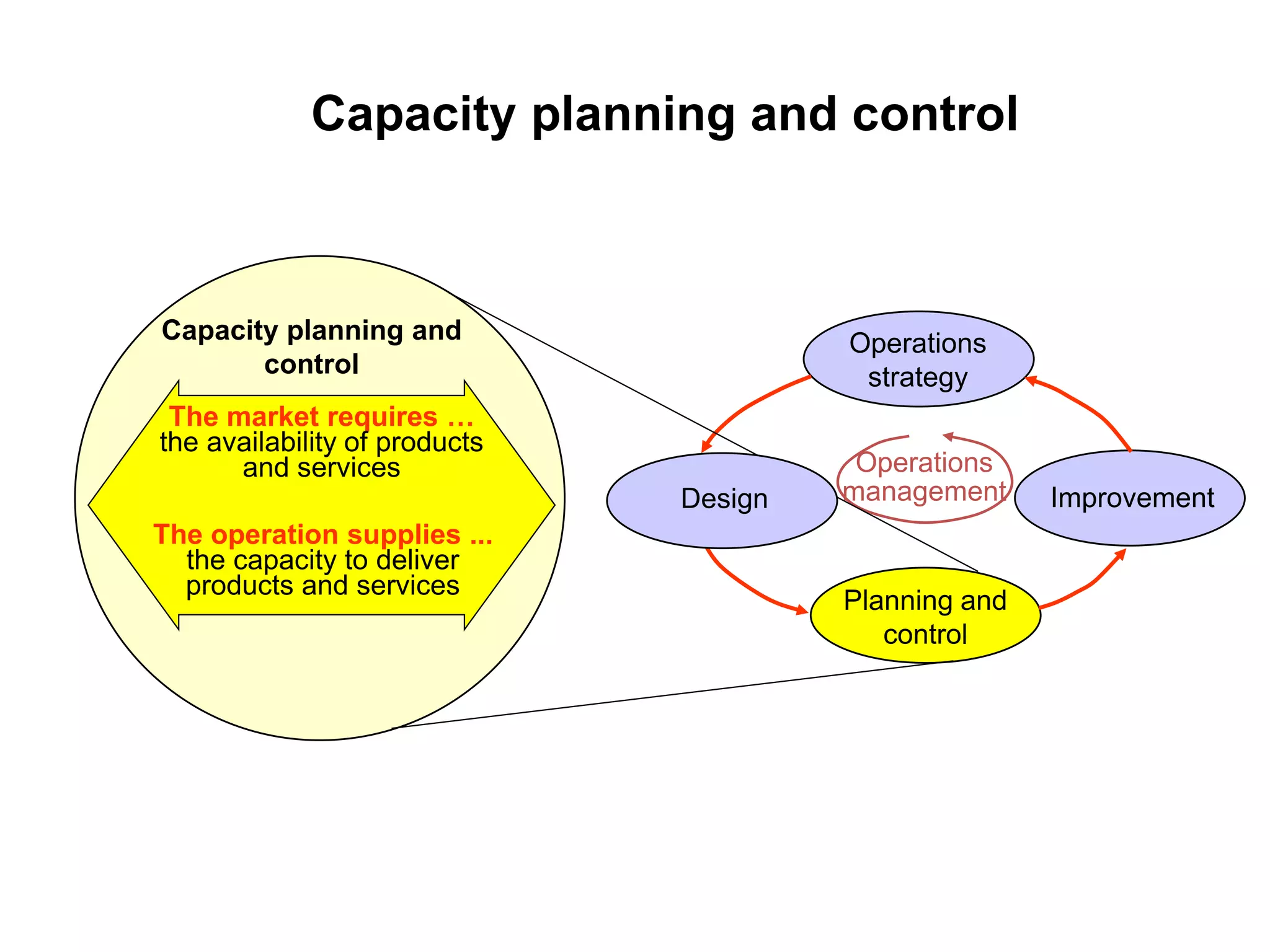

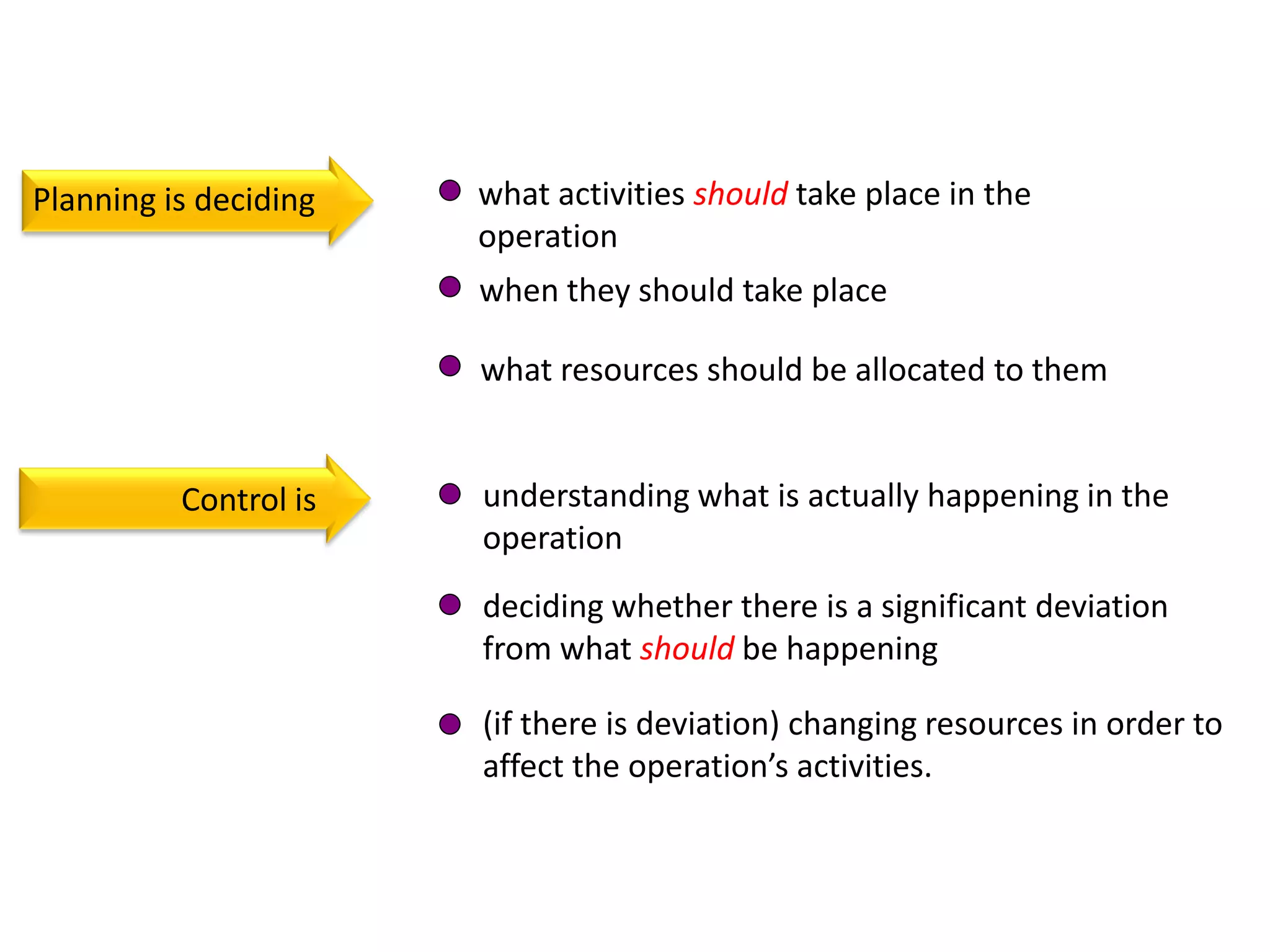

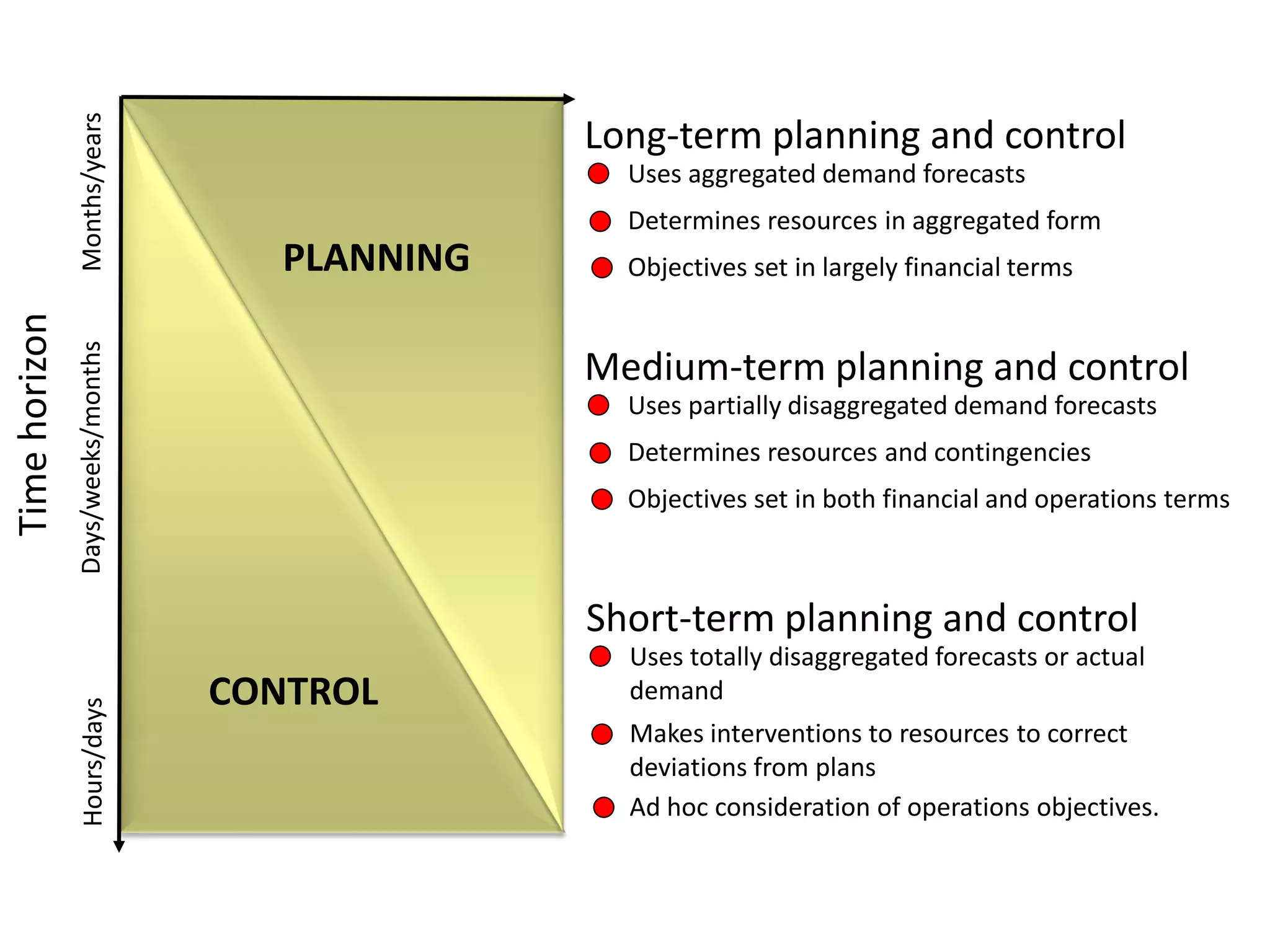

