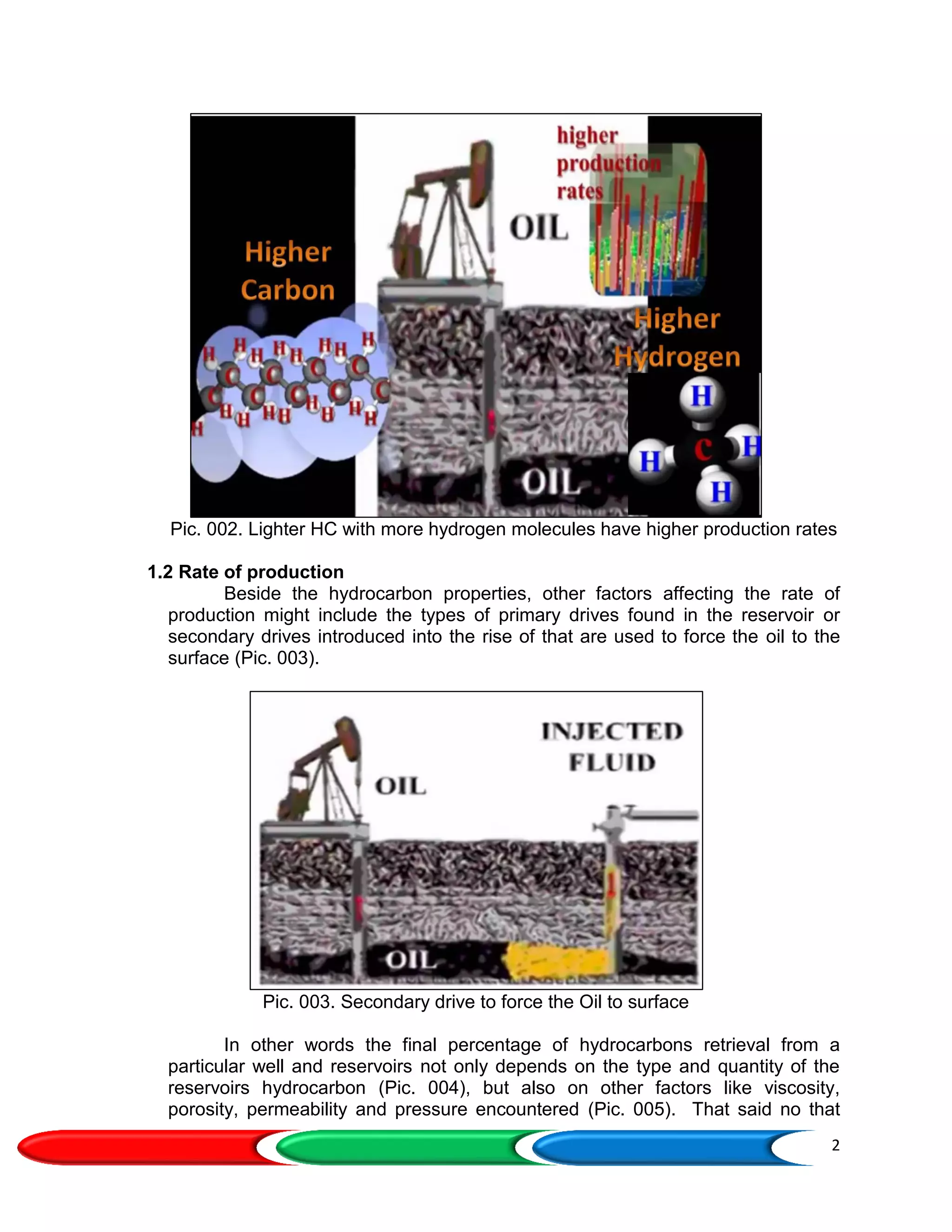

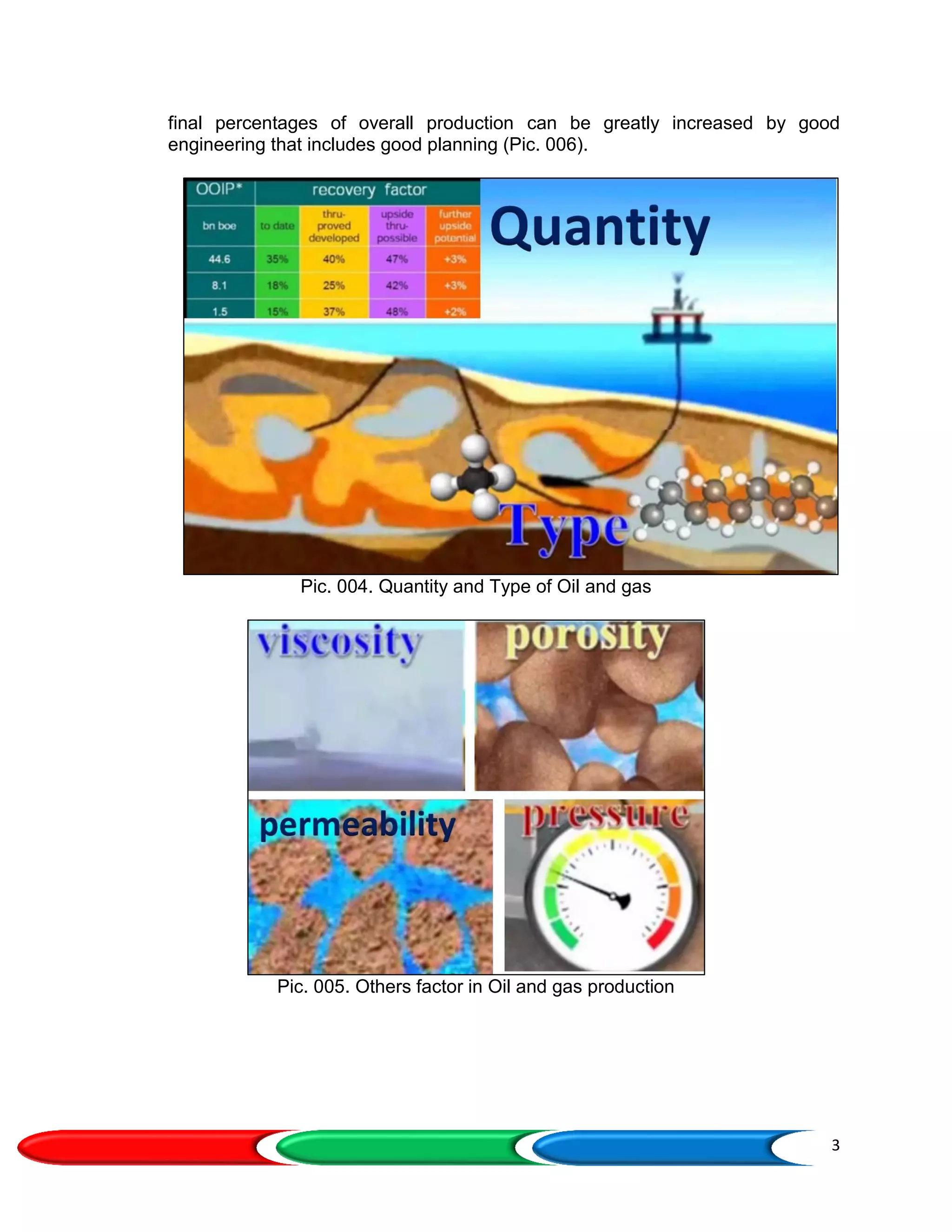

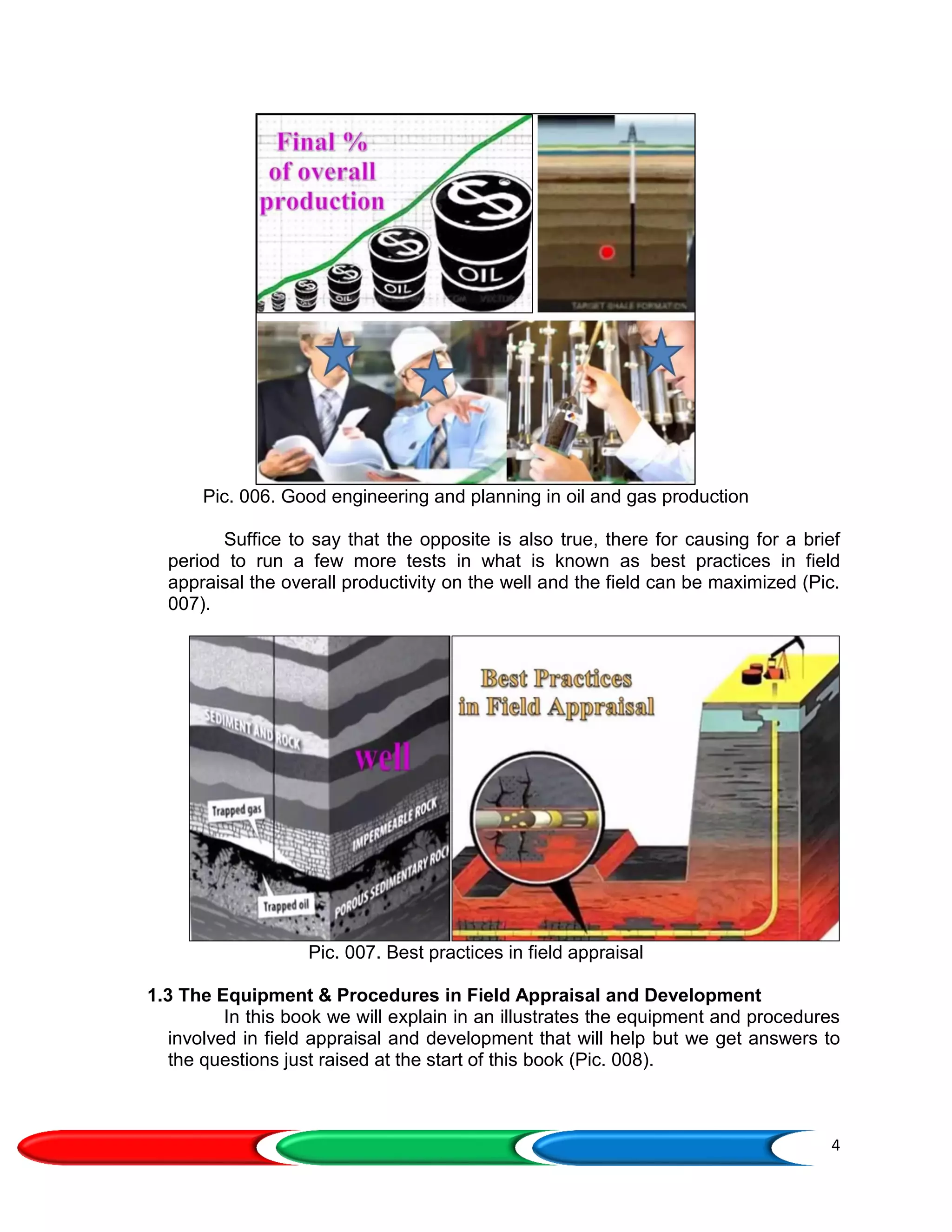

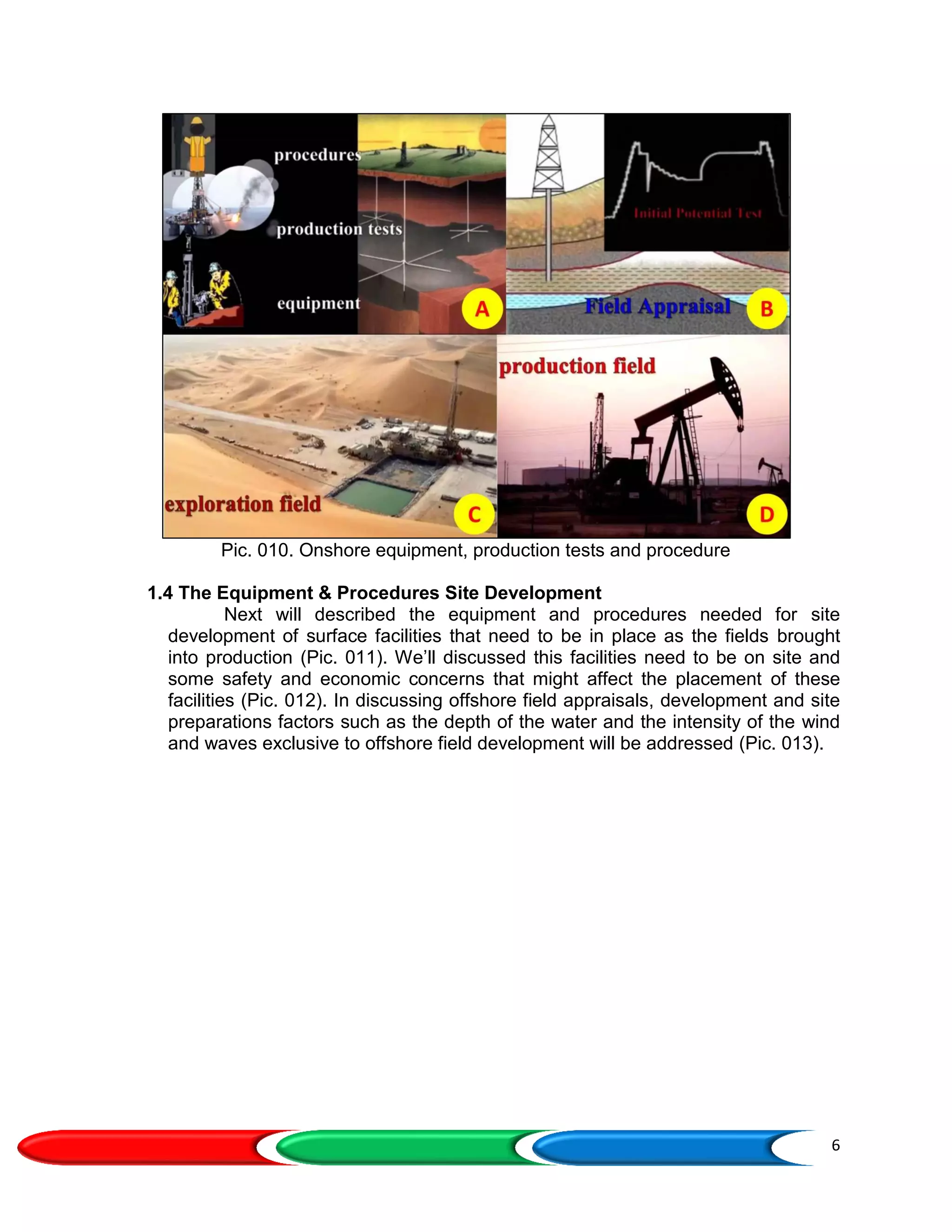

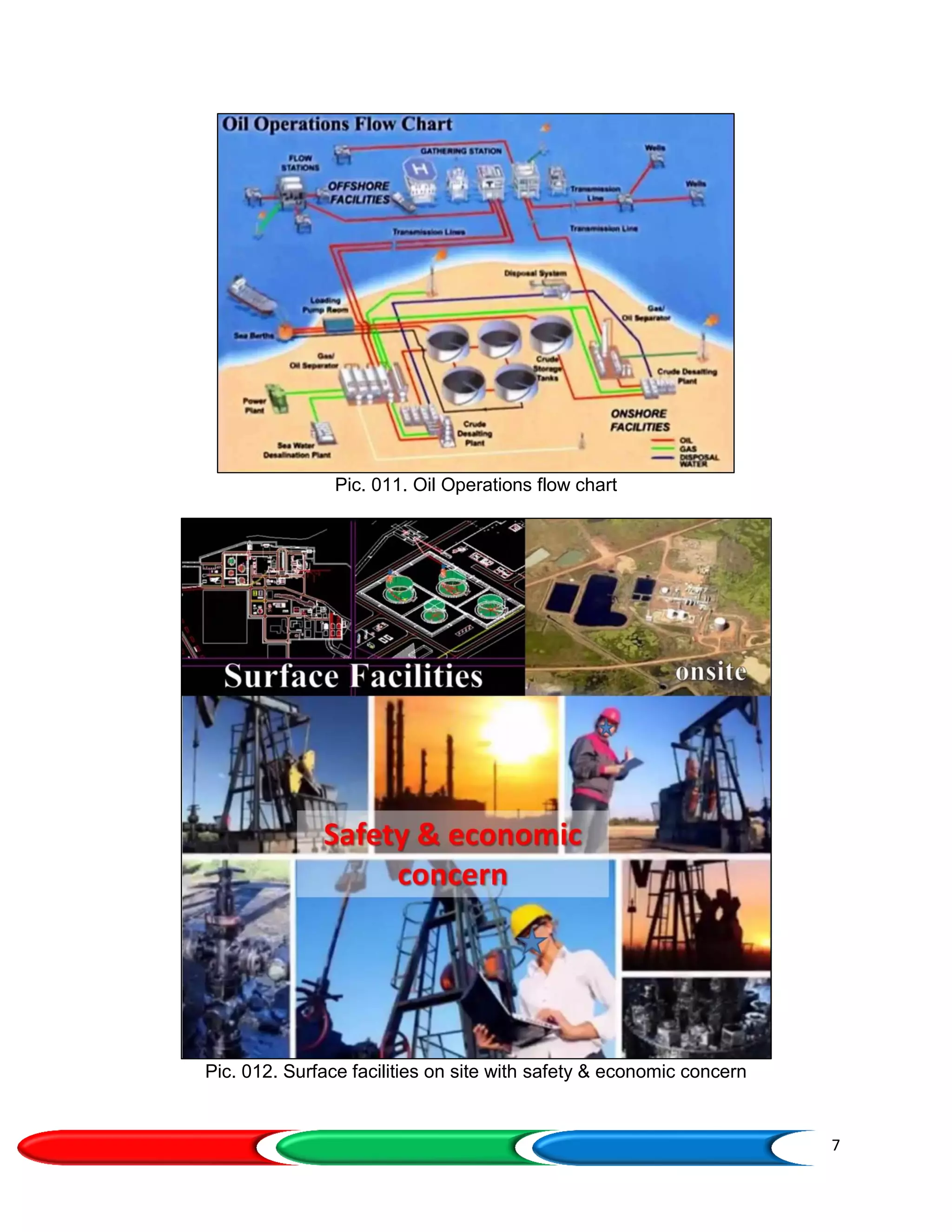

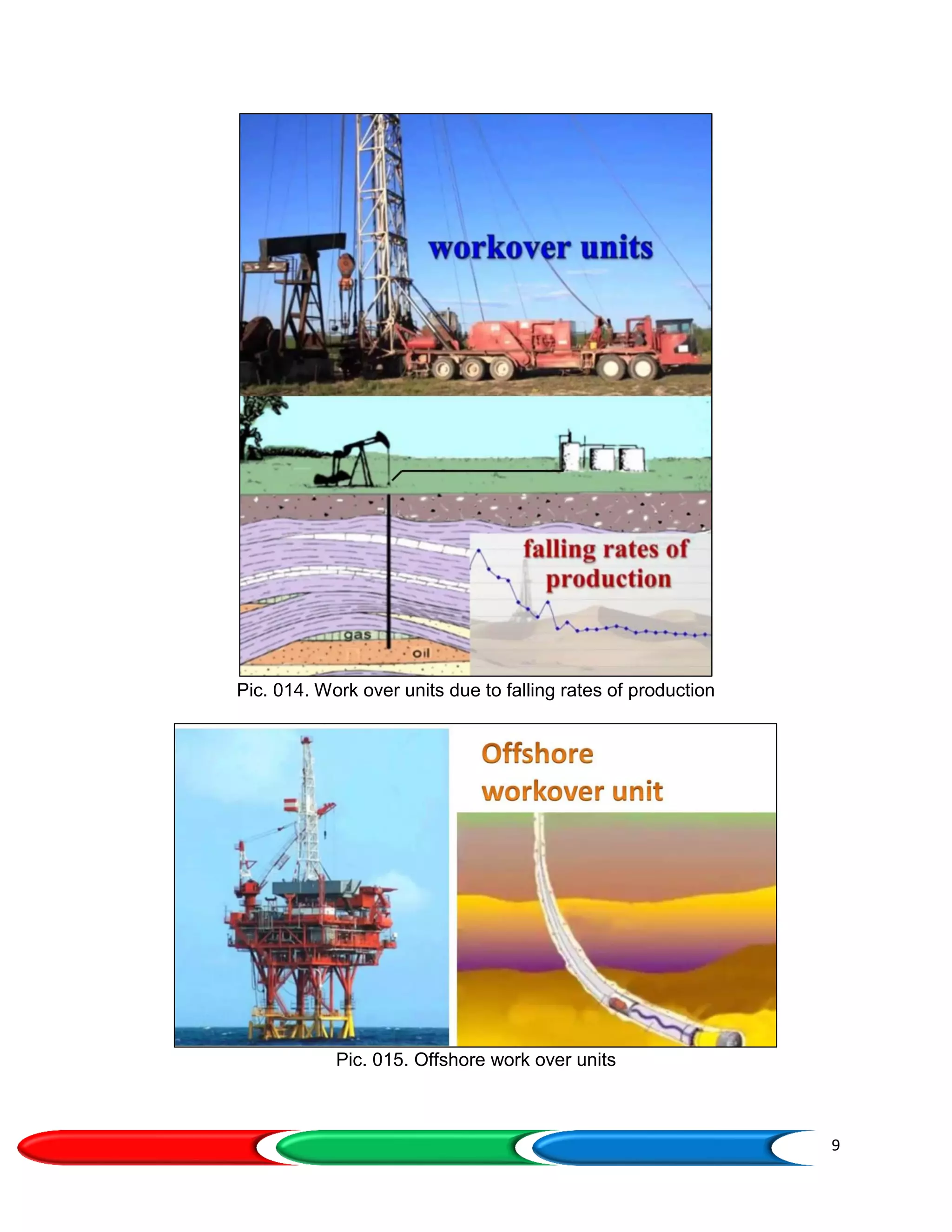

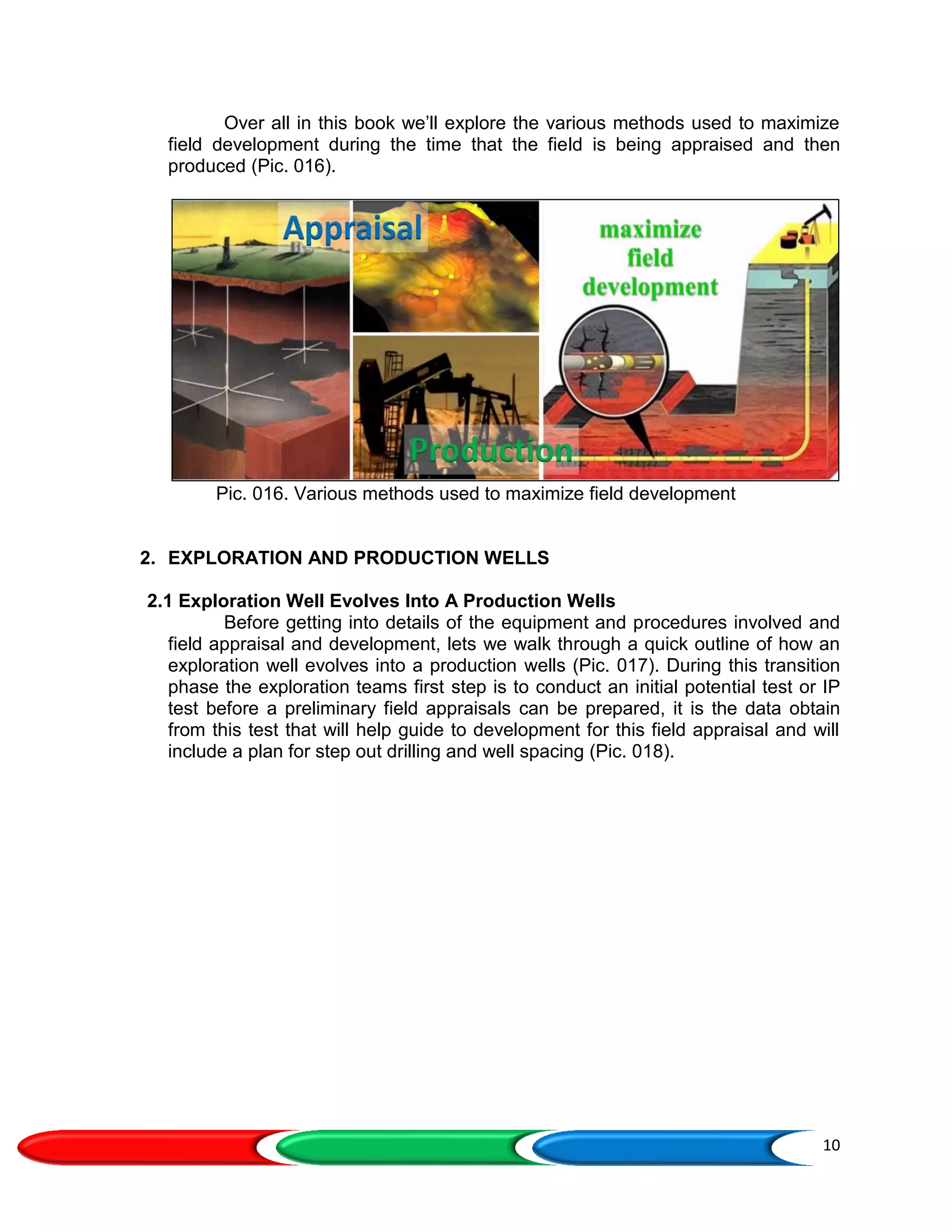

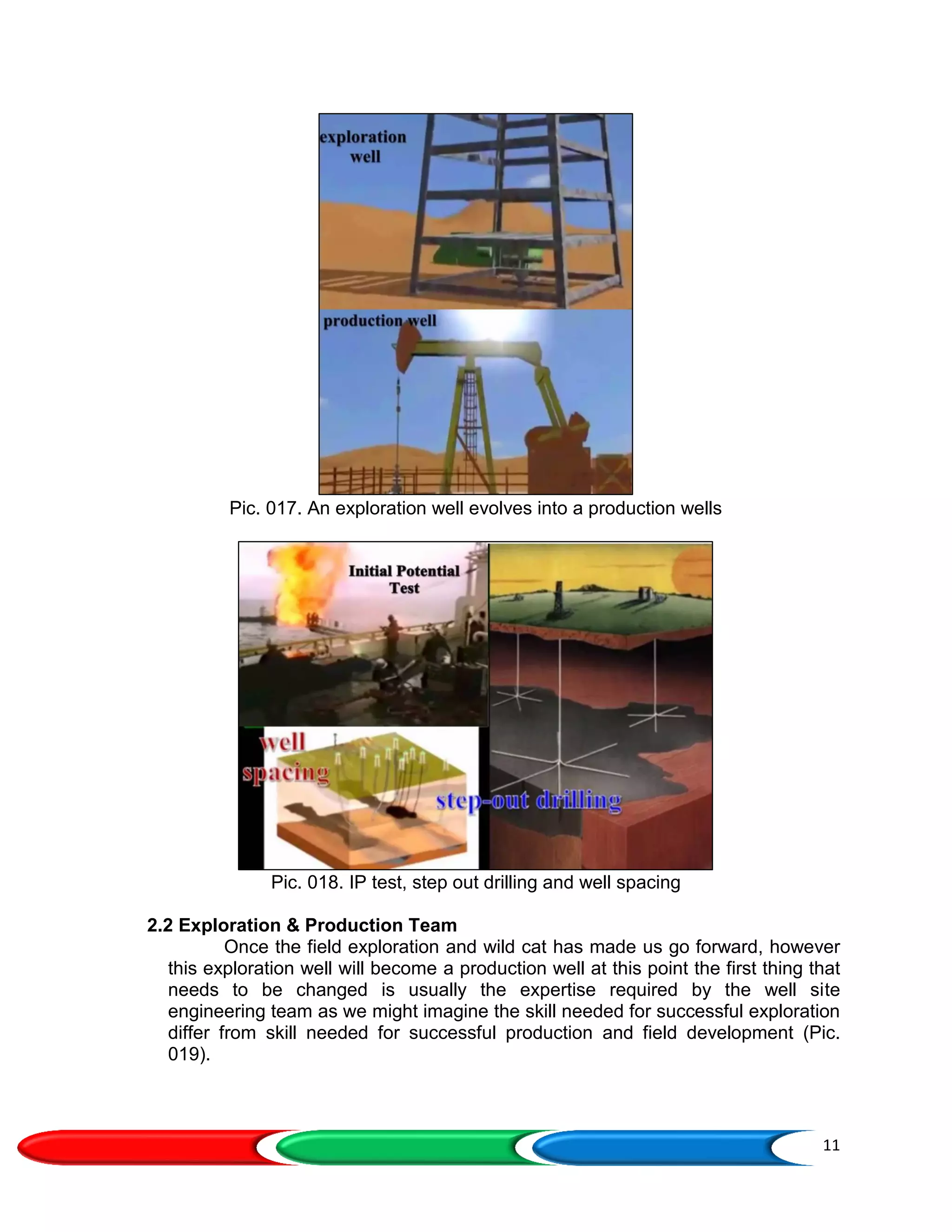

