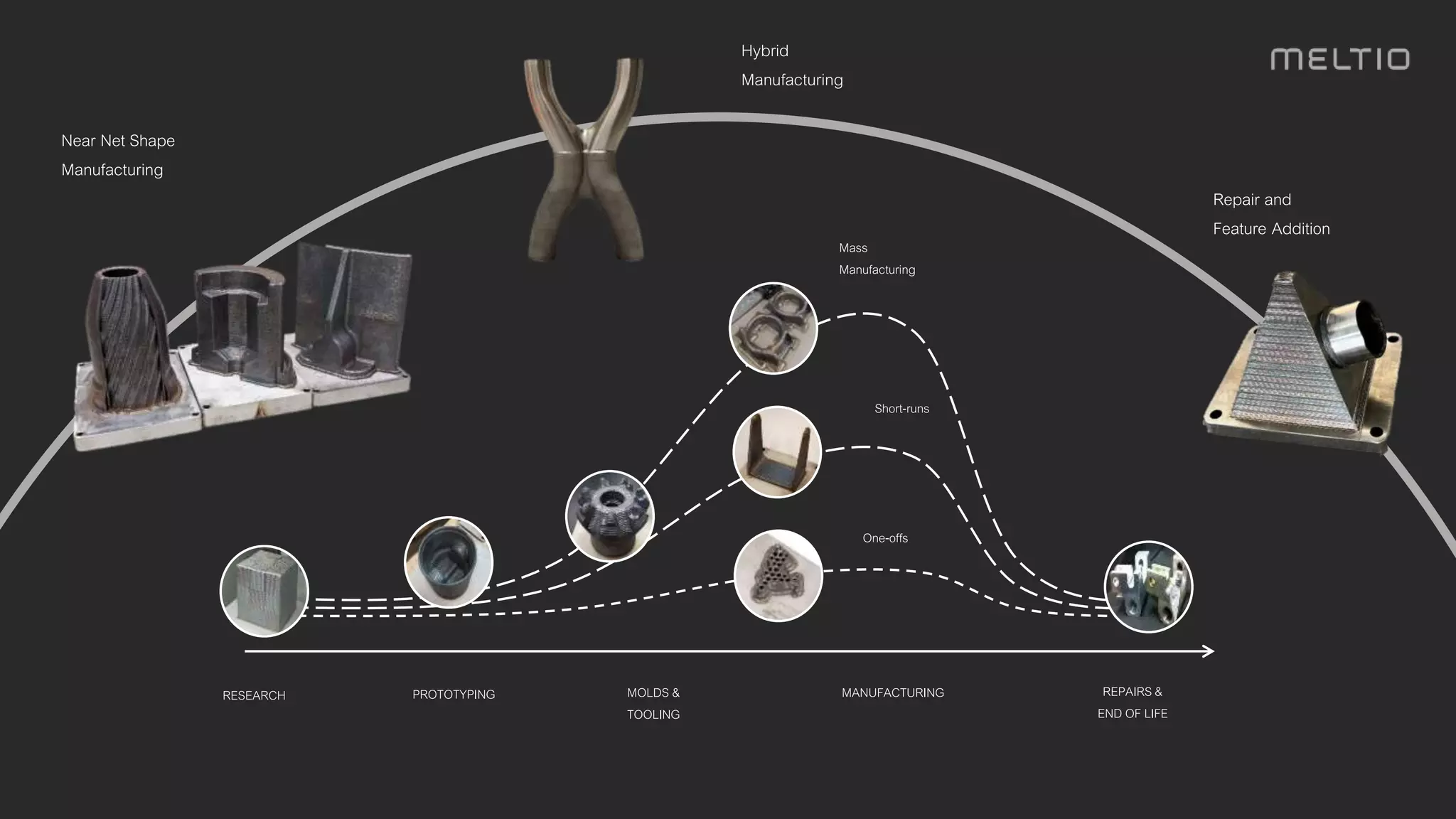

This document summarizes information presented by Brian Matthews, CTO of Meltio, about the company's multi-metal additive manufacturing technology. Some key points:

