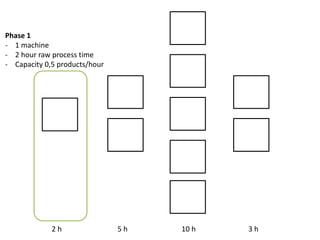

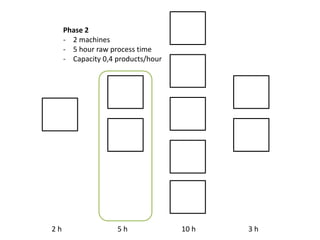

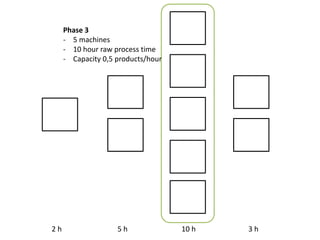

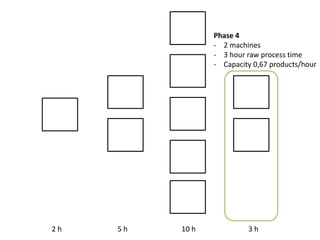

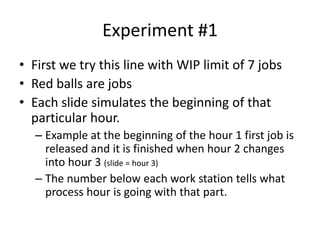

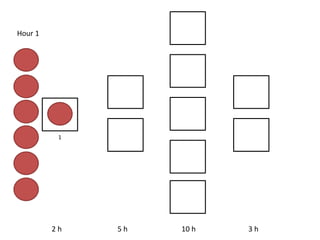

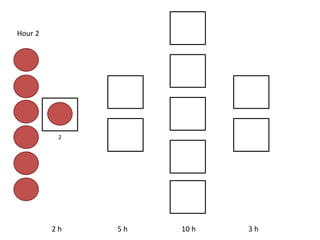

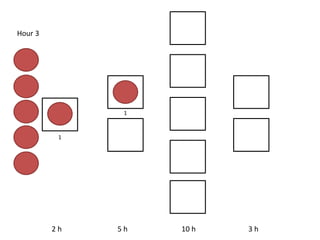

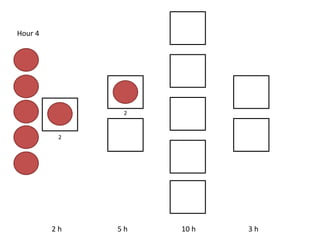

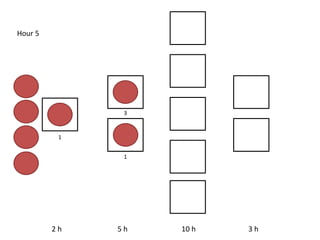

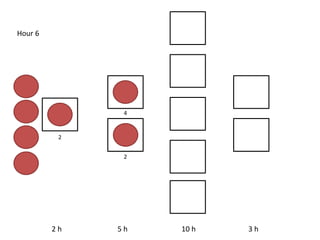

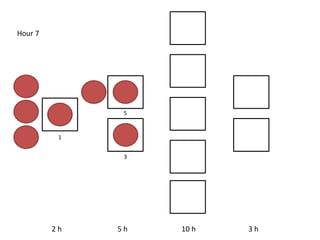

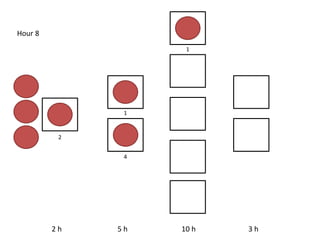

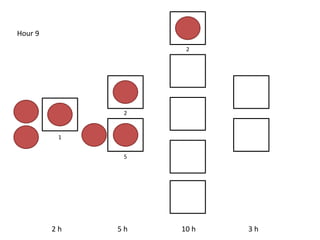

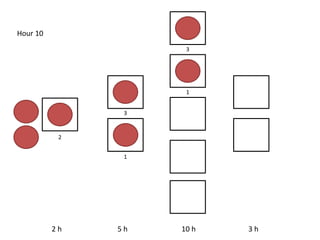

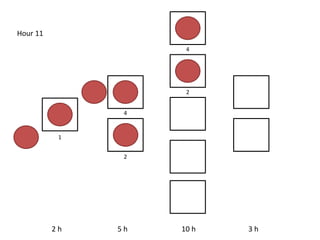

