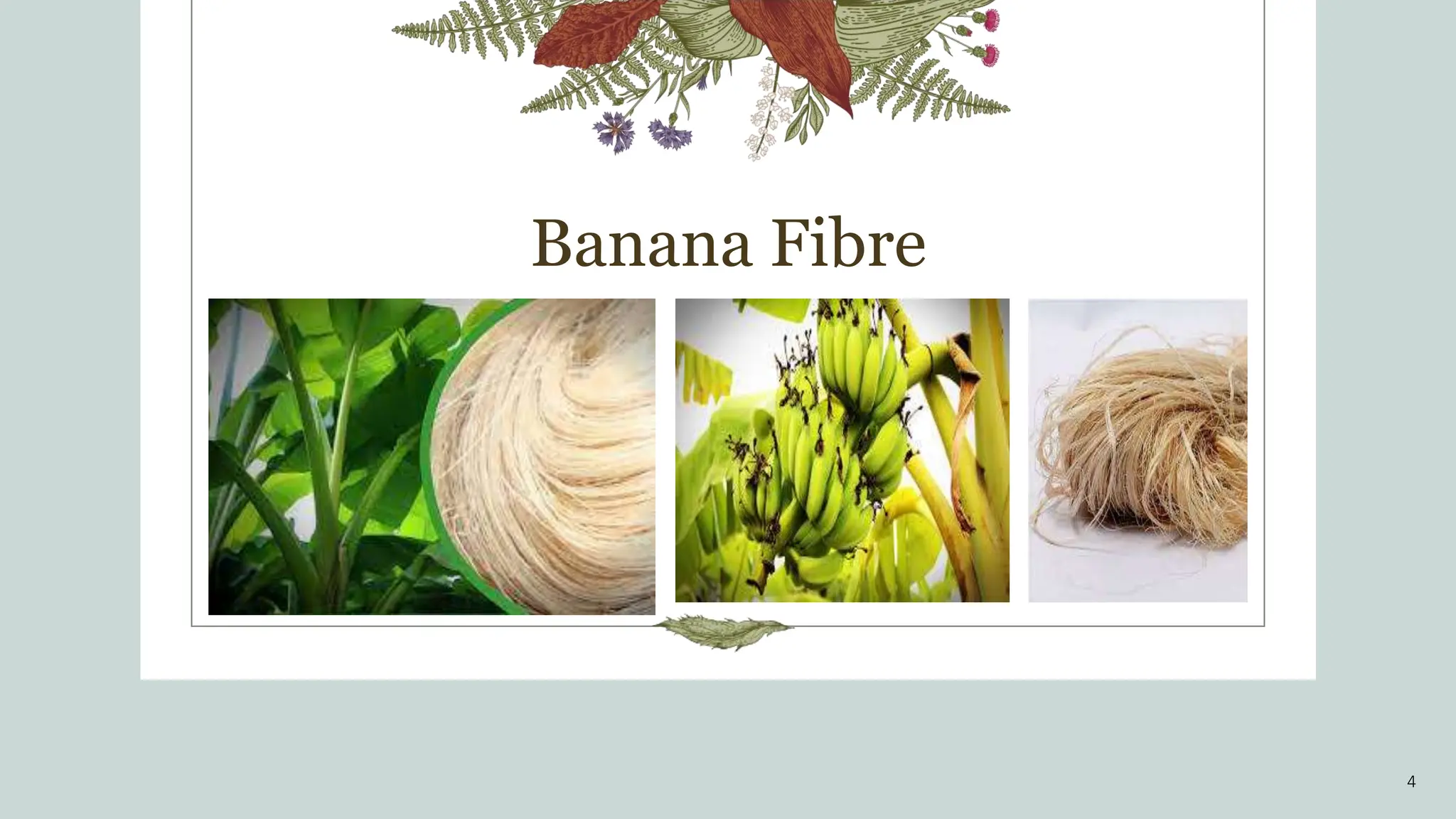

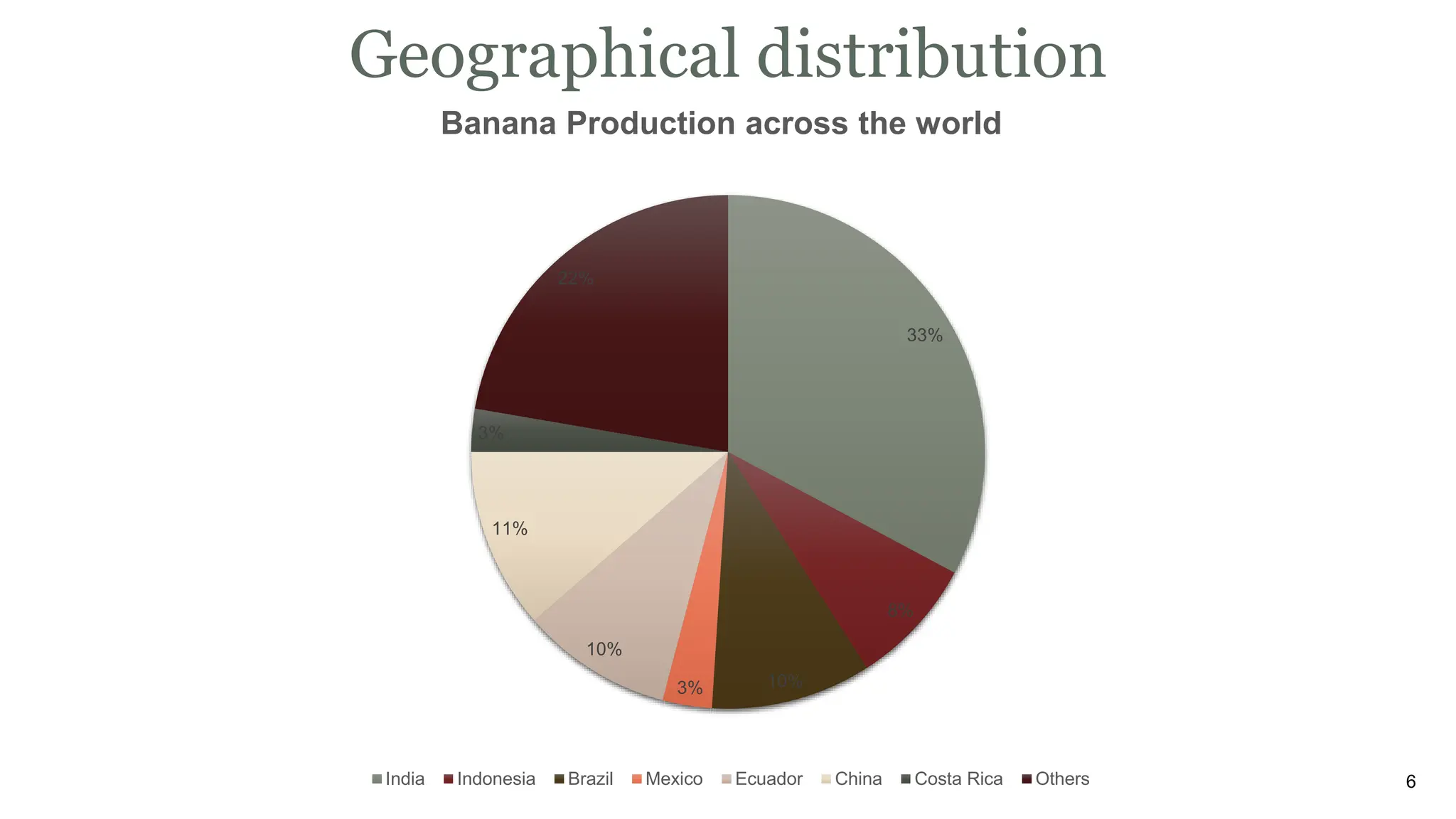

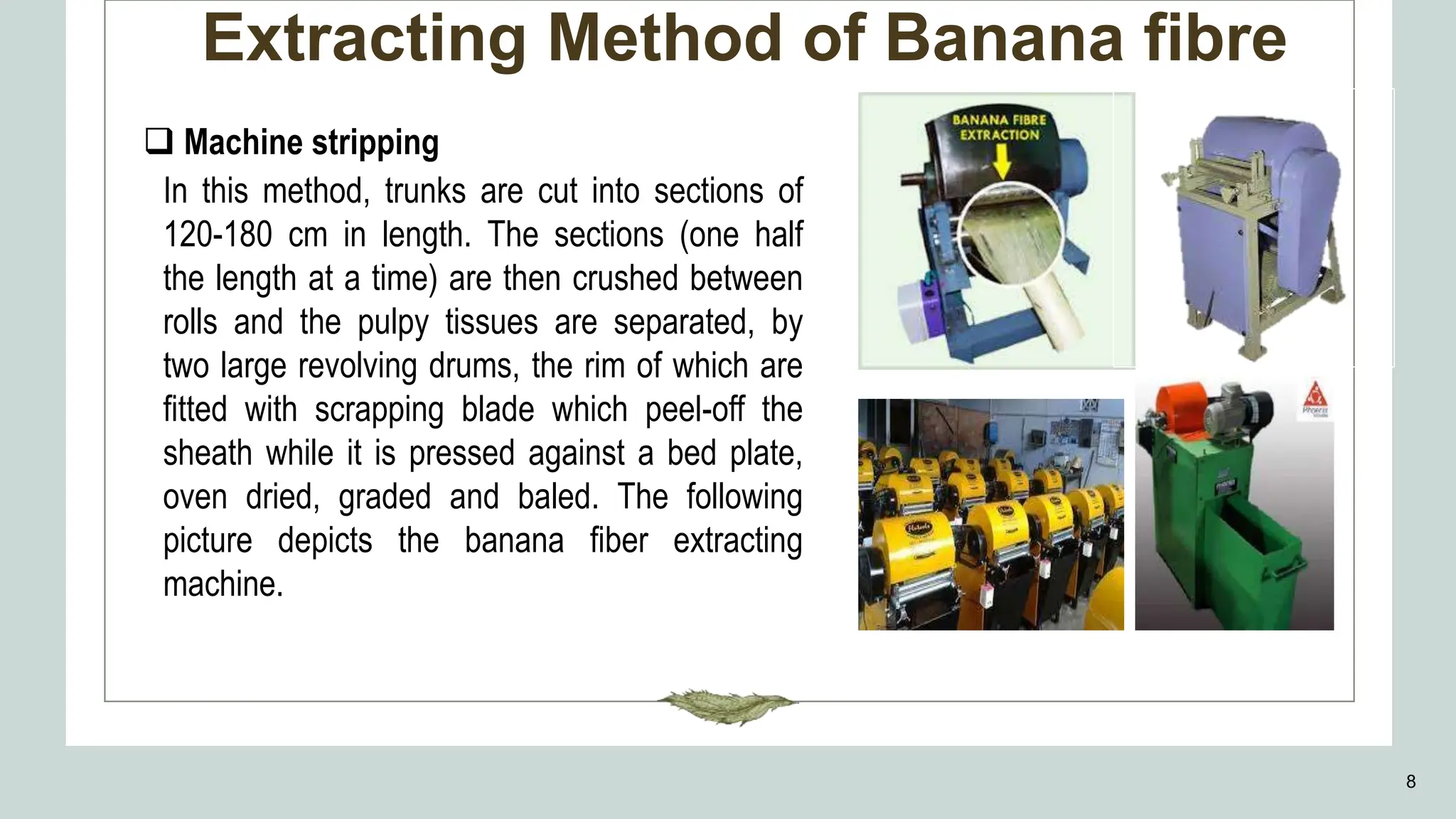

