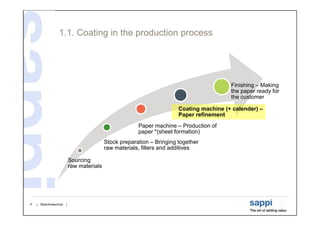

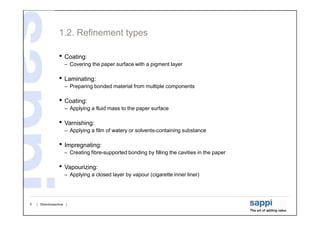

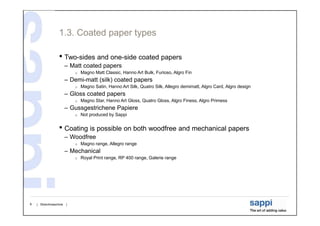

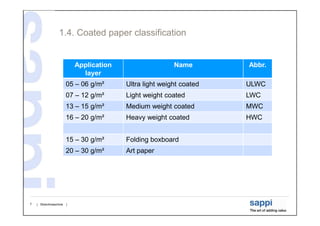

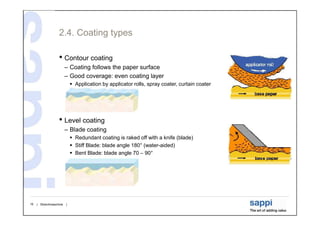

The document discusses the coating process used in paper production. Coating involves covering a paper surface with a pigment layer to enhance properties like visual appeal, ink absorption and smoothness. The key steps are: (1) preparing a water-based coating mixture of pigments, binders and additives; (2) applying the coating using methods like blade coating, curtain coating or size pressing; and (3) drying the coated paper using infrared heaters or airfoil dryers. Coating improves paper characteristics for printing or other end uses.