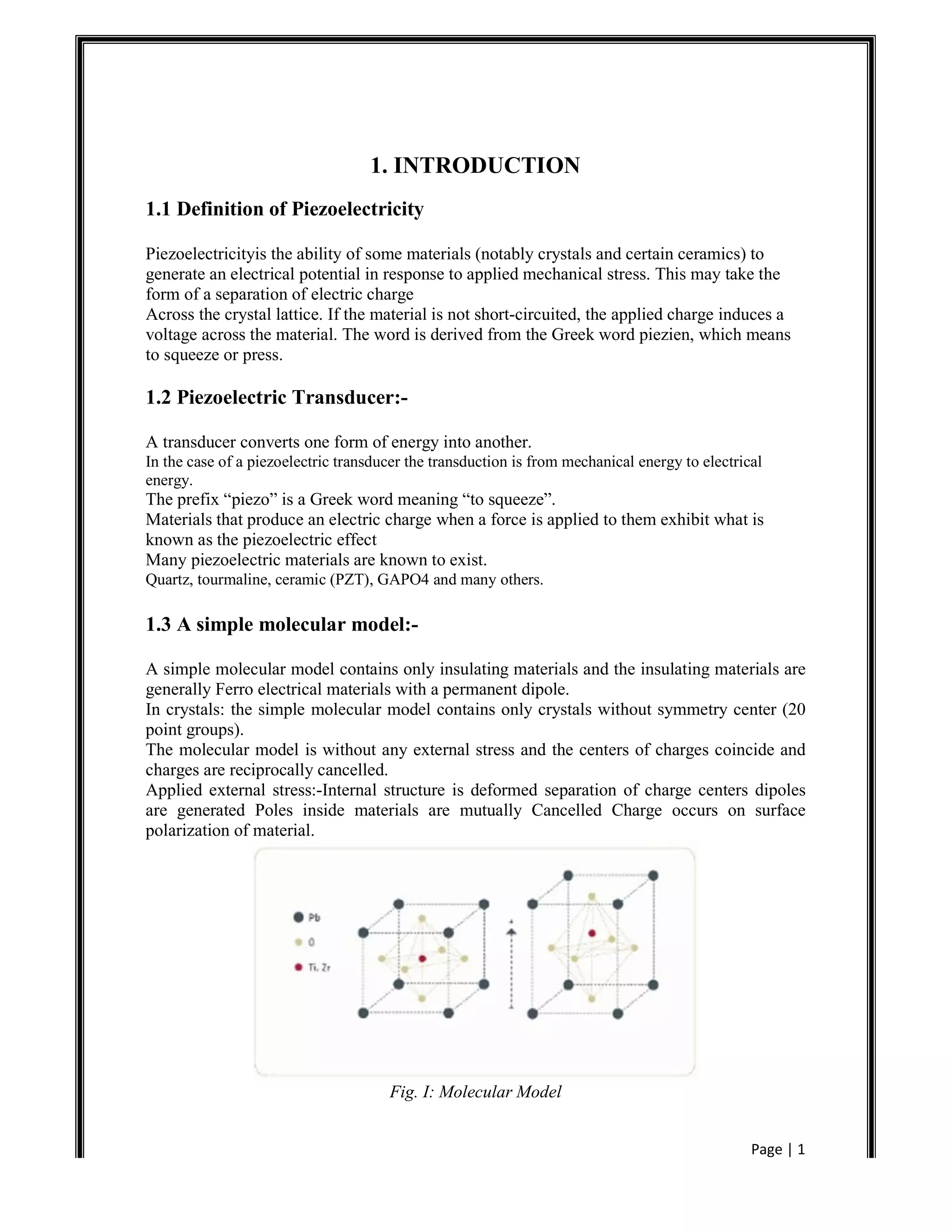

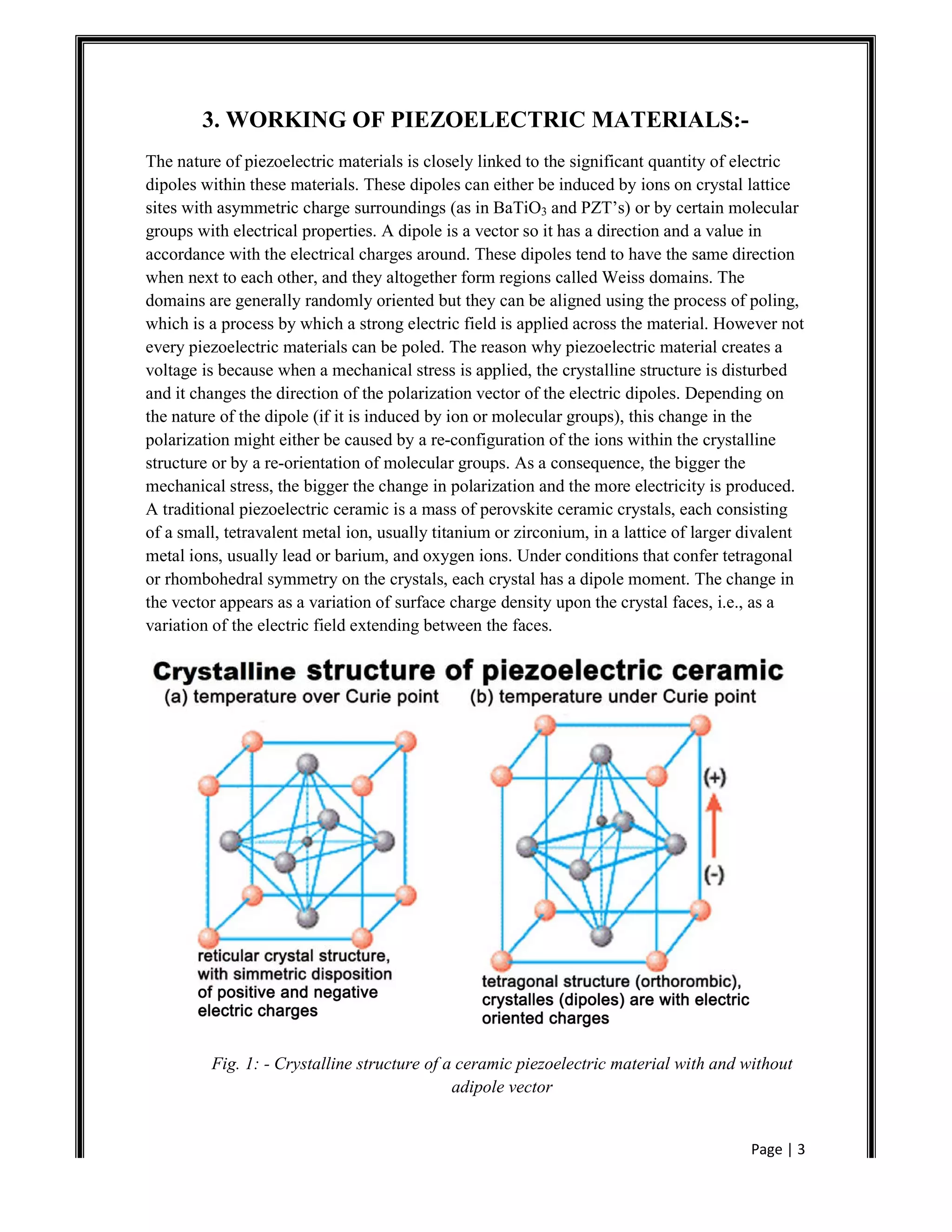

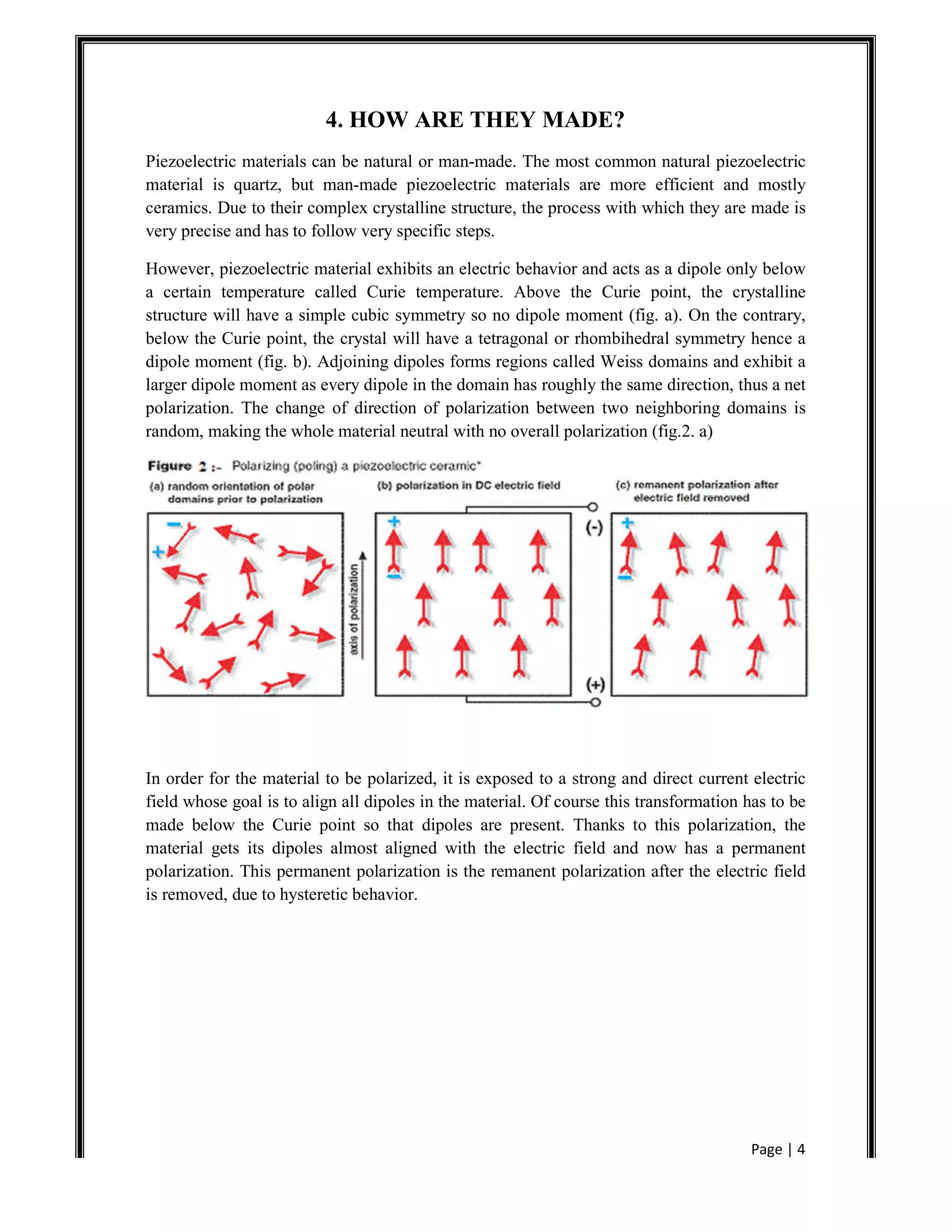