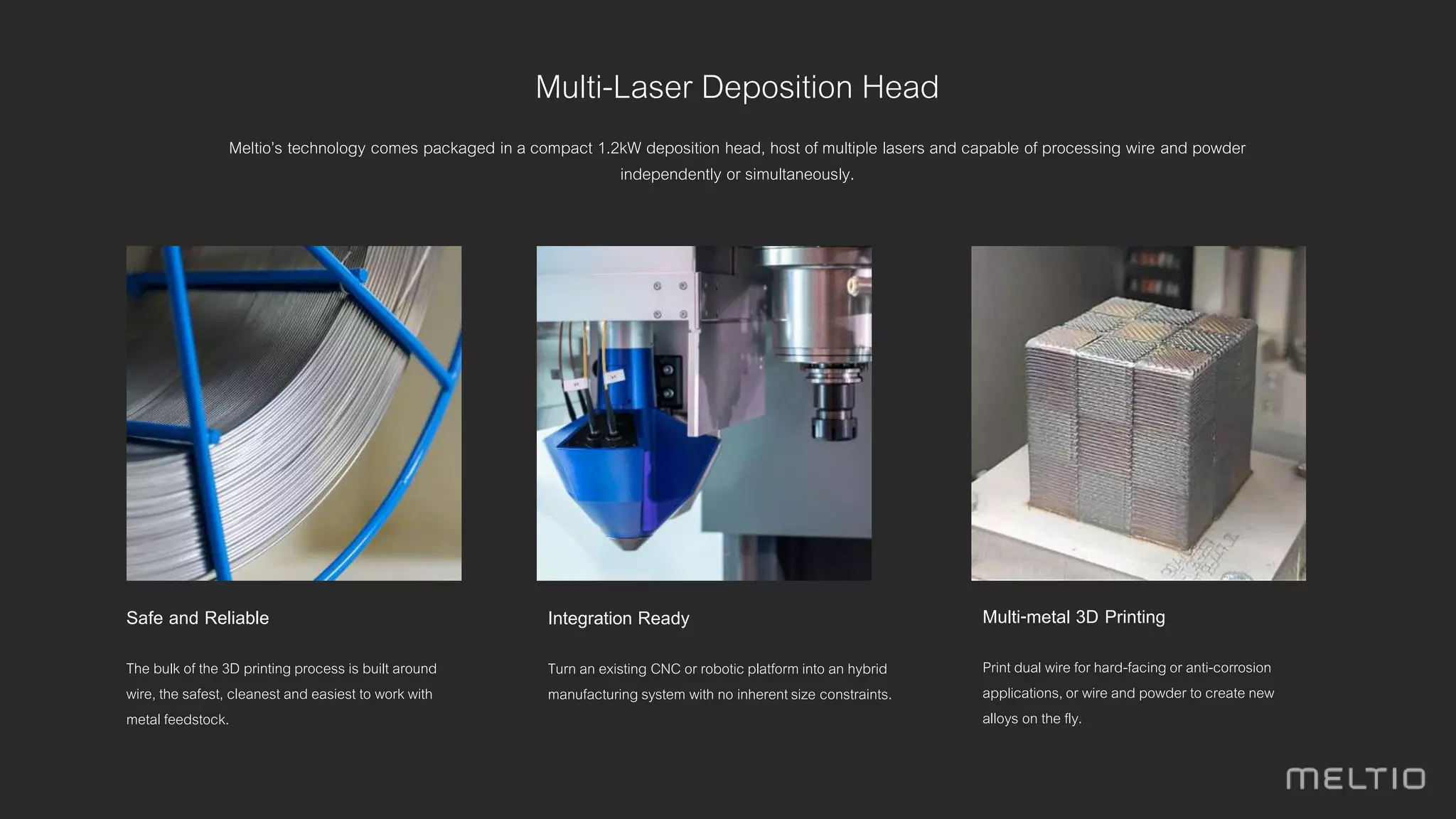

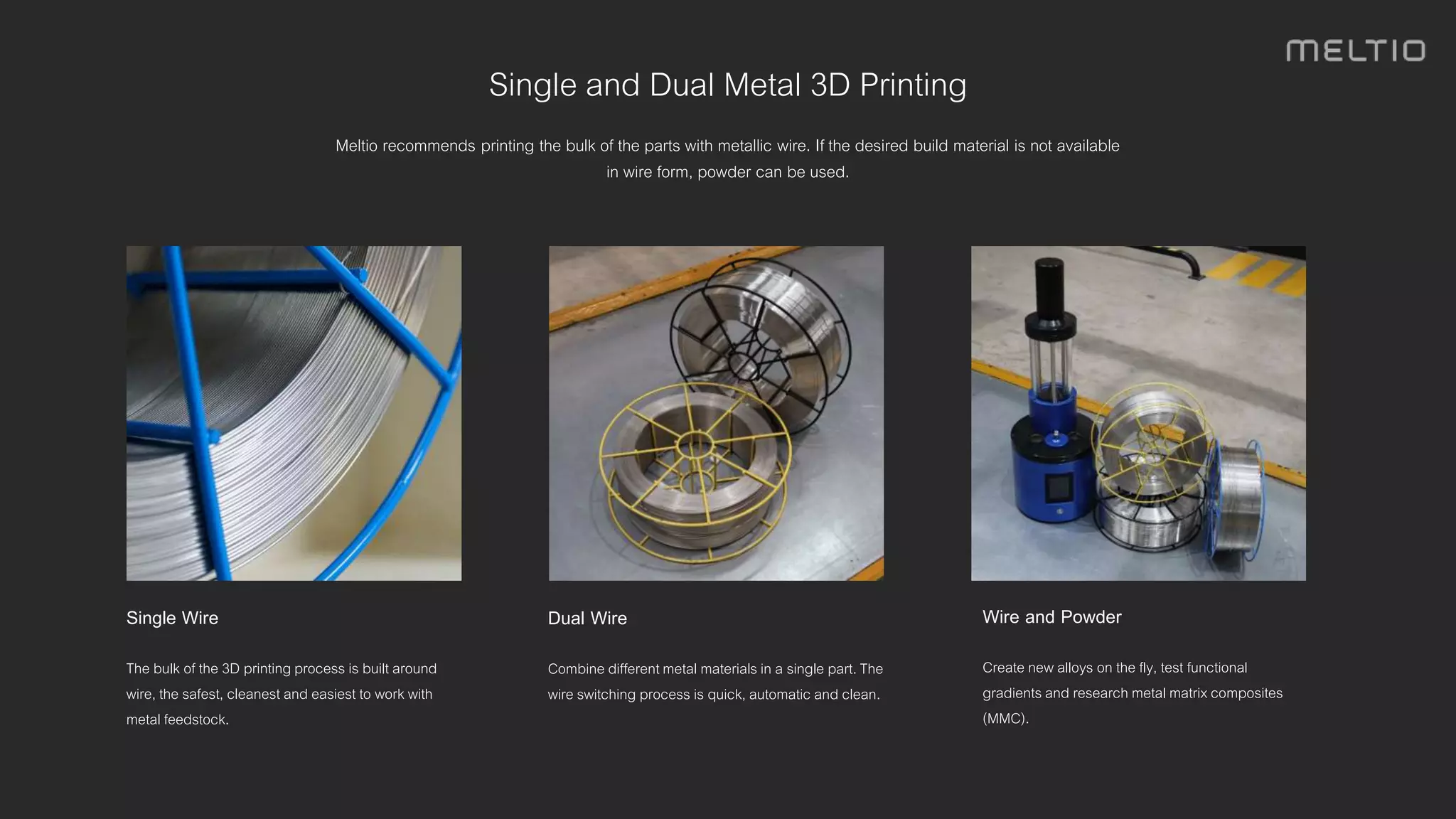

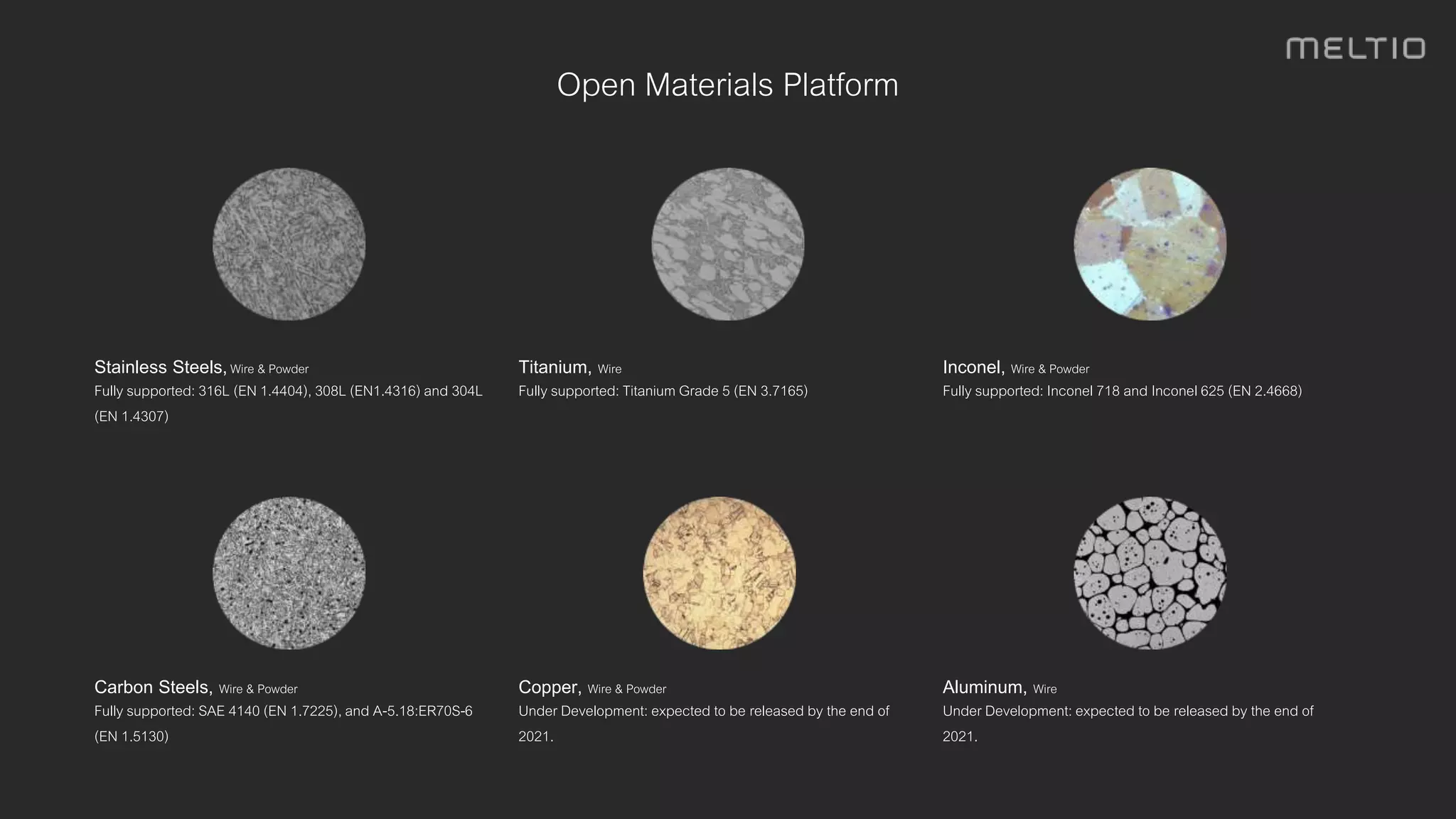

