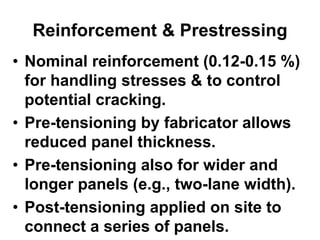

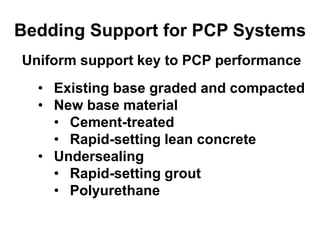

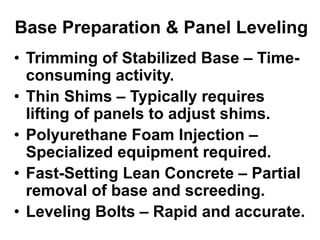

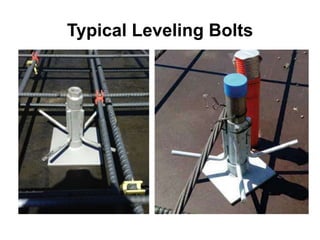

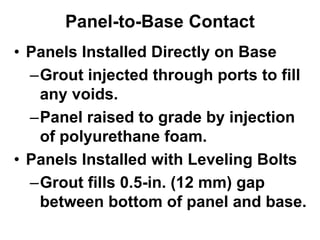

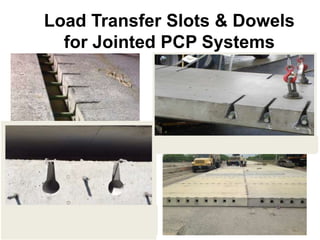

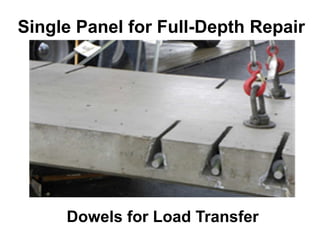

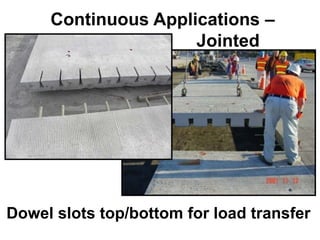

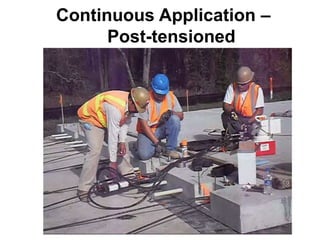

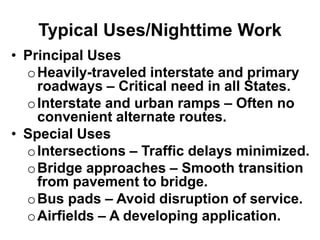

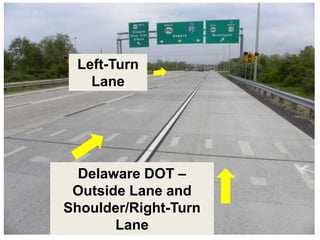

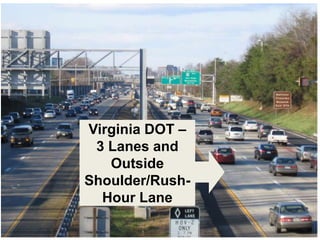

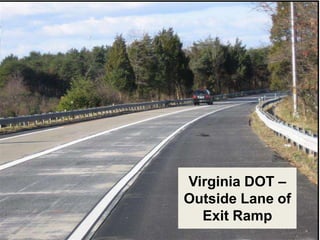

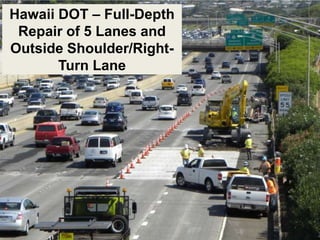

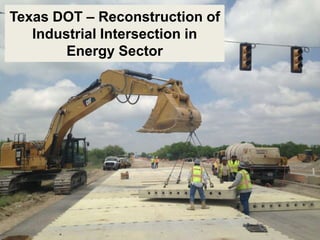

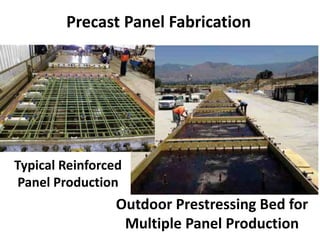

This document discusses the use of precast concrete panels (PCP) for repairing and rehabilitating high-traffic concrete and asphalt pavements. PCP allows for rapid renewal with short lane closure times and improved work zone safety. Nominal reinforcement and pre-tensioning of panels reduces thickness and allows for wider/longer panels. Proper bedding and leveling of panels is important for performance. PCP can provide 15-20 years of service for repairs or 40+ years for continuous applications. States commonly use PCP for heavily traveled interstates, ramps, intersections and other critical locations requiring minimal traffic disruptions.