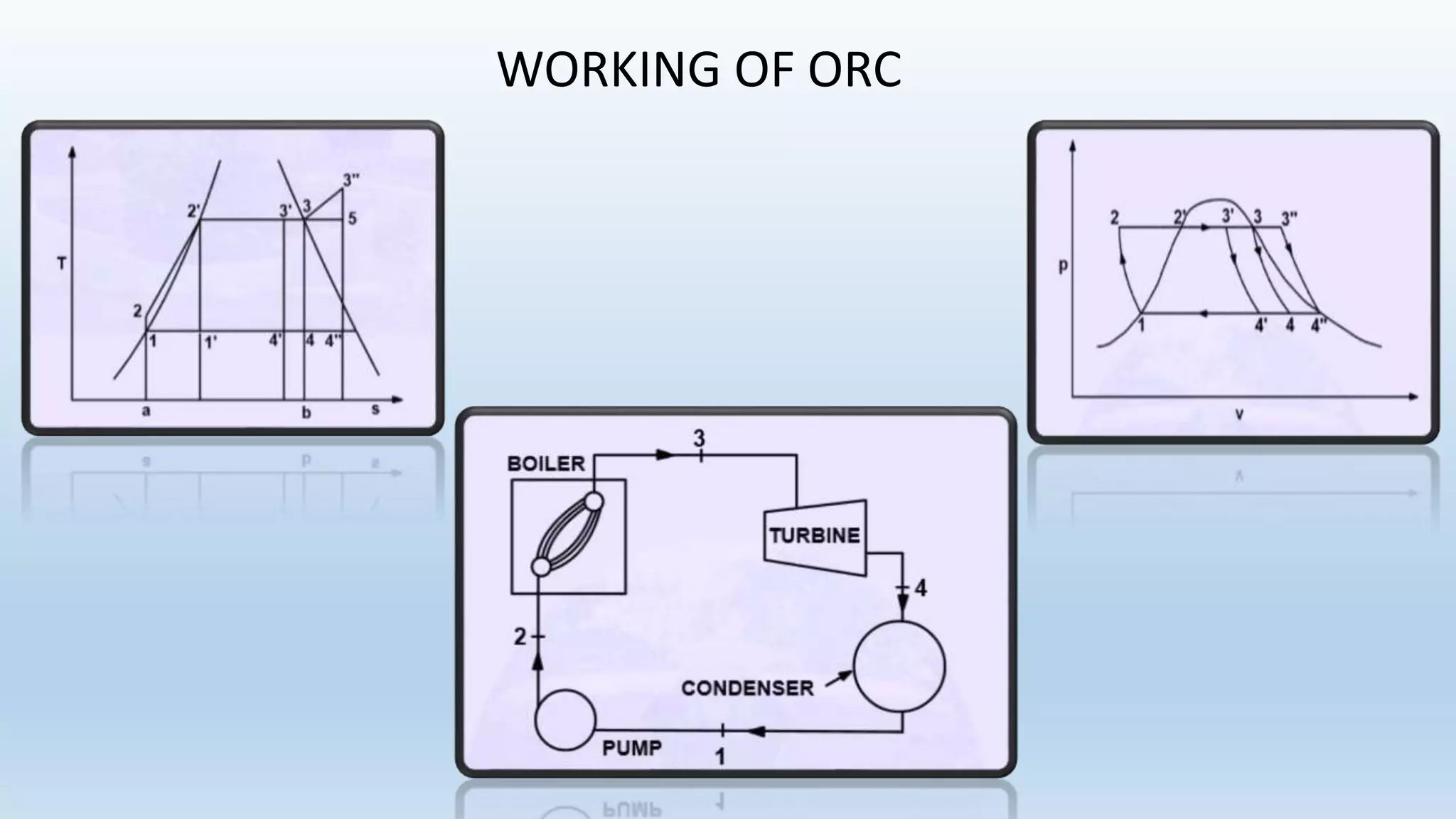

The document discusses the development of an Organic Rankine Cycle (ORC) system for power generation using low-grade heat sources, highlighting the environmental impacts of fossil fuel consumption and the need for sustainable energy solutions. It outlines the methodology of ORC, its advantages over traditional Rankine cycles, and the importance of selecting appropriate organic working fluids. The project aims to create a computational model for ORC, analyze fluid regimes, and design a model for experimental evaluation.