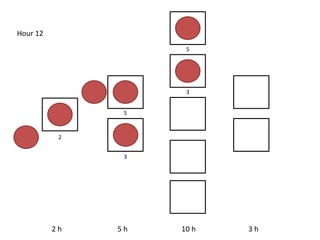

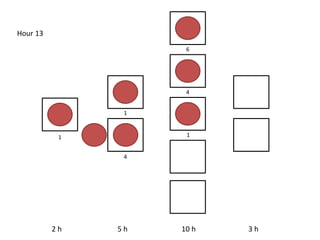

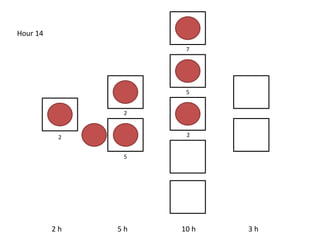

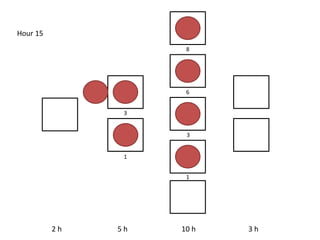

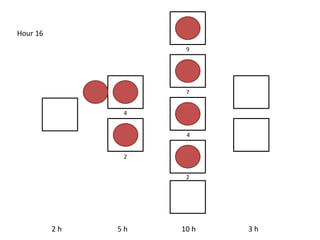

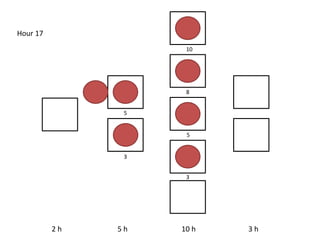

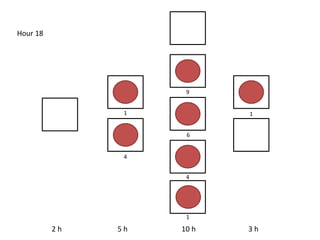

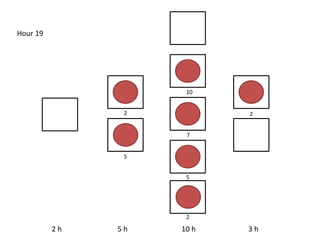

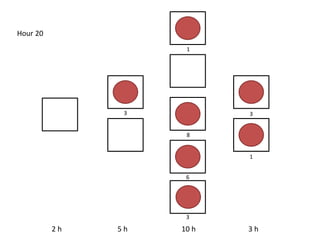

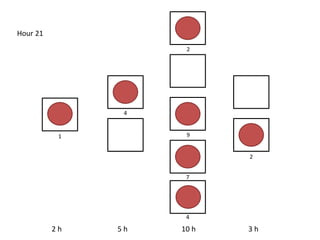

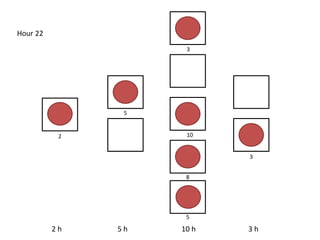

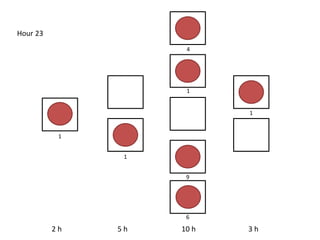

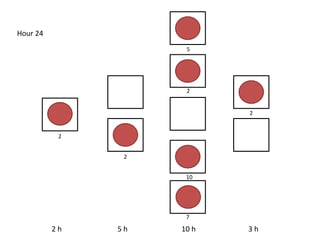

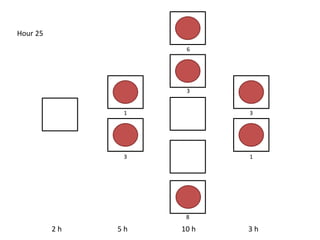

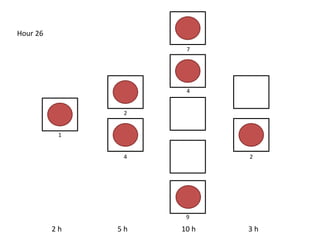