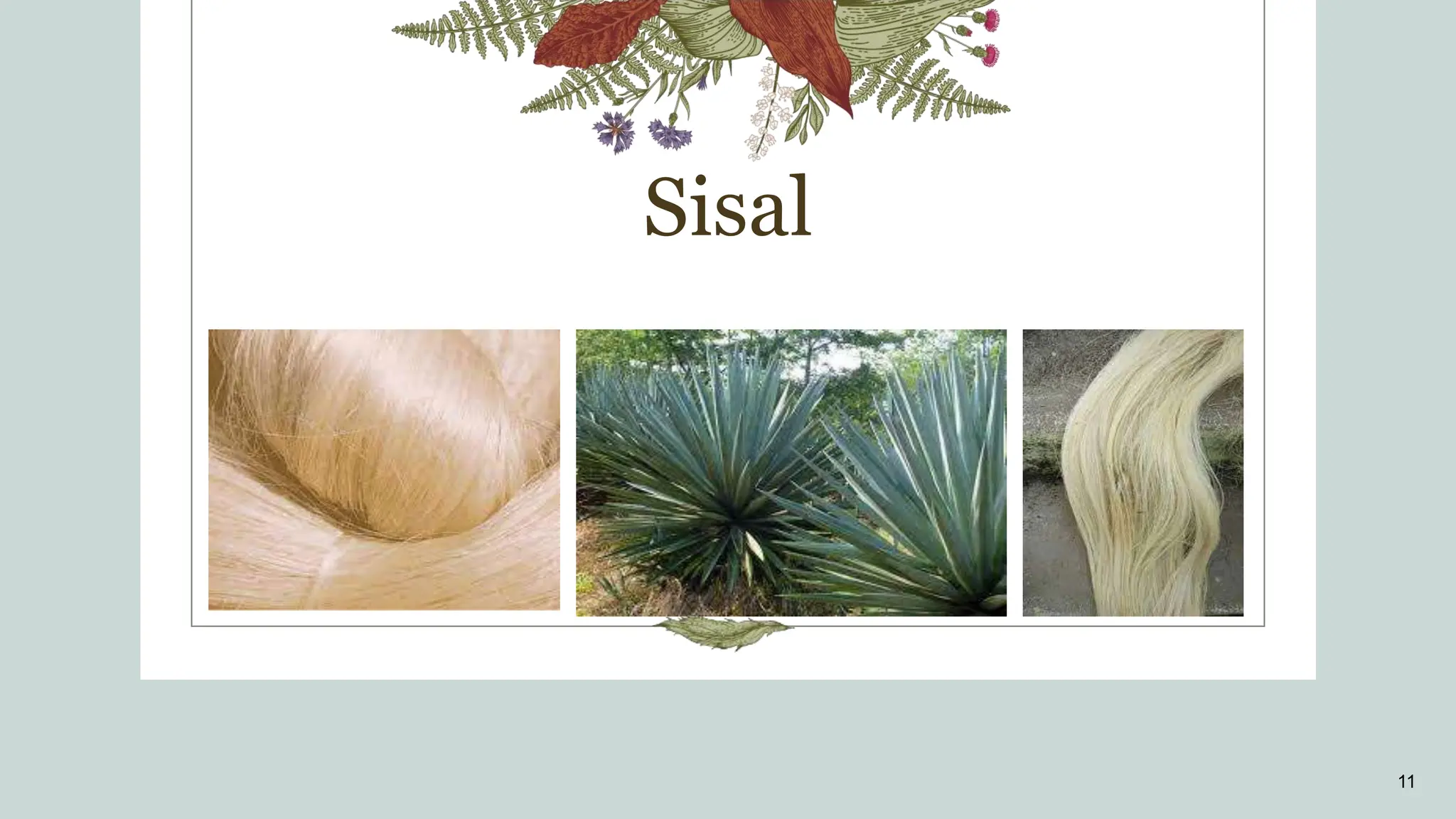

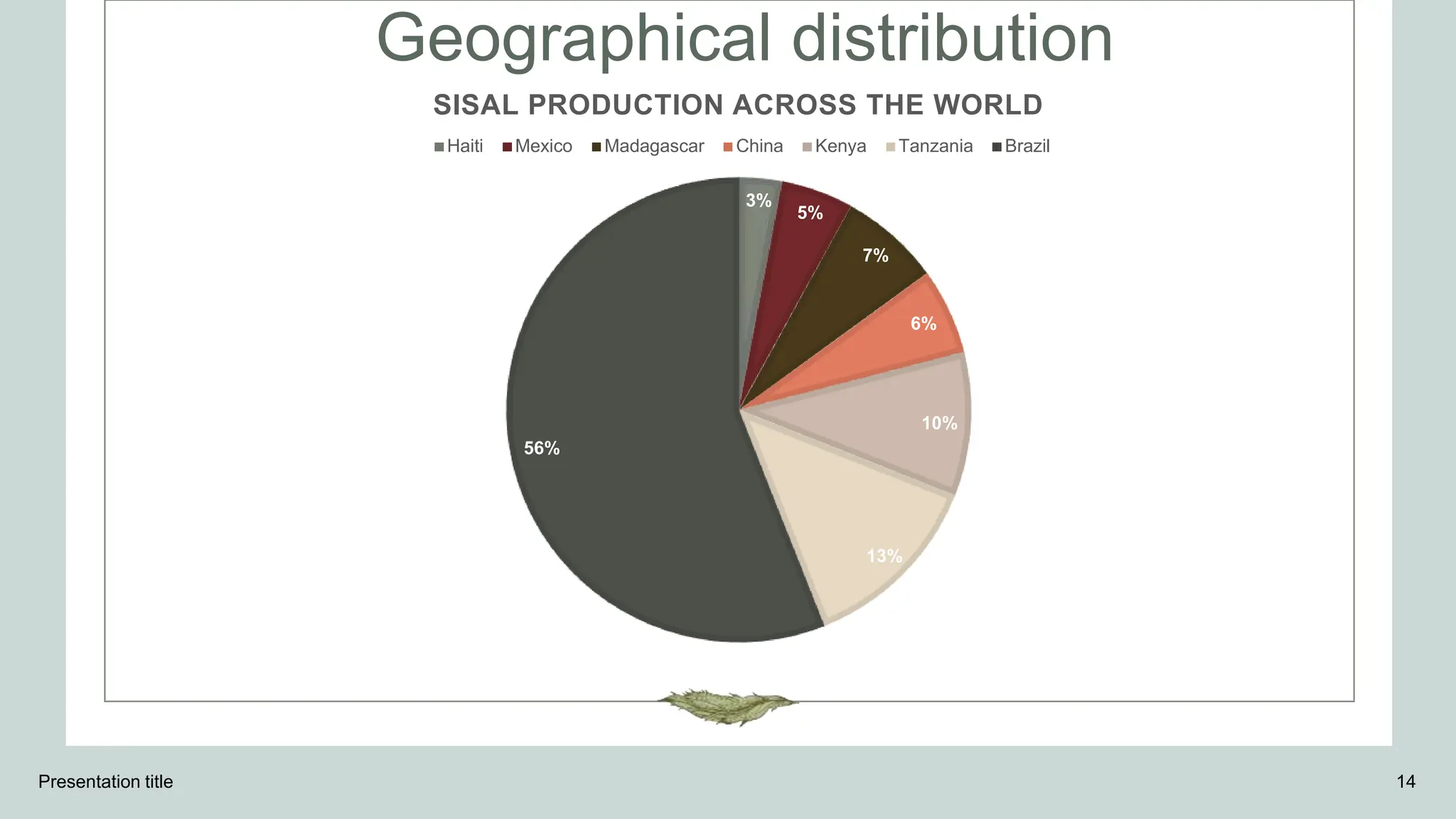

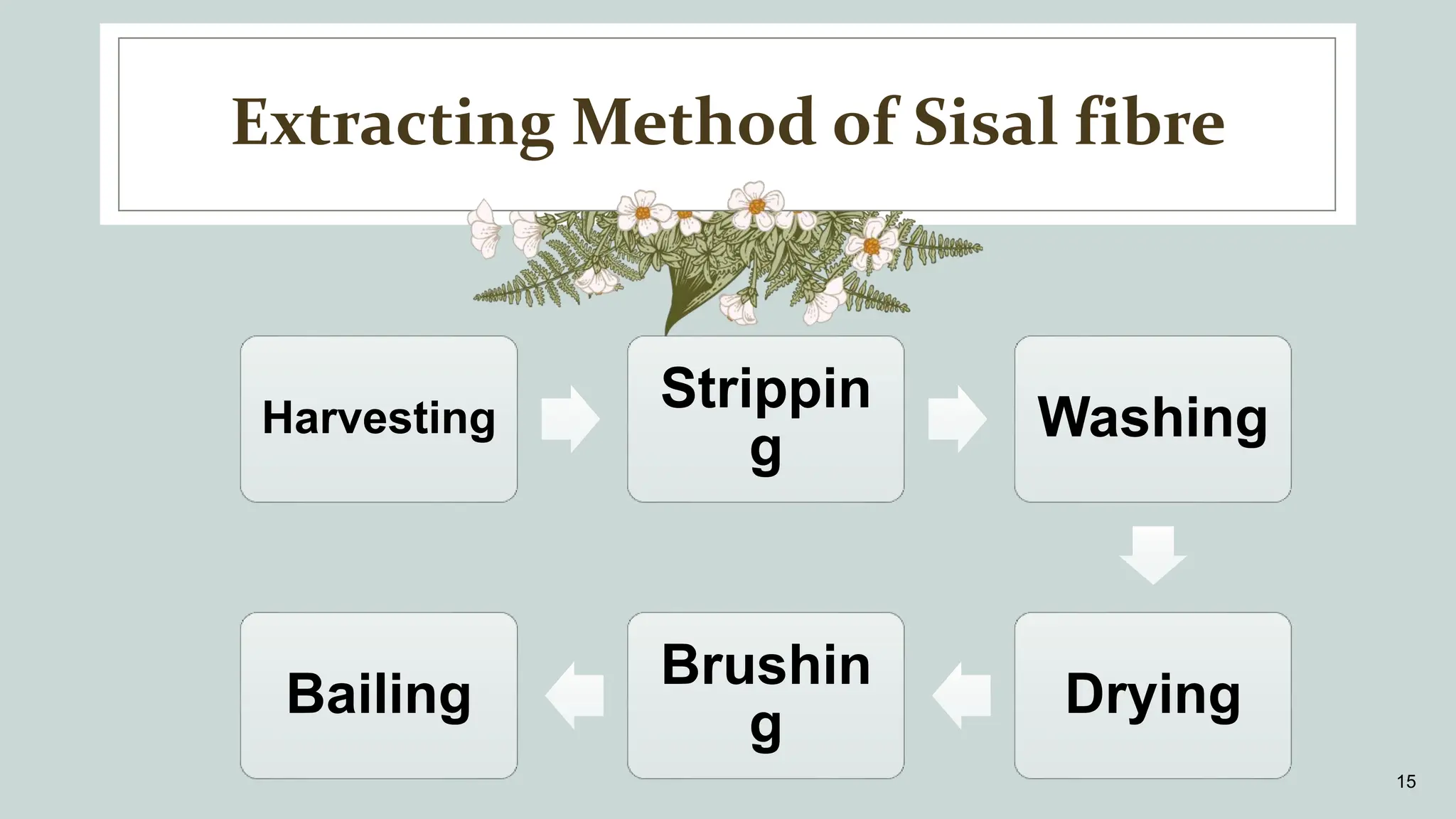

