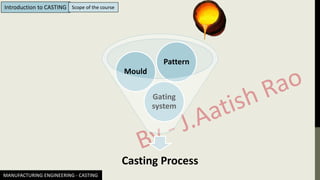

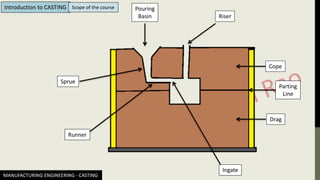

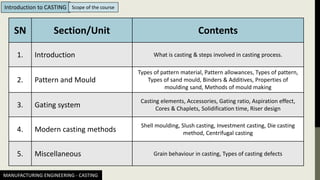

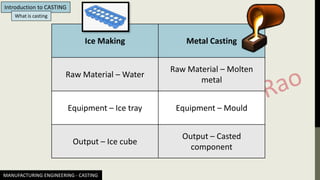

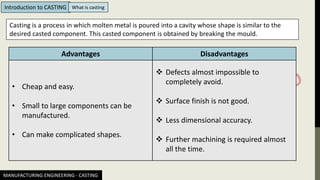

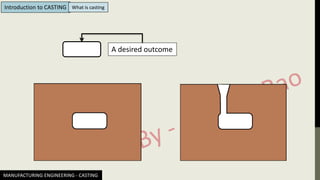

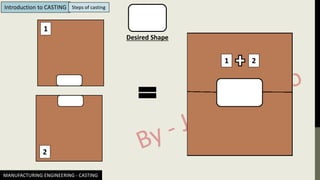

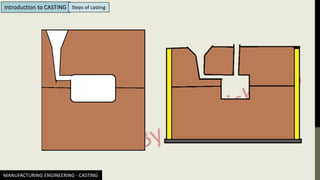

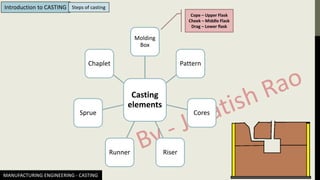

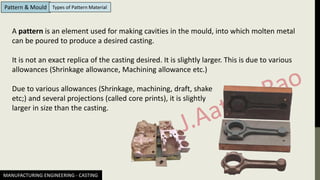

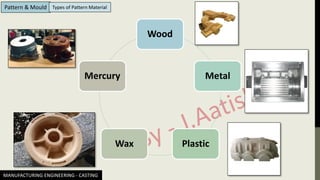

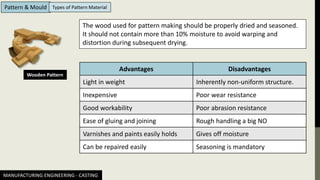

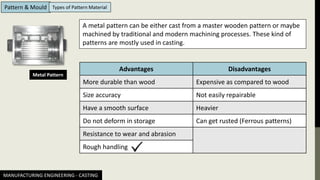

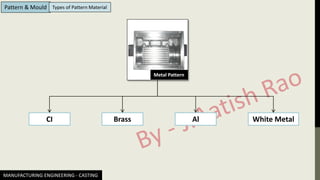

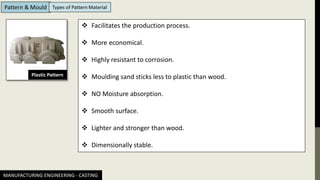

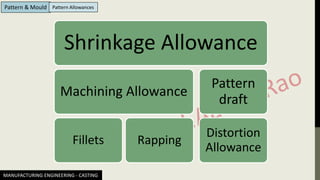

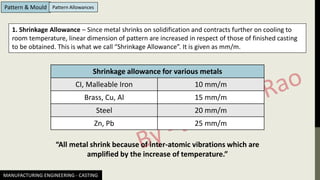

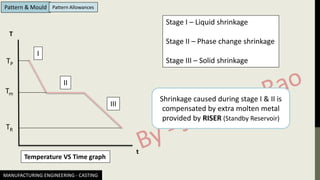

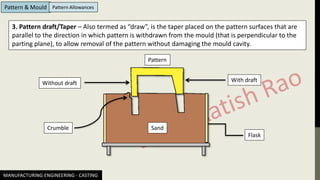

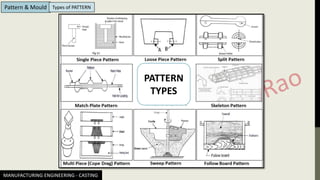

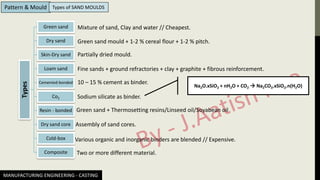

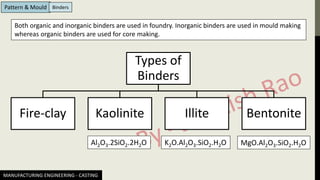

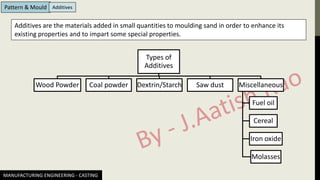