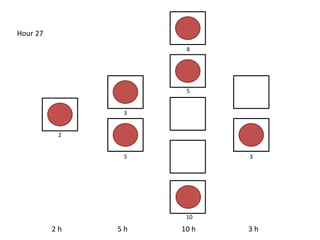

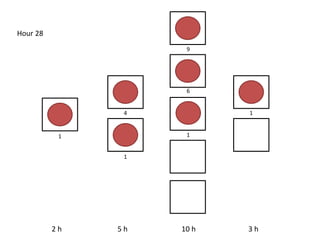

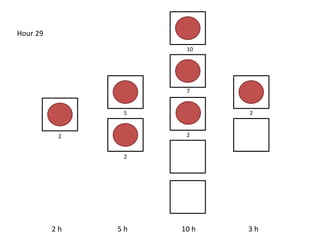

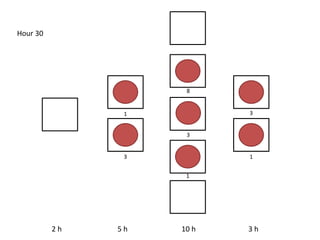

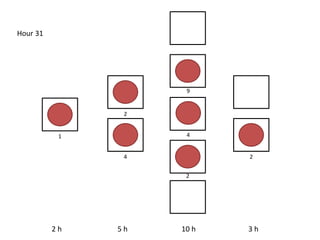

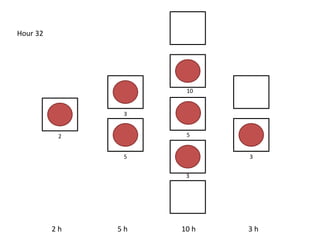

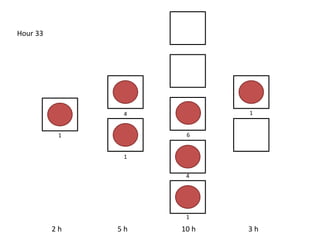

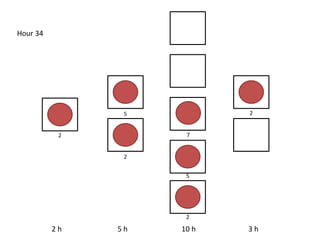

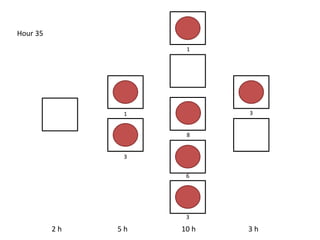

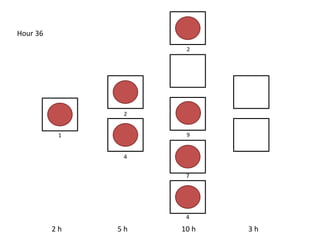

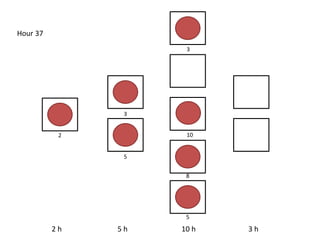

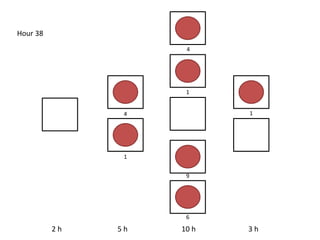

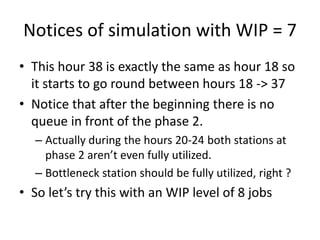

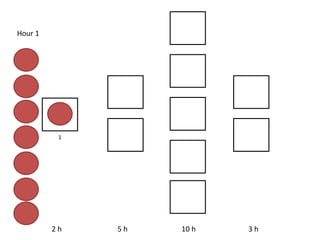

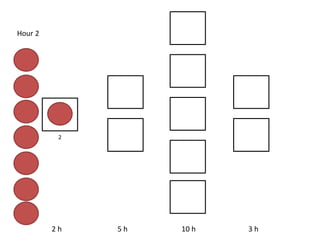

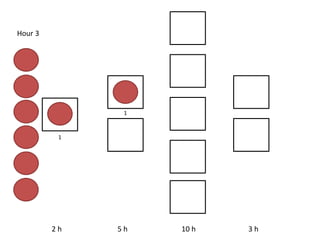