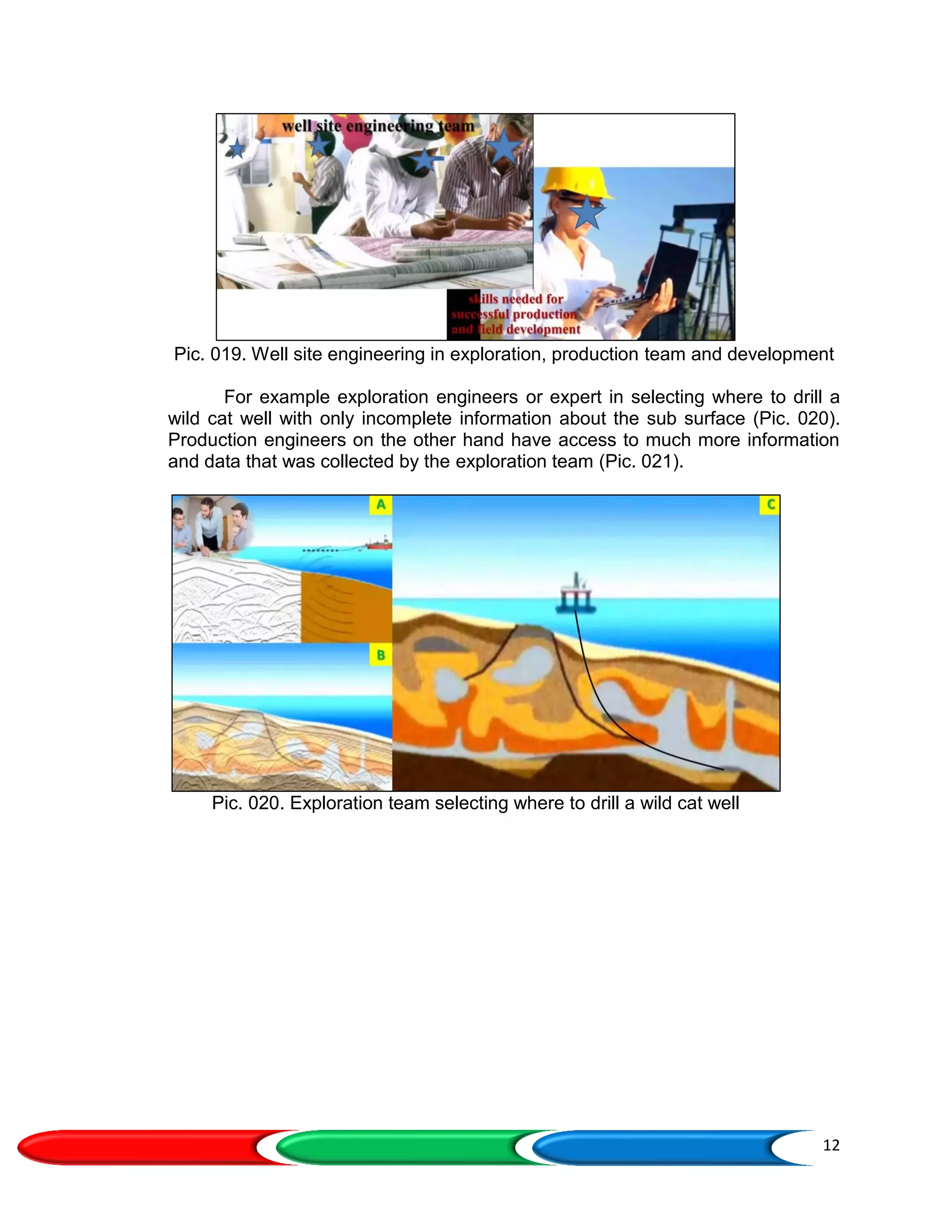

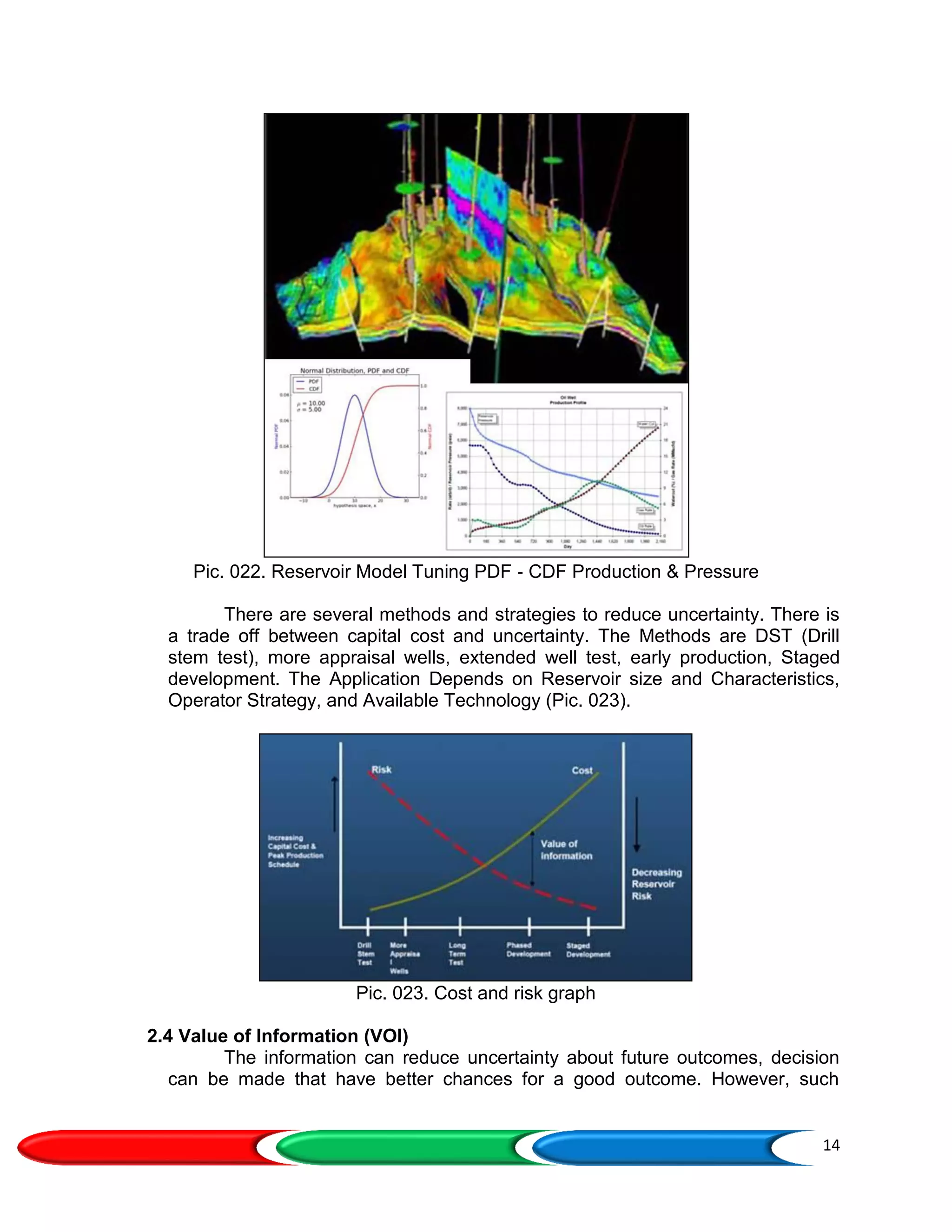

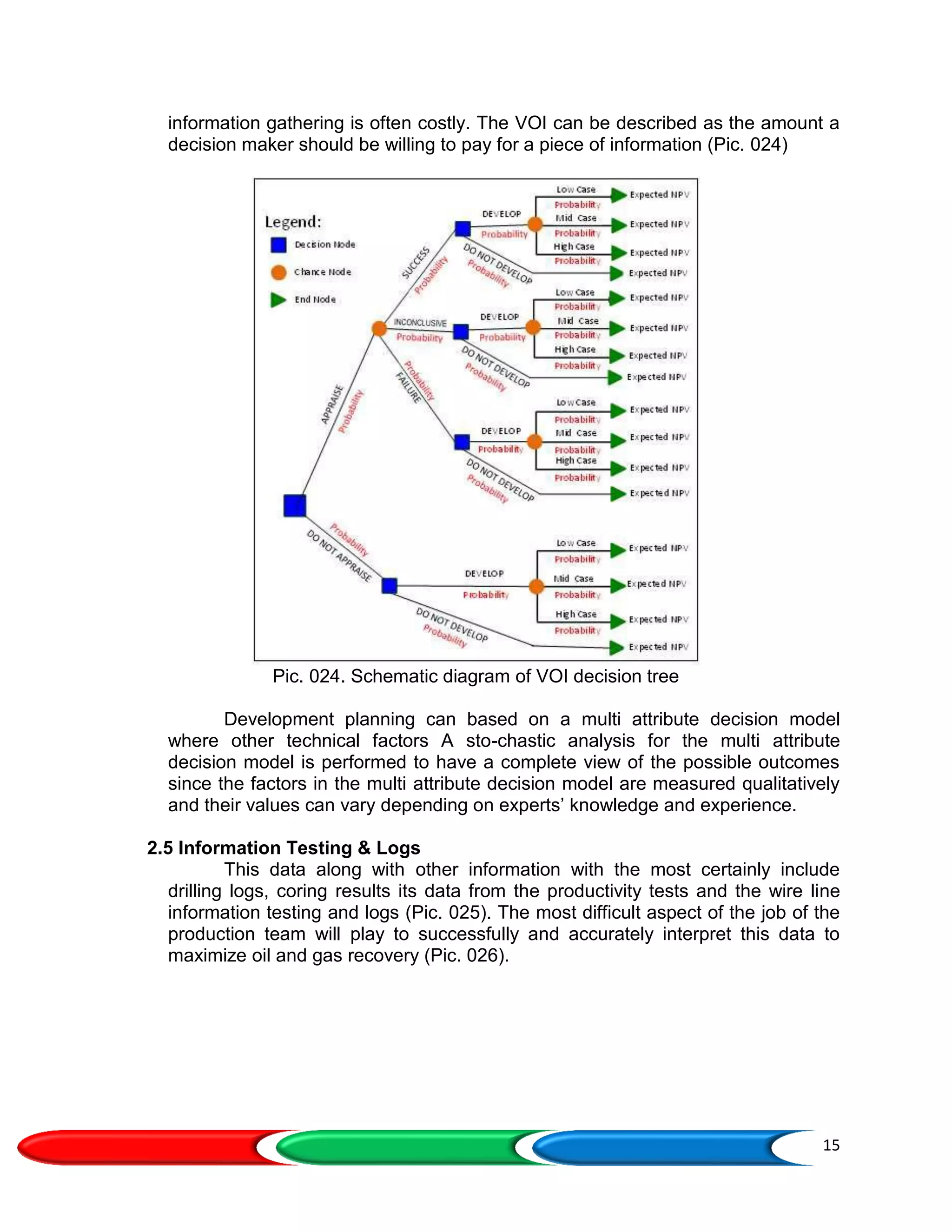

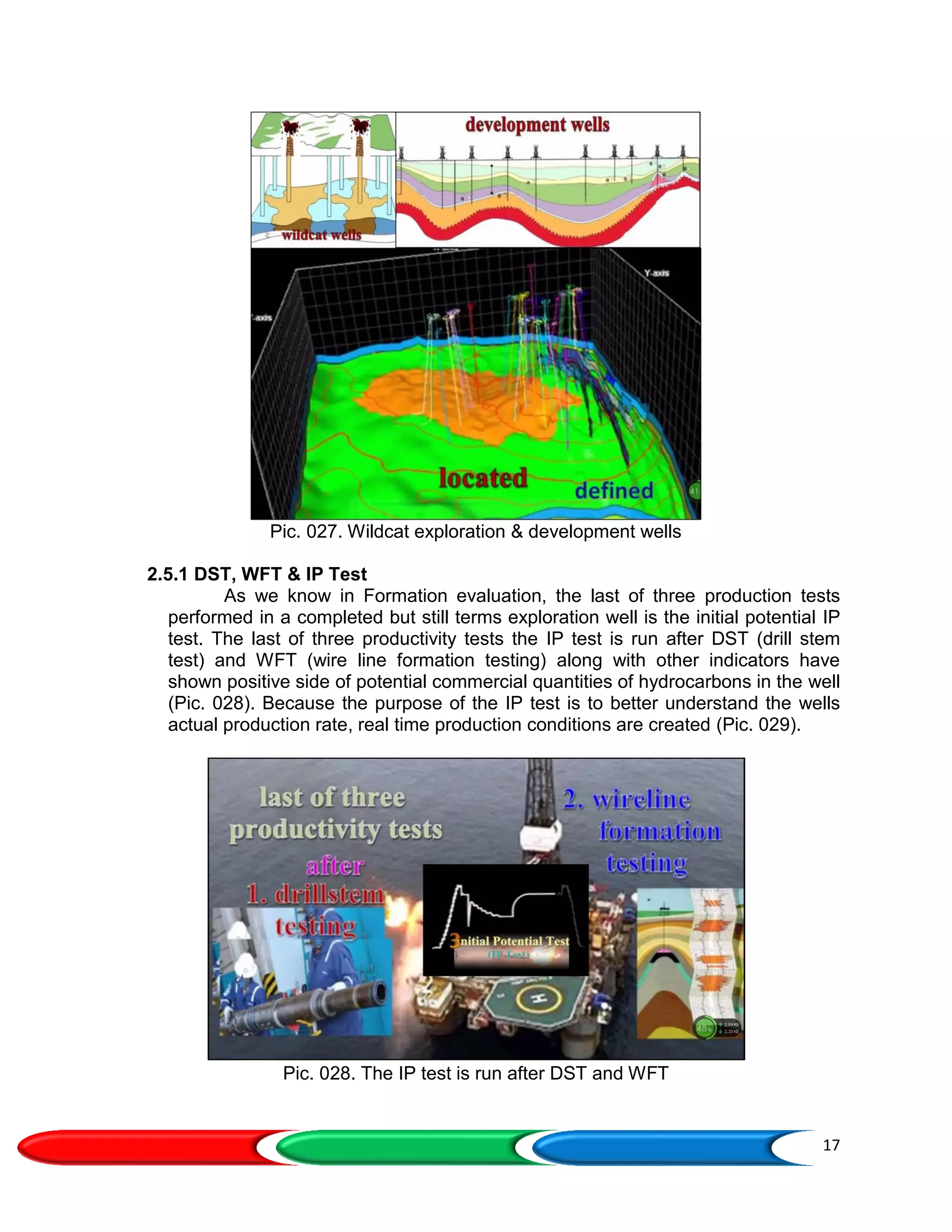

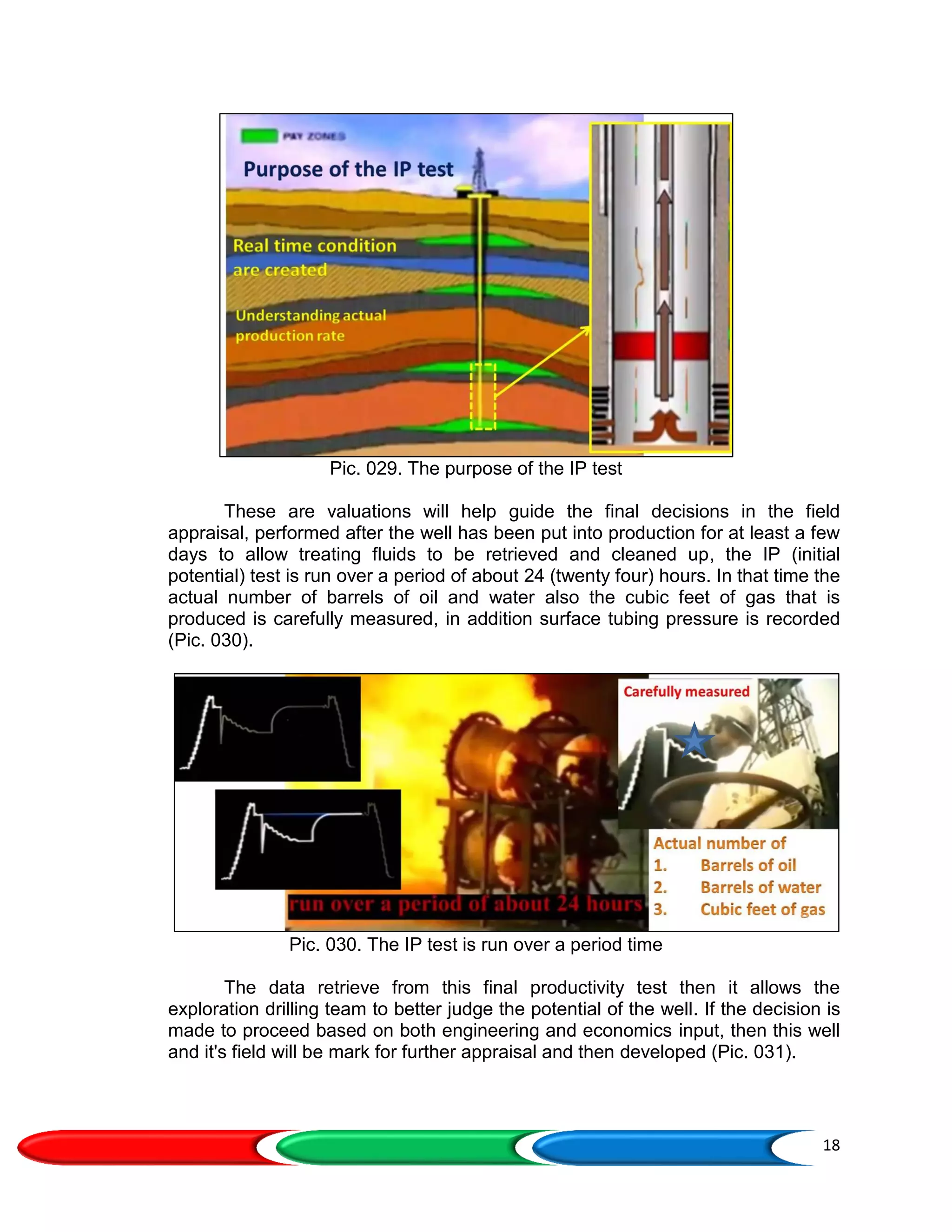

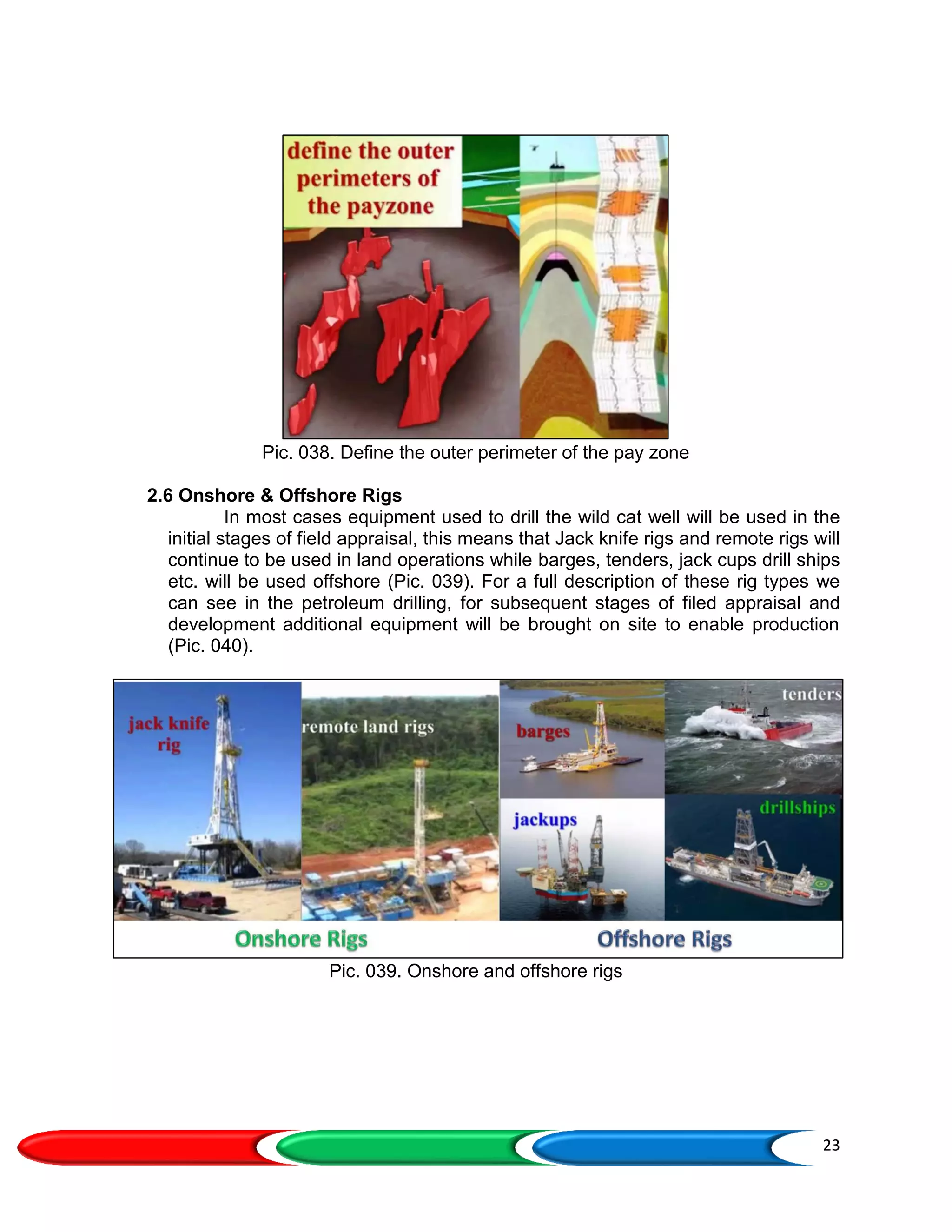

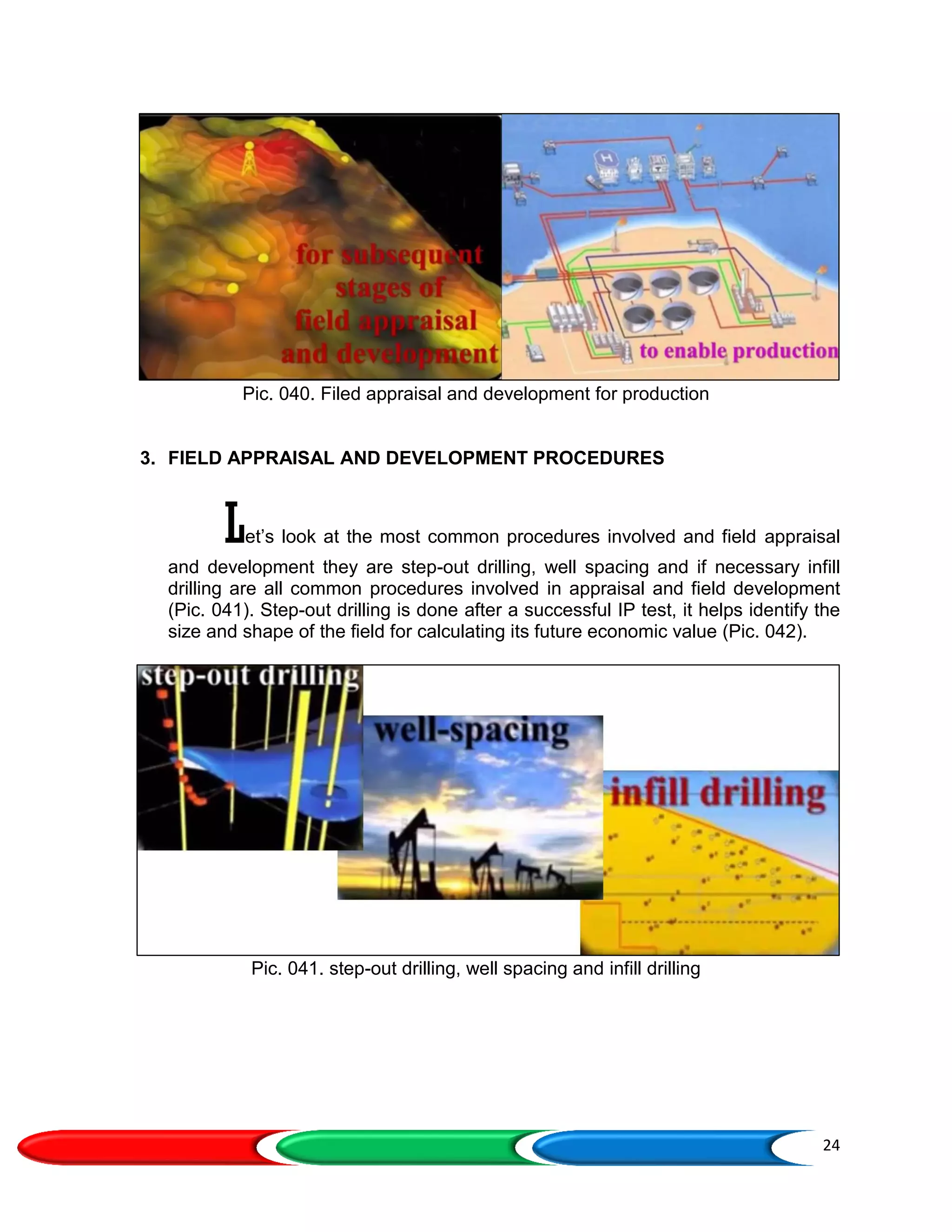

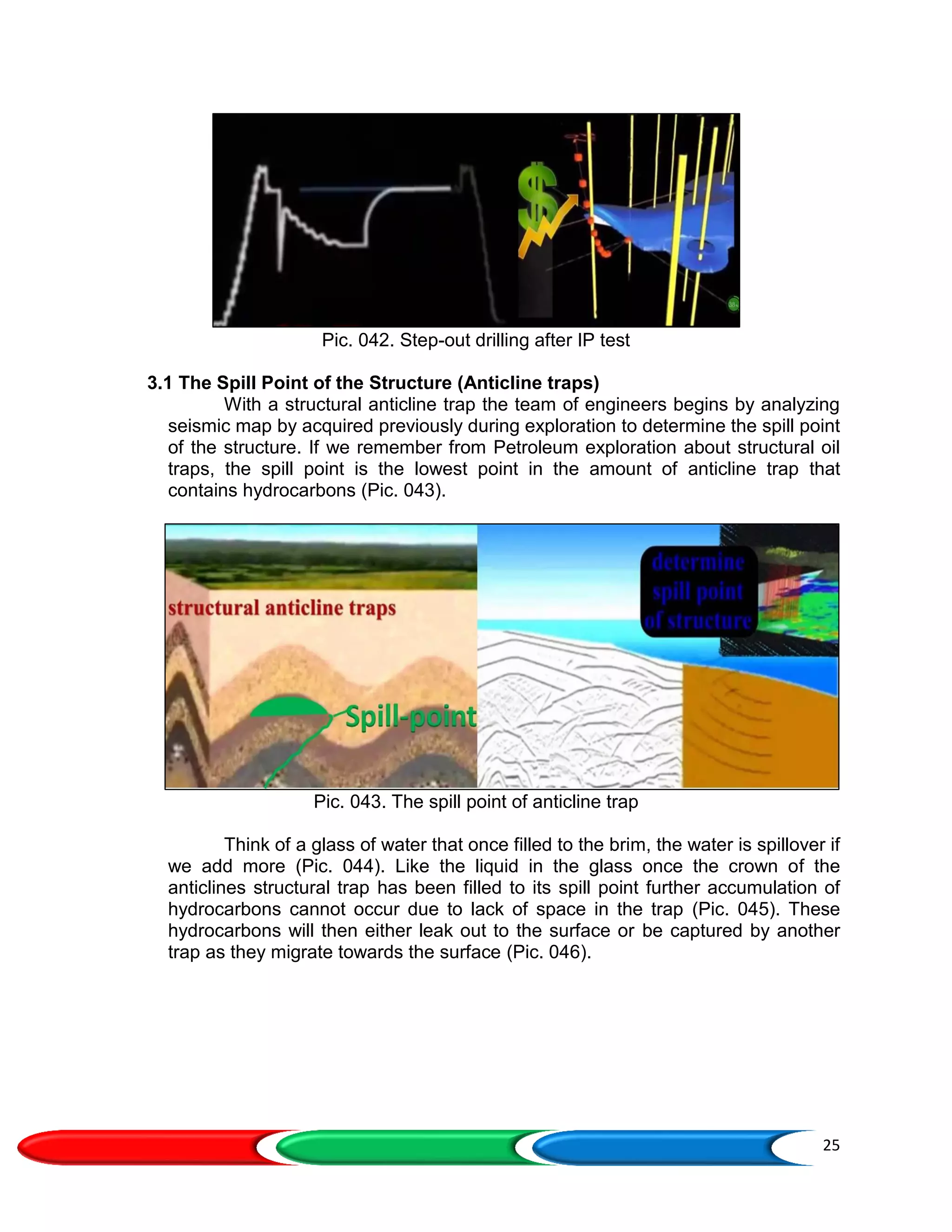

