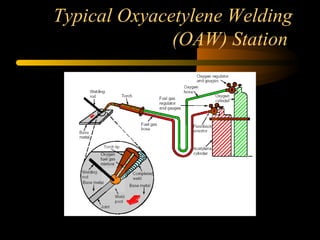

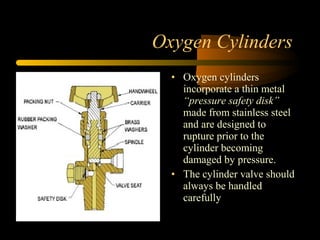

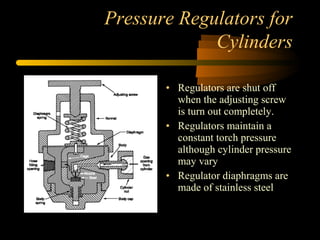

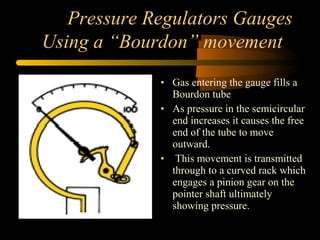

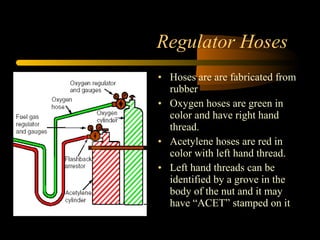

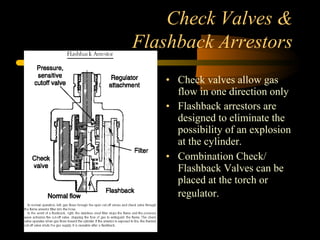

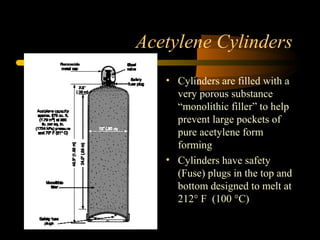

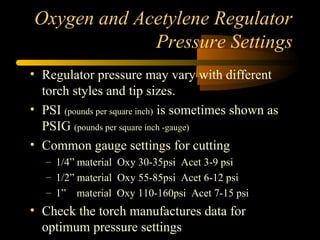

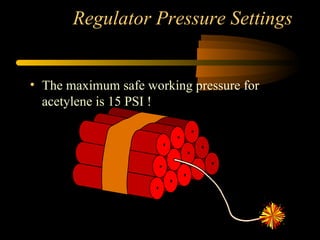

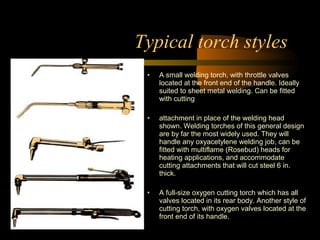

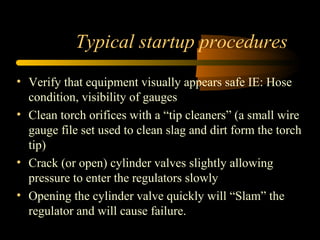

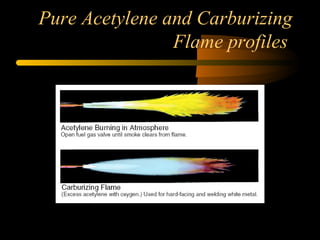

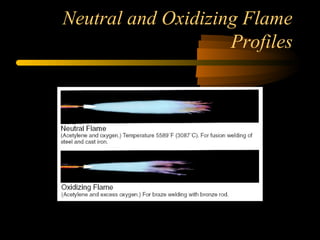

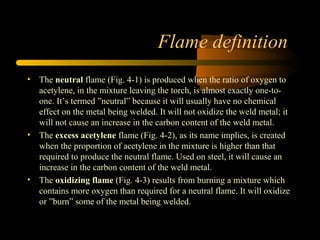

The document discusses gas welding using oxyacetylene, including descriptions of the equipment such as oxygen and acetylene cylinders, regulators, hoses, check valves and flashback arrestors. It also covers topics like cylinder transportation, regulator pressure settings, startup procedures, and the different types of oxyacetylene flames including neutral, carburizing, and oxidizing flames.