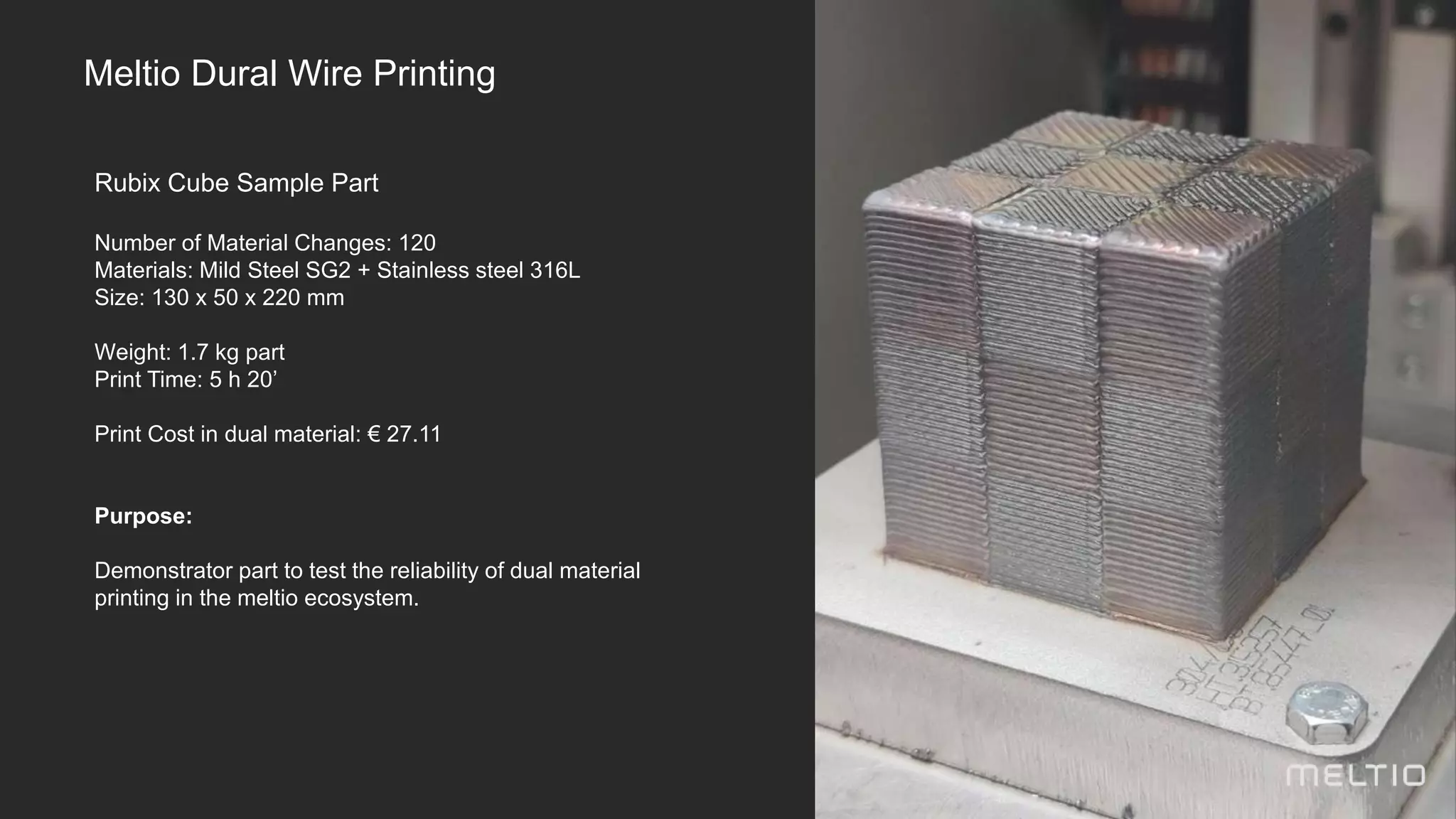

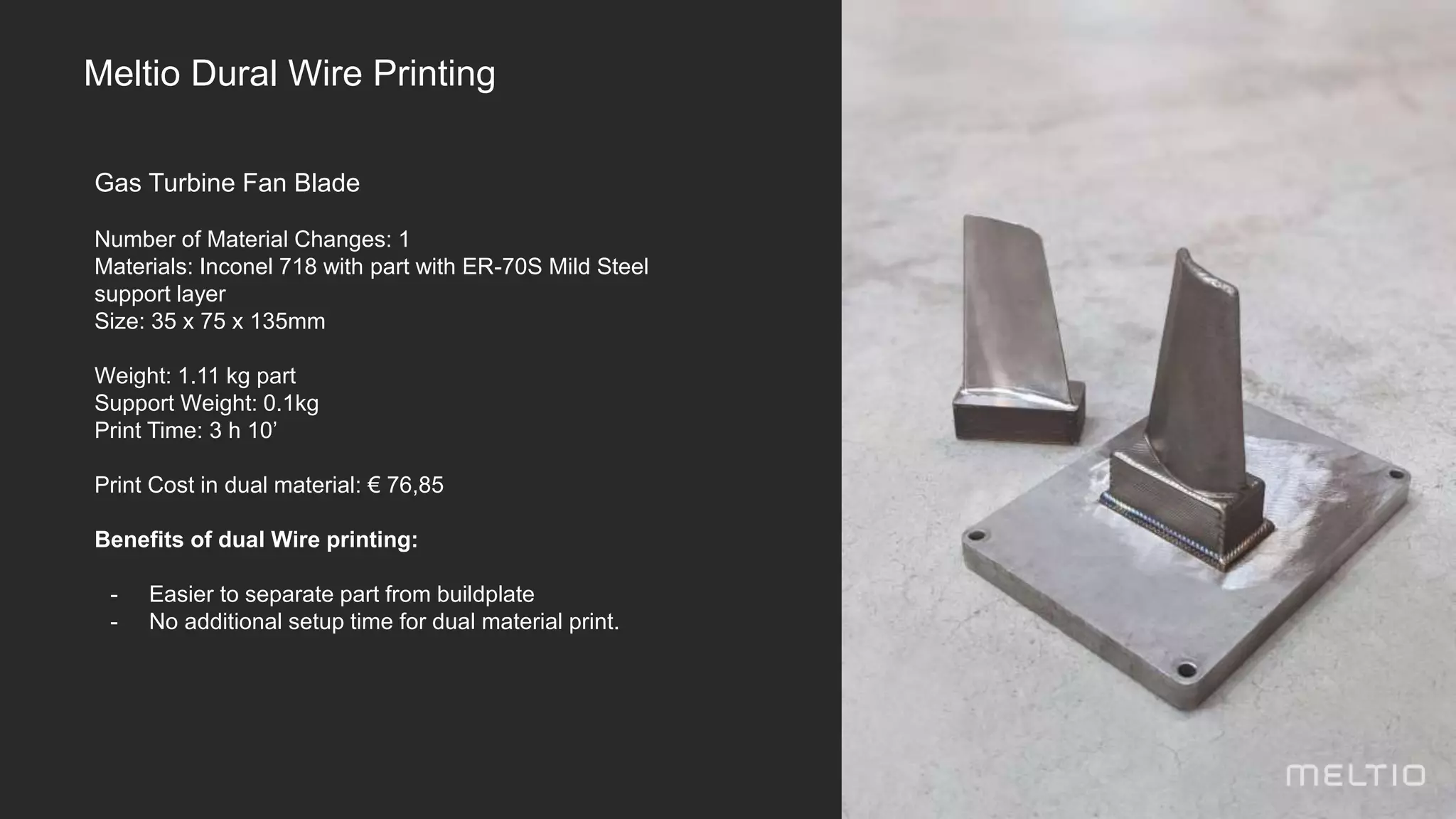

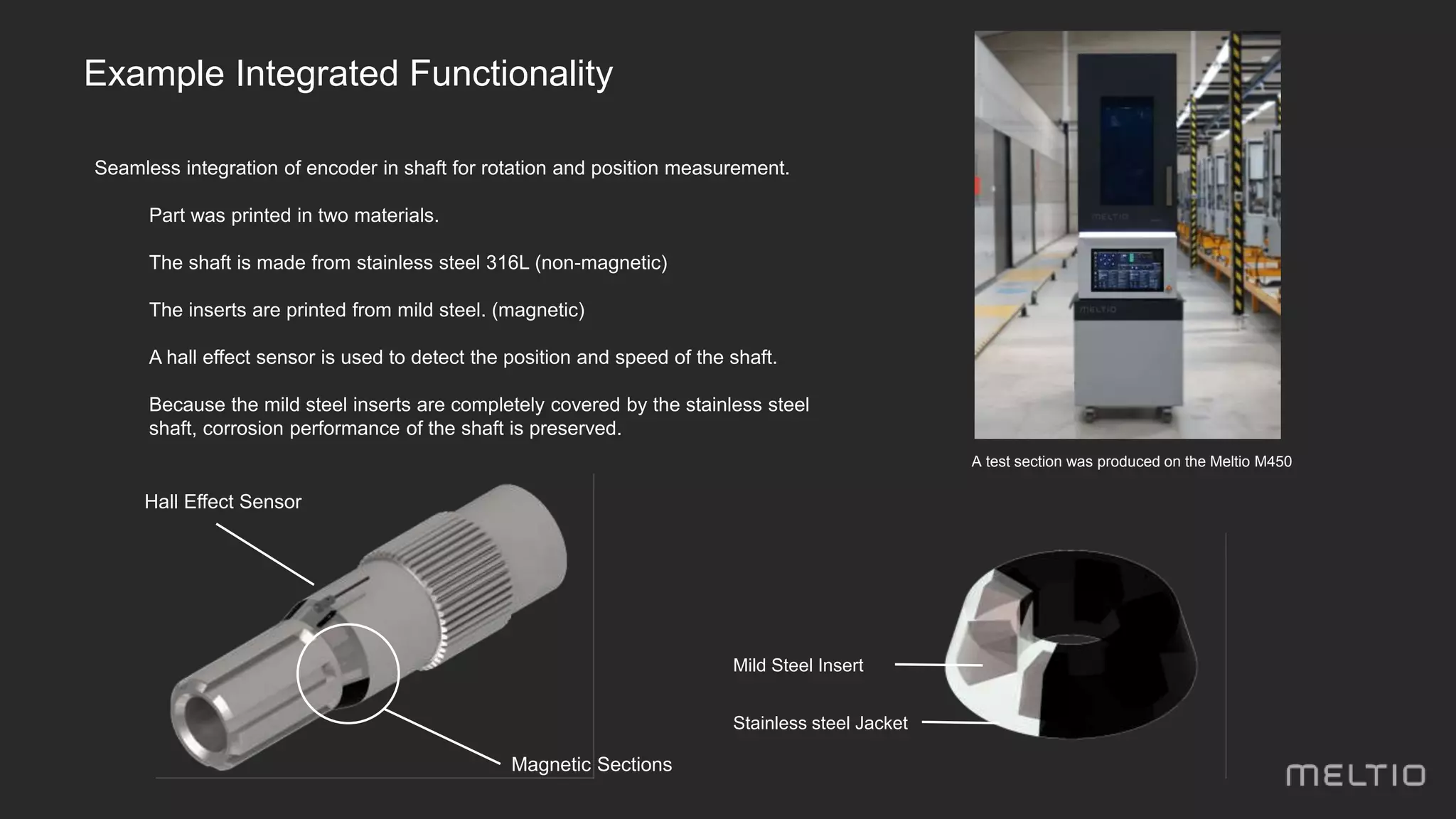

- Meltio has developed a multi-laser deposition head that can process wire and powder simultaneously or independently, allowing for multi-metal 3D printing.