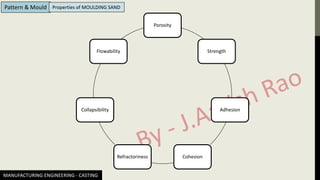

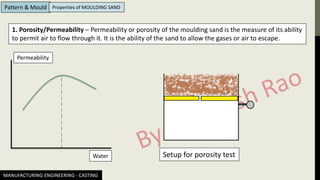

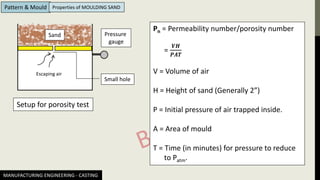

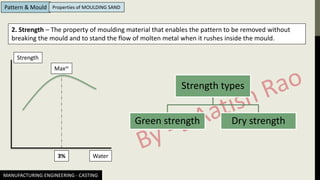

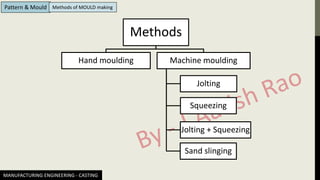

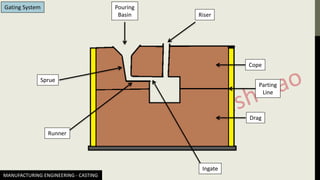

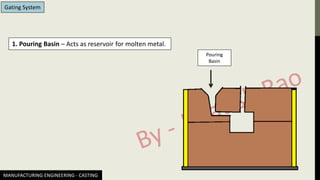

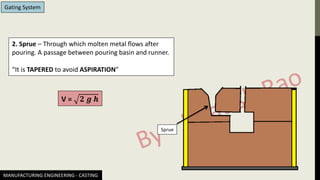

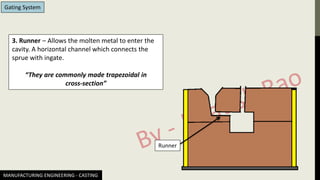

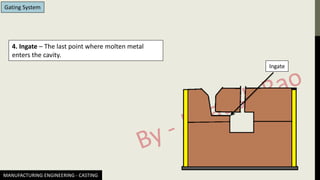

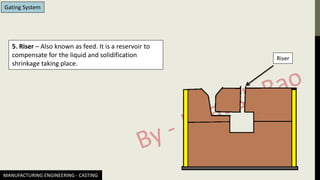

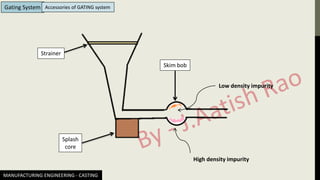

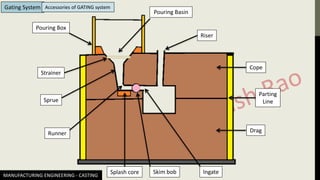

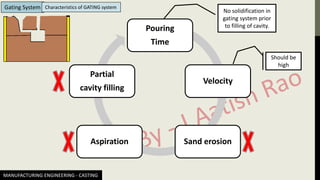

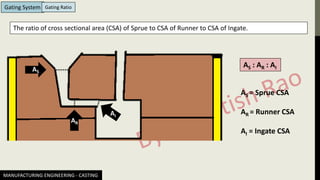

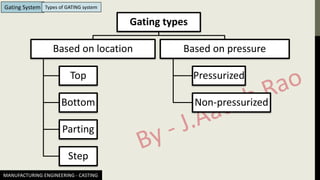

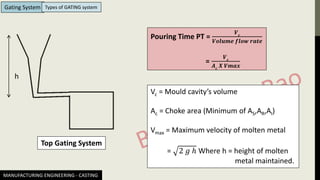

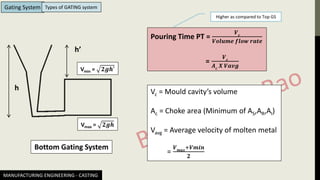

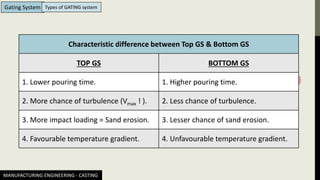

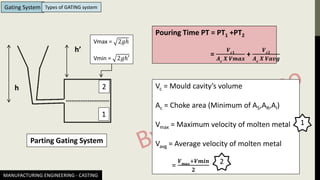

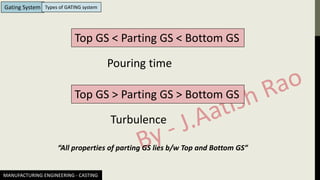

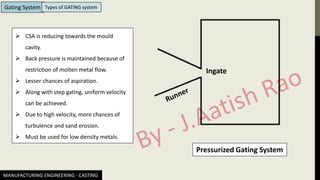

