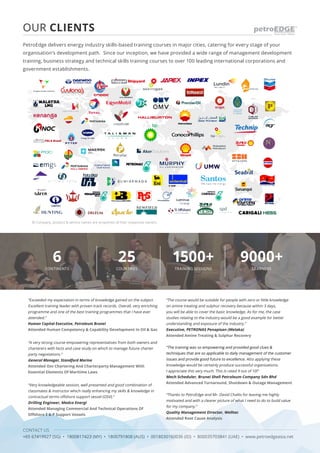

Petroedge is a leading provider of oil and gas training in the Asia Pacific, offering over 150 courses since its inception in 2007, with a focus on targeting specific organizational needs. The training programs have received positive feedback for their knowledgeable trainers, engaging materials, and comprehensive content, catering to professionals from various roles within the industry. With a commitment to addressing skills challenges and fostering sustainable learning, Petroedge remains a key player in the continuous development of oil and gas professionals.