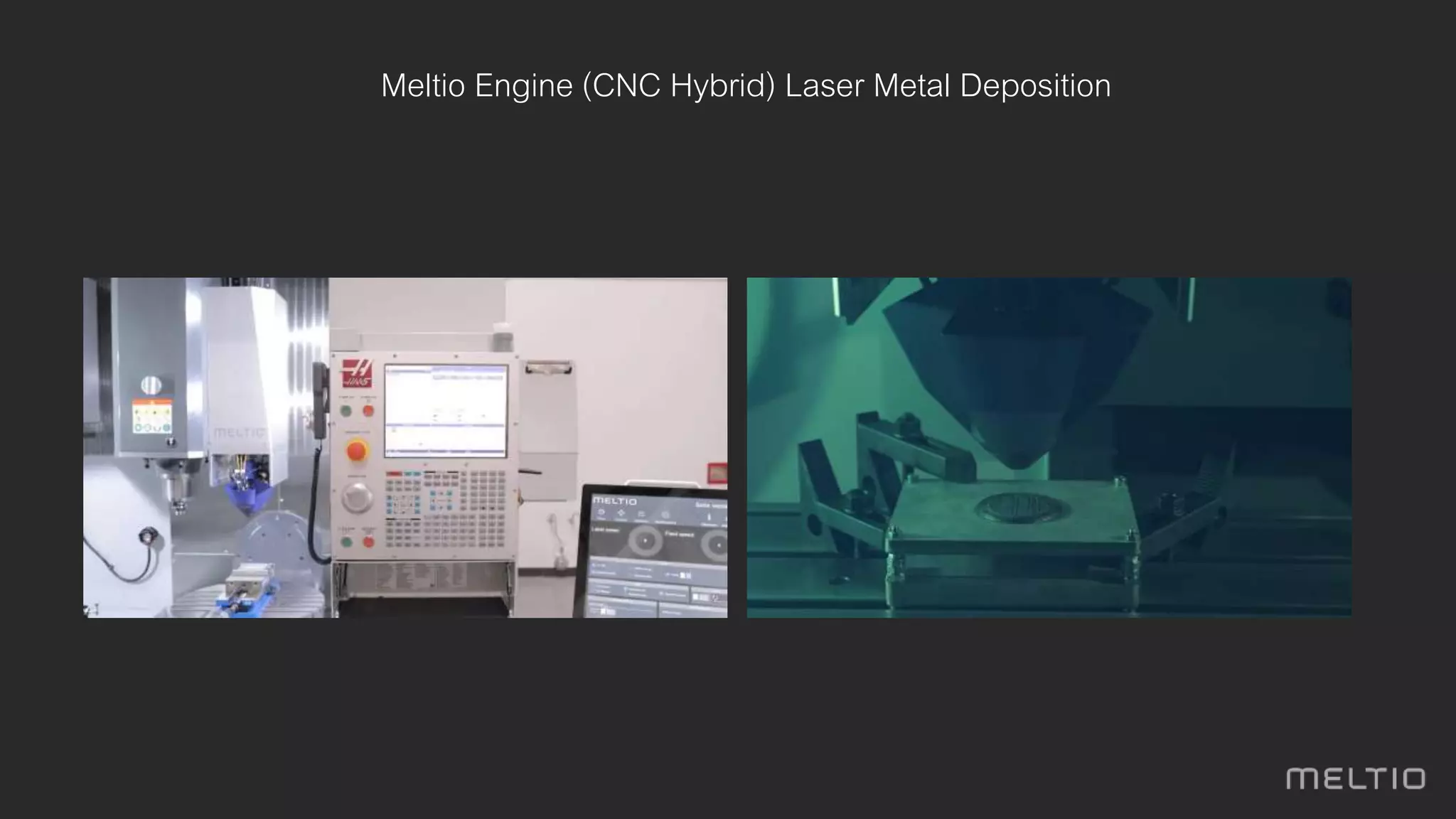

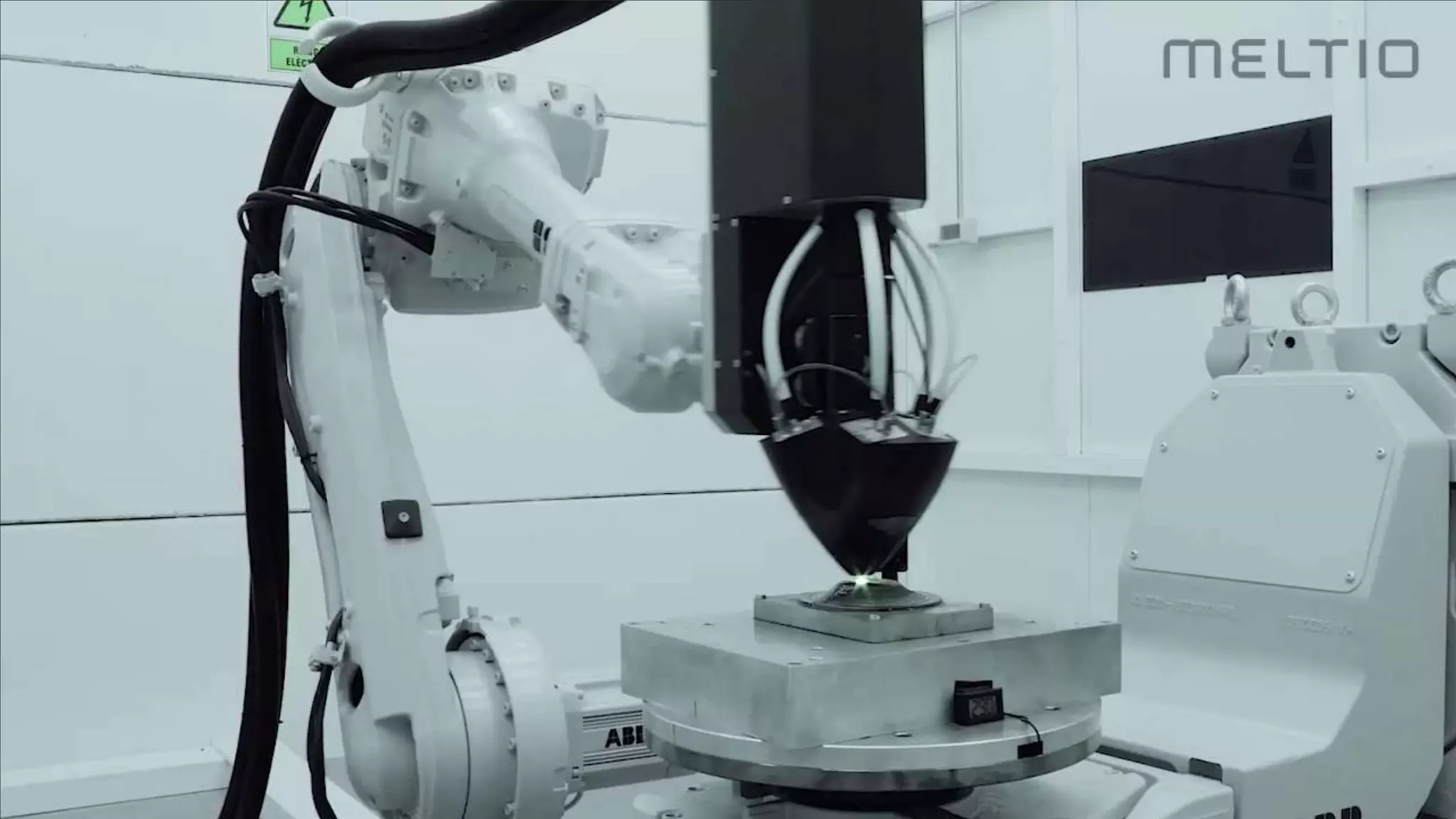

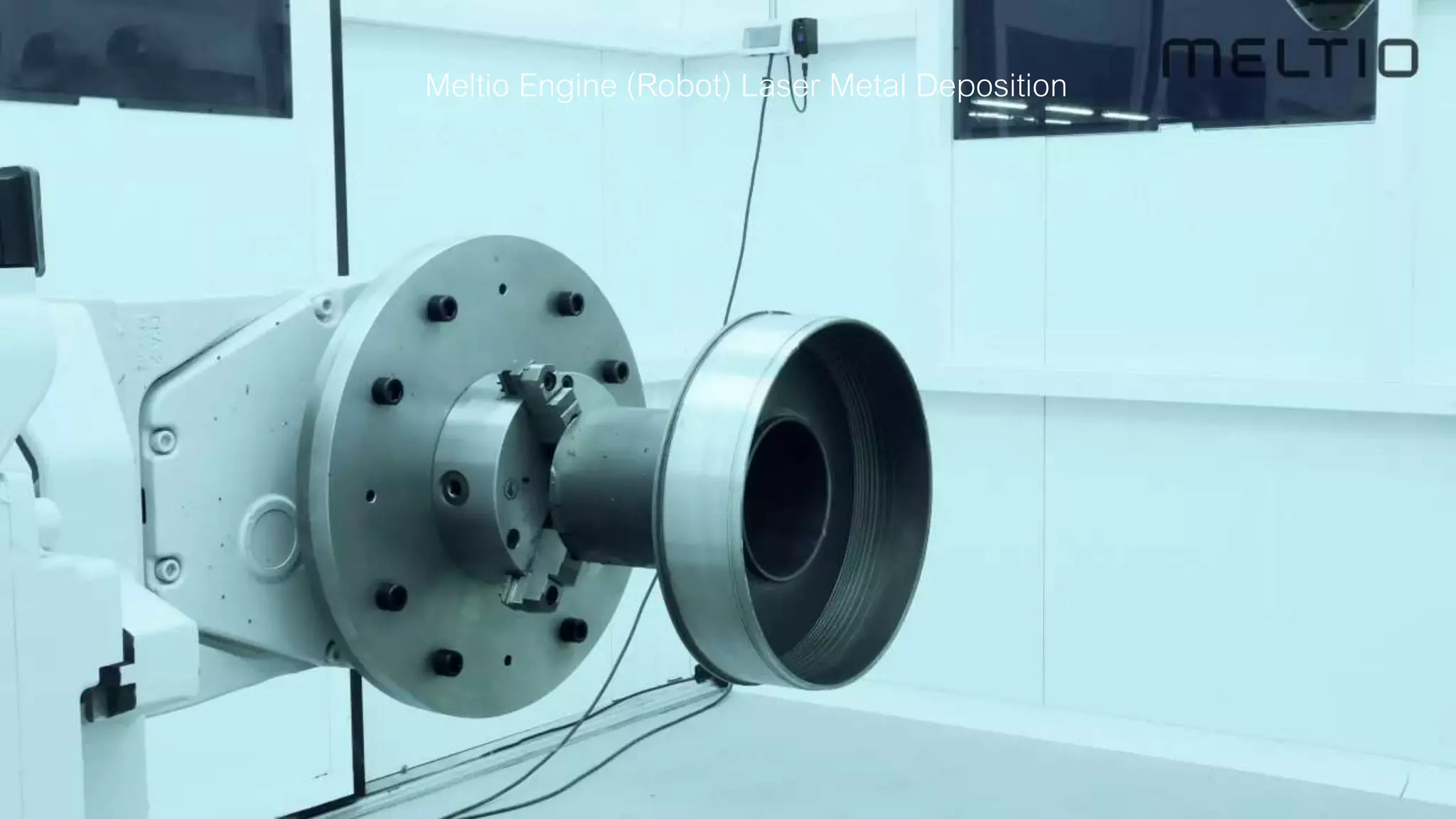

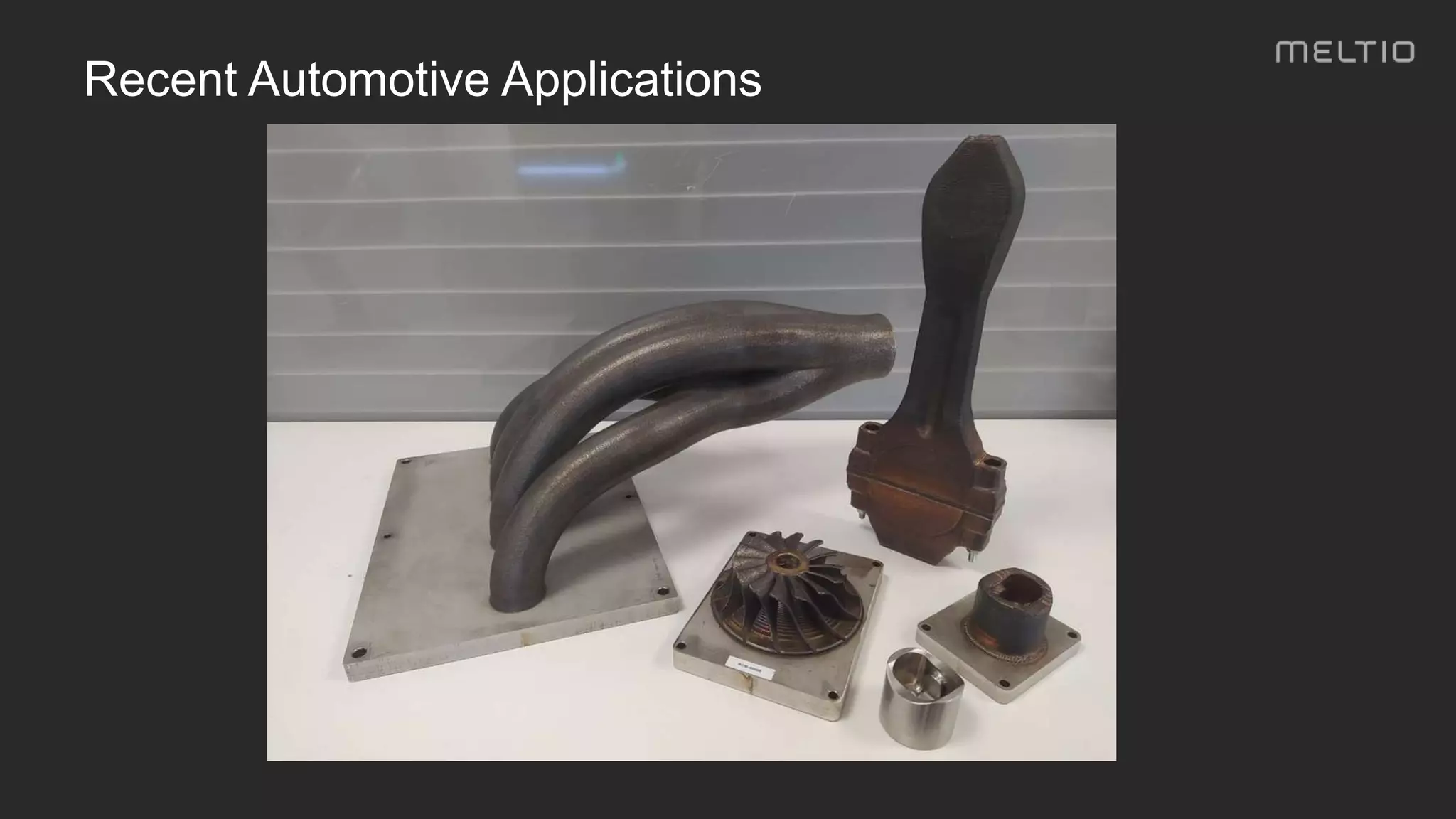

