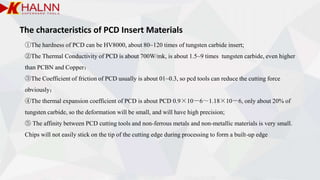

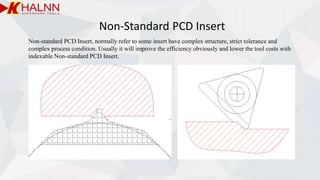

The document provides a comprehensive overview of polycrystalline diamond (PCD) tools, detailing their composition, characteristics, and applications across various industries. PCD tools exhibit superior hardness, thermal conductivity, and resistance to wear compared to traditional tungsten carbide tools, making them ideal for machining non-ferrous and non-metallic materials. Specific applications discussed include aluminum alloy components in the automotive industry, along with various types of PCD inserts, end mills, and drill bits suited for different machining processes.