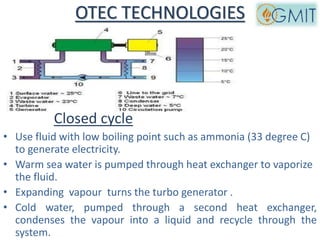

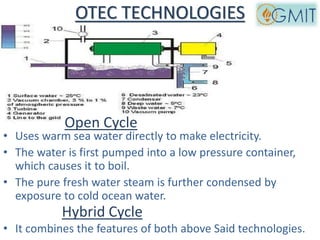

This document discusses ocean thermal energy conversion (OTEC), a renewable energy technology that generates electricity from the temperature difference between warm surface waters and cold deep ocean waters. OTEC works best with a temperature difference of 36°F and is viable in tropical coastal regions. There are two main cycles - open cycle which uses warm water directly and closed cycle which uses a fluid with a low boiling point. Some OTEC plants are currently operating in Japan and France. While OTEC has potential benefits, challenges include dissolved gases coming out of solution in the cold water intake and carefully sealing systems to prevent air inleakage.