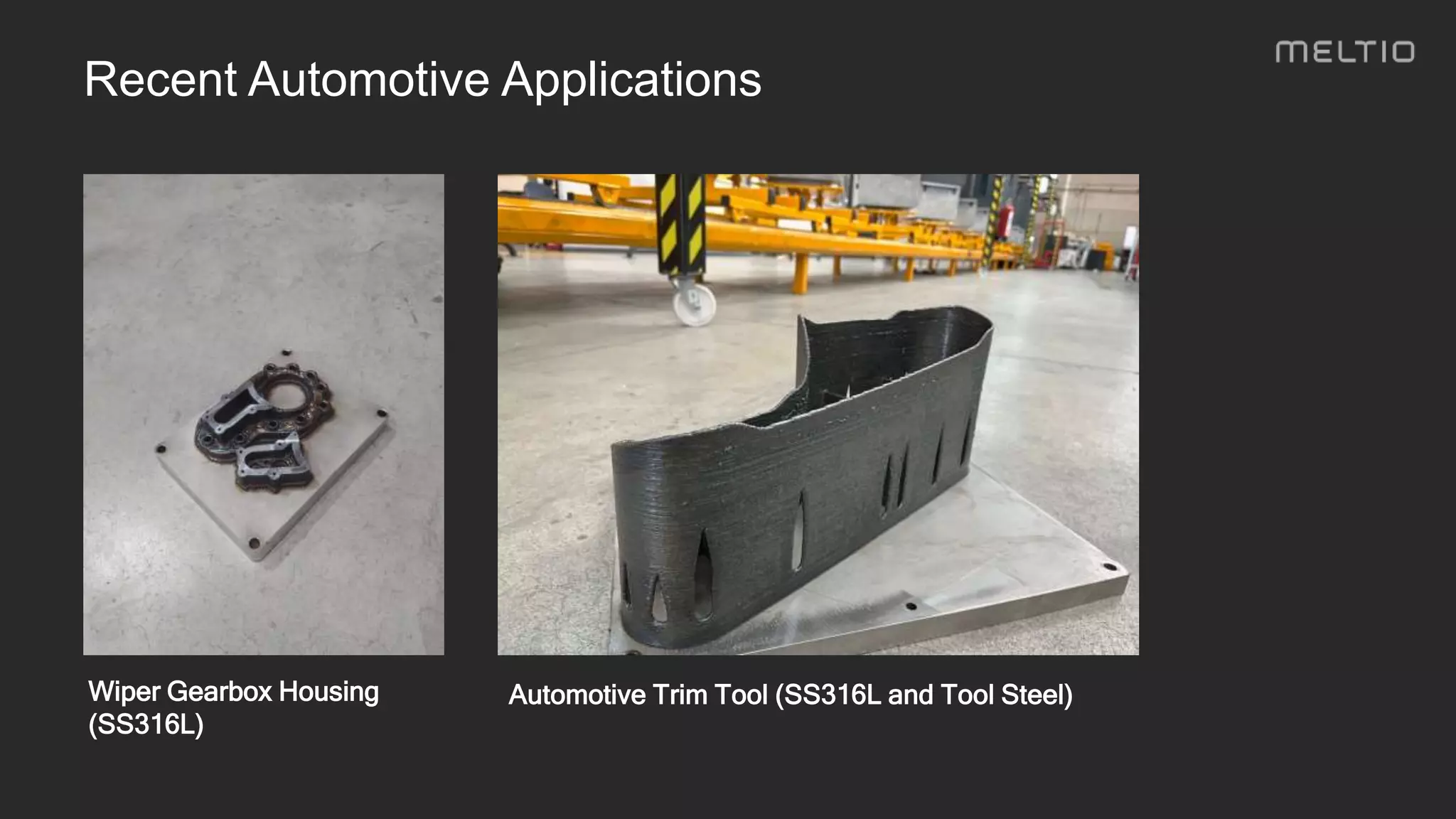

- Their technology integrates easily with existing CNC or robotic platforms and allows for printing of parts with different metals or creating new alloys on the fly.