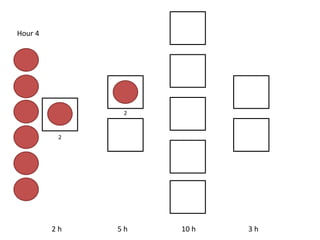

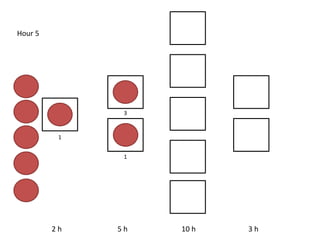

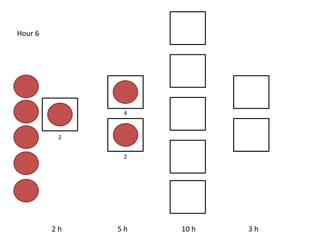

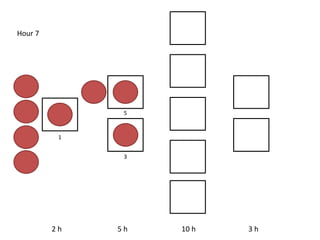

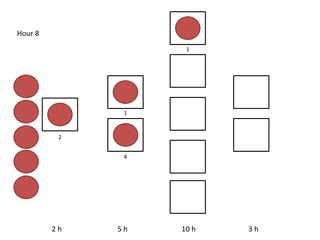

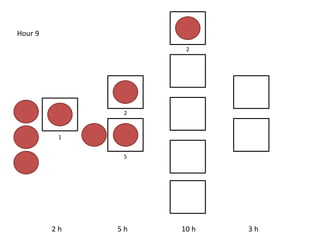

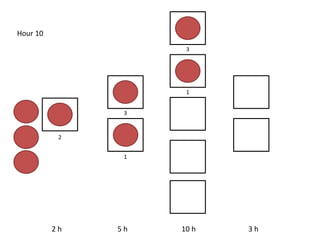

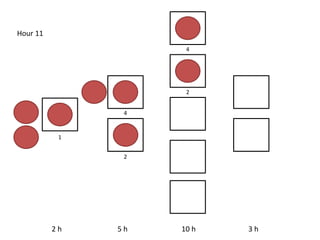

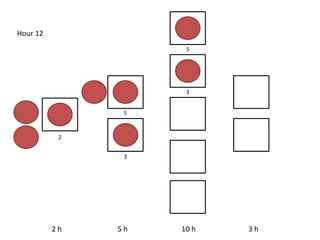

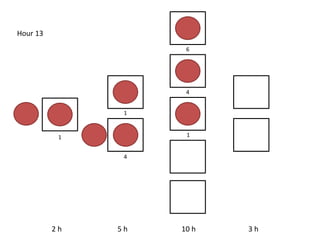

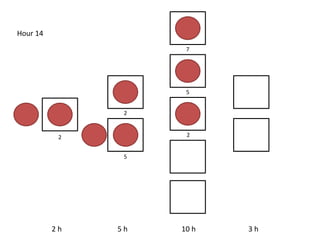

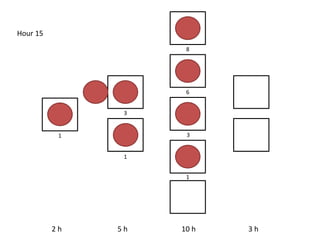

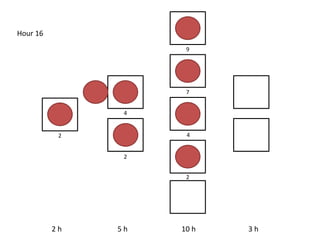

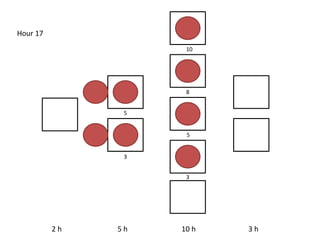

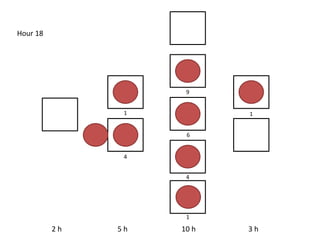

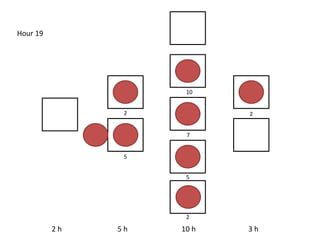