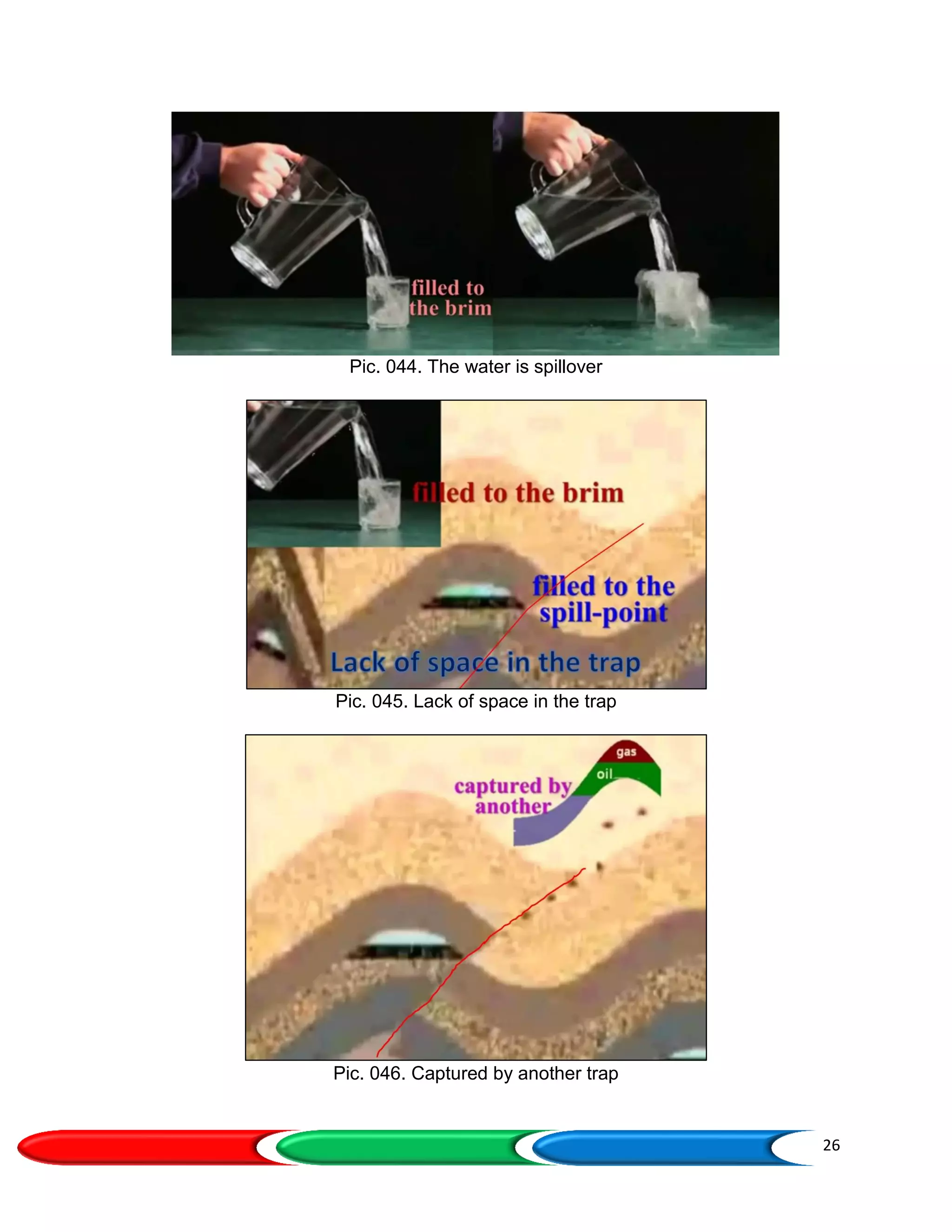

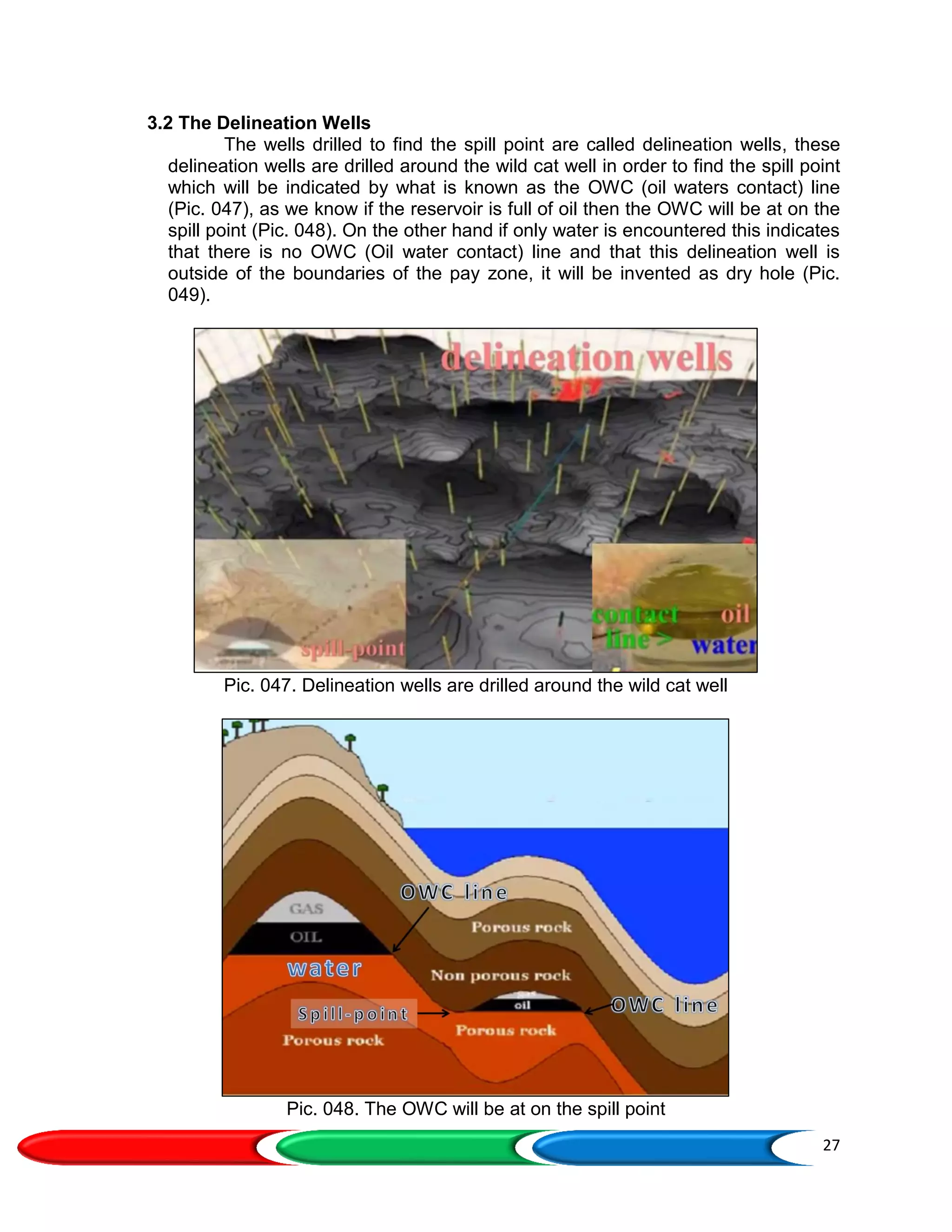

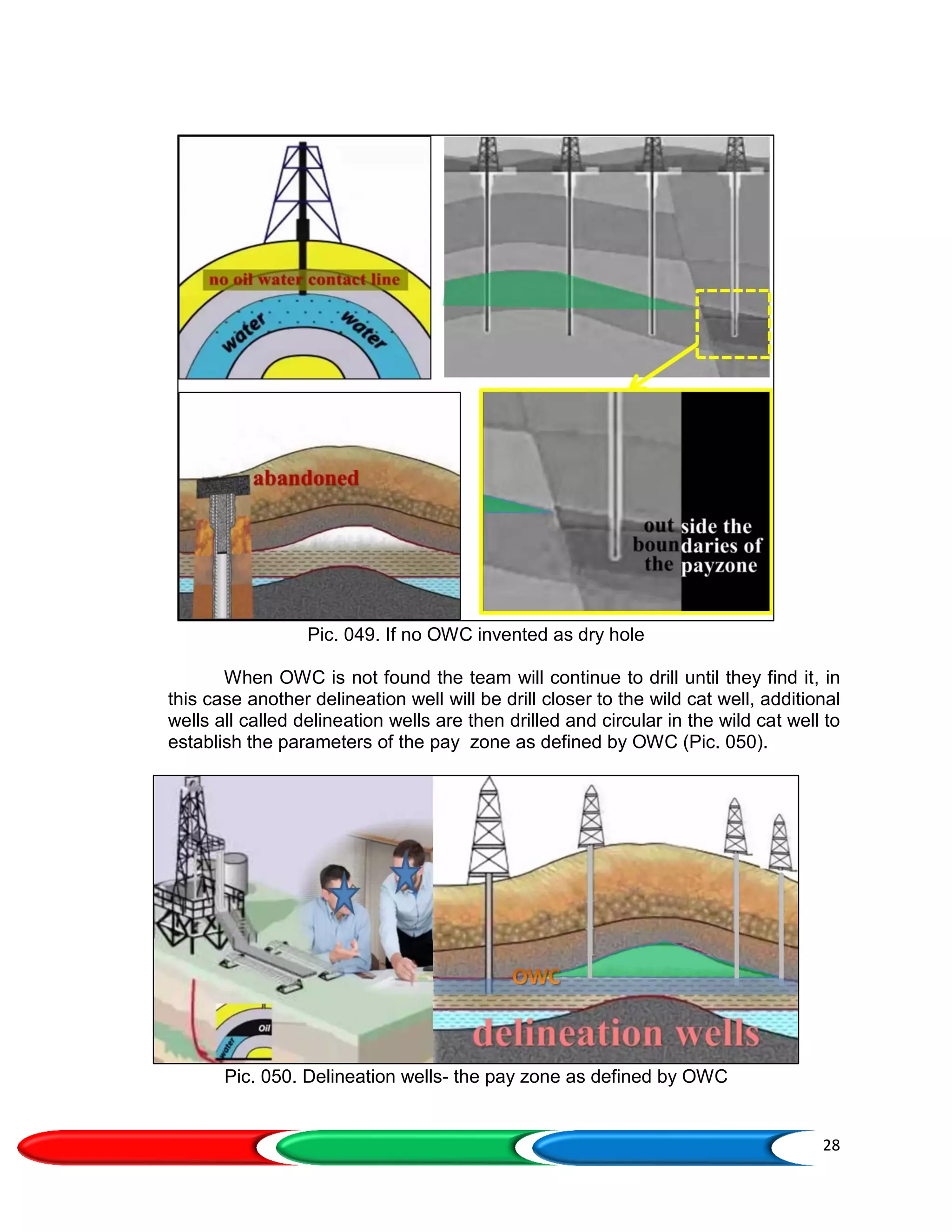

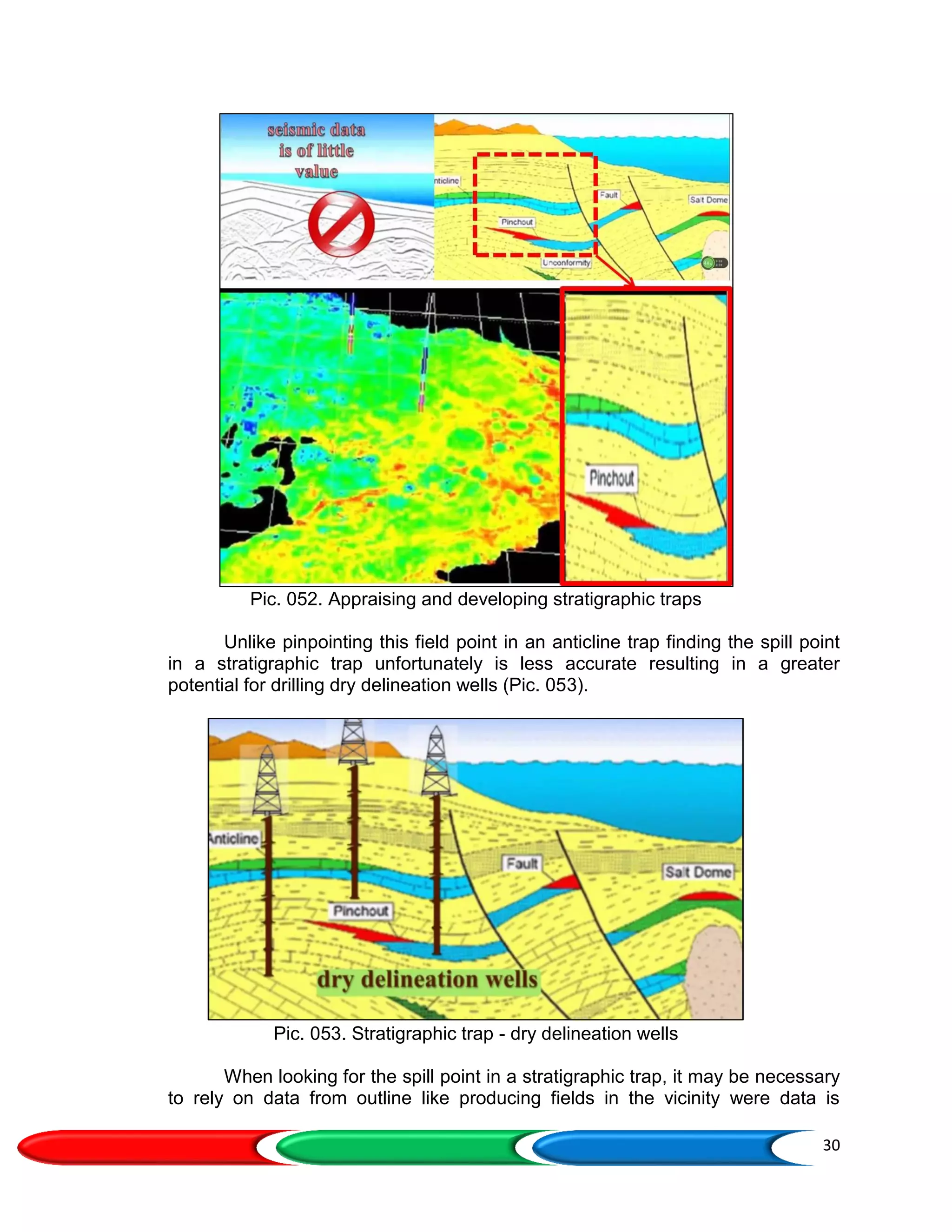

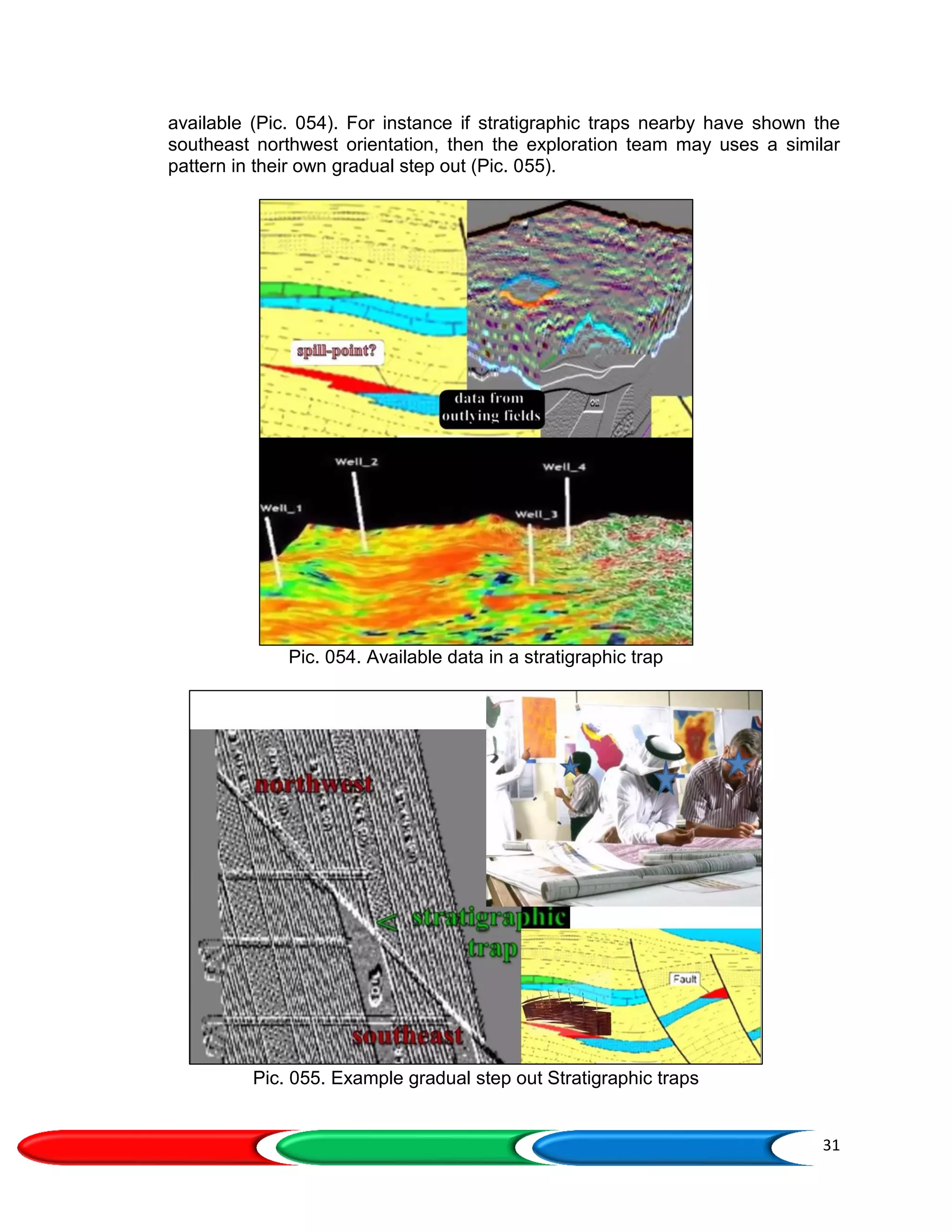

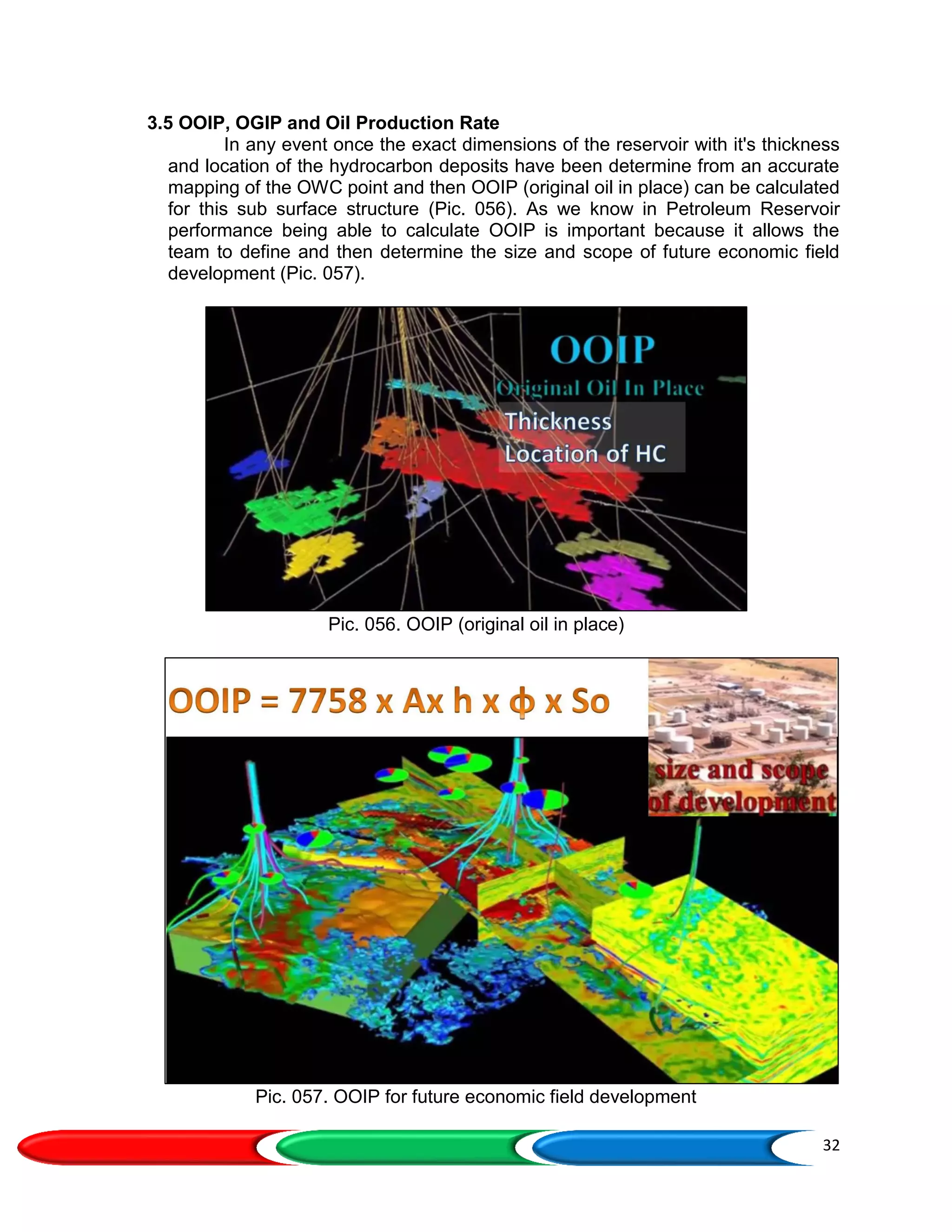

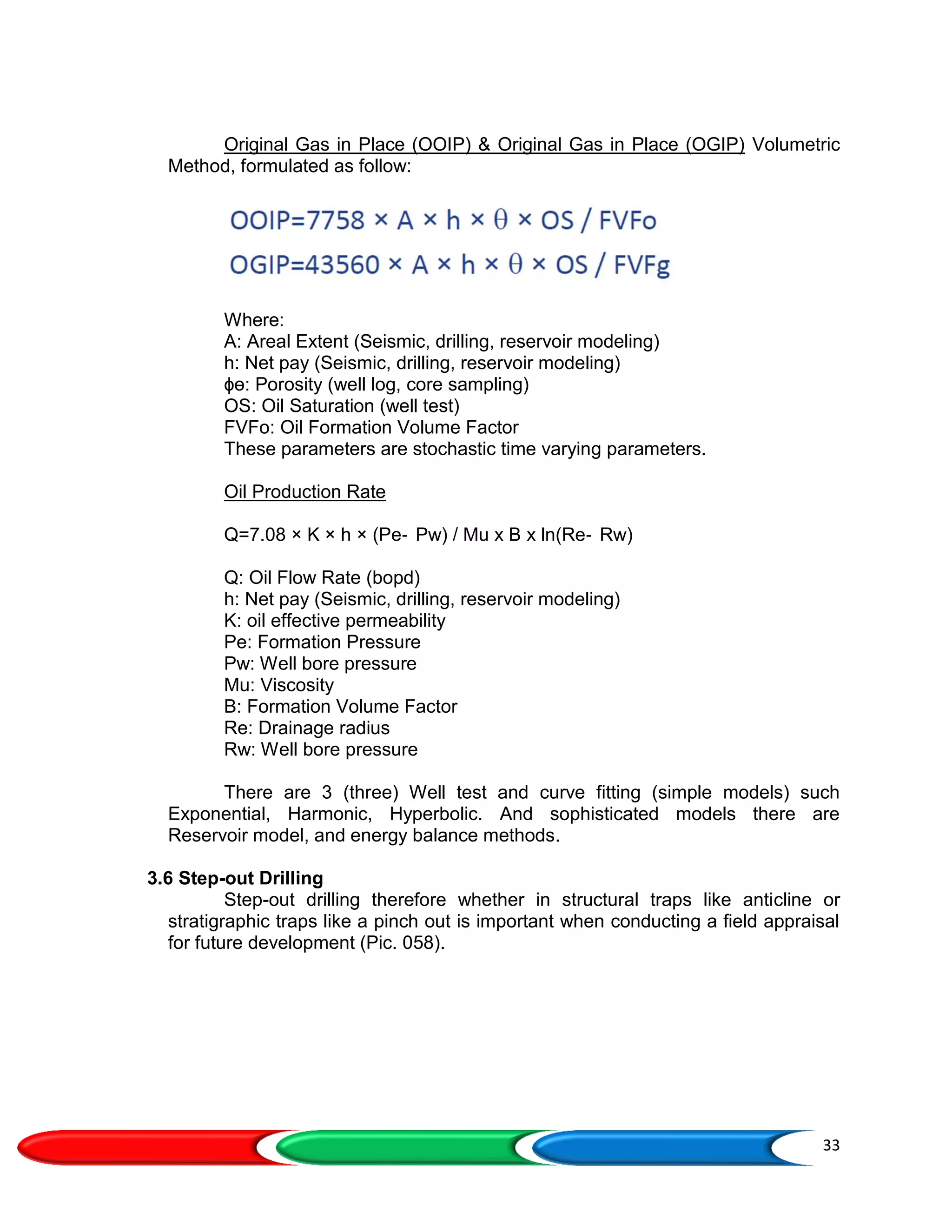

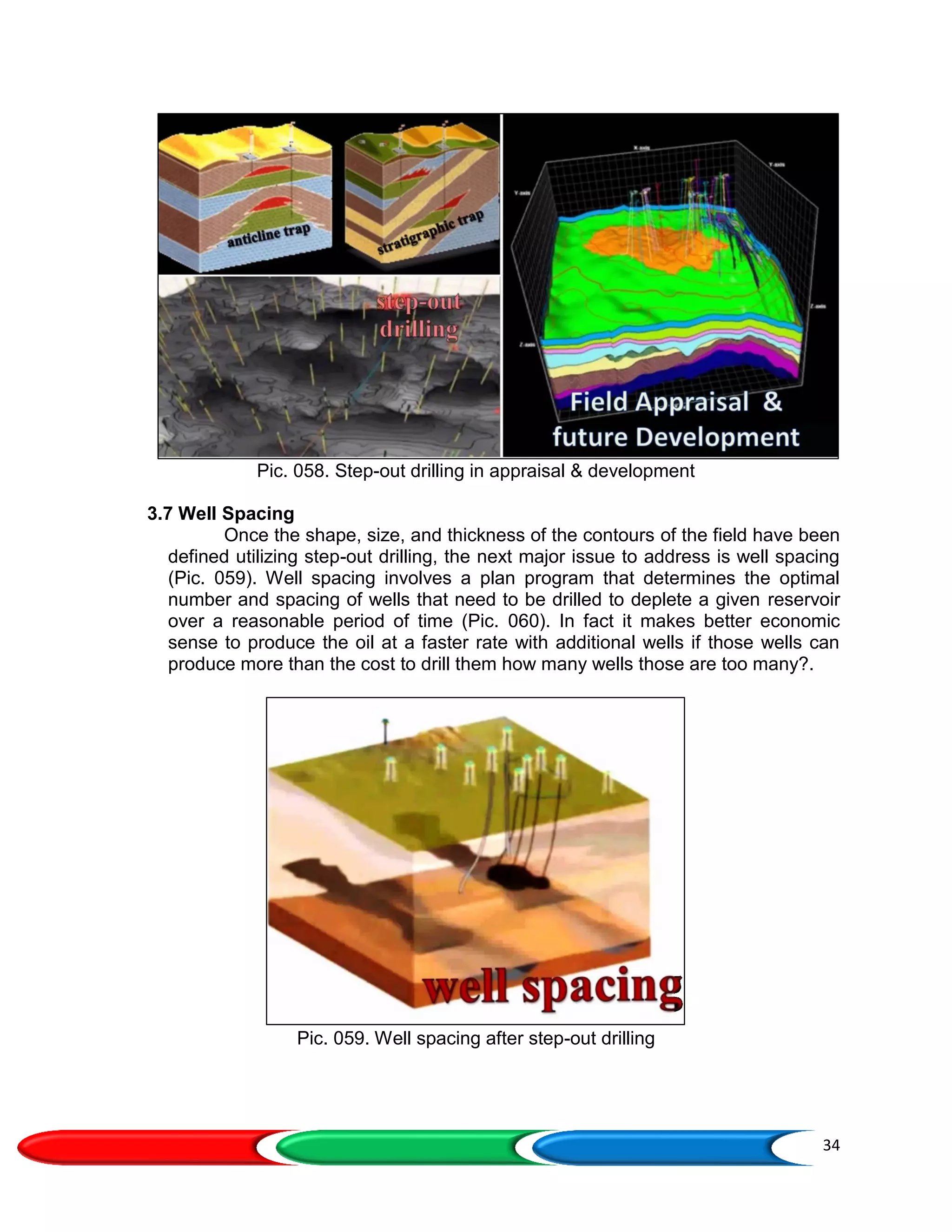

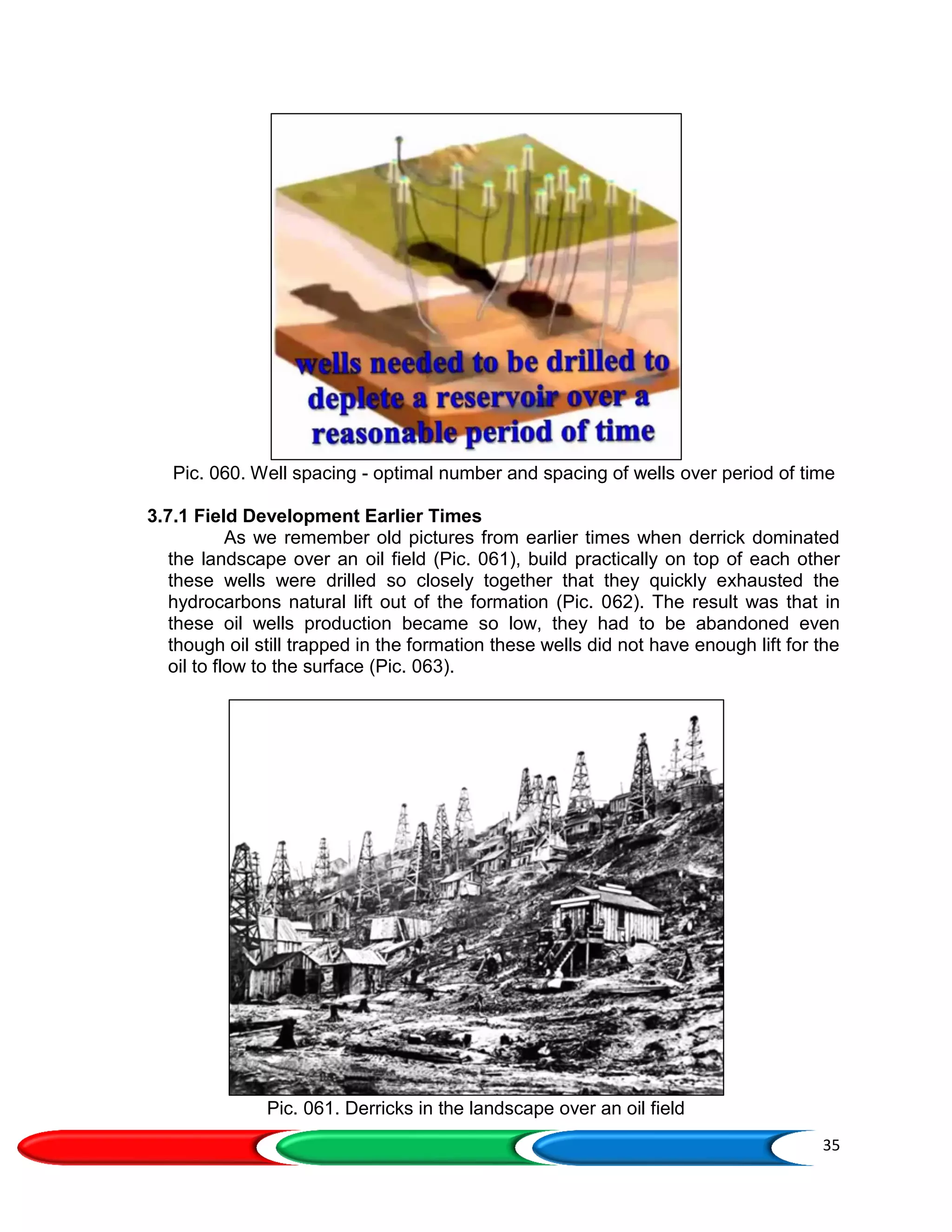

