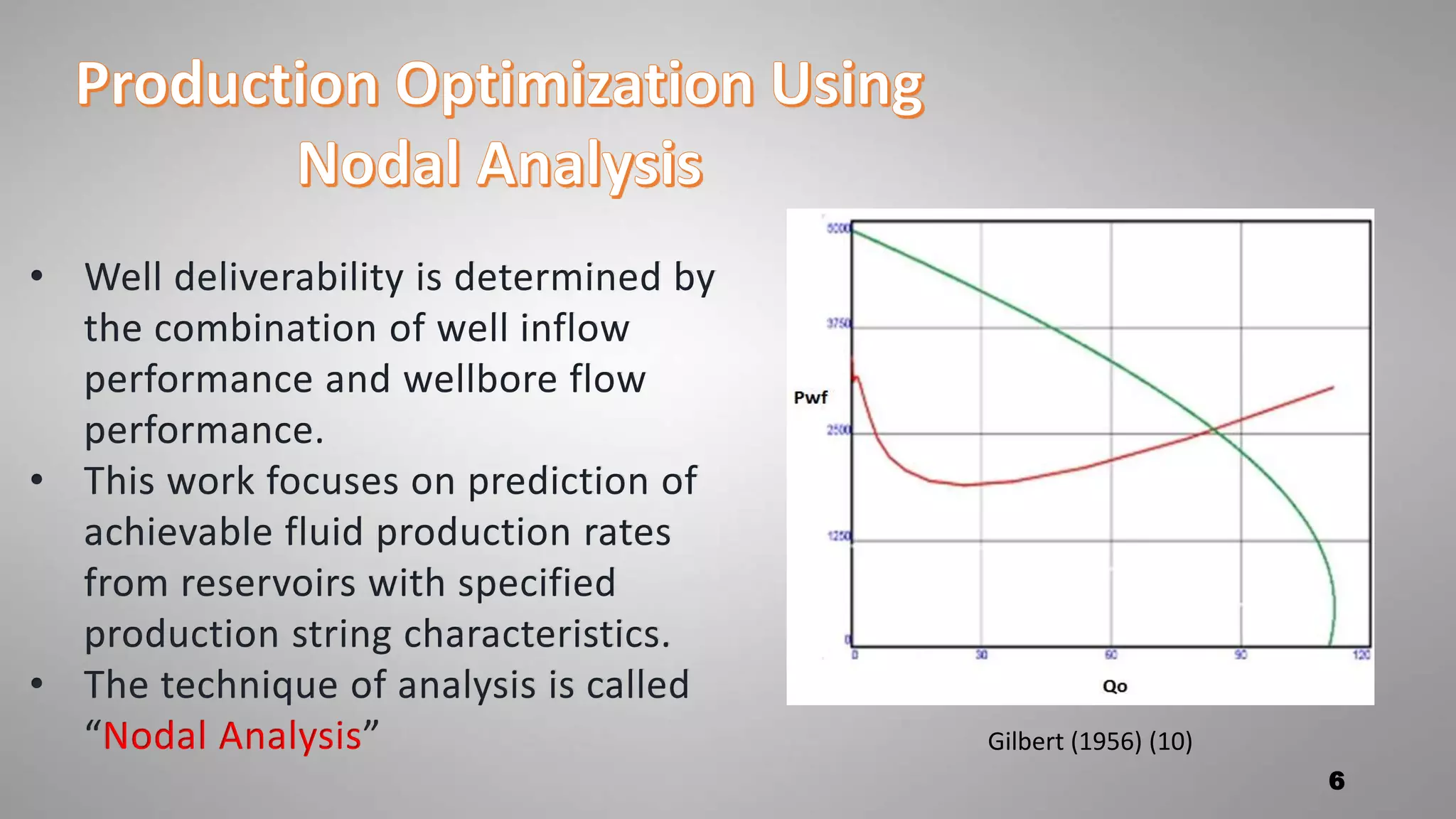

The document discusses optimization of production from horizontal wells using nodal analysis and the PROSPER software. It outlines factors that affect pressure losses in horizontal and inclined well sections and describes how nodal analysis can be used to model well deliverability and optimize parameters like well length. Results from PROSPER simulations show how inlet pressure, pressure drop, and flowrate increase with longer well lengths up to an optimal value. The document concludes horizontal wells can be optimized for production using nodal analysis and PROSPER to evaluate factors affecting pressure losses and choose well parameters.