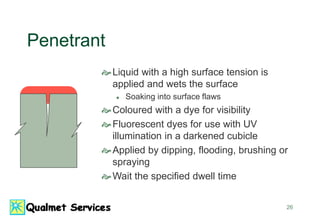

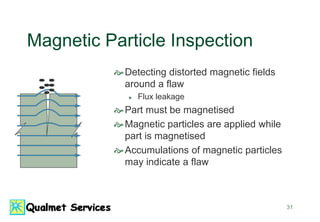

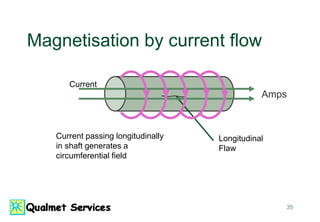

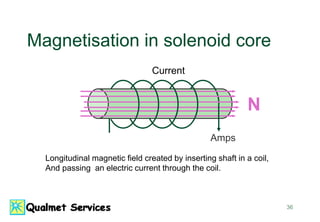

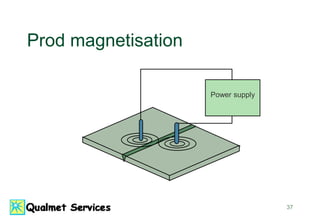

Non-destructive testing methods like liquid penetrant inspection and magnetic particle inspection can be used to find surface-breaking flaws in welds. Liquid penetrant inspection uses dyes that are drawn into surface cracks by capillary action and revealed with developers. Magnetic particle inspection magnetizes ferromagnetic materials and uses iron particles to indicate distortions in magnetic fields caused by subsurface flaws. Both methods are limited in their ability to find buried flaws and require clean surfaces to avoid false indications. Proper technique and interpretation of results by qualified inspectors are needed to effectively use non-destructive testing to evaluate weld quality.