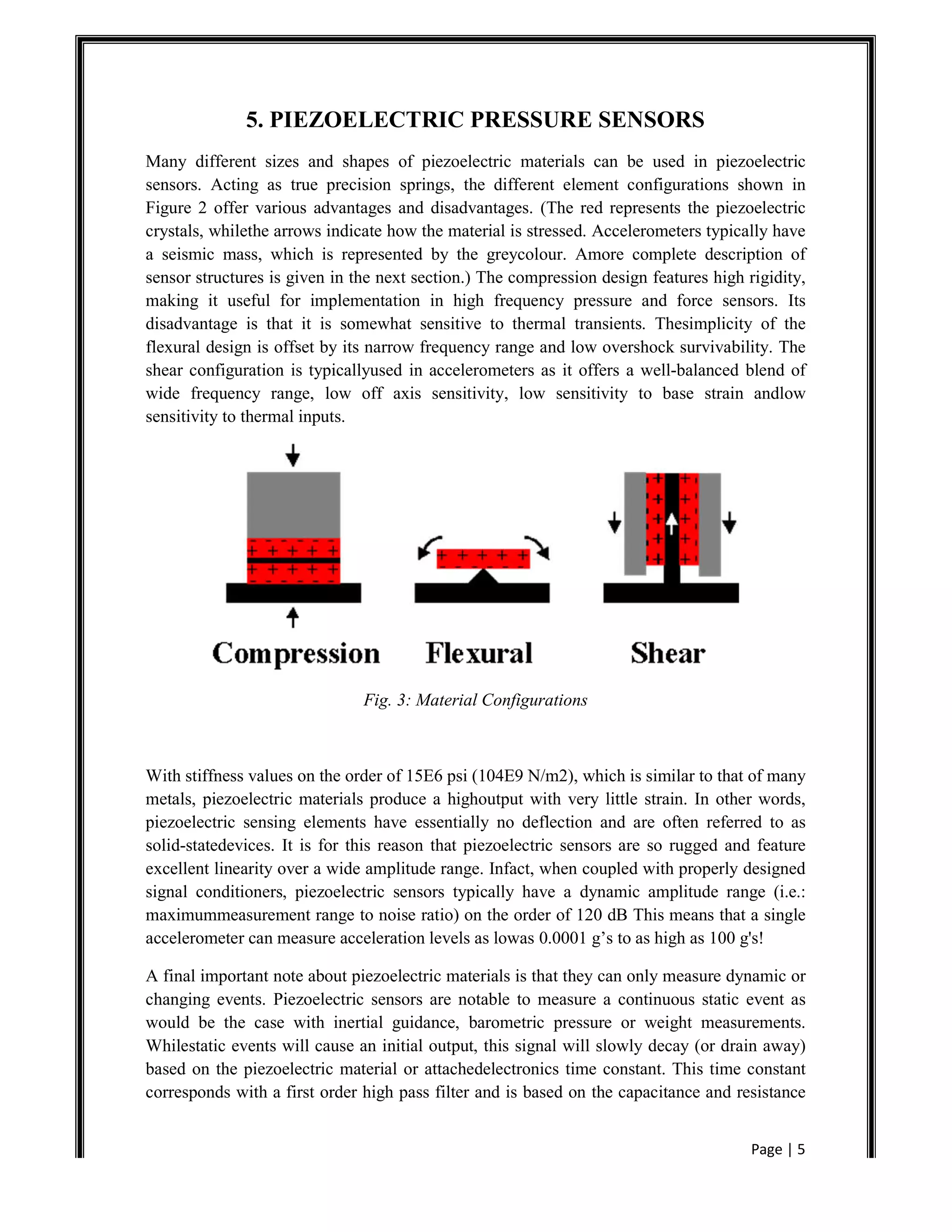

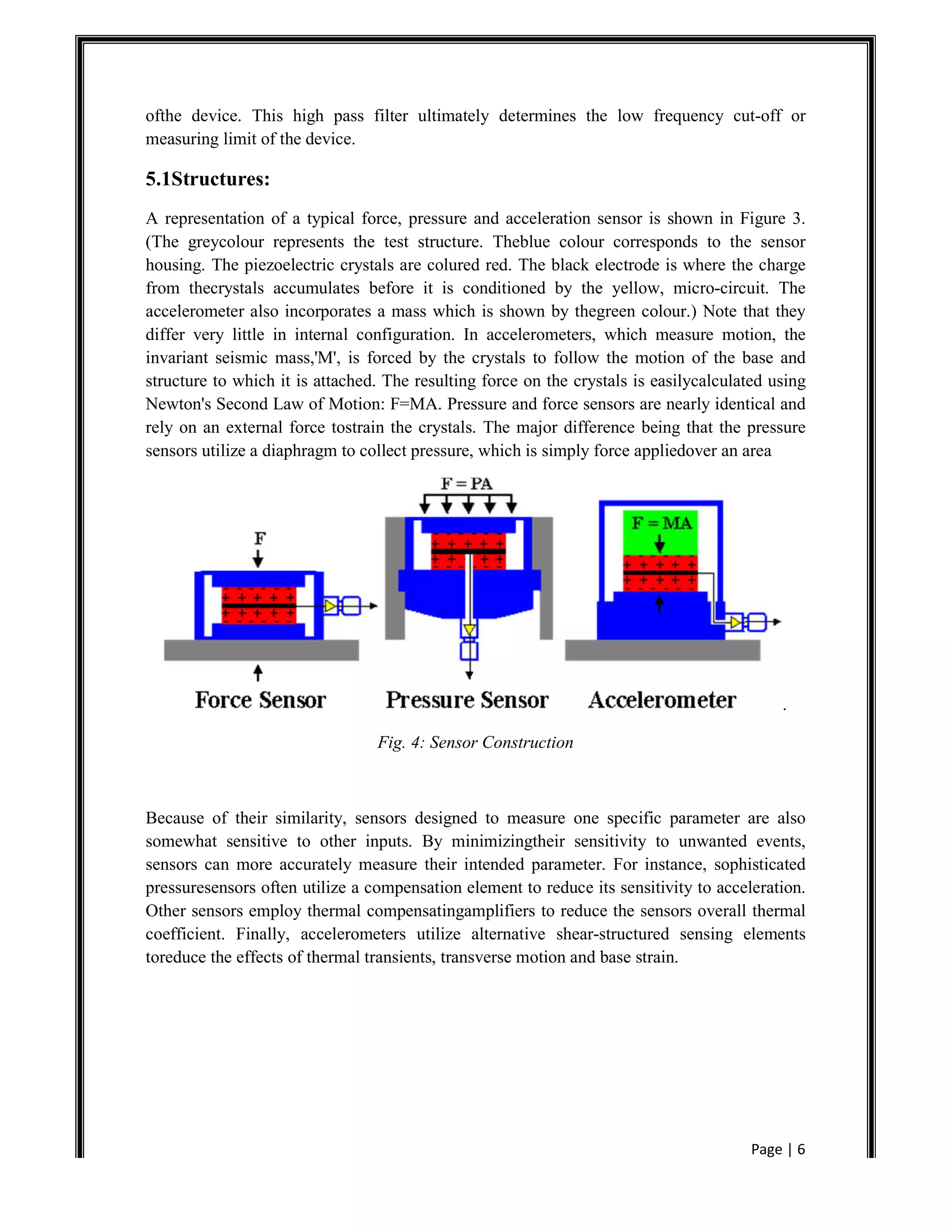

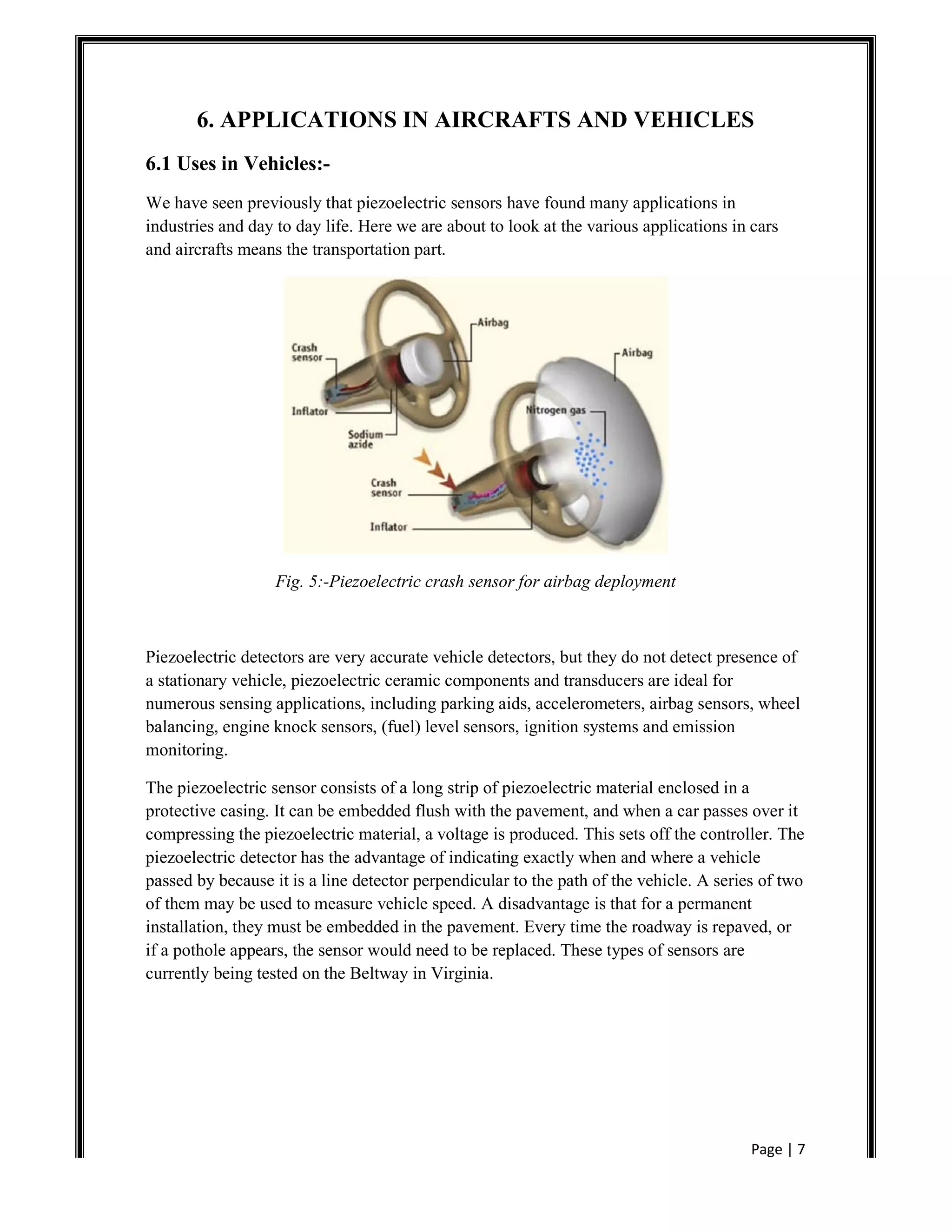