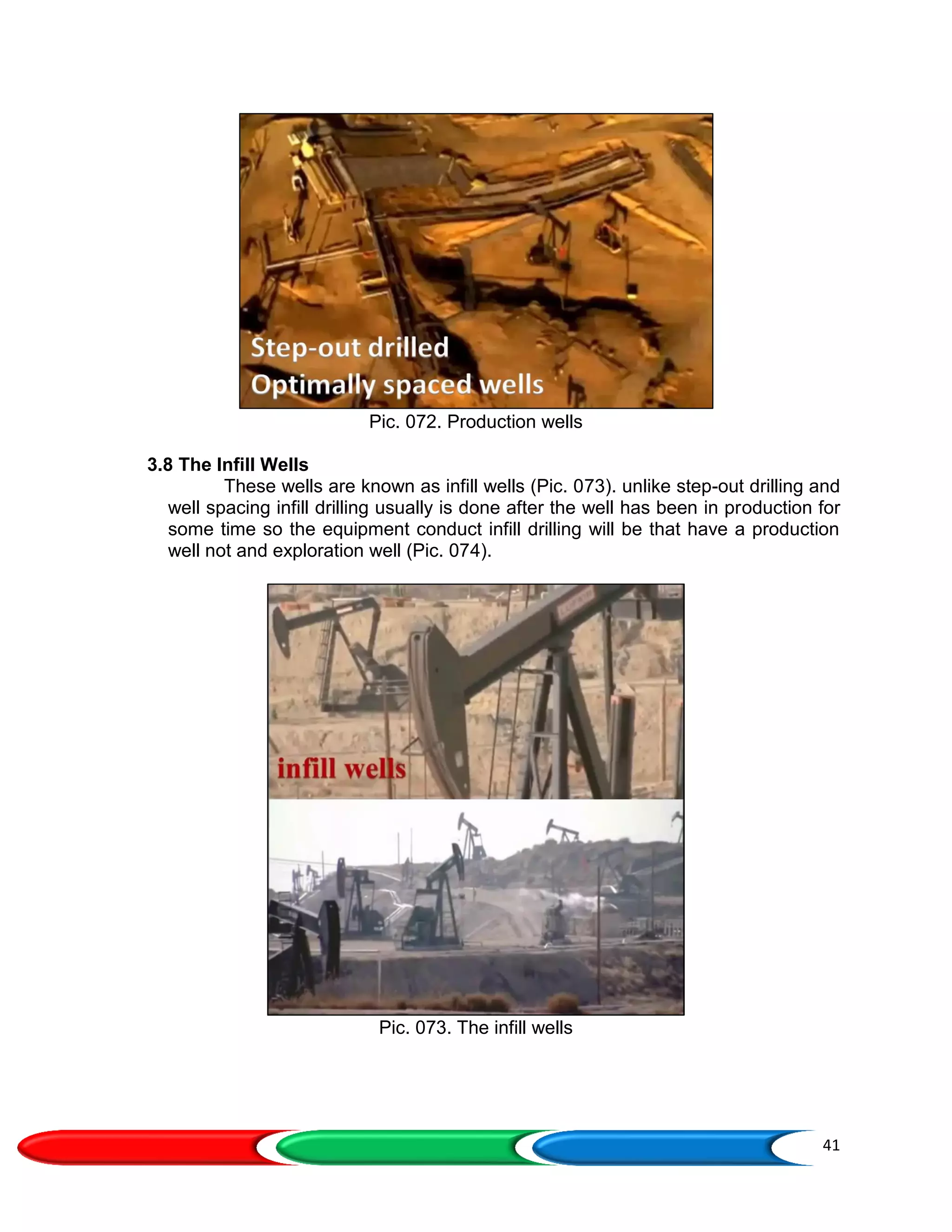

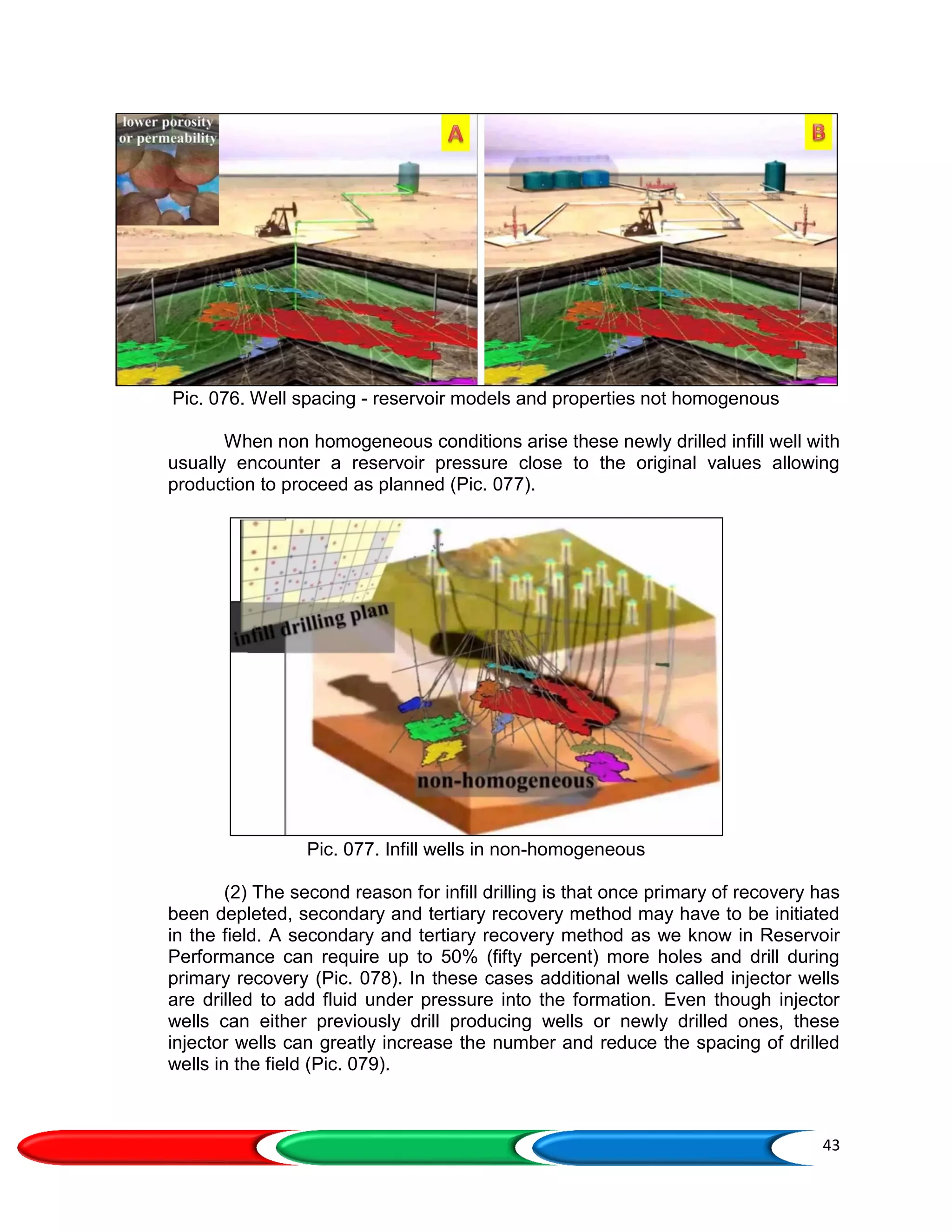

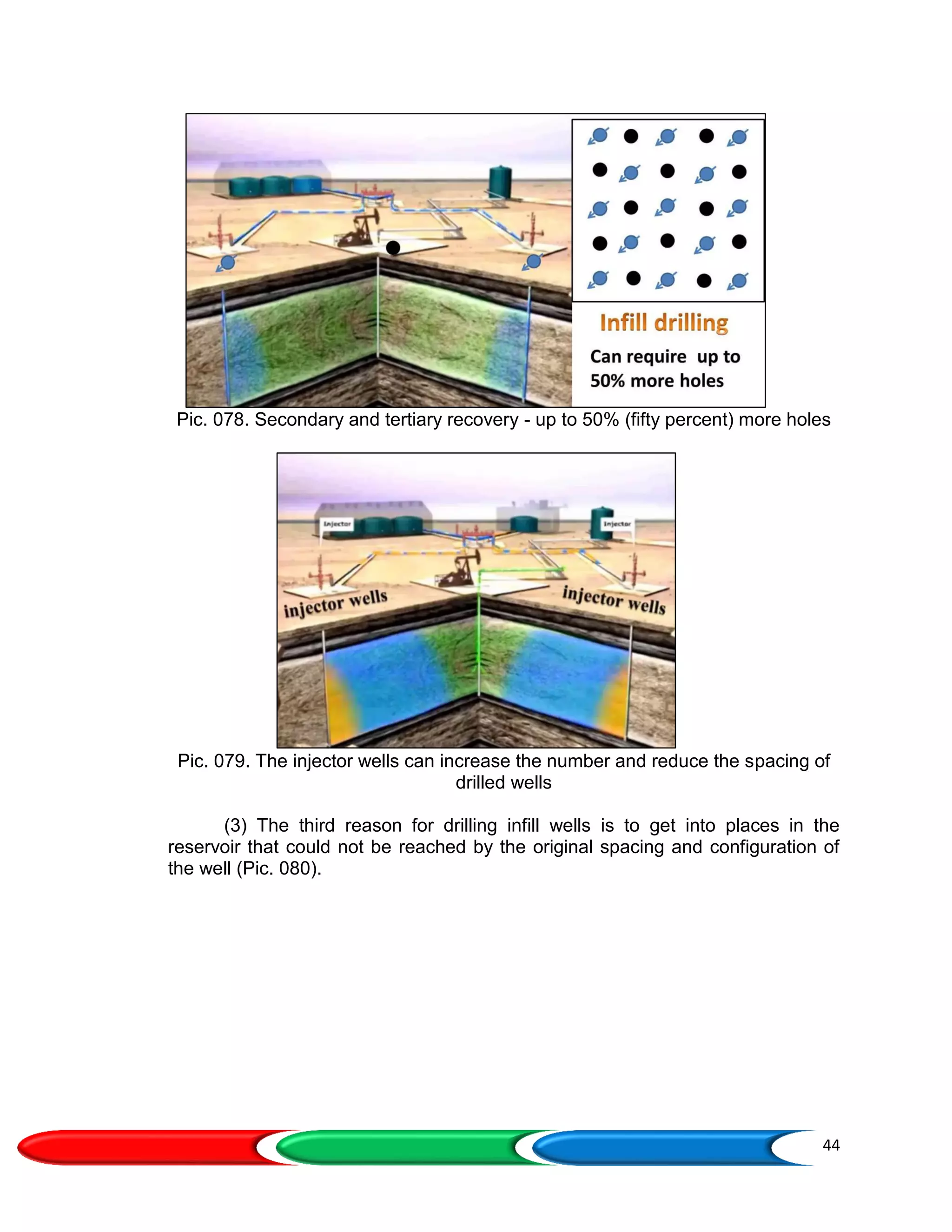

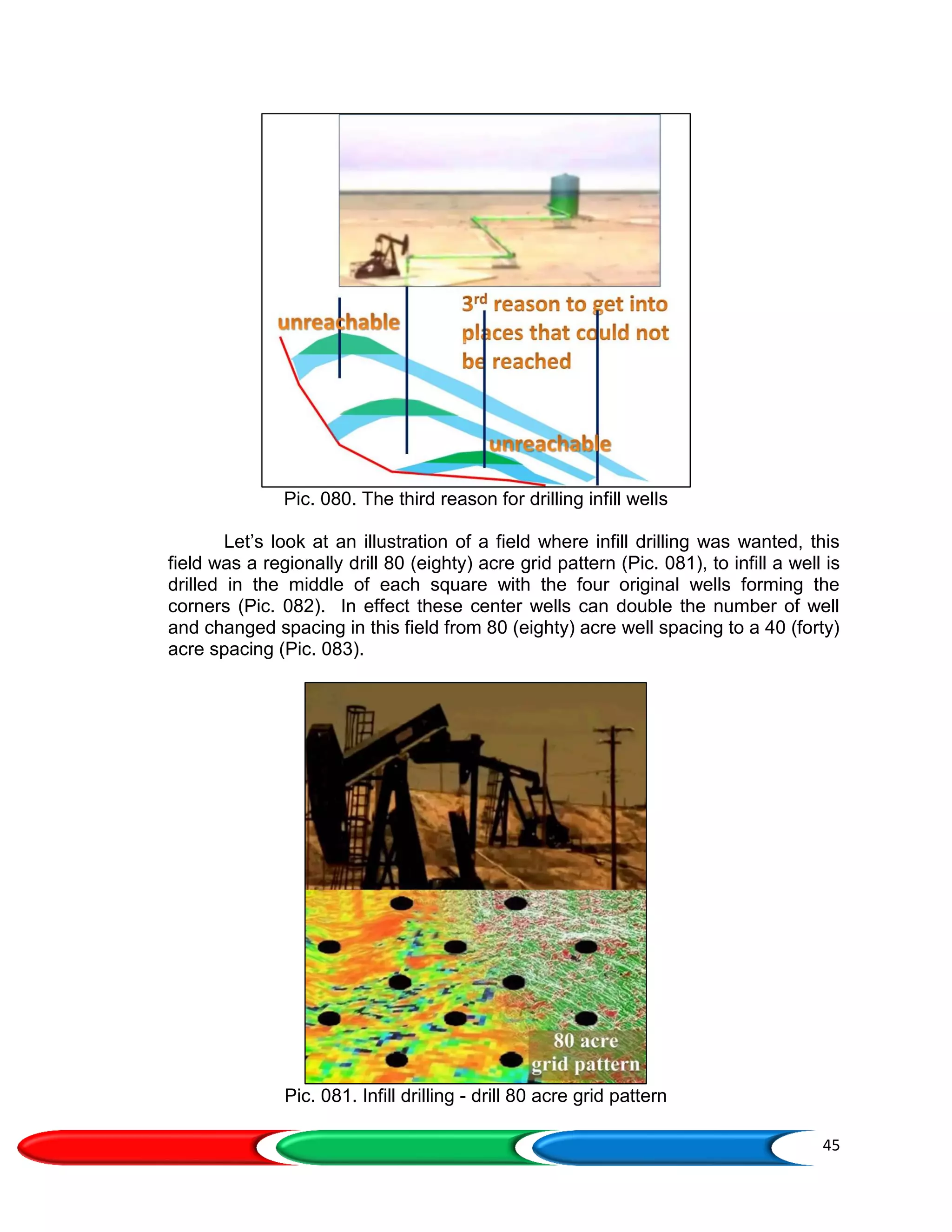

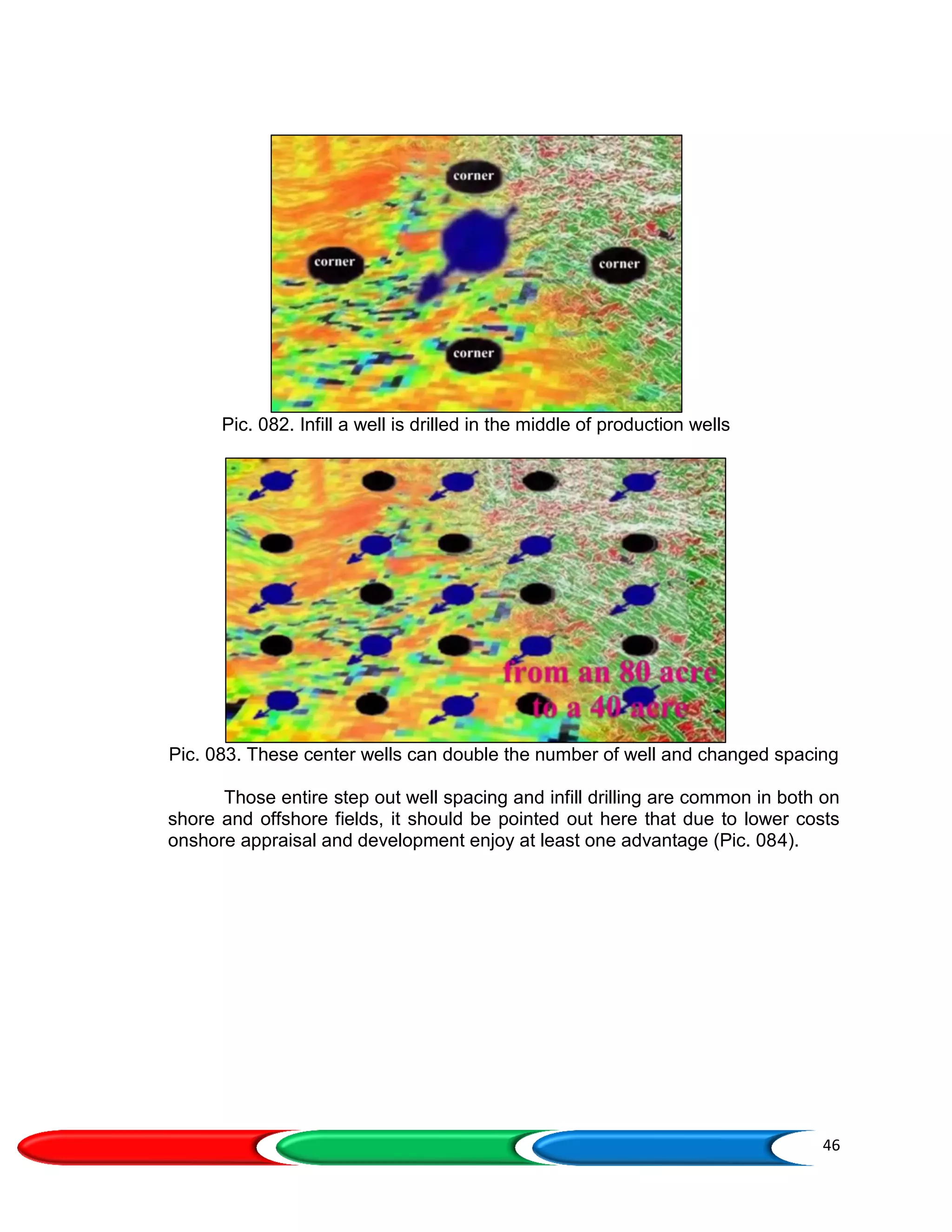

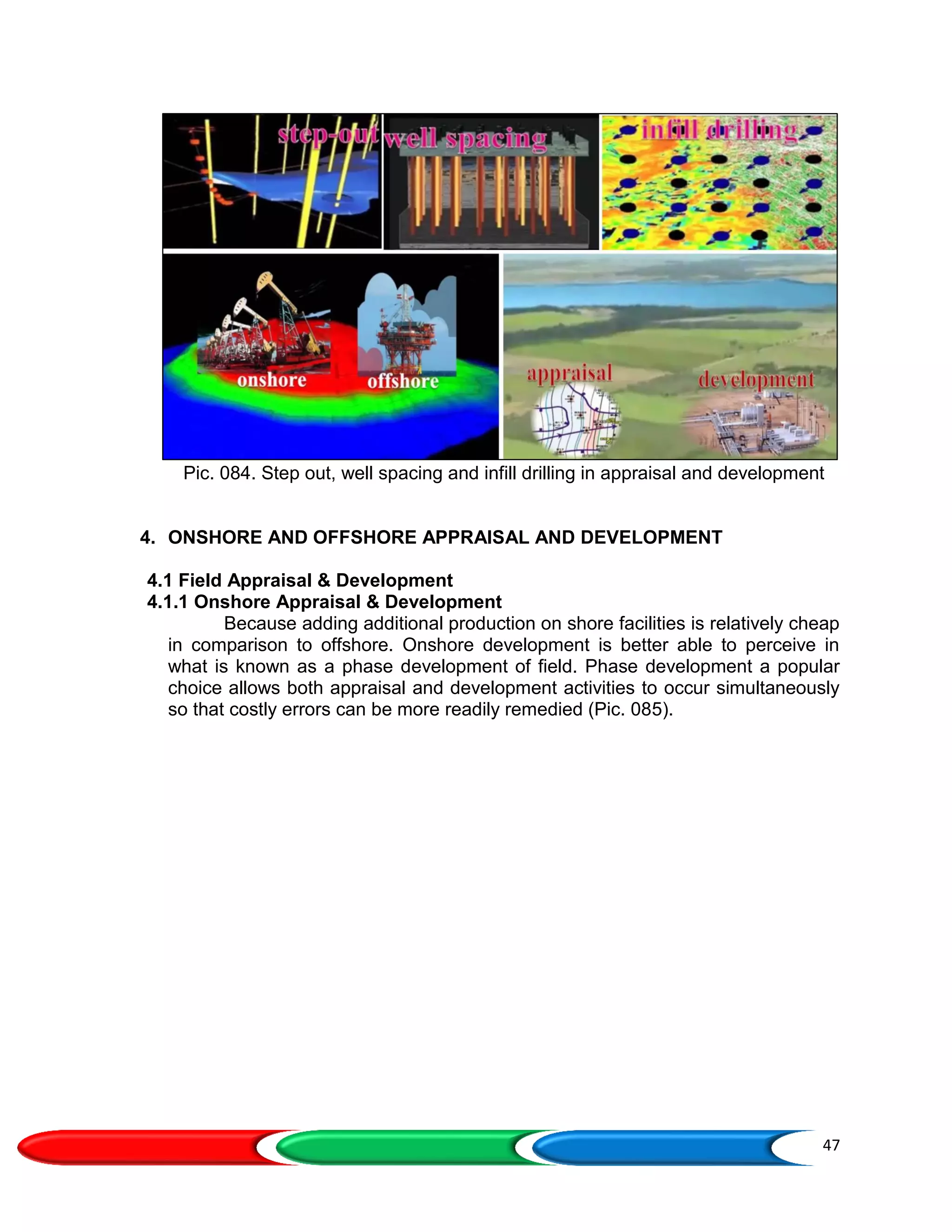

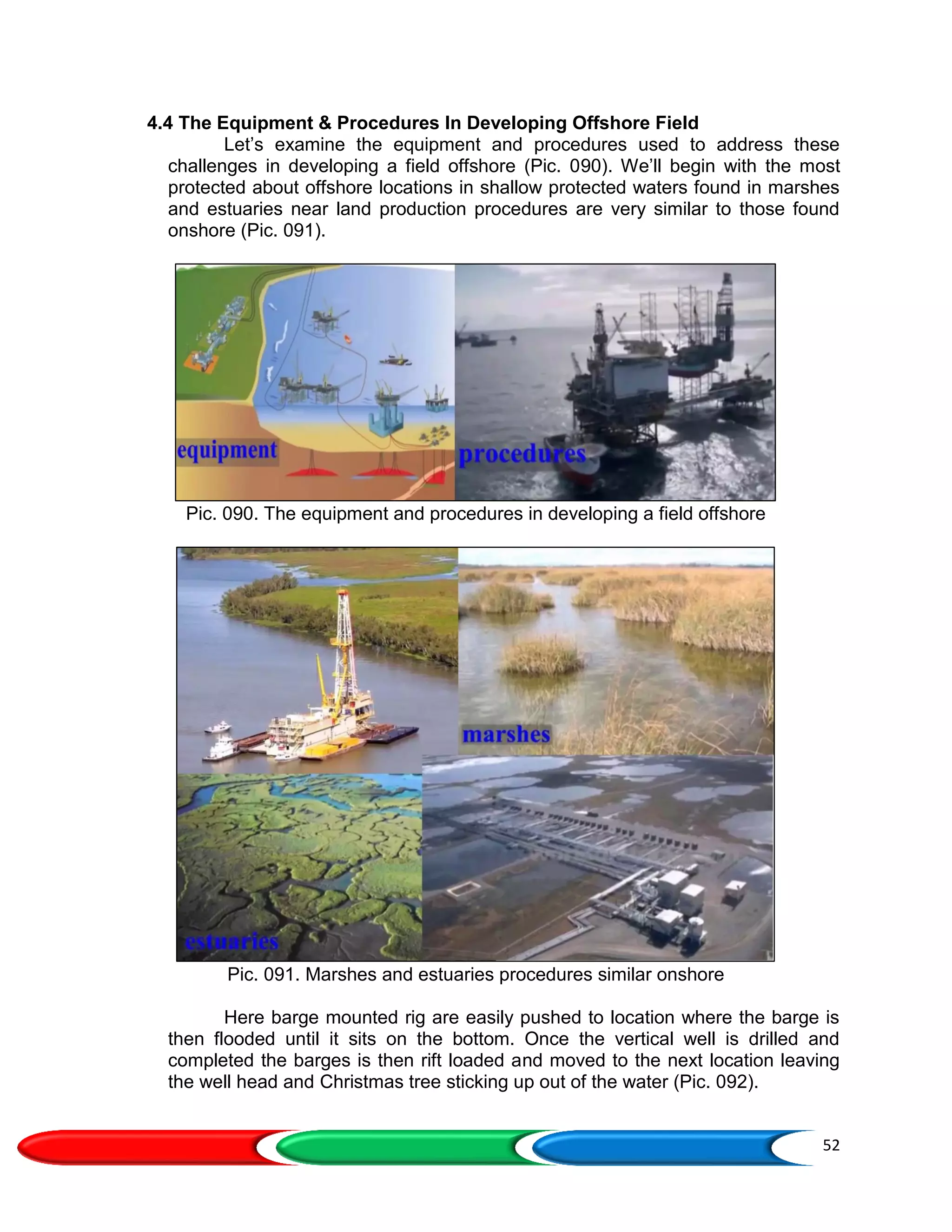

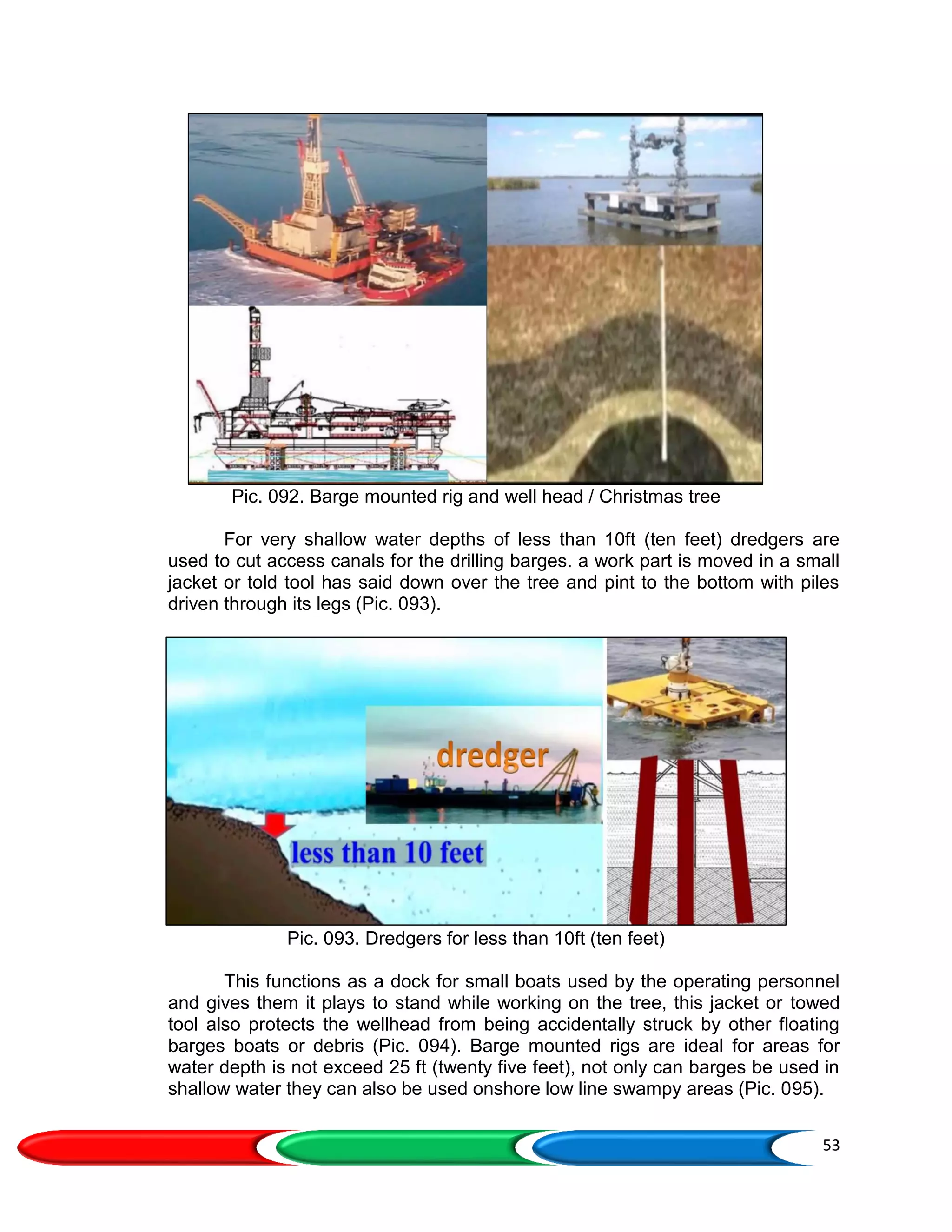

