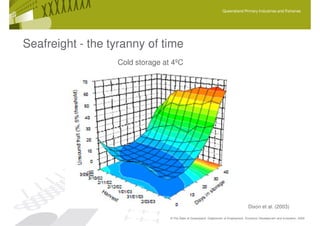

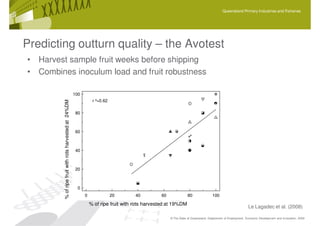

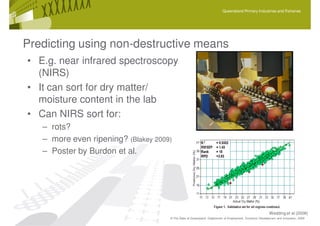

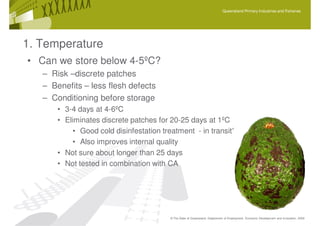

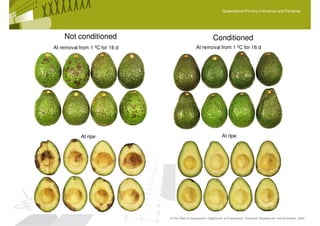

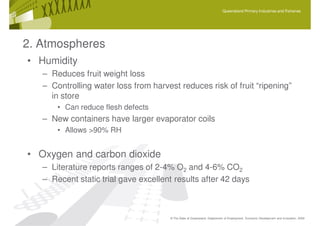

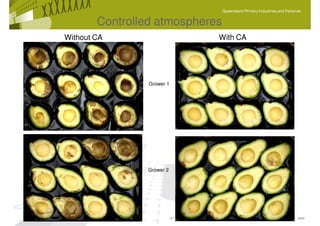

This document discusses challenges and options for exporting Australian avocados. It outlines different transportation methods like air, sea, and combinations which involve tradeoffs between cost and maintaining quality over the longer shipping times. Best practices are needed from the field to delivery to minimize quality risks. Methods for predicting fruit quality include assessing disease loads and fruit robustness. Non-destructive testing using near infrared spectroscopy may help sort fruits by factors like dry matter and rots. Maintaining proper storage conditions is also important for quality during shipping.