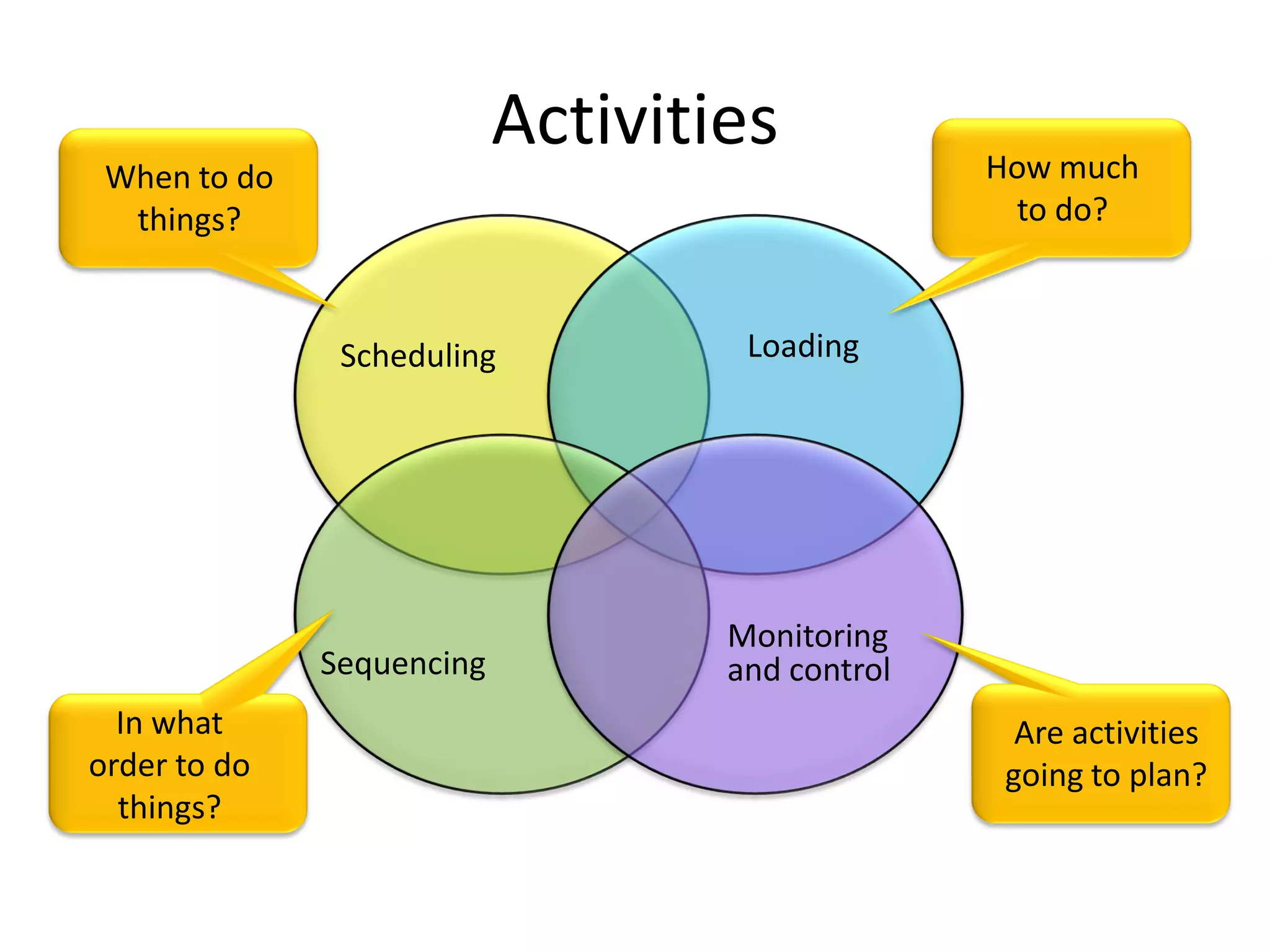

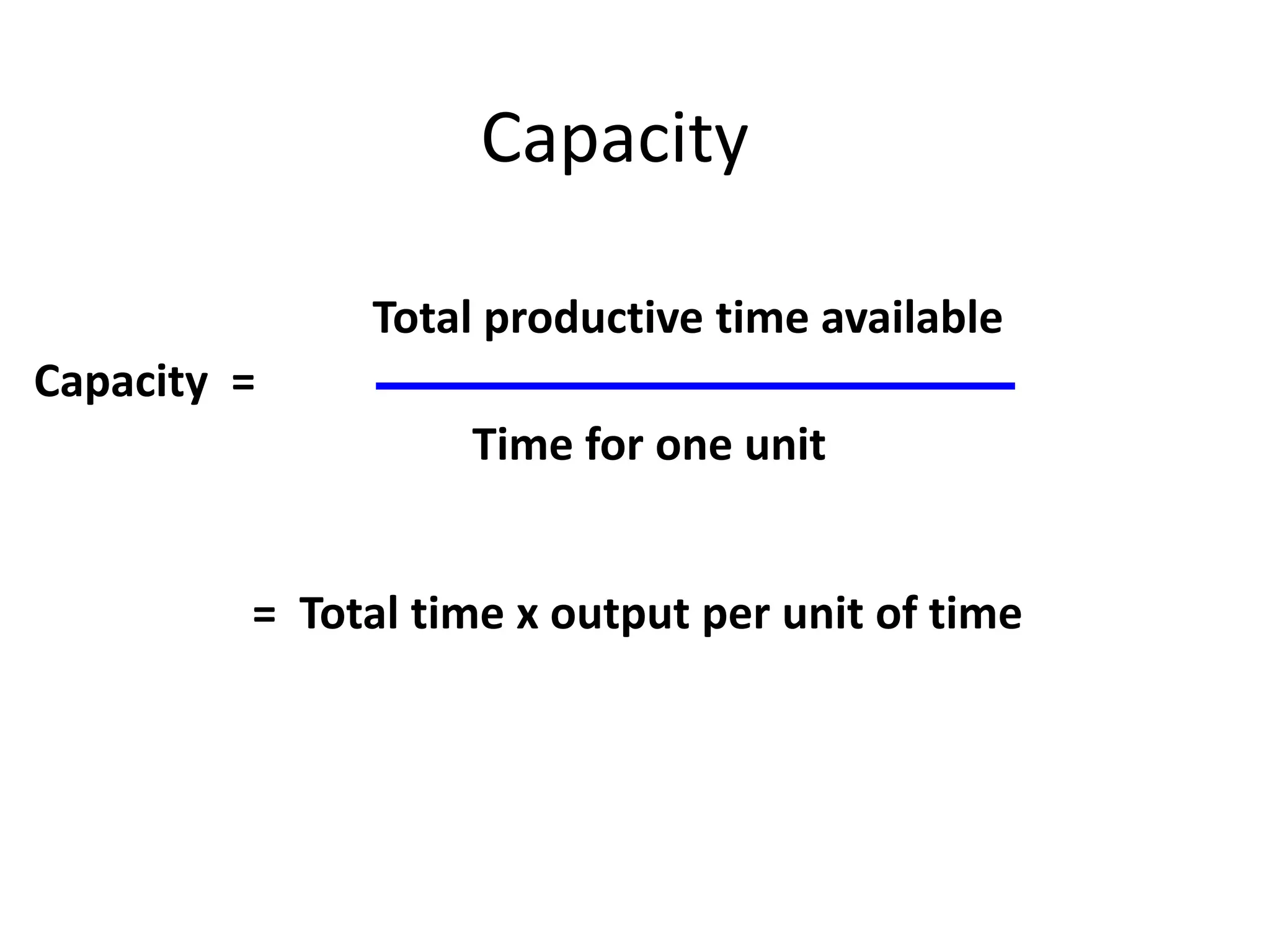

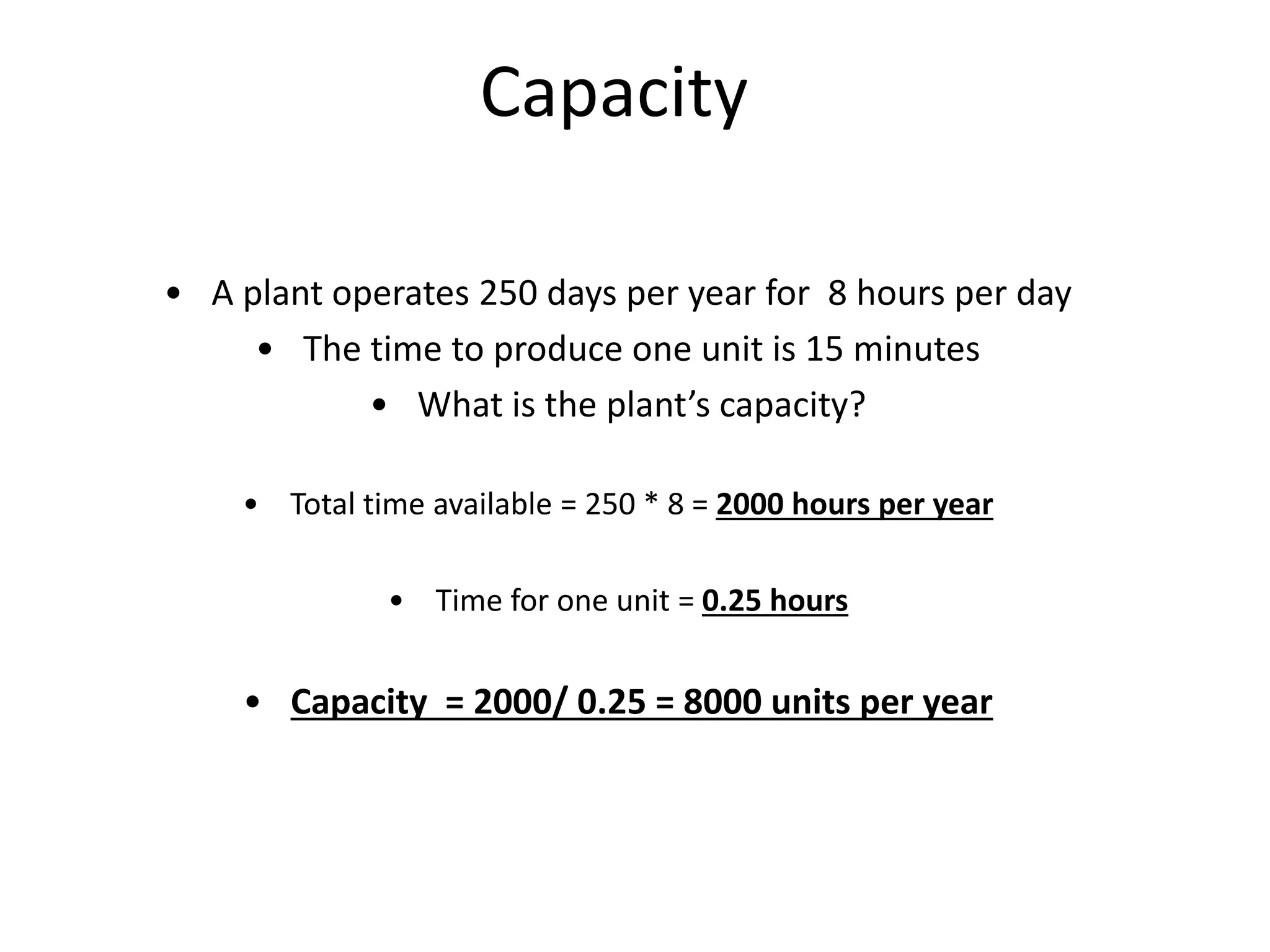

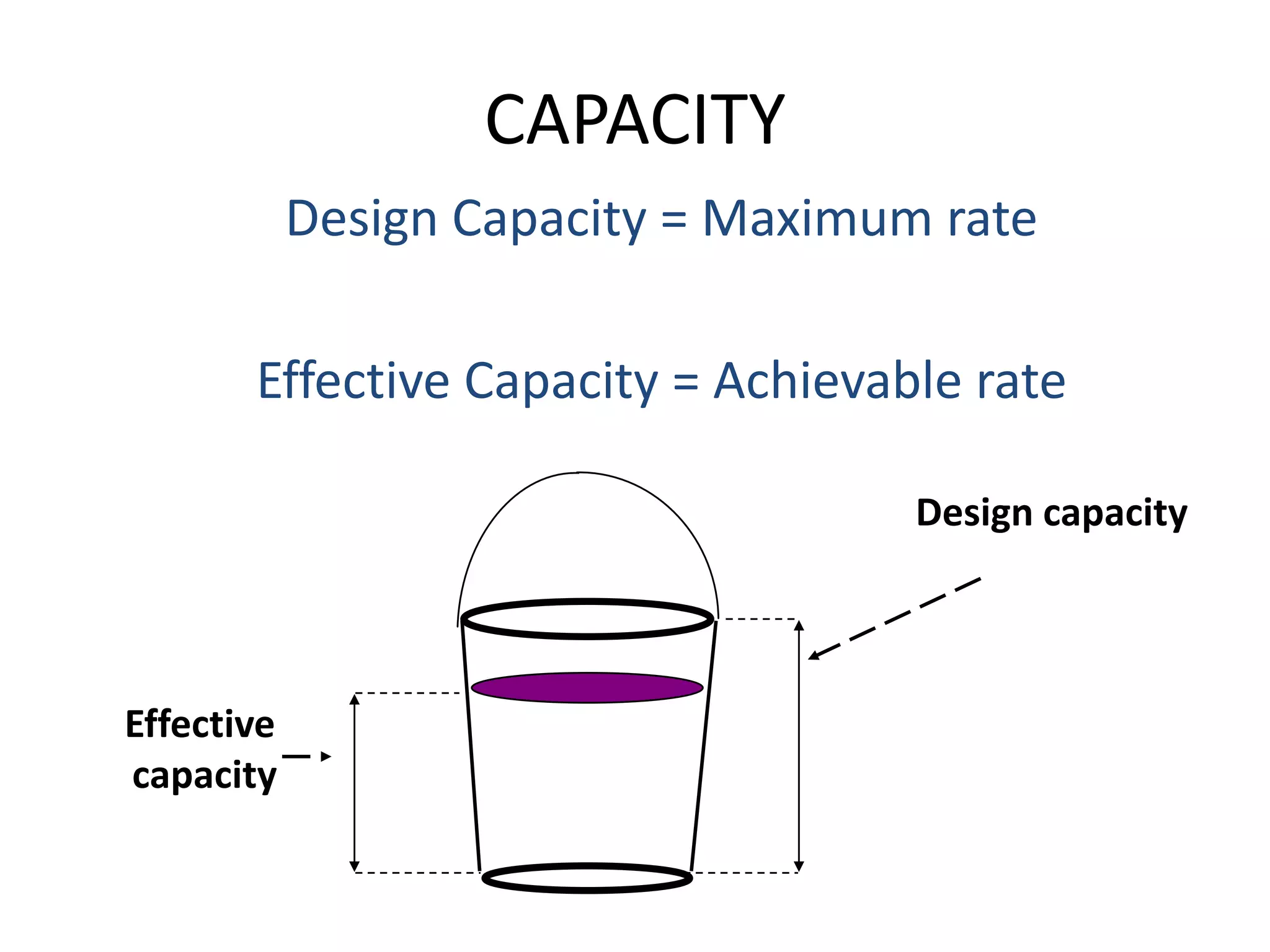

