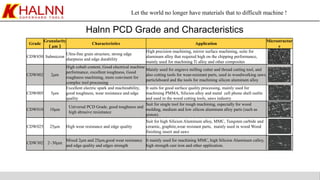

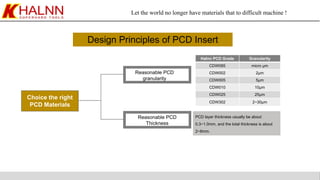

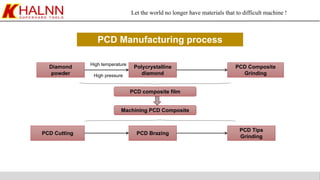

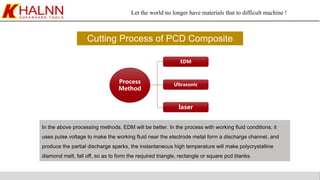

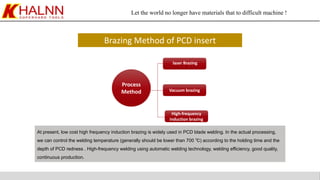

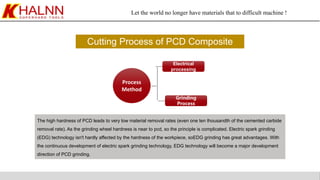

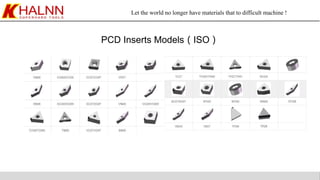

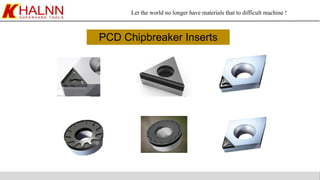

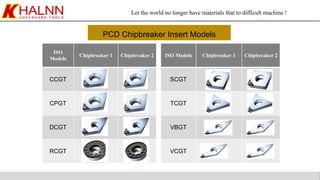

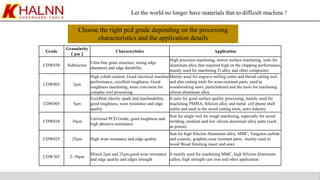

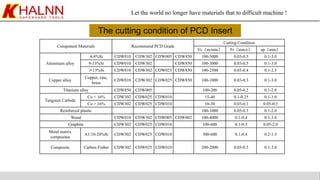

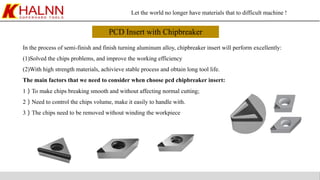

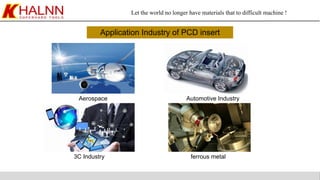

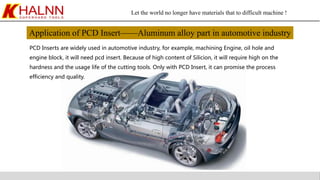

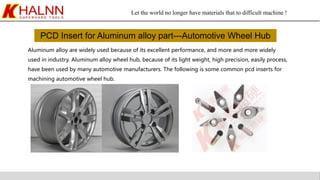

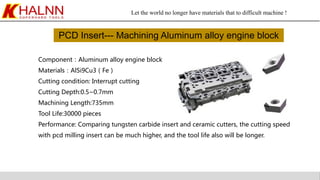

The document provides an overview of polycrystalline diamond (PCD) inserts, detailing their material properties, production processes, and various applications in machining. It emphasizes the advantages of using PCD inserts for difficult-to-machine materials, highlighting specific grades, characteristics, and the respective industries served, such as automotive and aerospace. Additionally, it discusses optimal cutting conditions, techniques for insert selection, and manufacturing methods to improve machining efficiency.