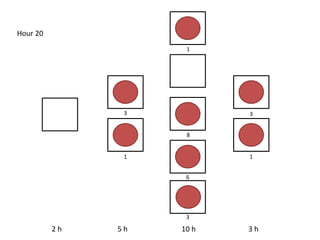

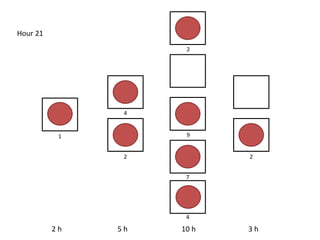

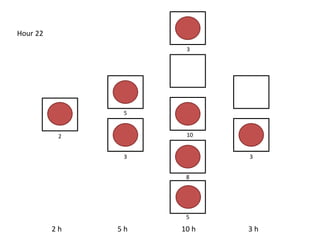

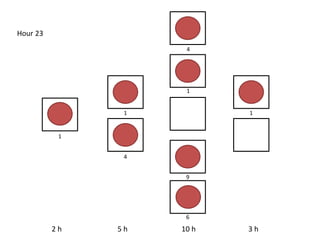

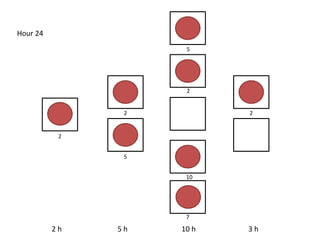

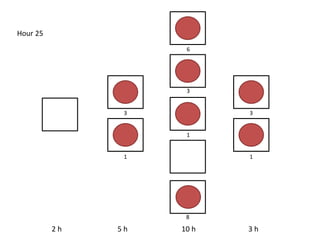

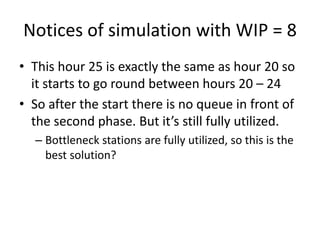

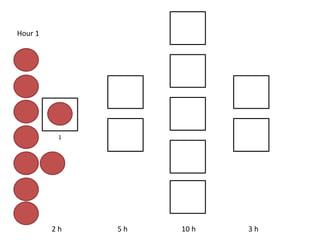

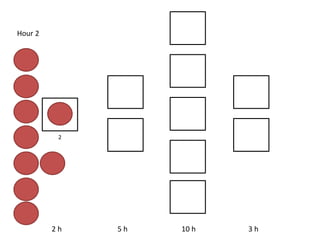

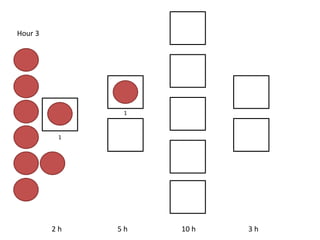

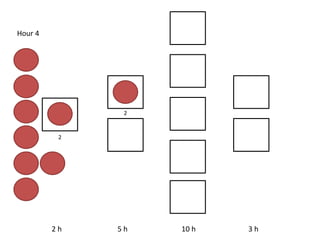

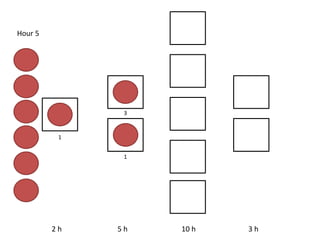

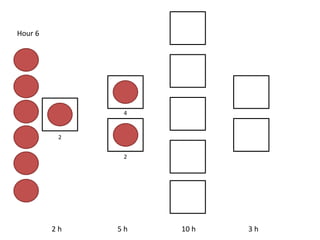

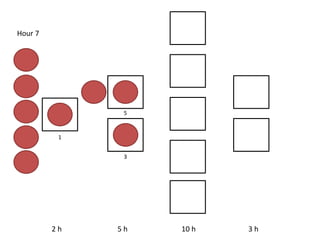

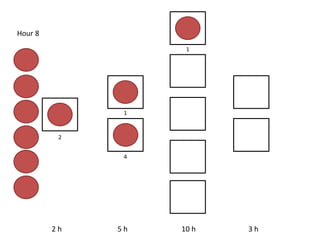

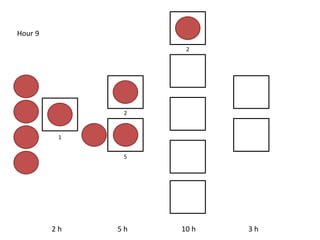