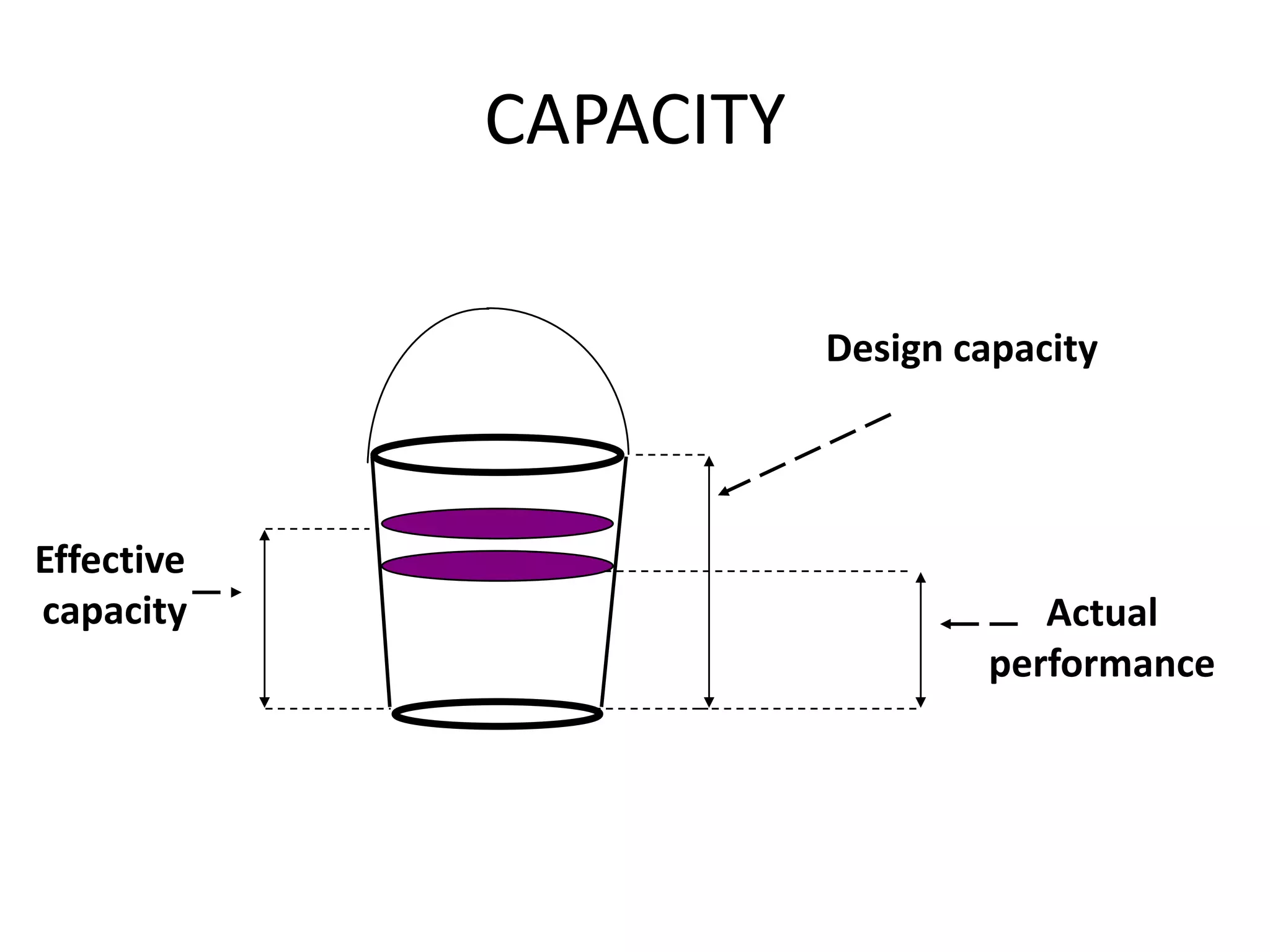

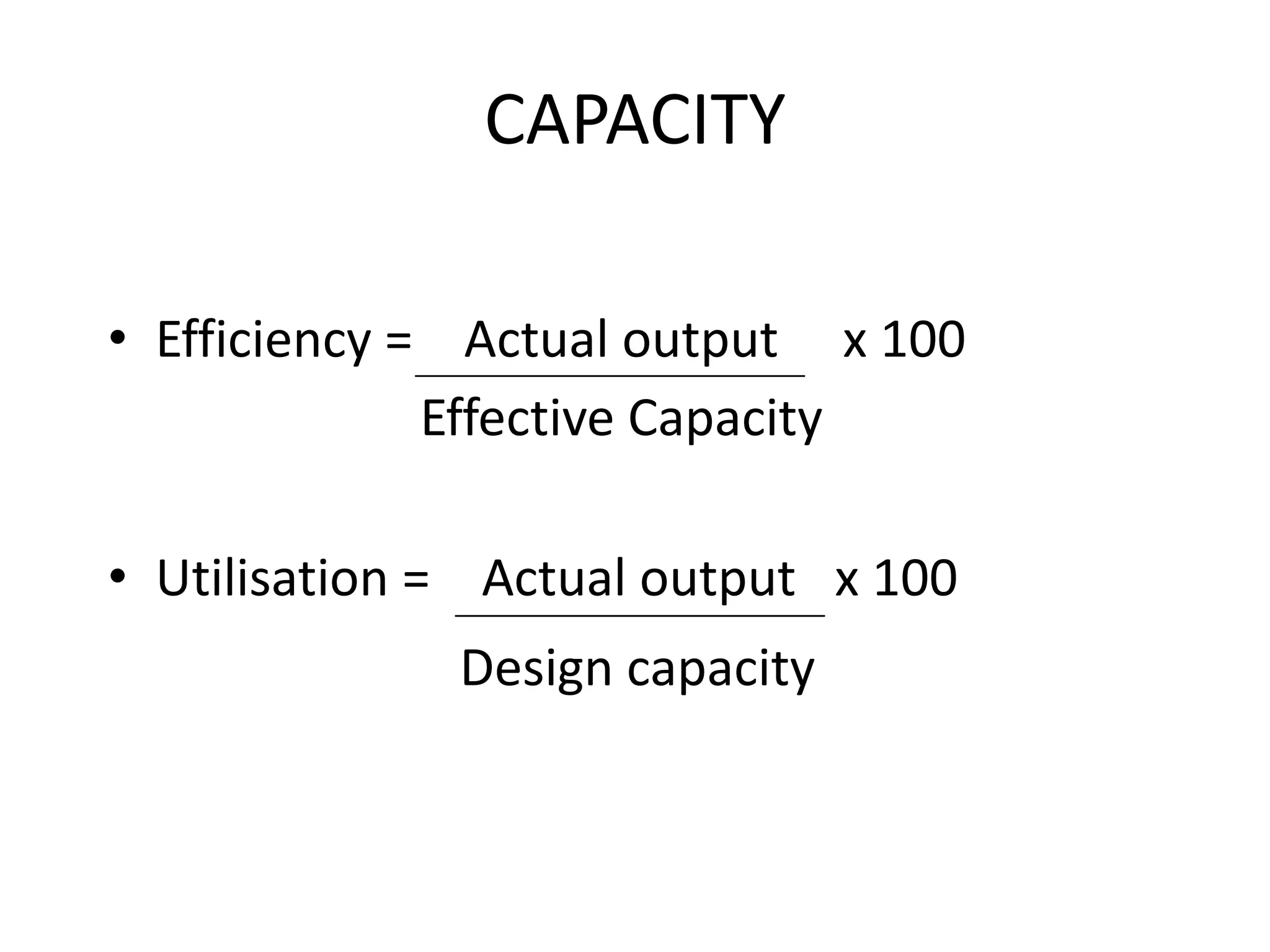

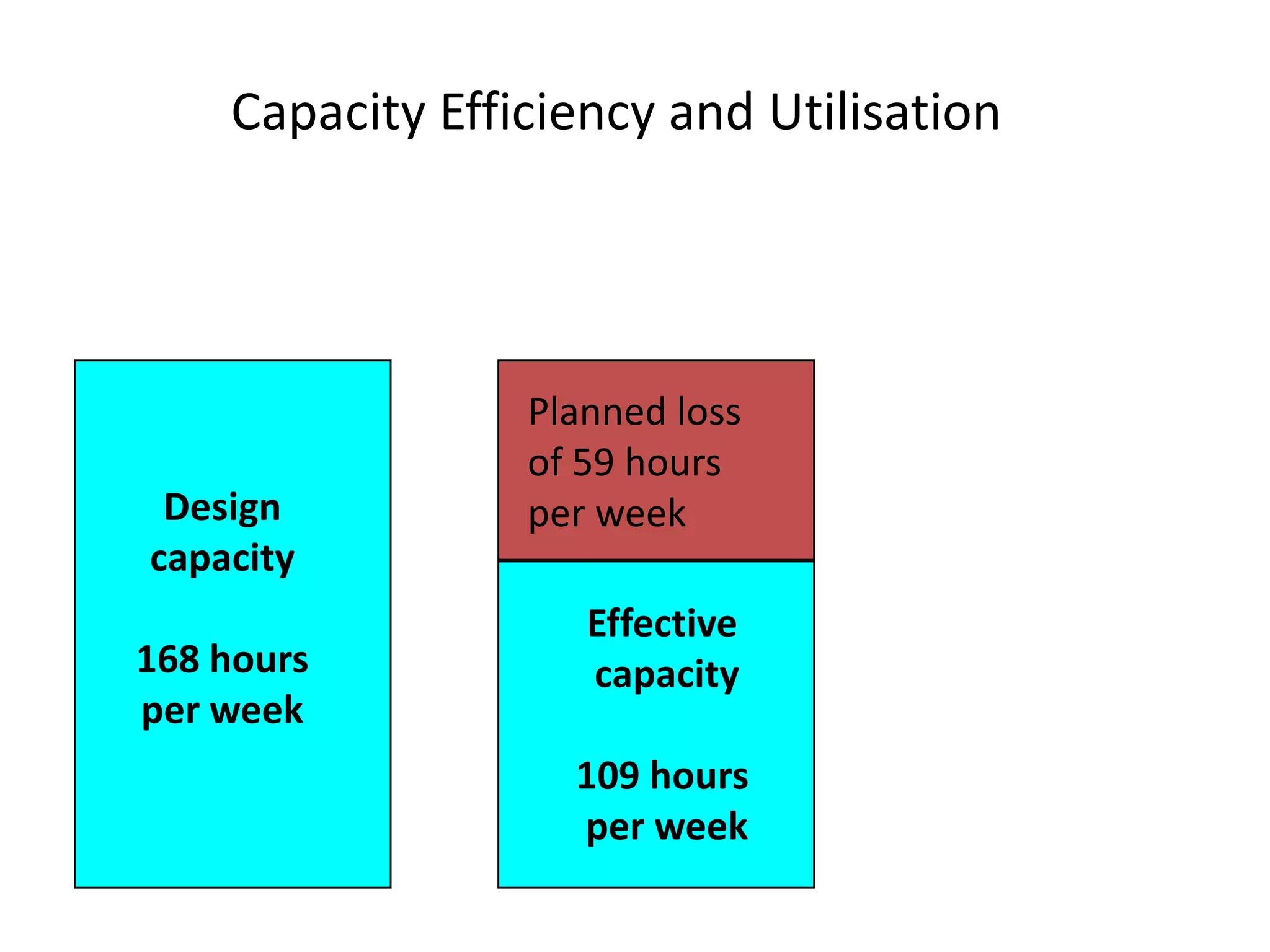

