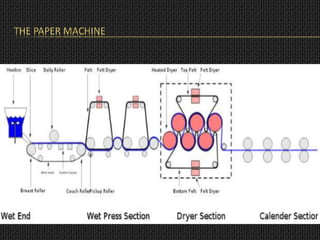

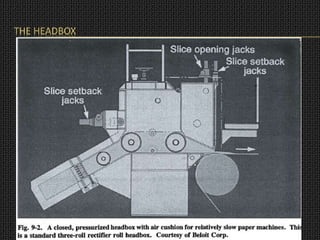

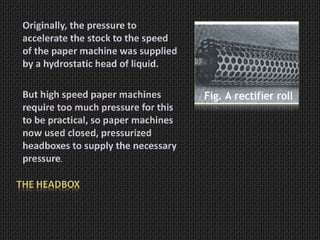

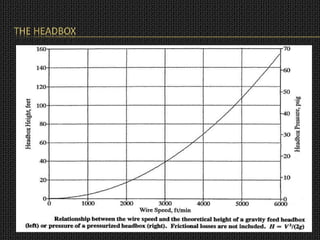

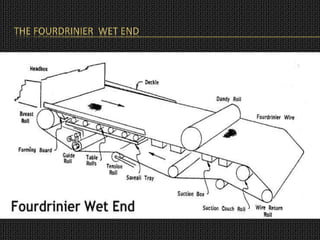

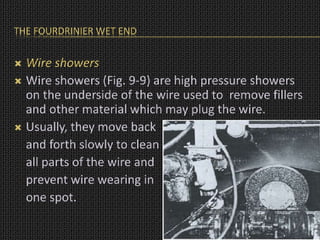

The document summarizes the key steps and components in the paper manufacturing process using a paper machine. It describes the basic components of the paper machine including the headbox, which deposits the pulp slurry onto the wire screen, and the fourdrinier wet end, where water is removed from the web through gravity, foils, and suction before entering the press and dryer sections. It provides details on key components in the wet end like the slice, forming board, table rolls, and couch roll that work to remove water and form the paper web.