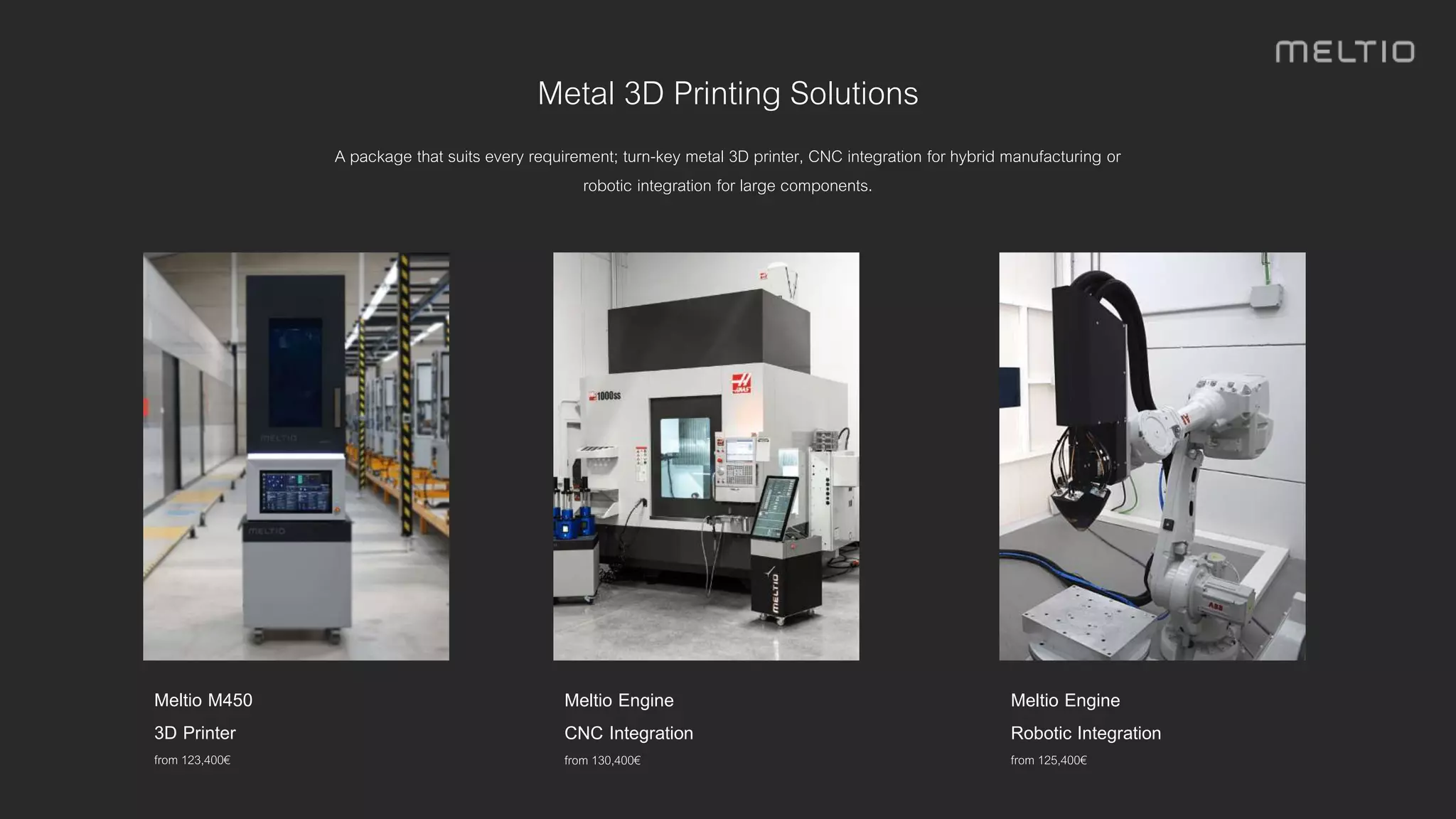

- They offer metal 3D printing solutions in the form of turnkey printers, CNC integrations, and robotic integrations to suit different requirements.