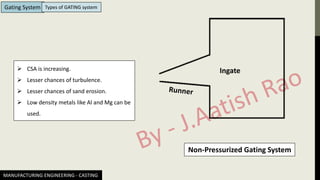

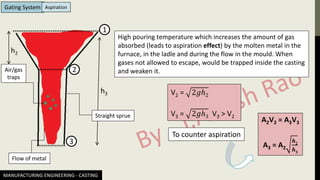

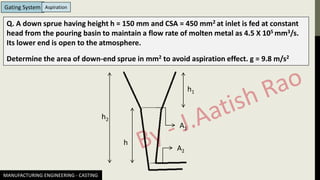

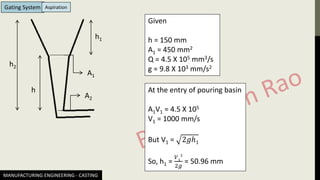

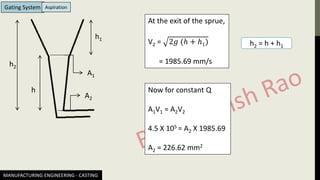

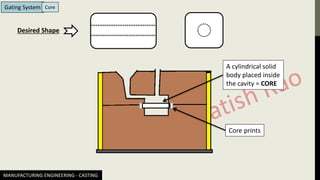

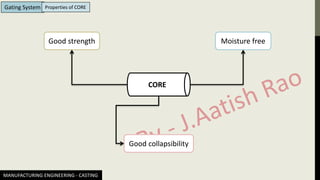

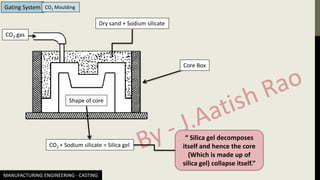

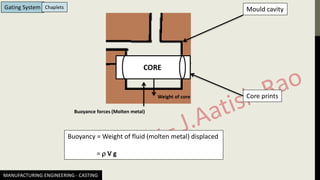

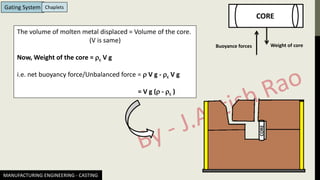

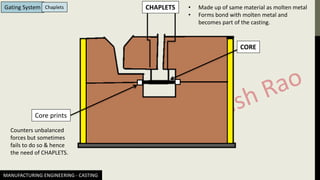

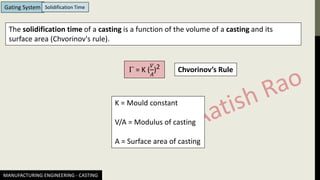

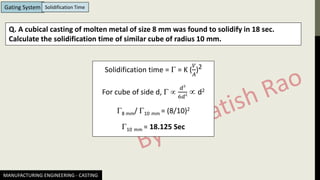

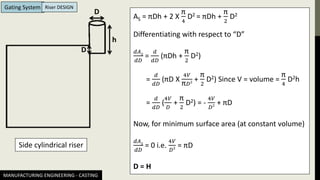

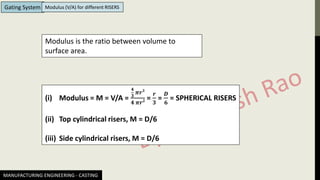

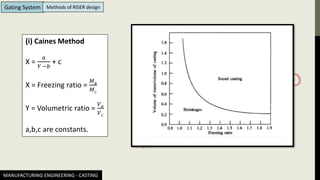

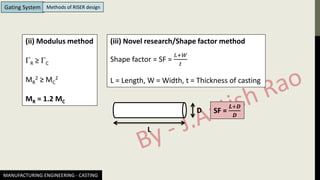

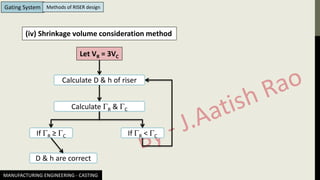

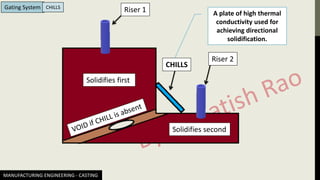

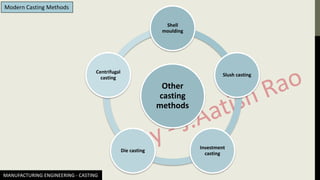

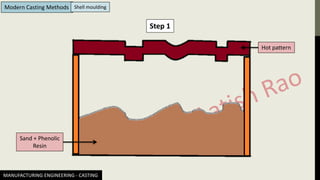

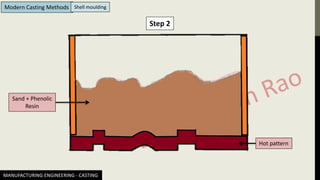

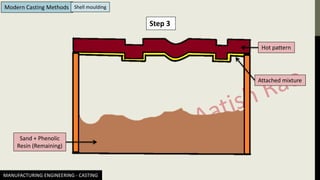

