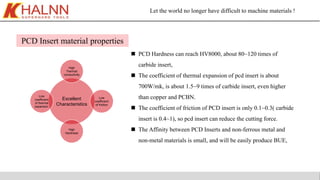

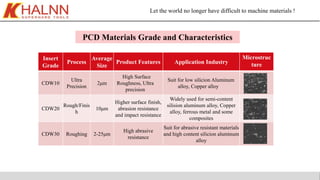

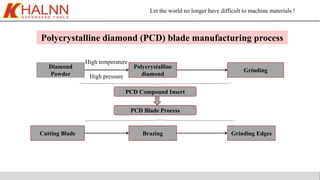

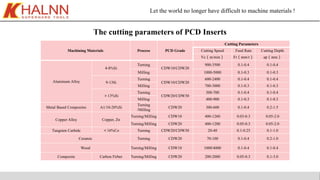

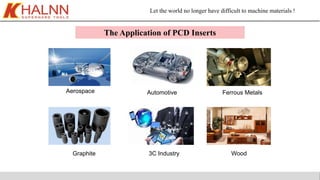

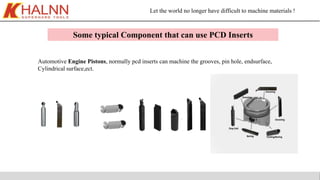

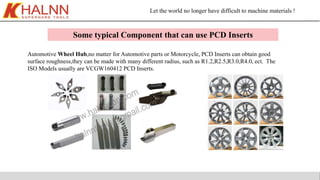

The document discusses the properties and benefits of polycrystalline diamond (PCD) inserts, emphasizing their high hardness, low coefficient of friction, and excellent thermal conductivity which make them suitable for machining difficult materials. It highlights various grades and applications of PCD inserts in industries such as automotive and aerospace, along with their machining parameters for different materials. The document concludes by presenting case studies that demonstrate the efficiency and longevity of PCD tools in machining aluminum alloy components.