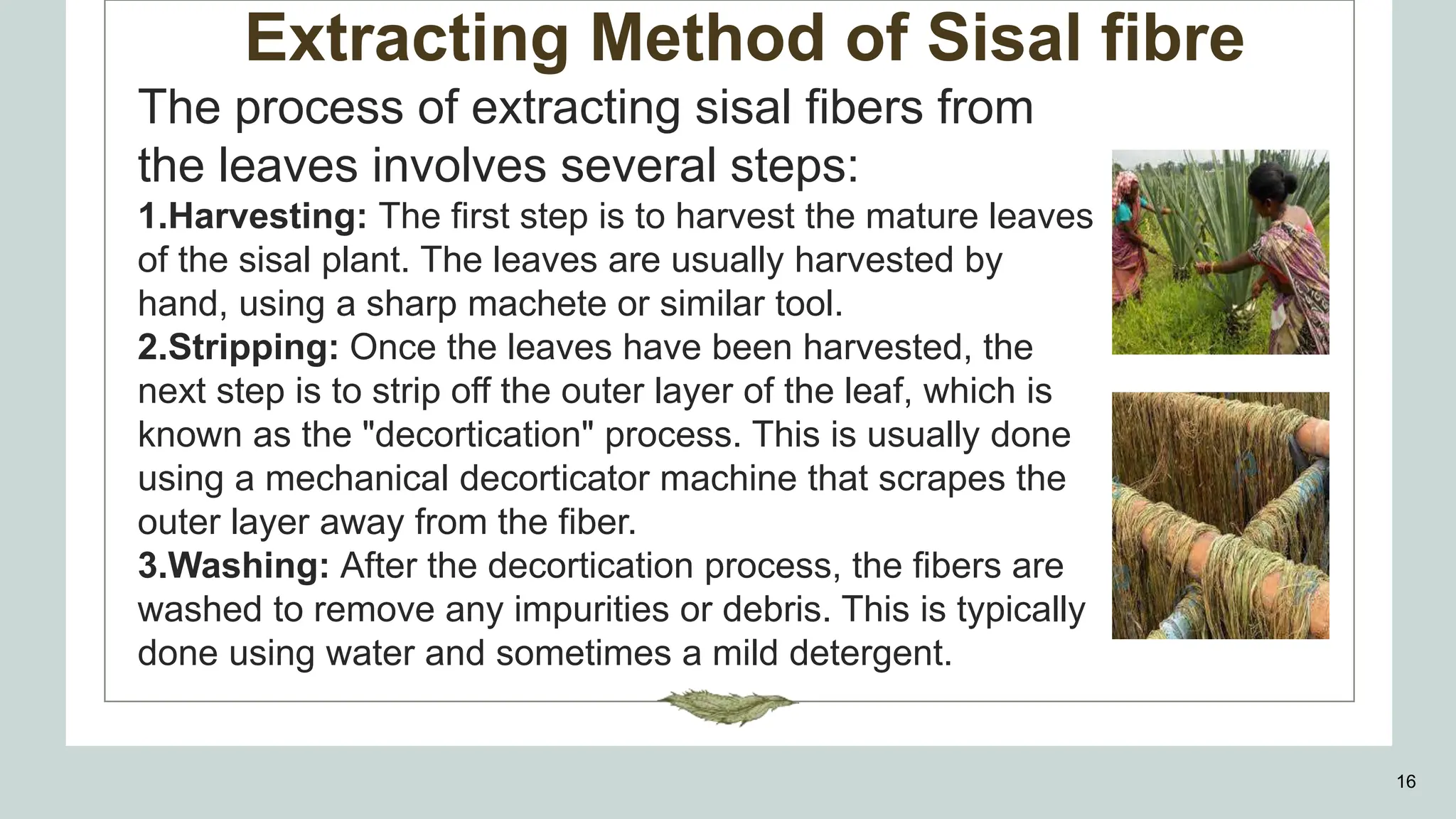

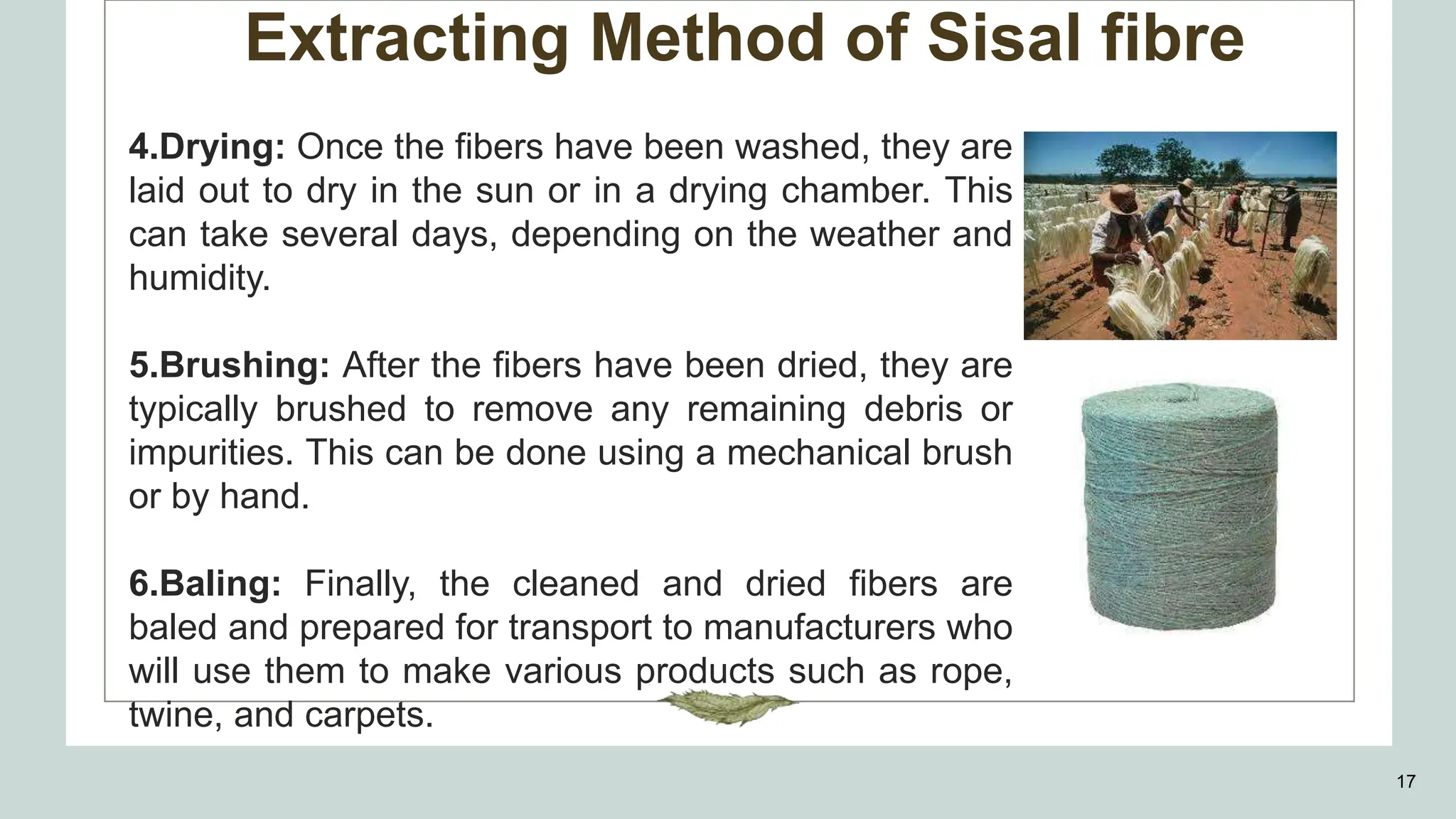

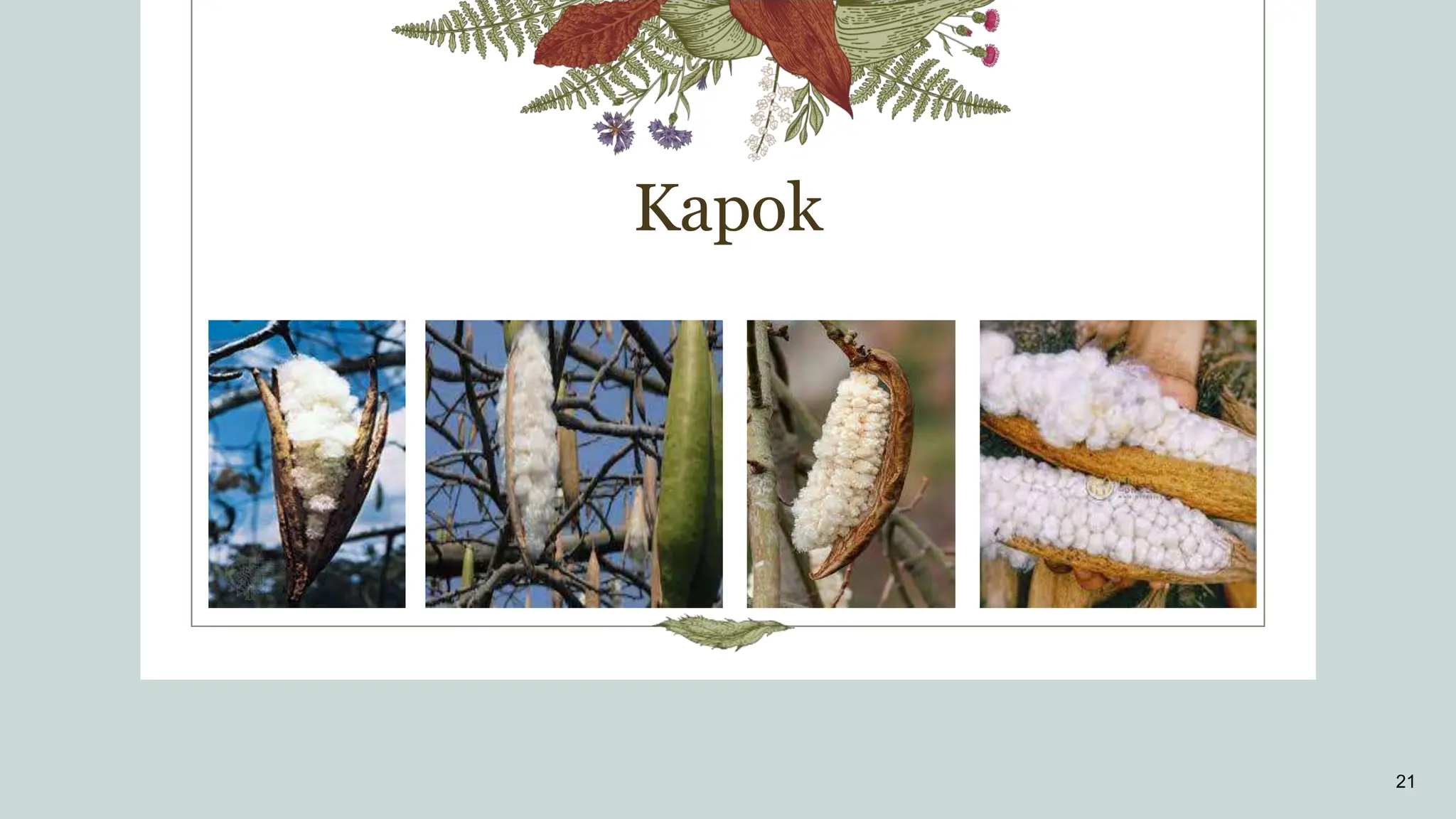