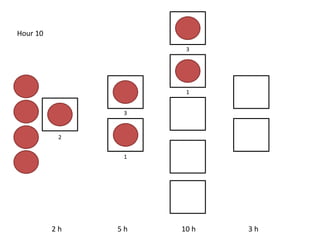

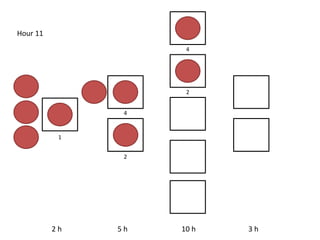

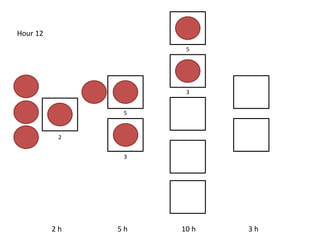

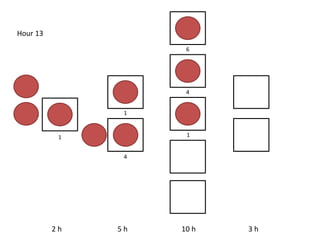

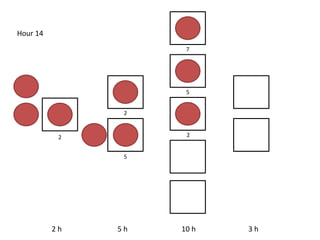

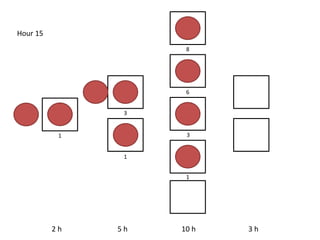

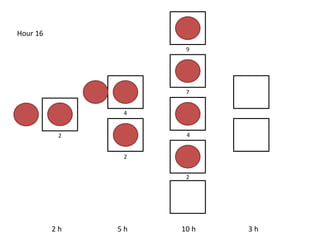

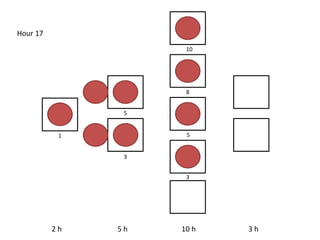

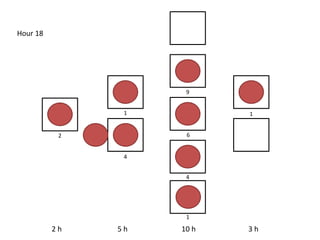

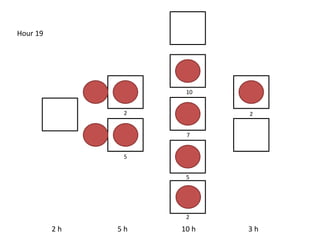

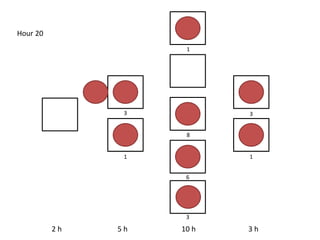

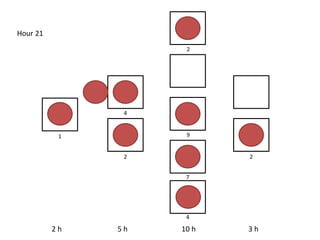

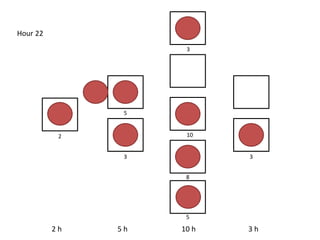

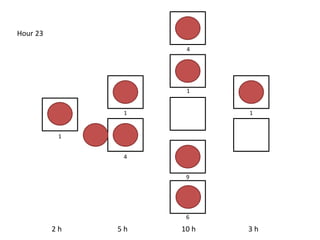

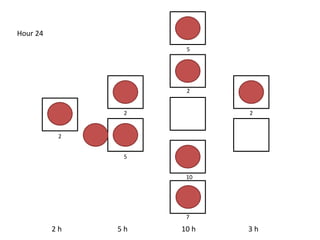