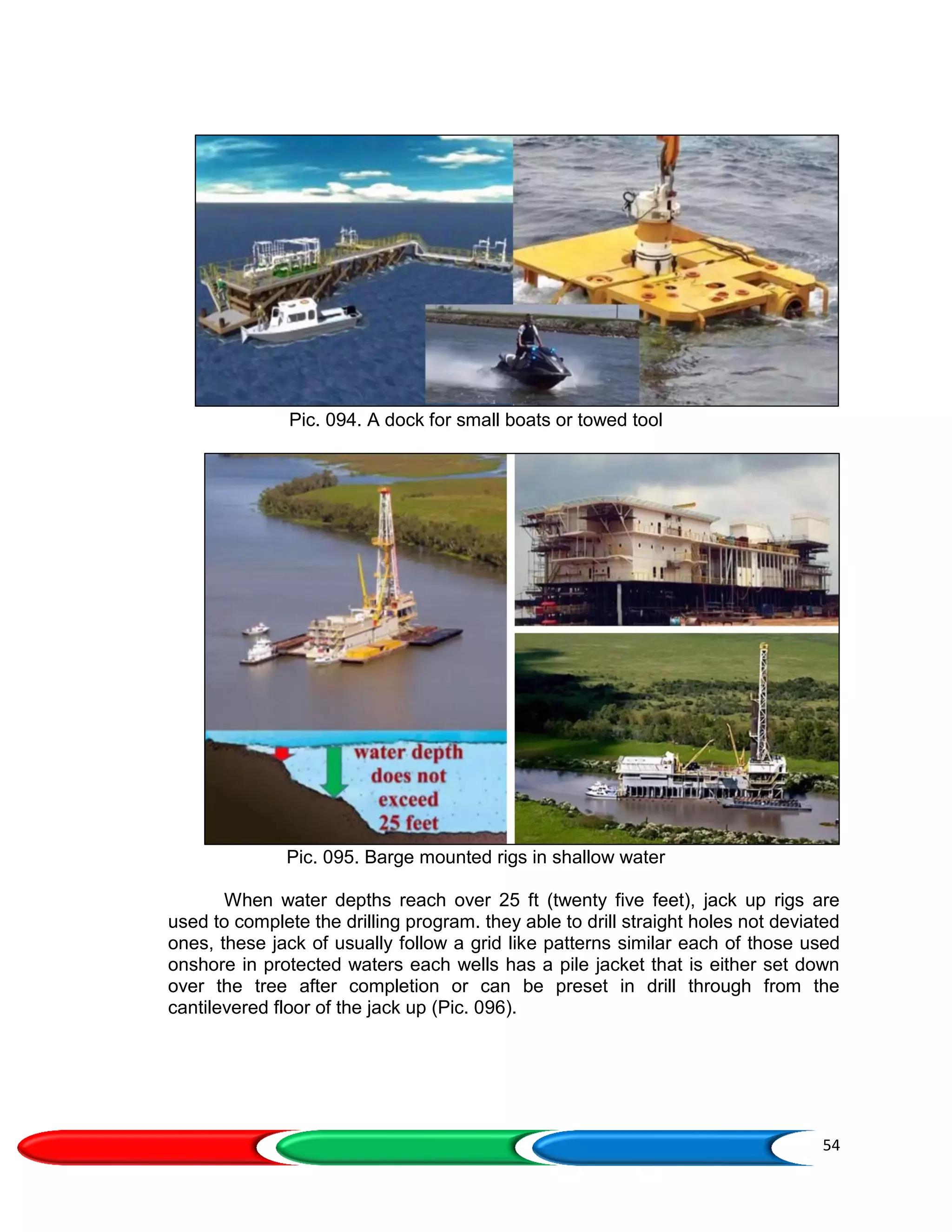

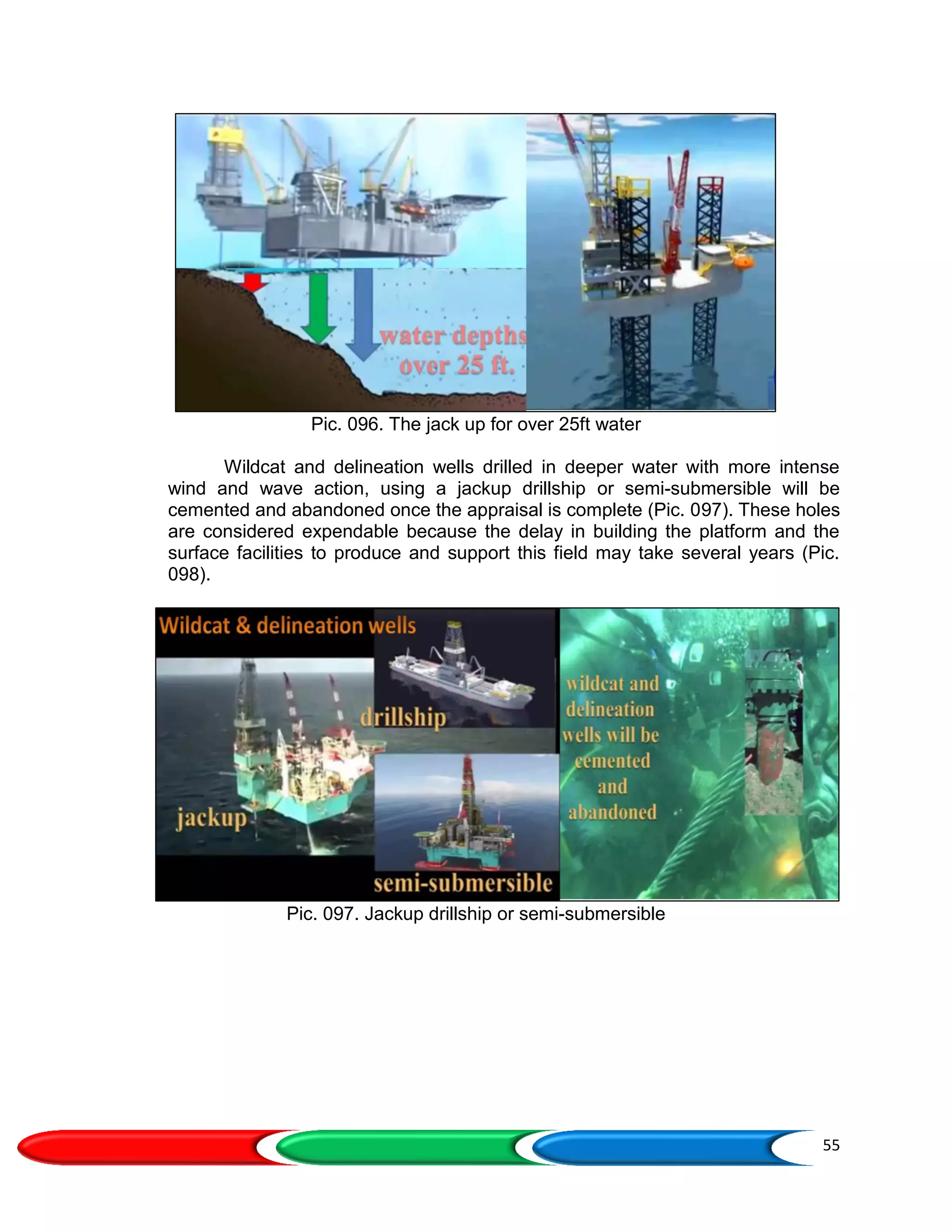

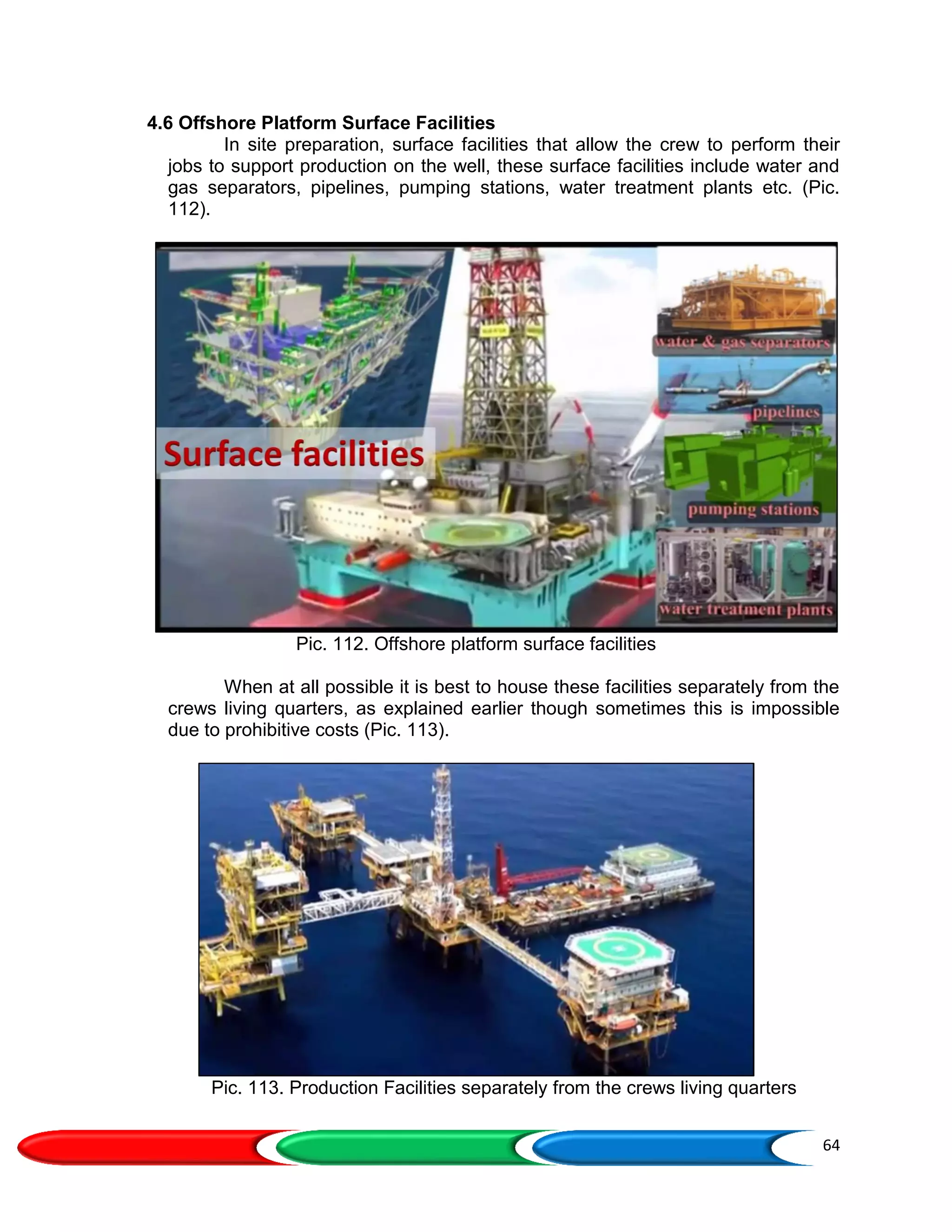

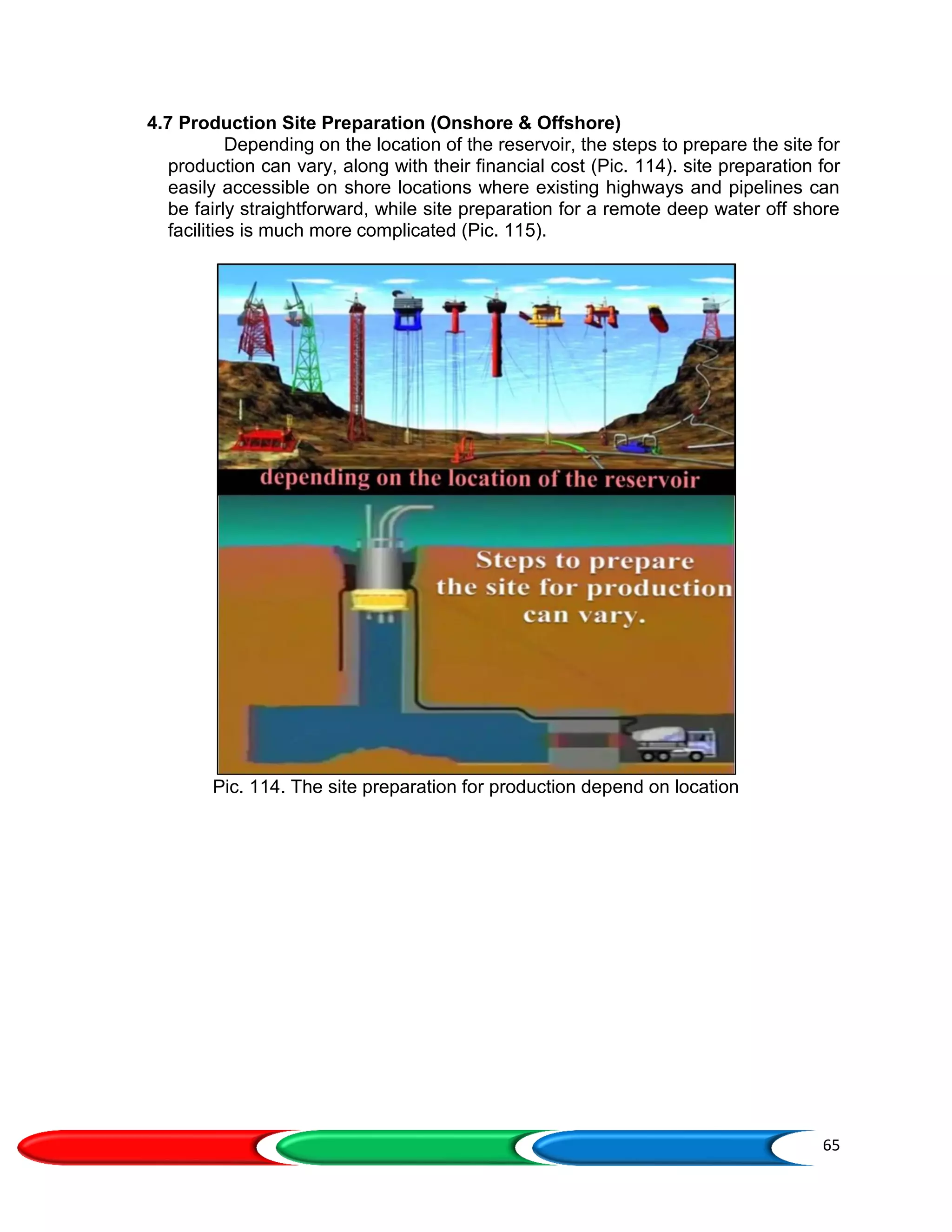

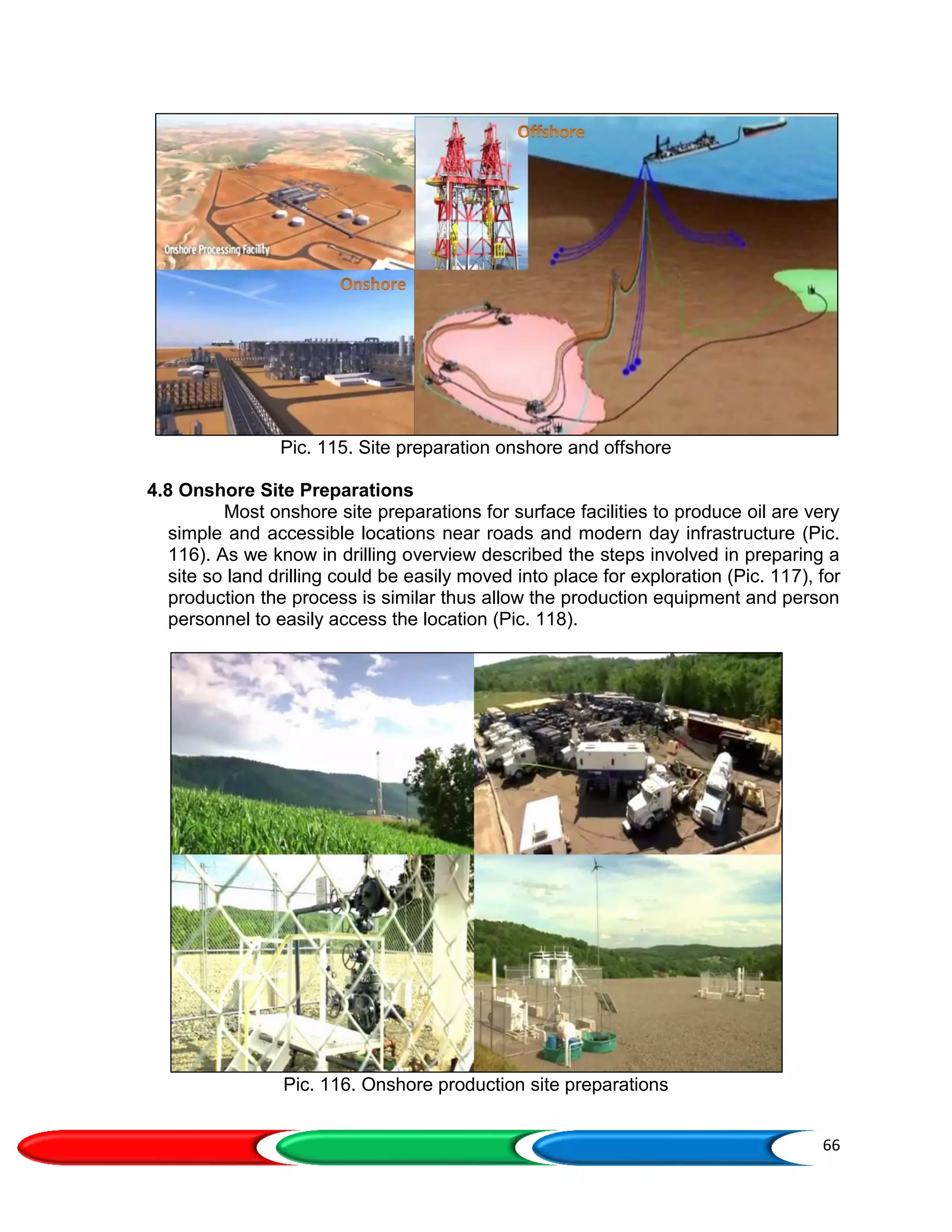

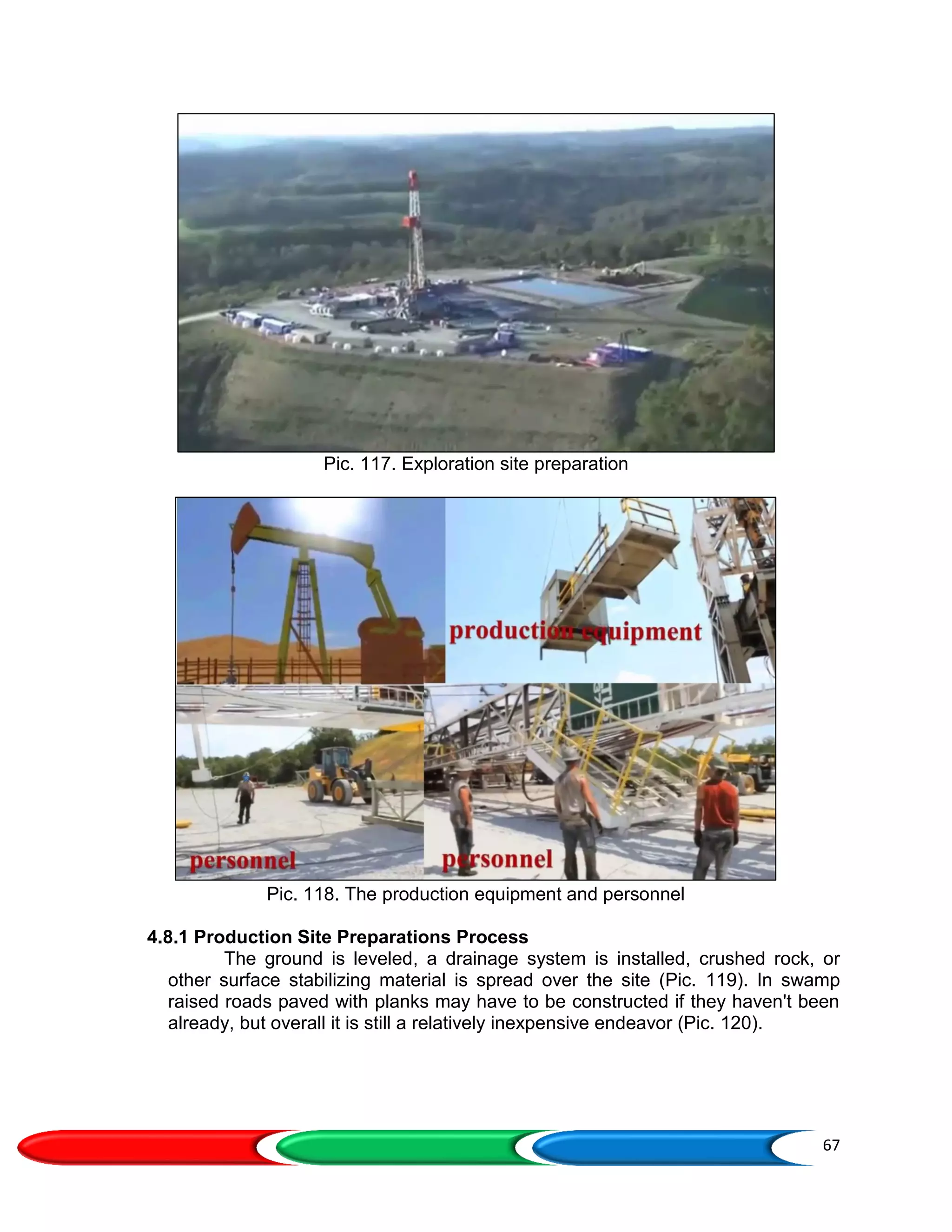

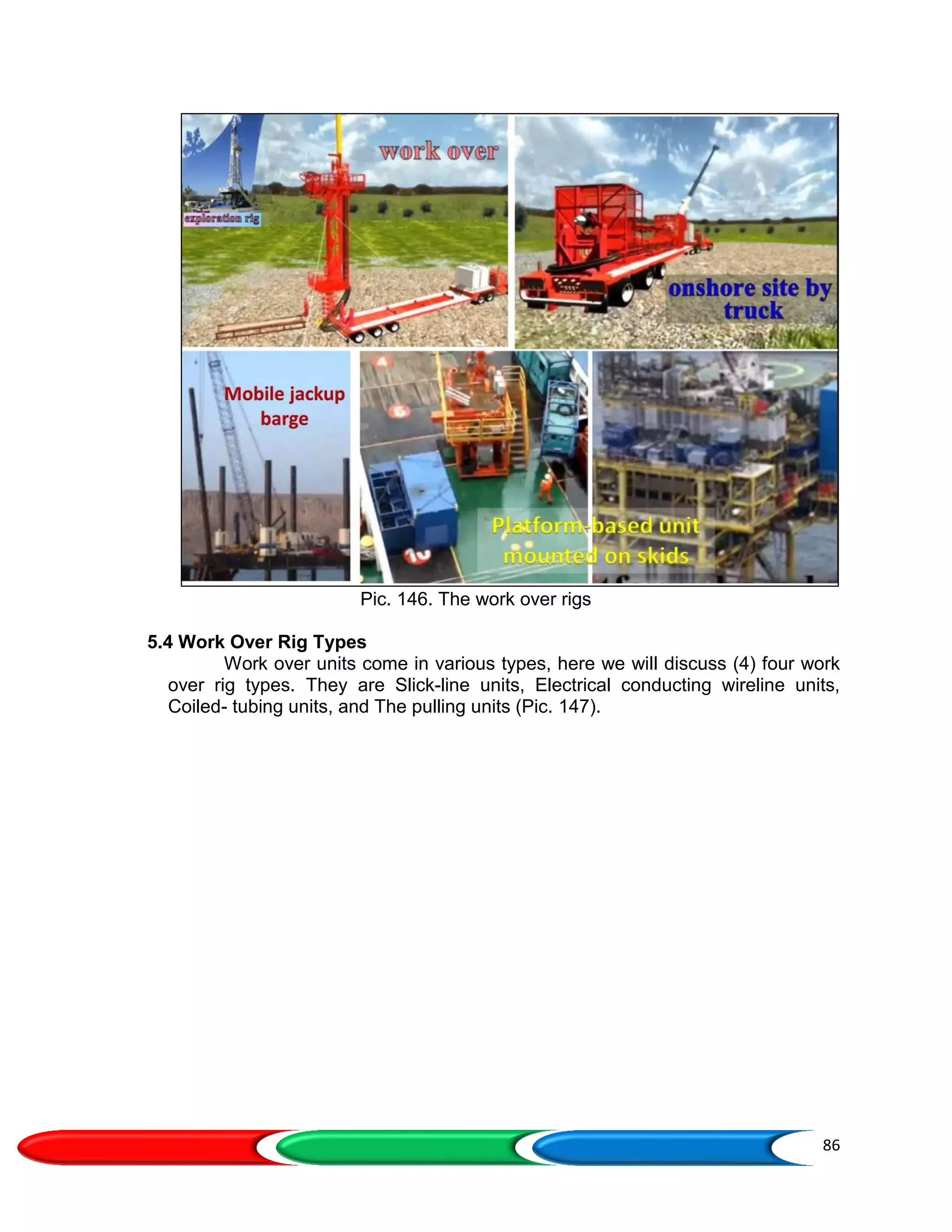

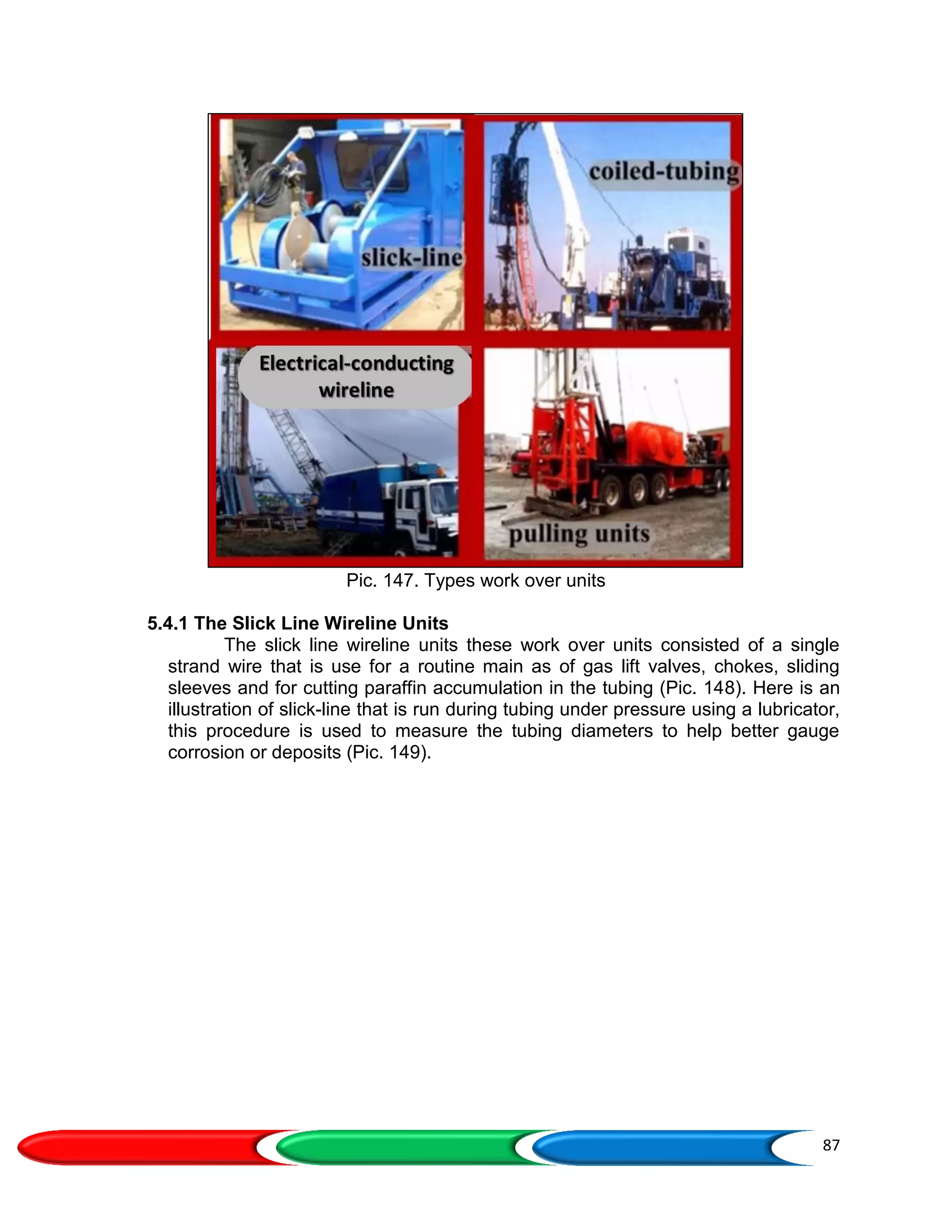