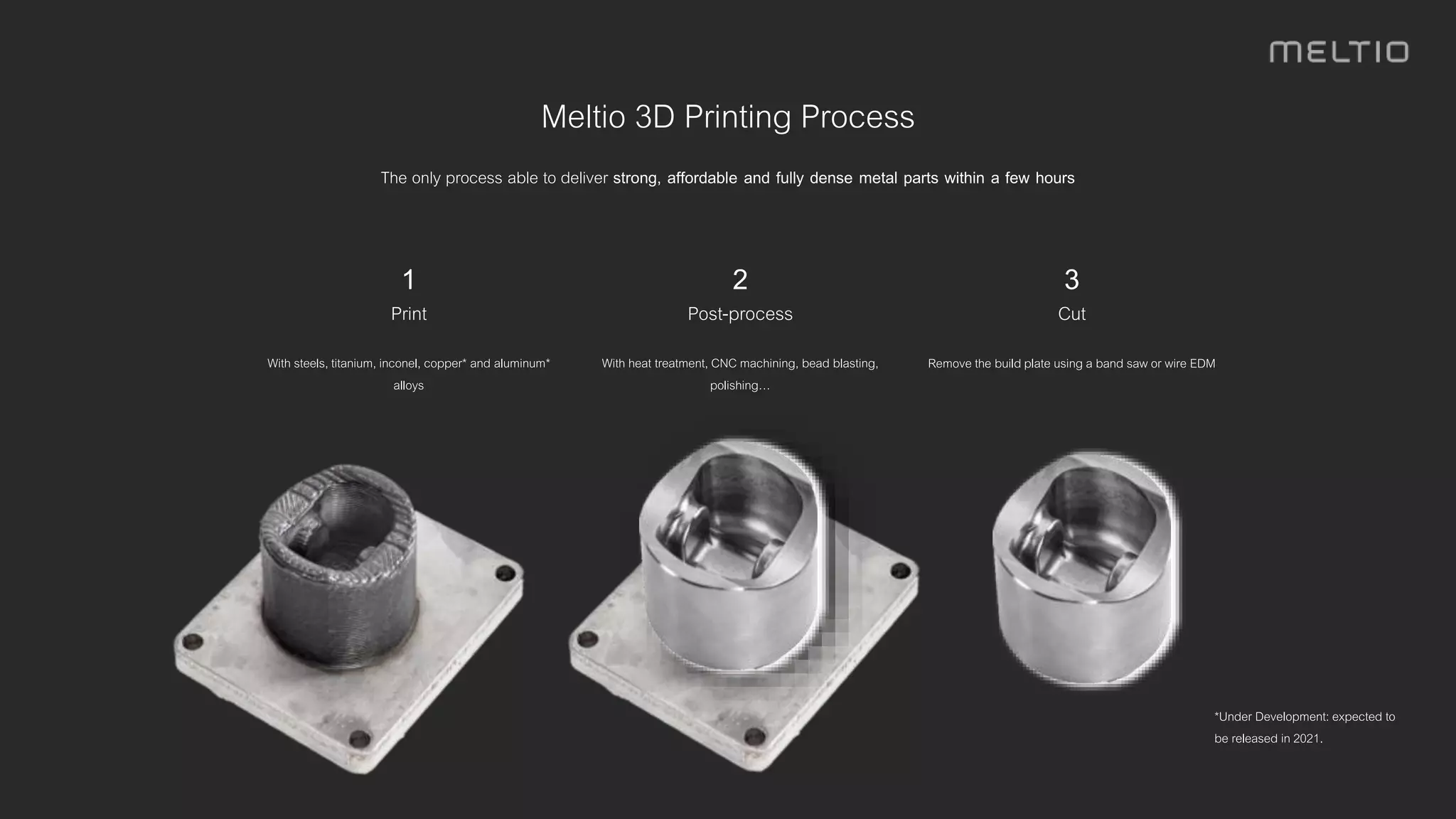

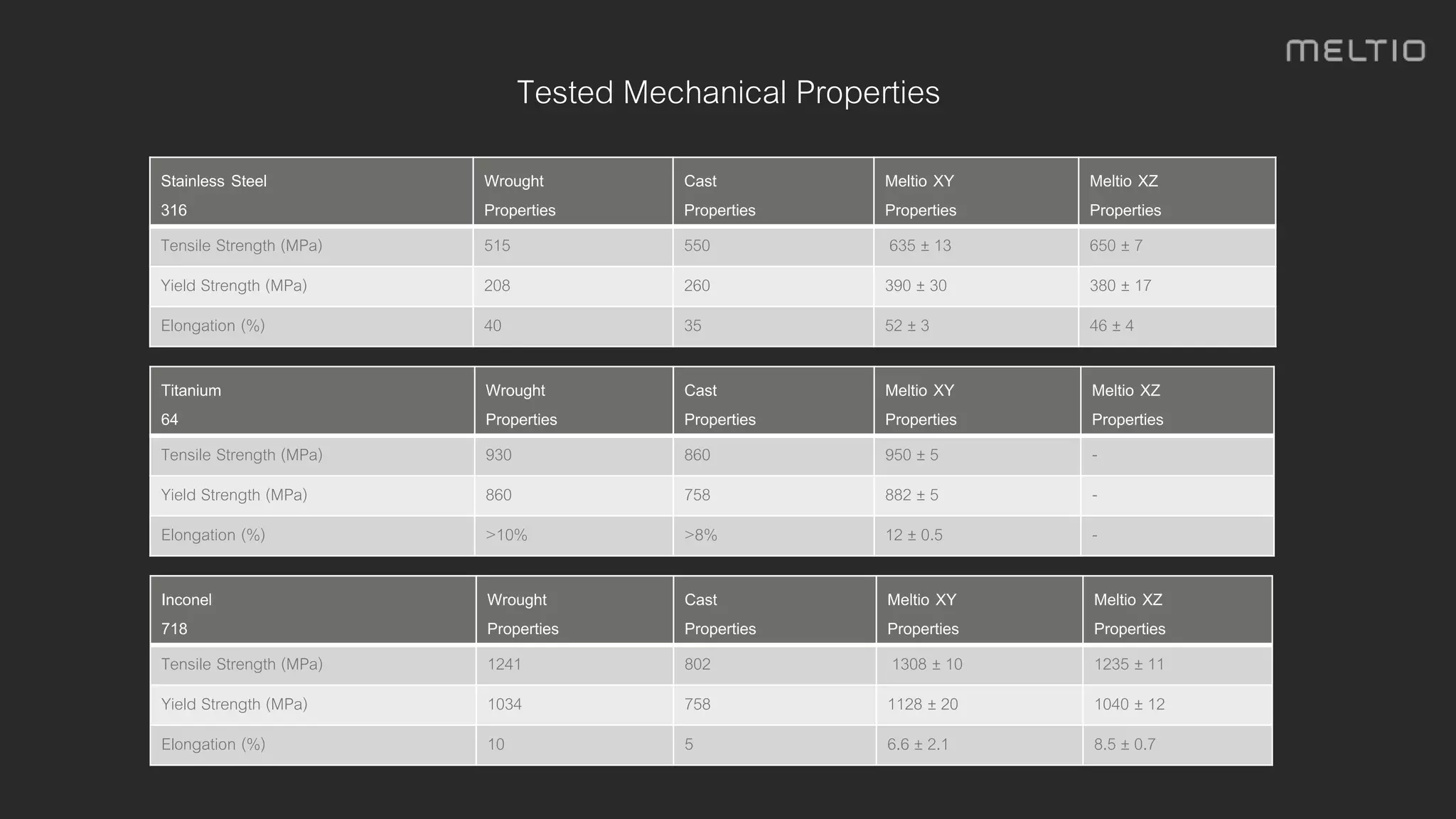

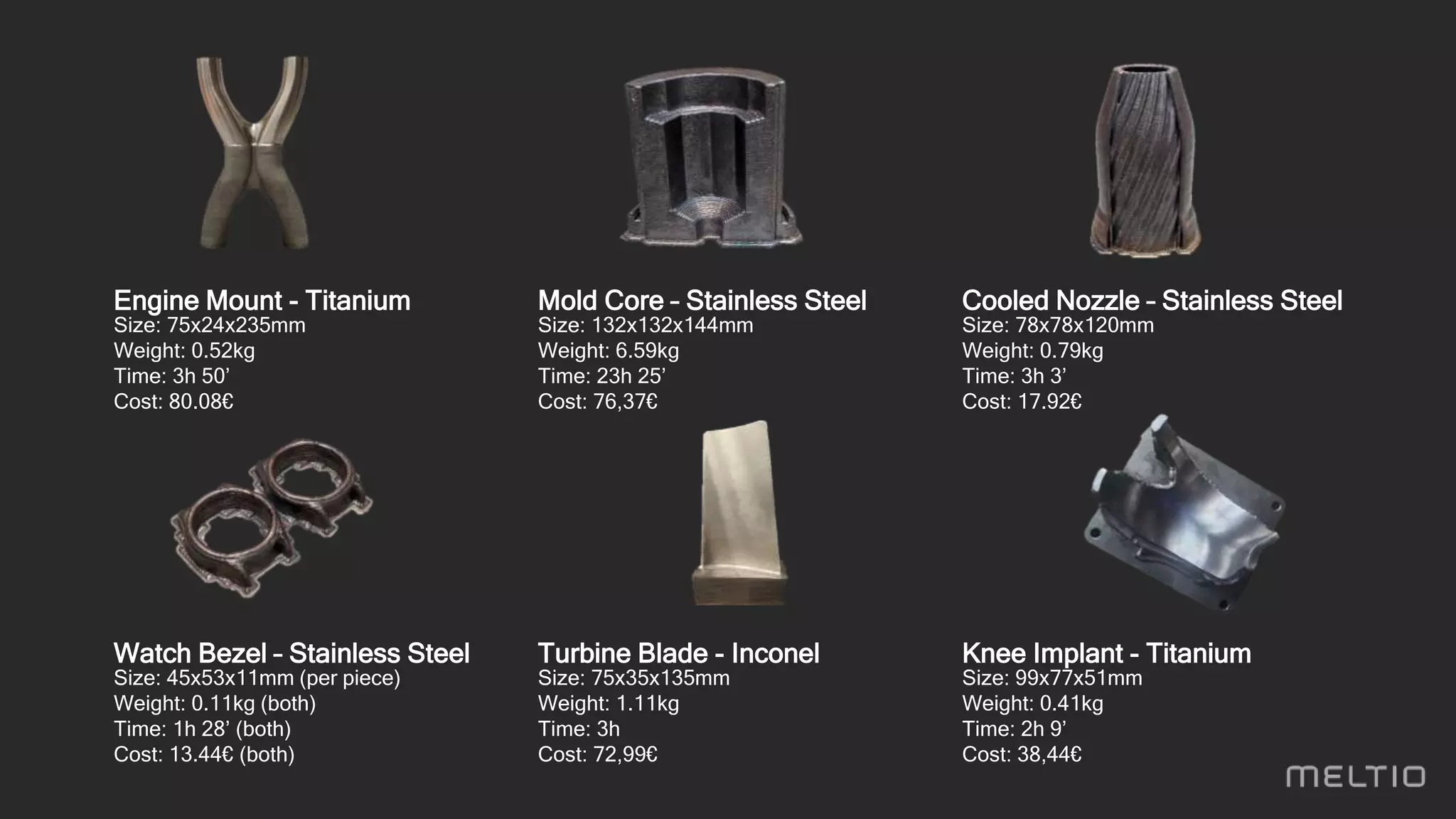

- Meltio's process can deliver strong, affordable, and fully