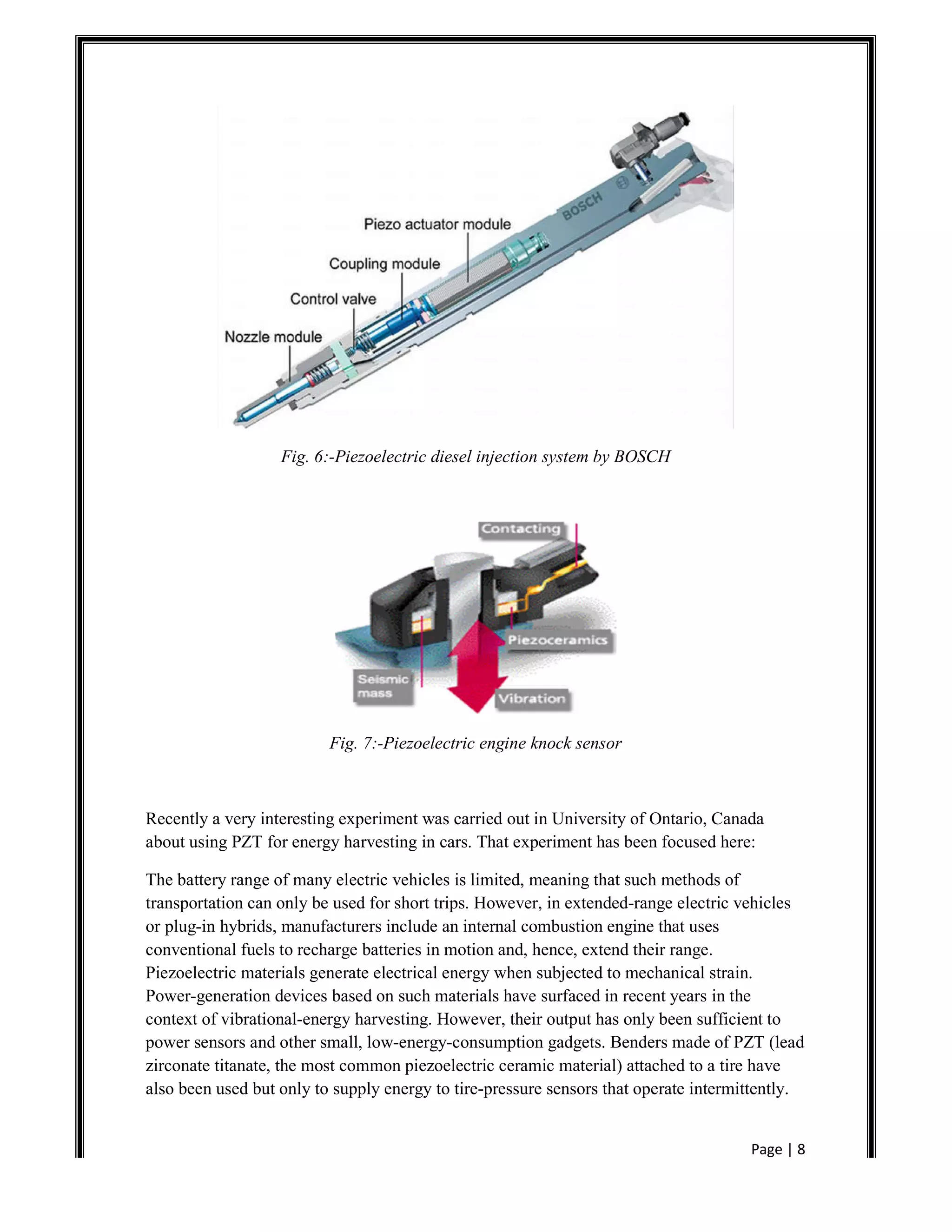

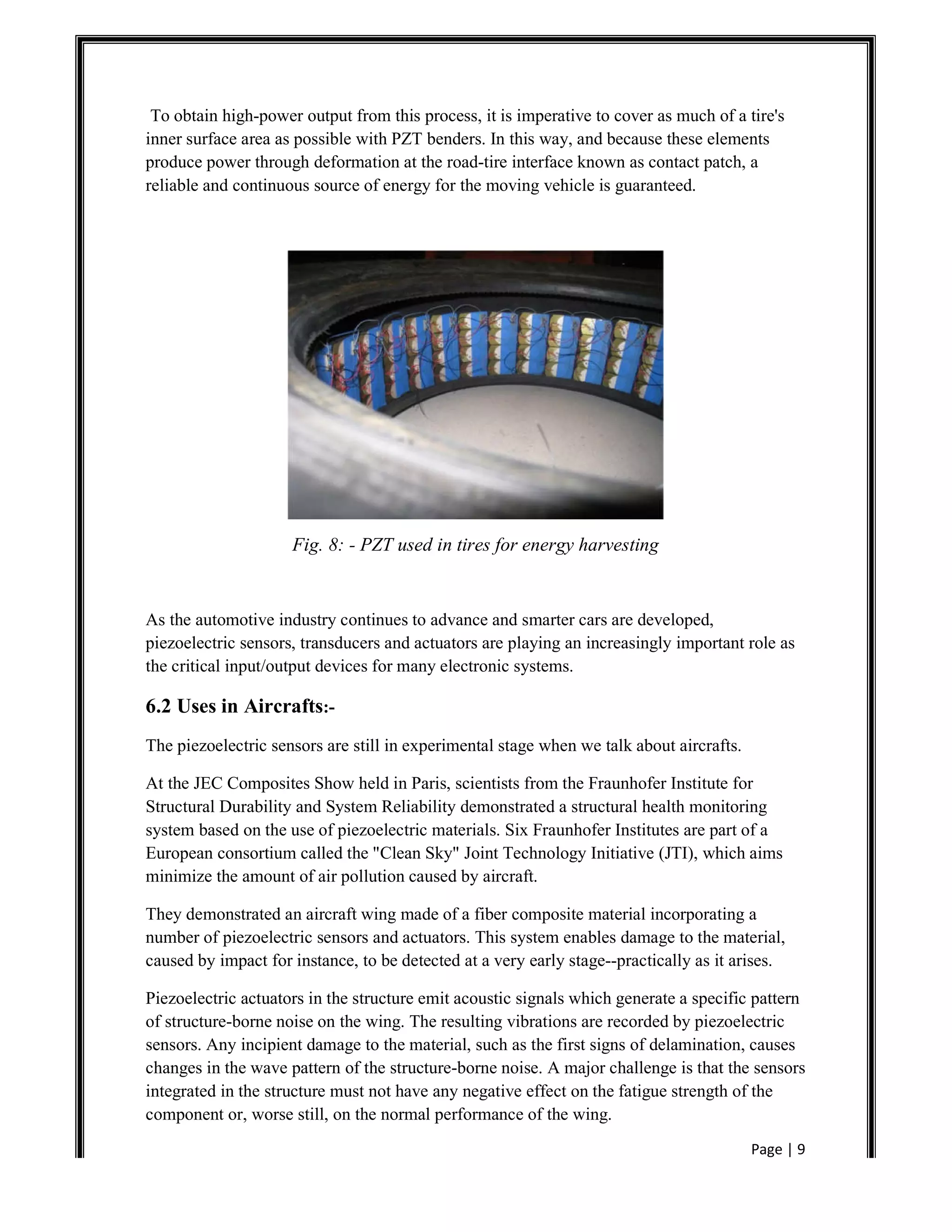

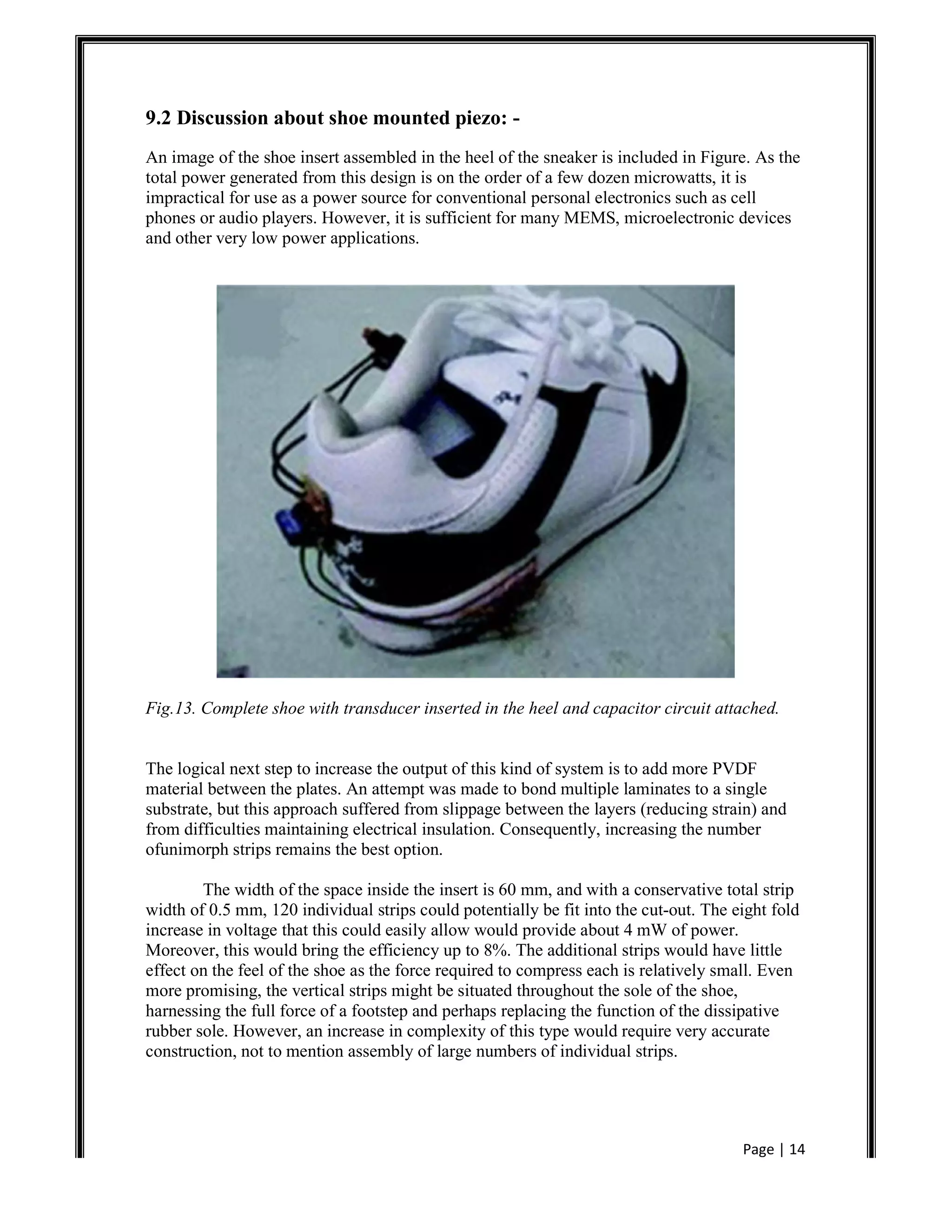

