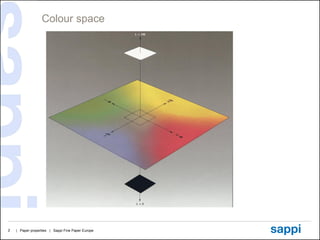

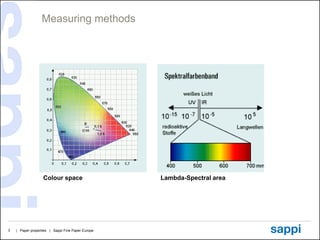

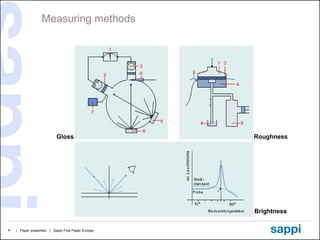

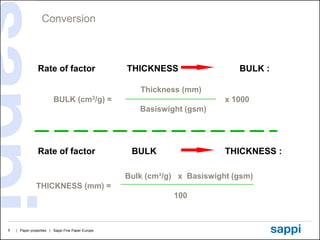

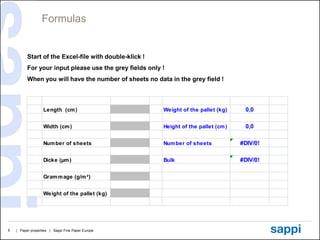

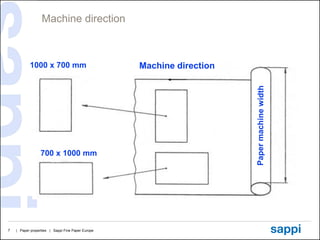

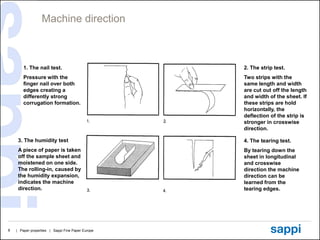

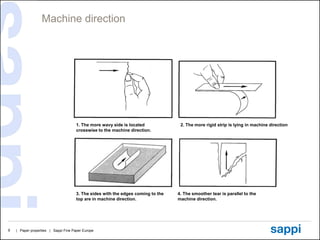

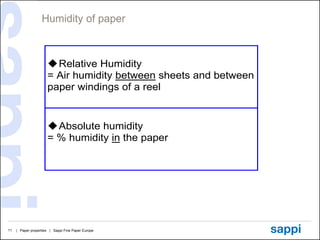

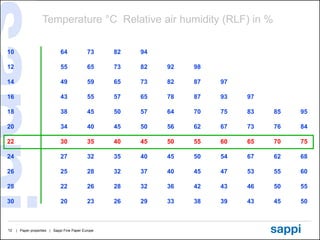

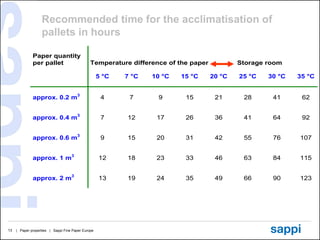

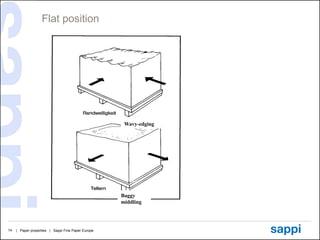

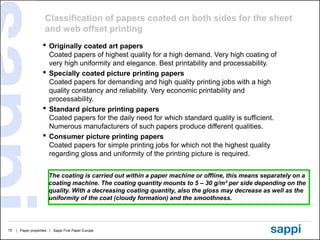

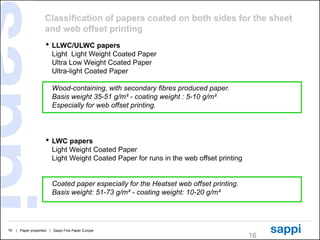

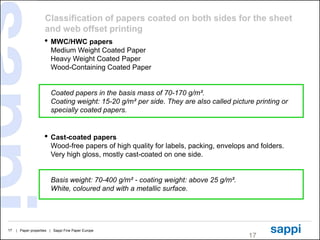

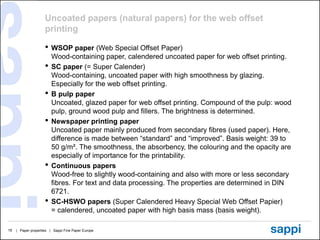

This document discusses various paper properties including color space, measuring methods, thickness, bulk, formulas, machine direction, humidity, temperature effects on acclimatization time, classifications of coated and uncoated papers for printing, and technical support contact information. It provides information on paper testing methods, calculations, recommendations, and classifications.