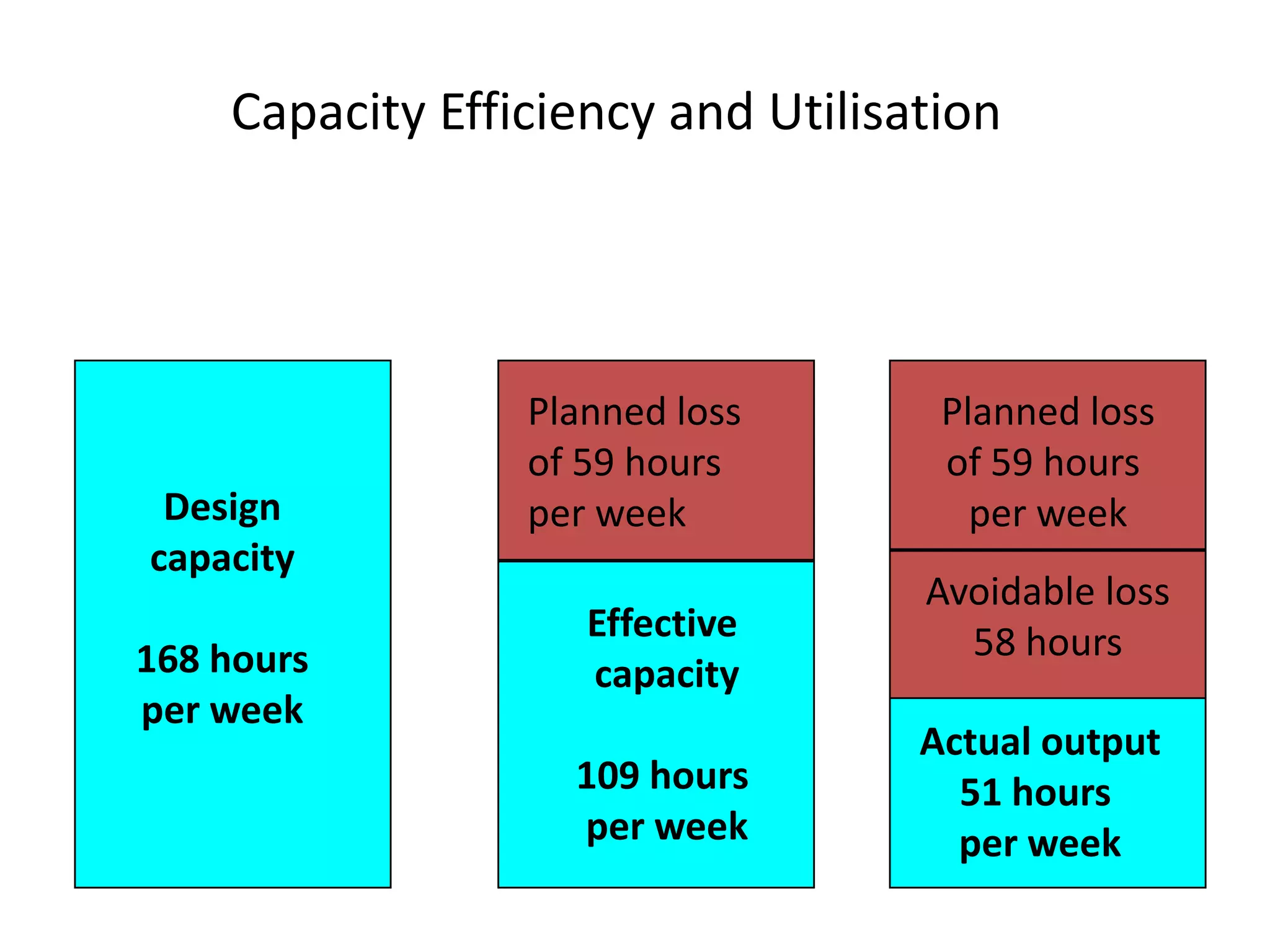

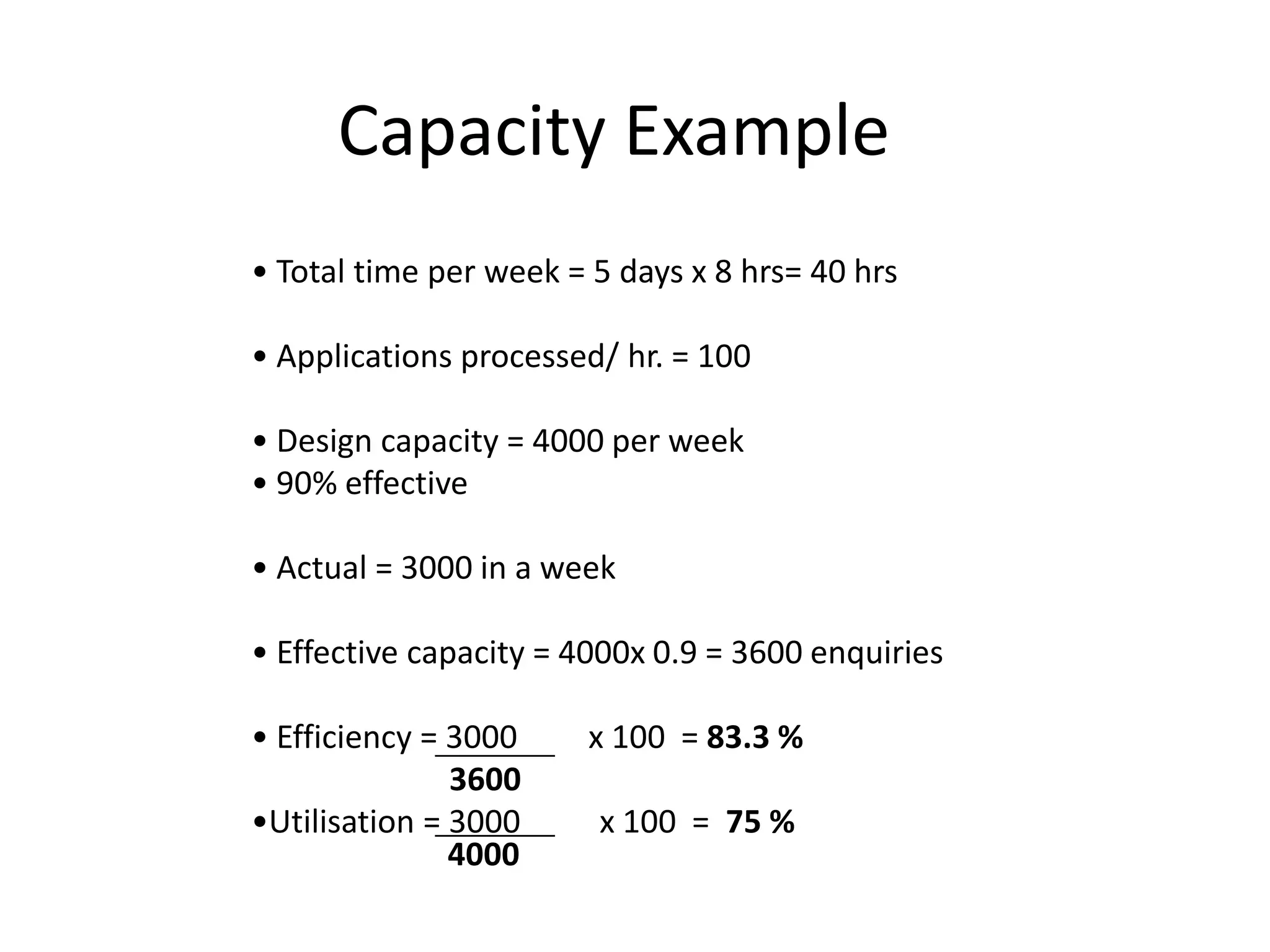

Planning involves deciding what activities should take place, when they should take place, and what resources should be allocated. Control involves understanding what is actually happening and deciding if there are deviations from the plan, then changing resources if needed. Planning looks further into the future using aggregated data, while control has a shorter time horizon and uses more detailed data. Capacity is the maximum output possible and can be measured in units per time period. Effective capacity is the achievable output rate which is usually lower than design capacity.