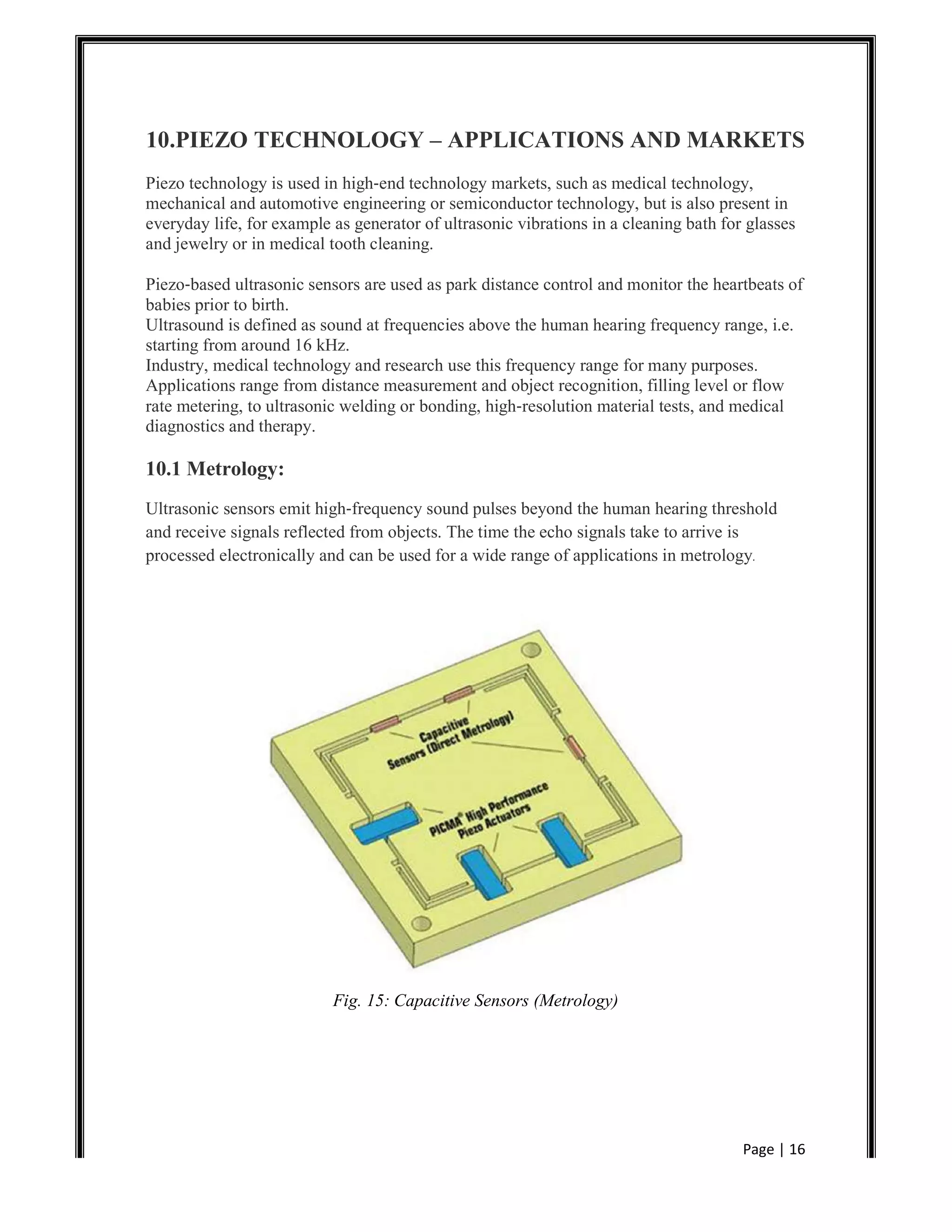

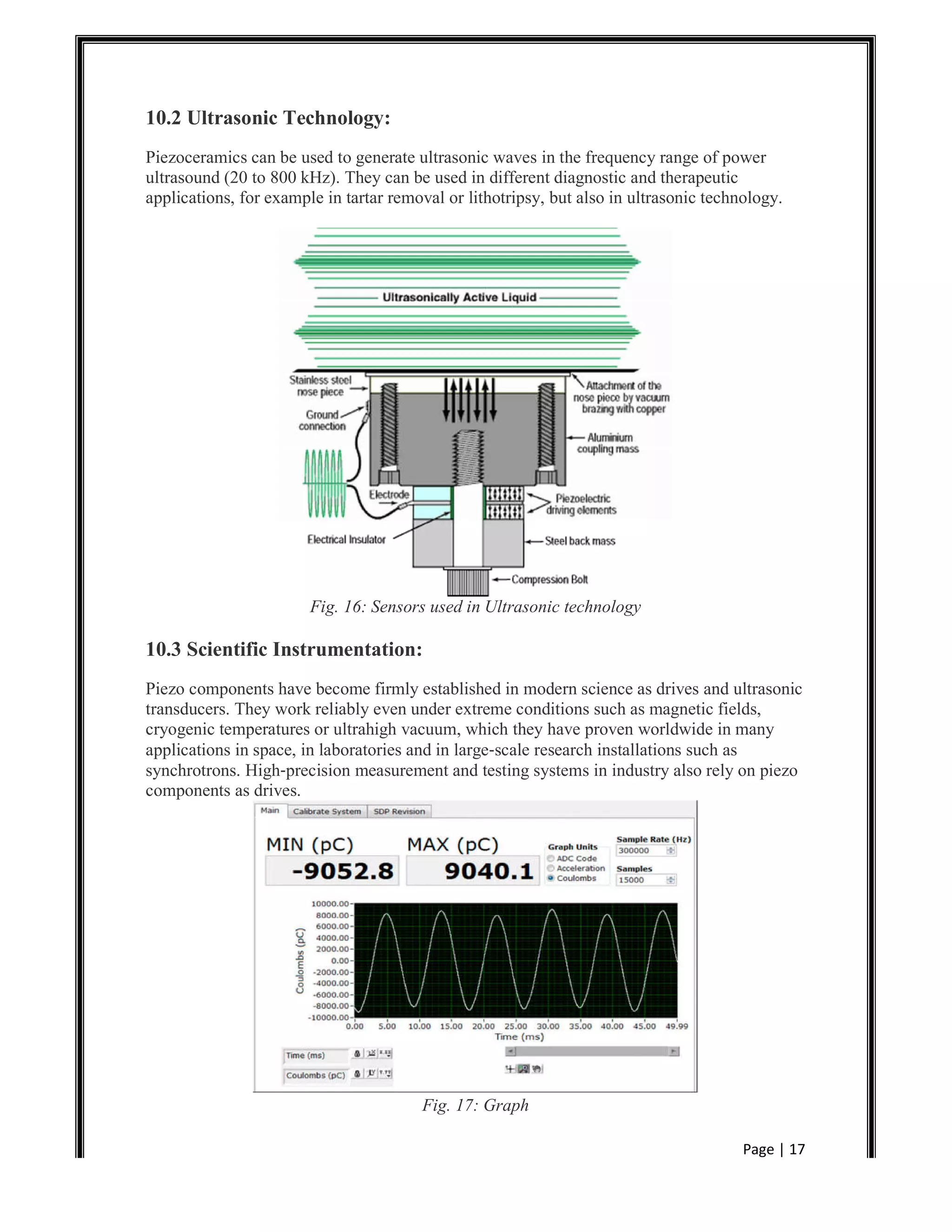

The document explores piezoelectricity, defined as the generation of electrical potential from mechanical stress in specific materials like crystals and ceramics. It details the history of its discovery by the Curie brothers, the mechanisms behind piezoelectric materials, and their various applications in sensors, vehicles, and aircraft, emphasizing their growing importance in technology. Additionally, it highlights the production, working principles, and challenges of utilizing piezoelectric materials in dynamic sensing environments.