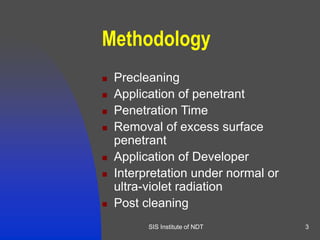

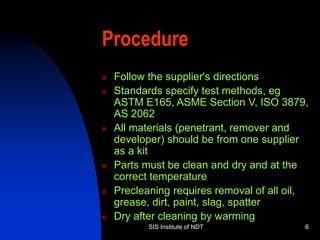

The document discusses penetrant testing, which is a non-destructive testing method used to detect surface-breaking defects in materials. It explains the principles and methodology of penetrant testing, including precleaning, applying penetrant, removing excess penetrant, applying developer, and interpreting results. The advantages and disadvantages are outlined. Proper procedures and standards are emphasized to ensure effective testing.