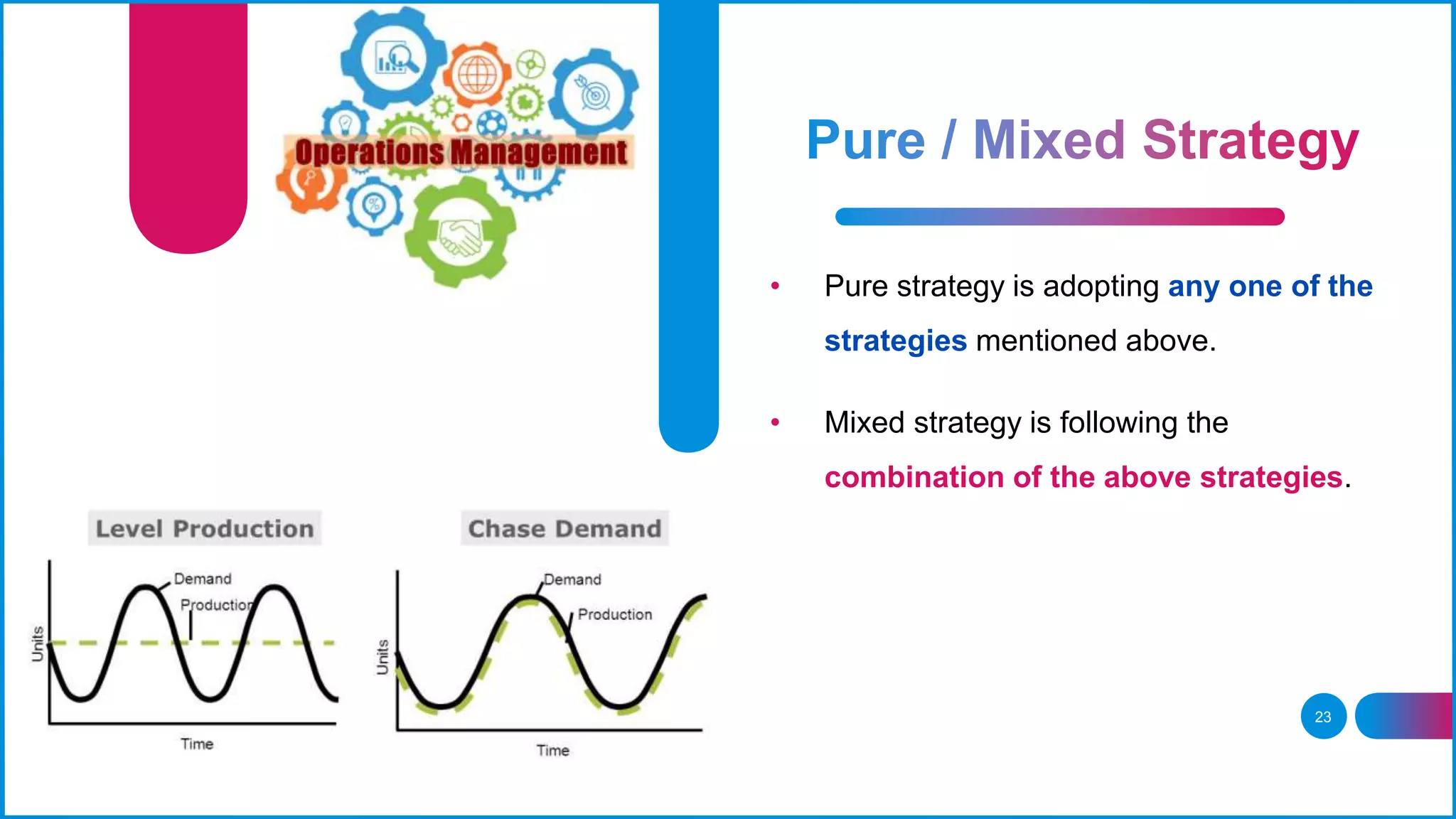

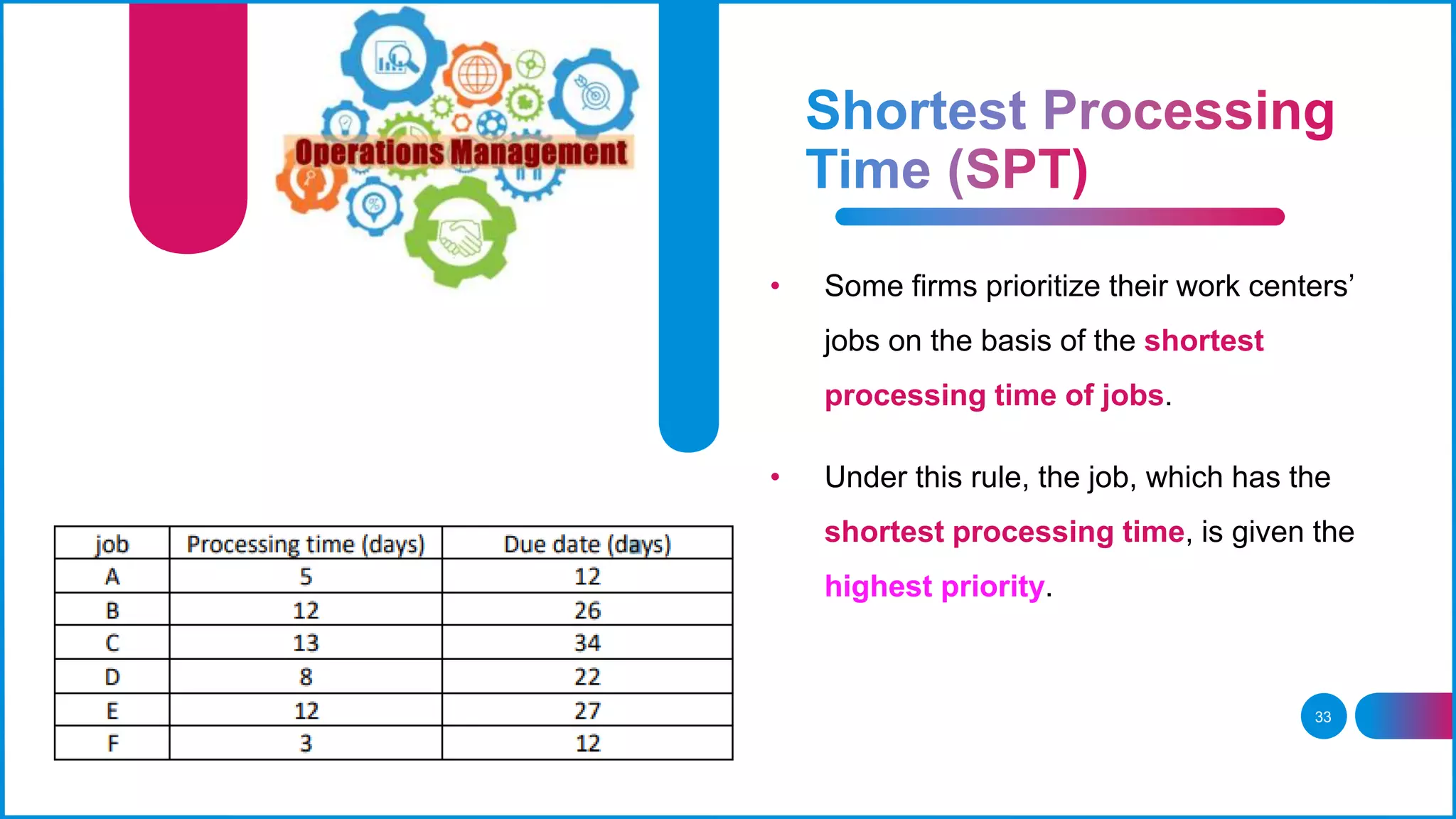

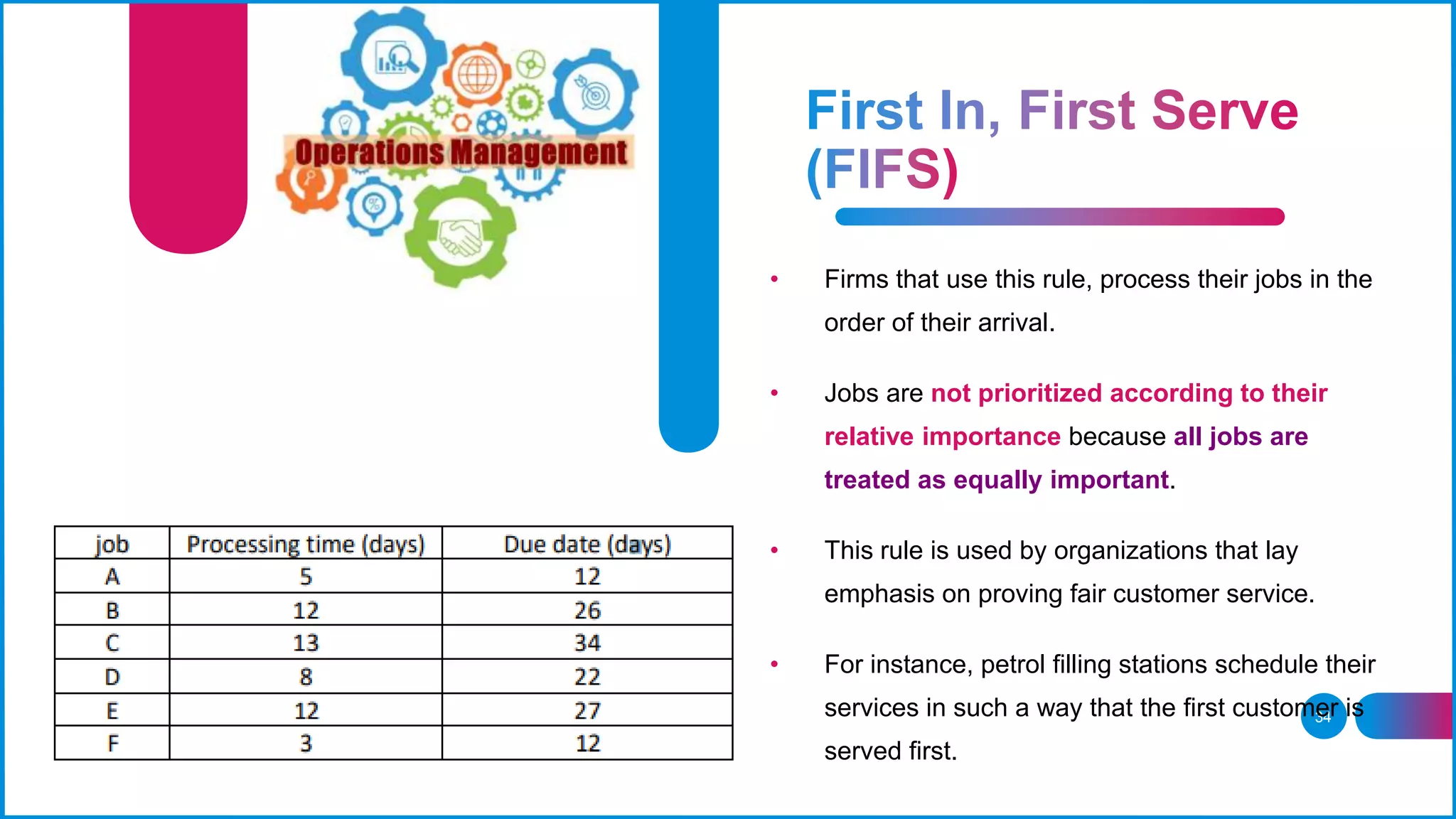

Operations management involves planning and controlling the process of production and redesigning business operations in the production of goods or services. It includes functions like facility location, production planning and control, quality control, and maintenance management. The goal is to efficiently convert inputs into outputs to maximize profit while meeting customer needs. Production planning involves routing, scheduling, and loading operations to determine resource requirements, operation sequences, and work assignments.