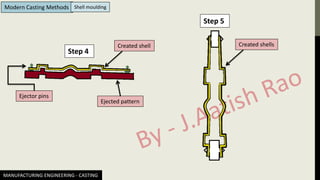

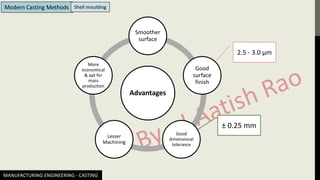

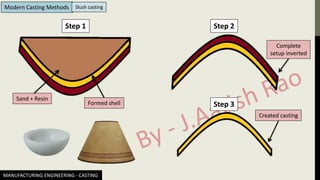

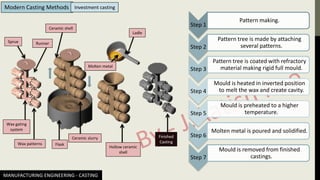

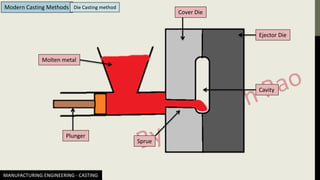

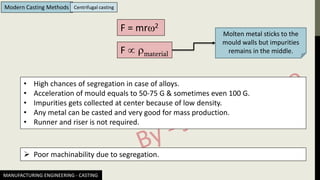

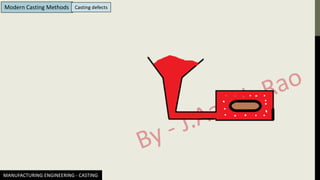

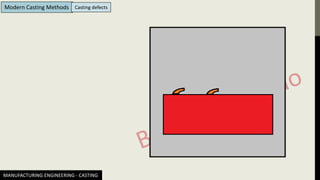

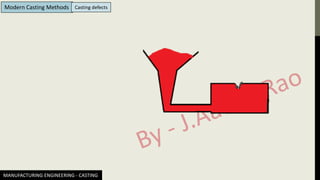

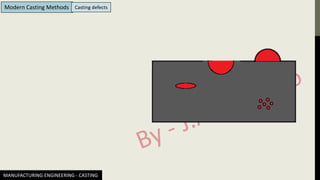

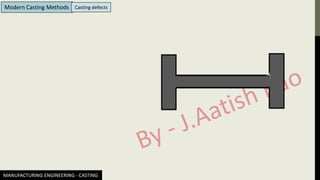

The document provides a comprehensive overview of manufacturing engineering, specifically focusing on casting processes, including types of patterns and molds, materials used, and their properties. Key topics include the steps in casting, advantages and disadvantages of various casting methods, and the defining characteristics of gating systems. Additionally, it covers techniques for ensuring proper mold creation and the importance of pattern allowances in successful casting outcomes.