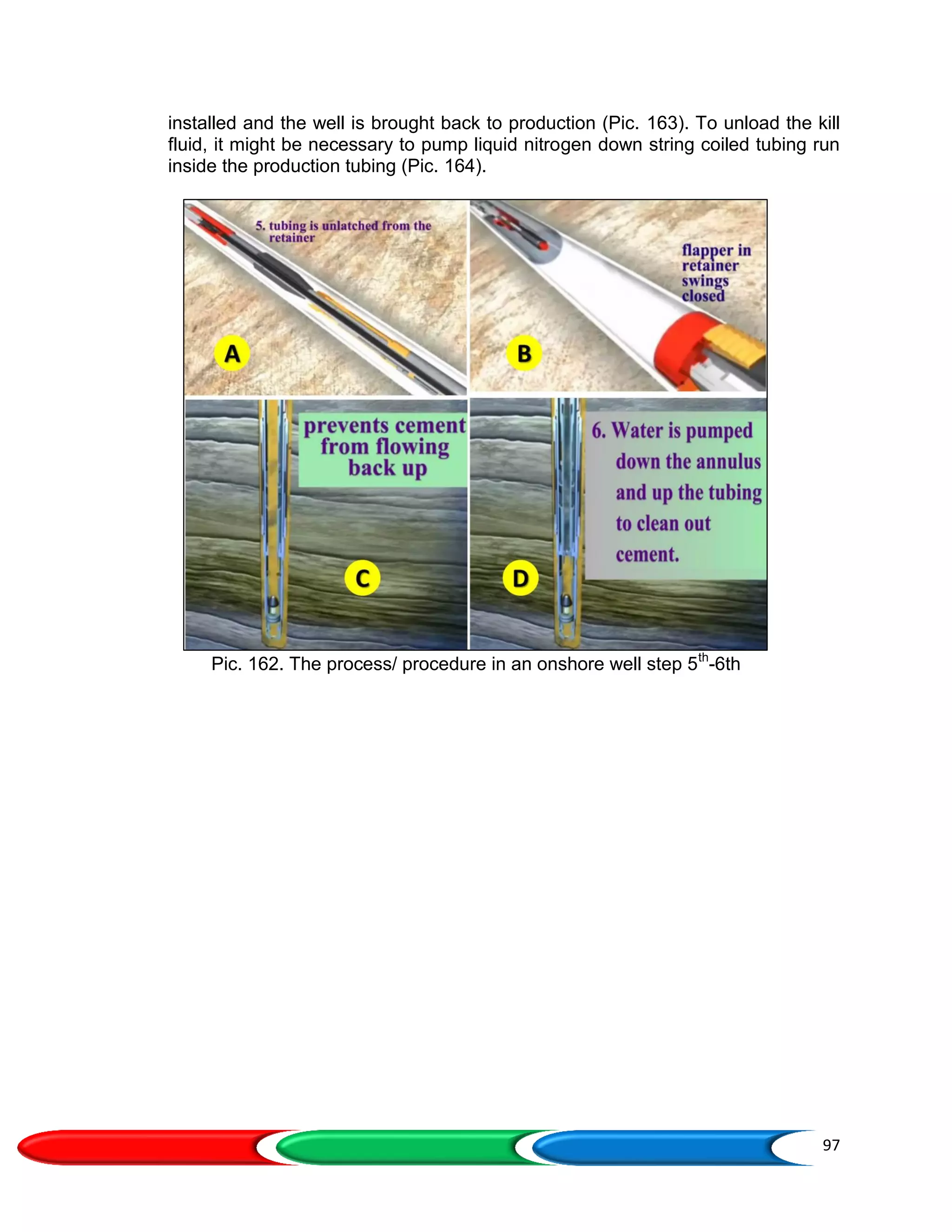

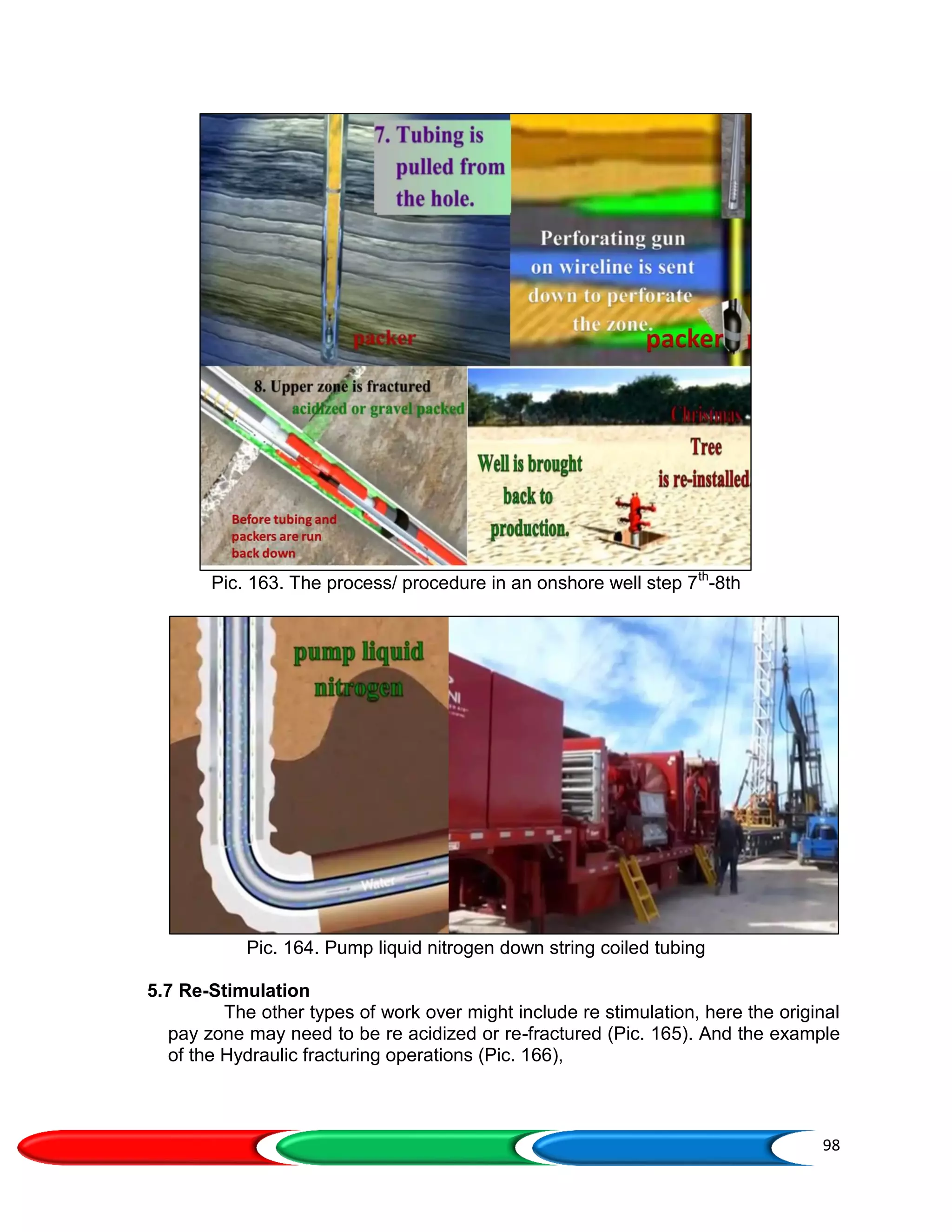

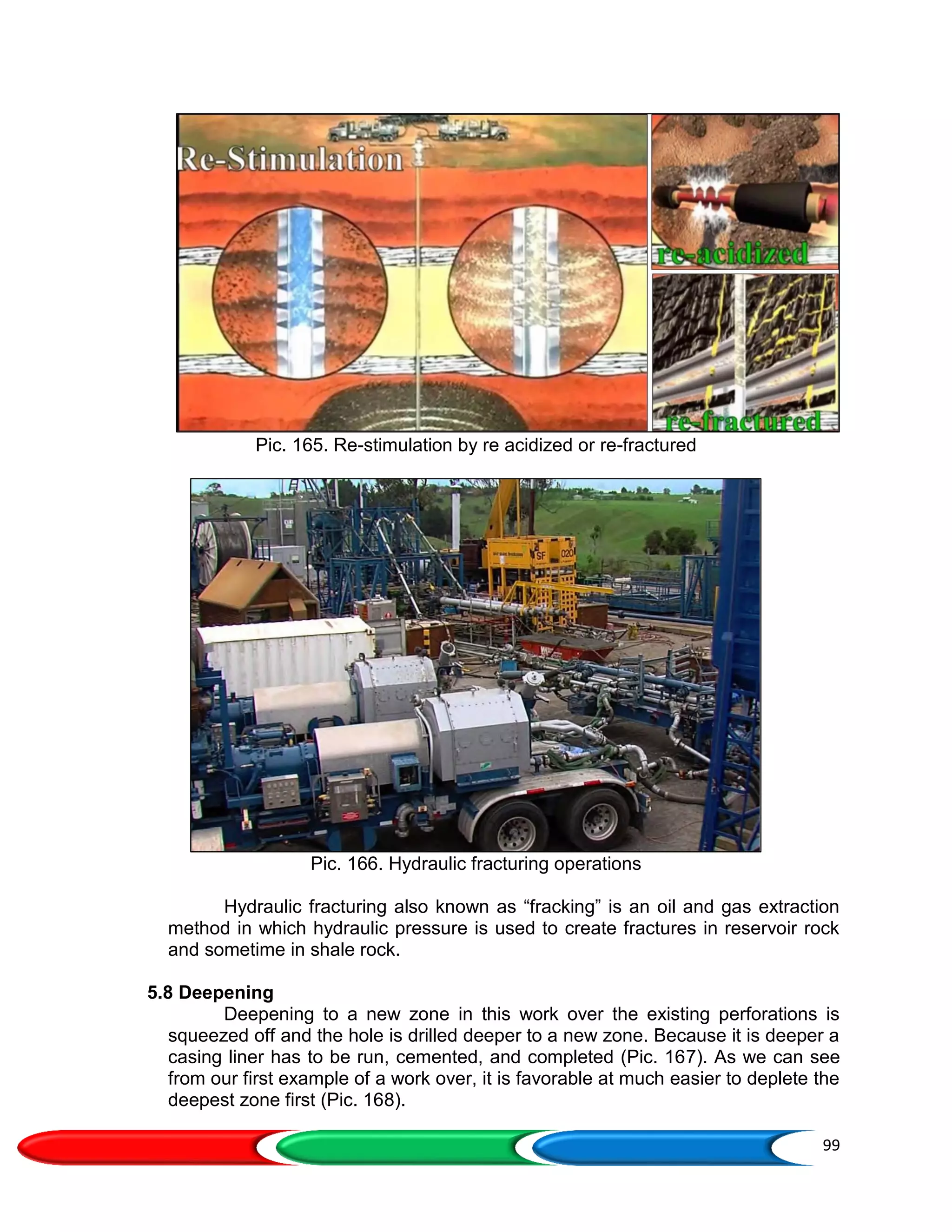

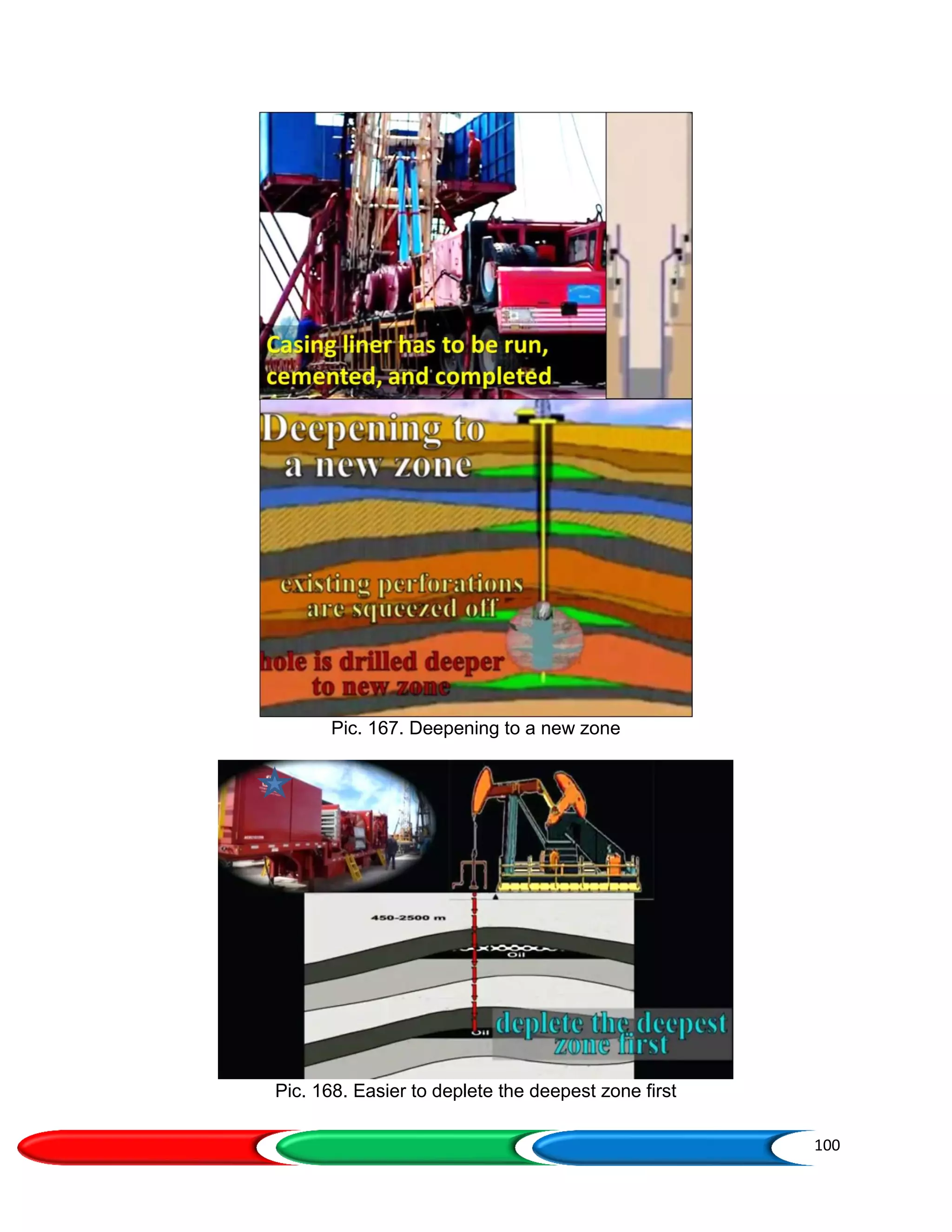

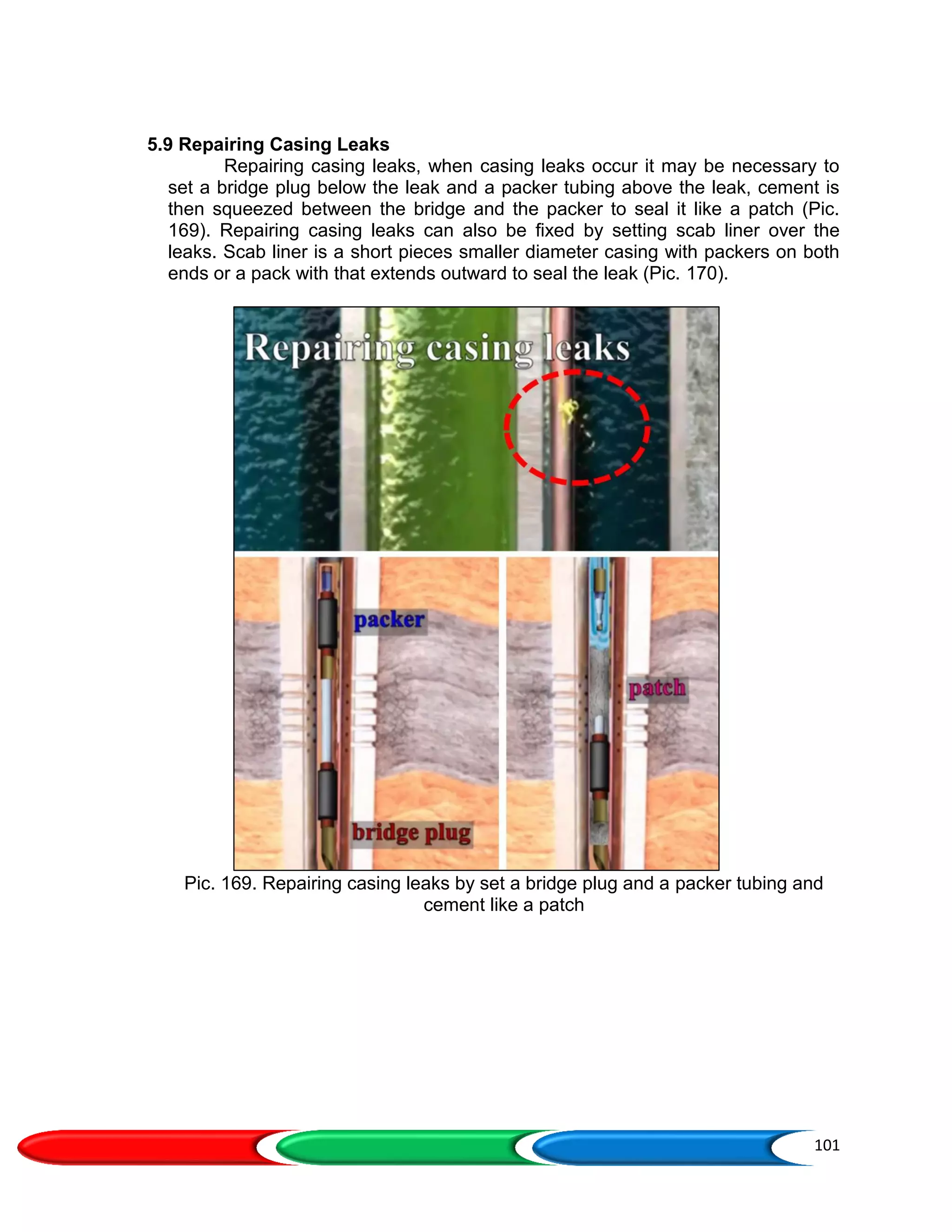

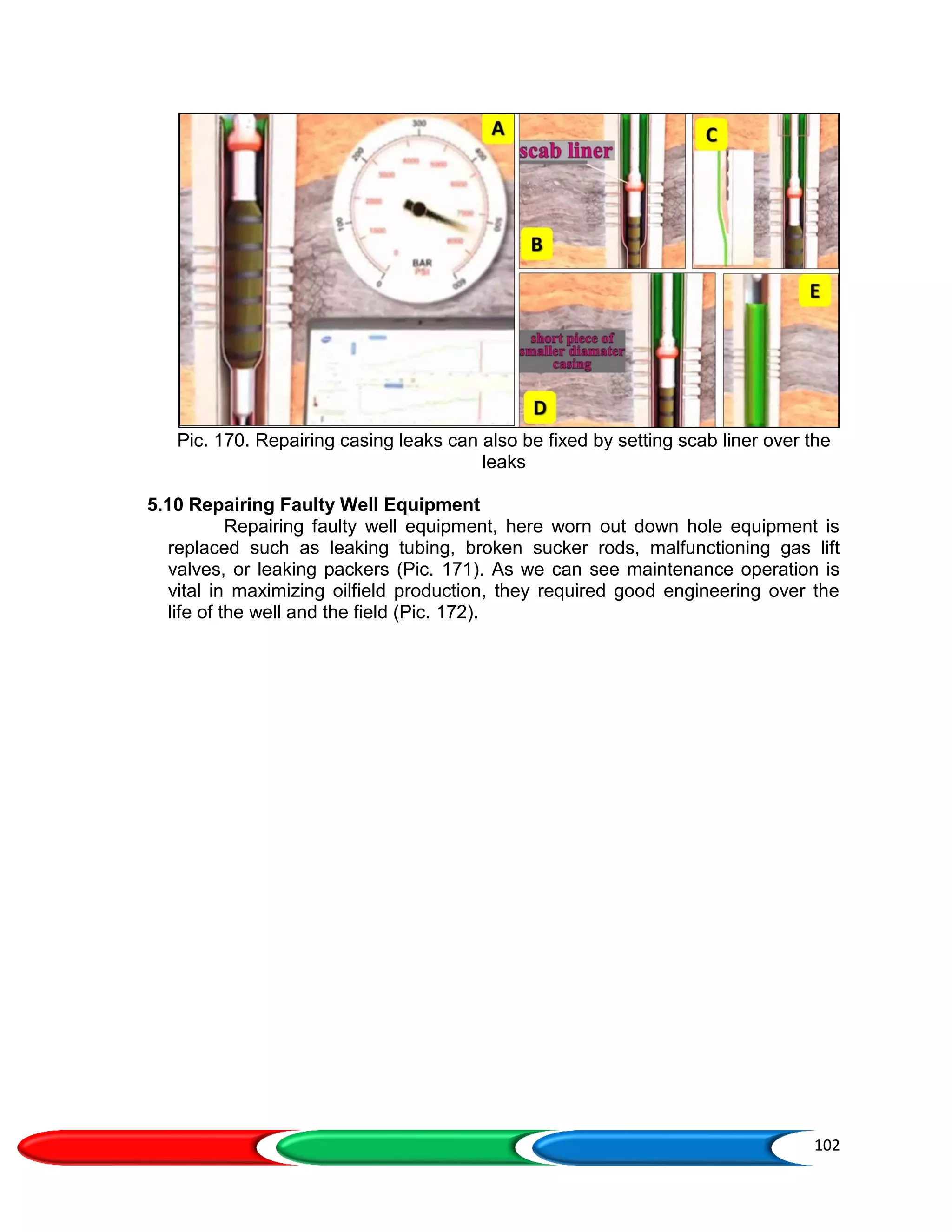

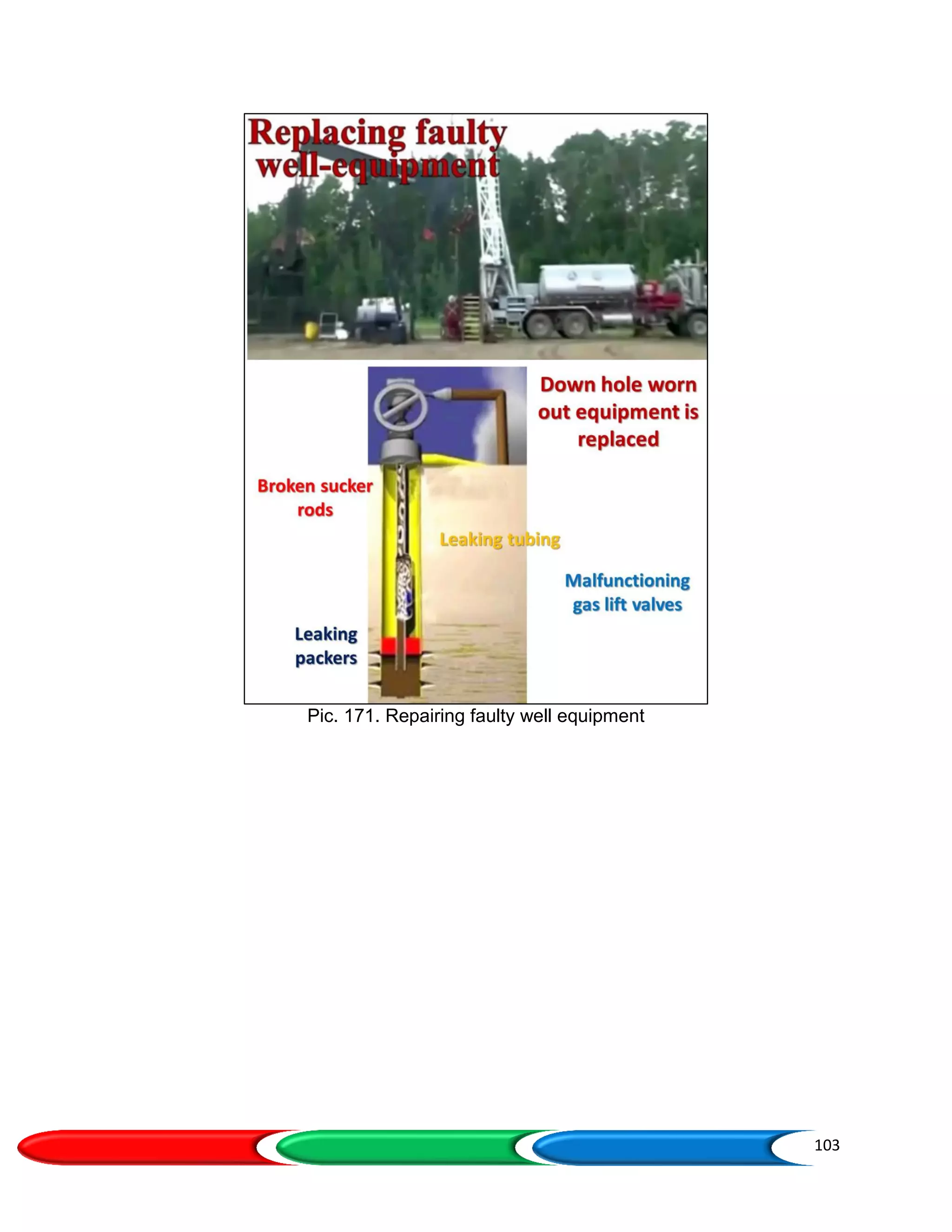

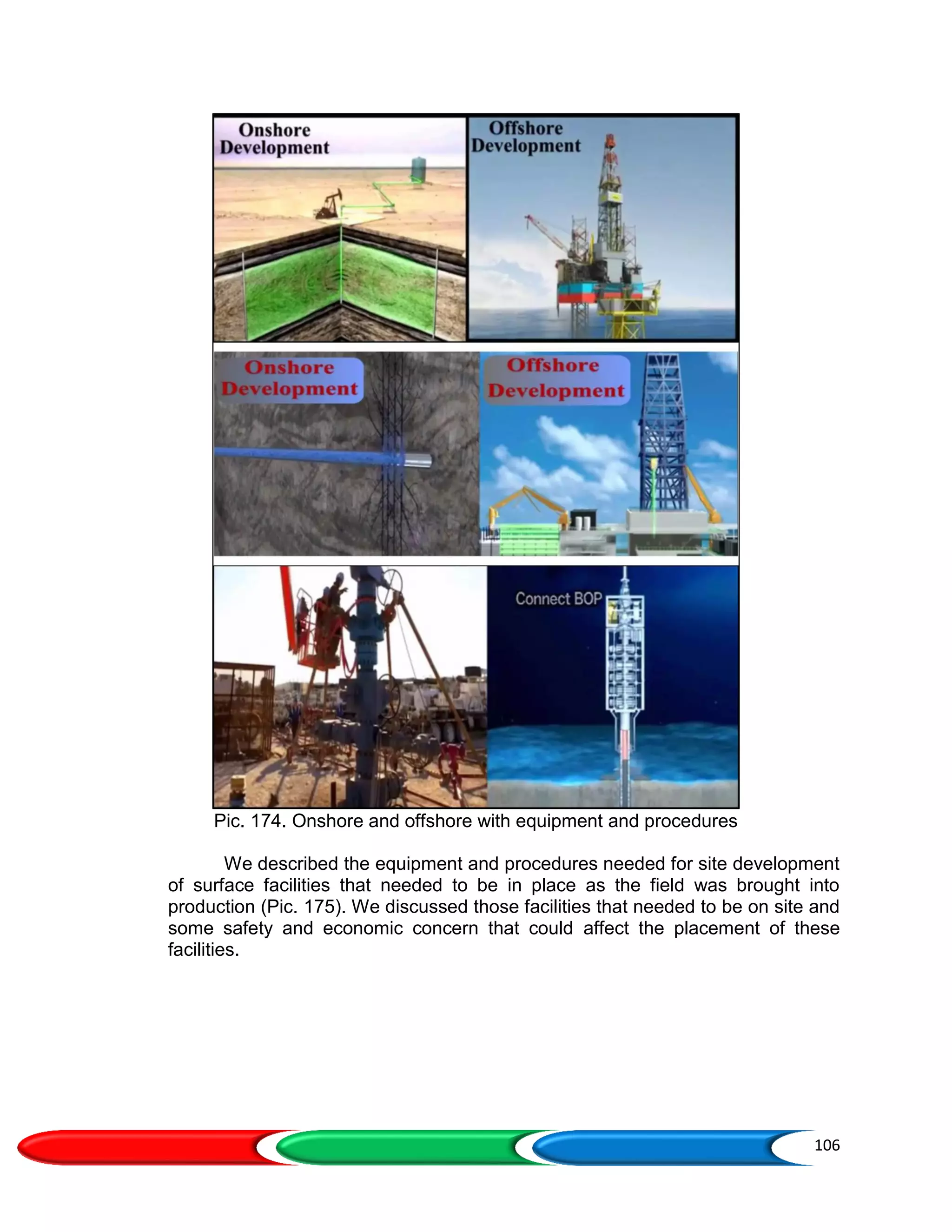

This document provides an overview of petroleum appraisal and development. It describes hydrocarbon production rates and the equipment used in field appraisal and development. It discusses the evolution of exploration wells into production wells and the appraisal phase of field development. It covers procedures for appraising and developing onshore and offshore fields, including delineation wells, step-out drilling, well spacing, and infill wells. It also describes improving hydrocarbon production through workover operations, re-stimulation, and repairing casing leaks and faulty well equipment. Suggestions are requested for the next book on overview of the petroleum and mining industries.