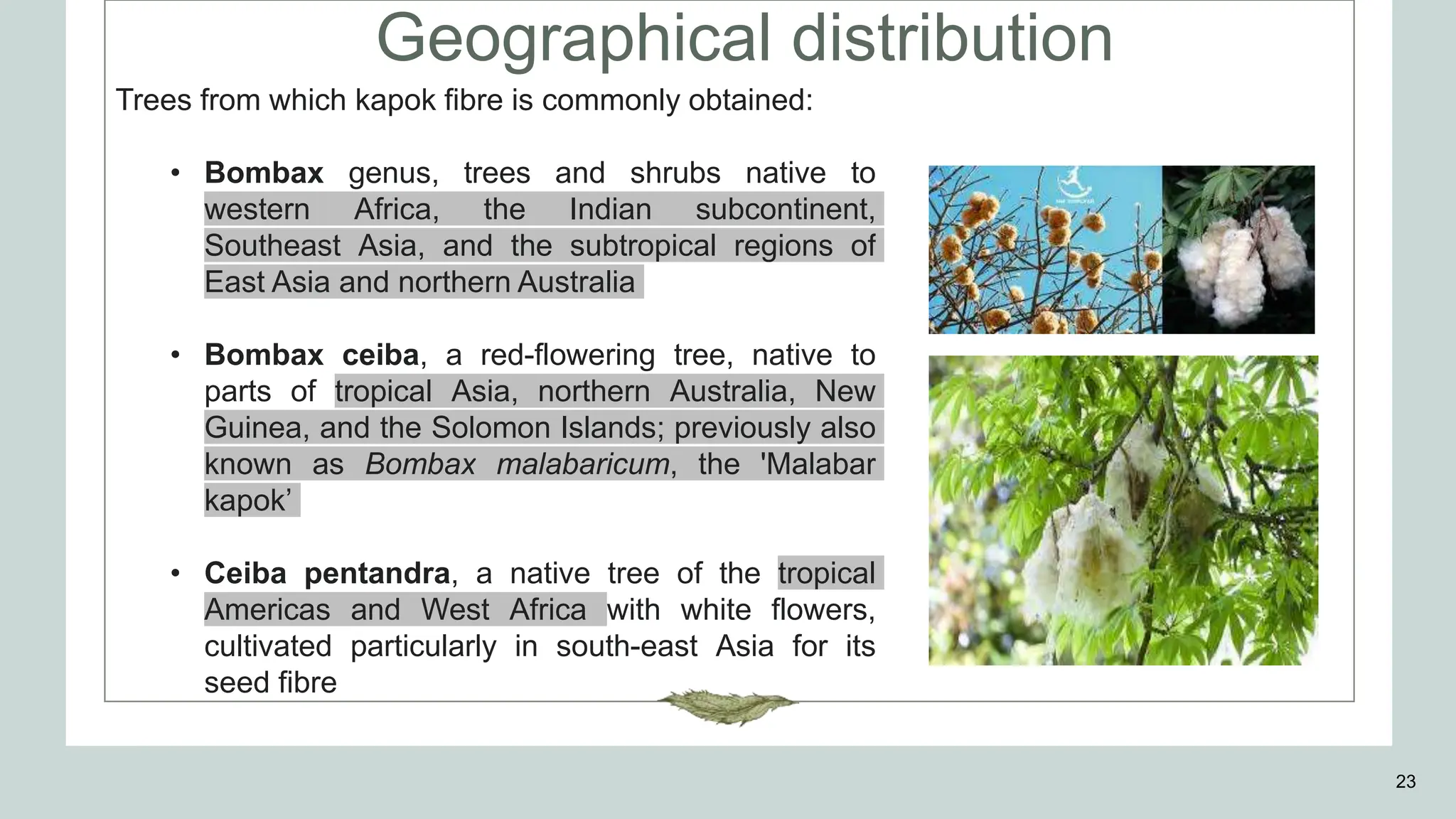

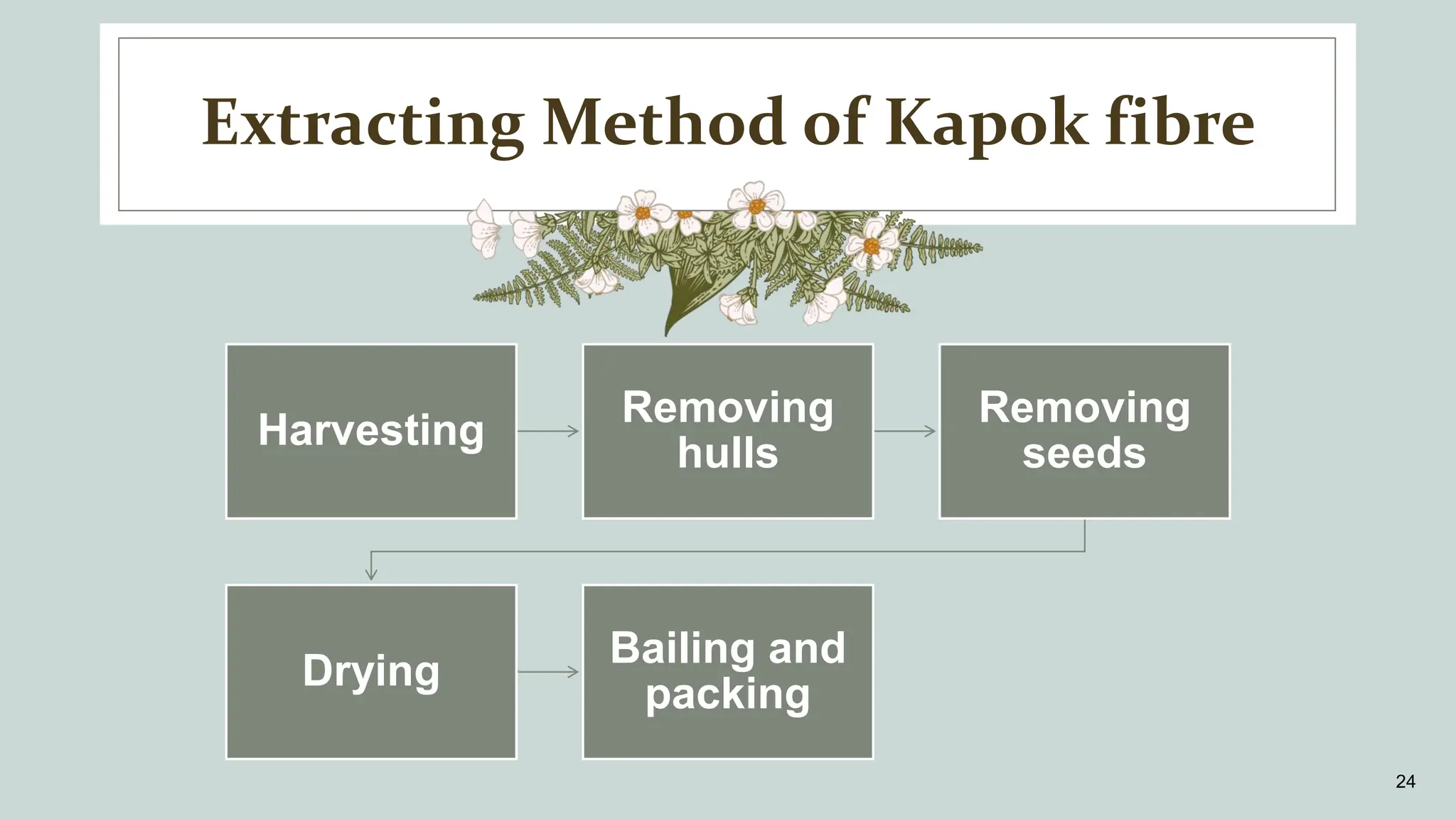

This document provides information about uncommon natural cellulosic fibers, including banana fiber, sisal, kapok, and their sources, geographical distribution, extraction methods, properties, and end uses. It discusses how banana fiber is obtained from banana plant pseudo-stems and extracted through manual or machine stripping. Sisal fiber is obtained from agave plants and extracted via harvesting, stripping, washing, drying, brushing and baling. Kapok fiber comes from bombax trees and its extraction involves harvesting pods, removing hulls and seeds, and drying the fiber.