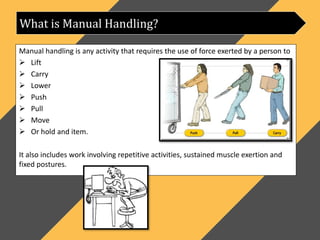

The document provides an induction for new employees on safety procedures and legislative requirements at the workplace, including responsibilities of employers and employees, emergency procedures, equipment safety checks, hazard identification and risk management, ergonomics, manual handling techniques, and incident reporting processes. Key Tasmanian safety legislations are outlined as well as the inspection and consultation process used to ensure compliance. Resources for further safety information are also listed.