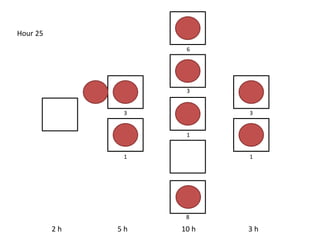

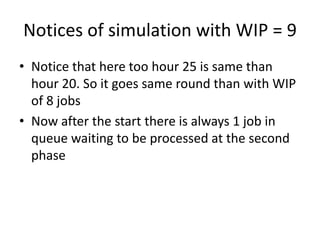

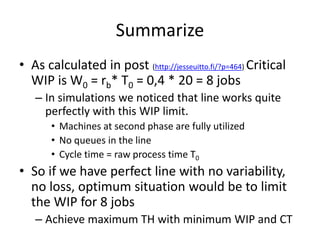

The document outlines a simulation of a production line with varying Work In Progress (WIP) limits of 7, 8, and 9 jobs across three phases, analyzing its impact on job processing and cycle times. It concludes that a WIP limit of 8 jobs allows for full utilization of machines in phase 2 without any queue, achieving optimal performance with a cycle time equal to the raw process time of 20 hours. The findings suggest that for a perfect line with no variability, a WIP limit of 8 jobs maximizes throughput while minimizing WIP and cycle time.