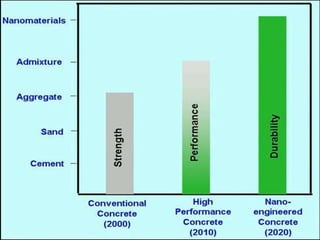

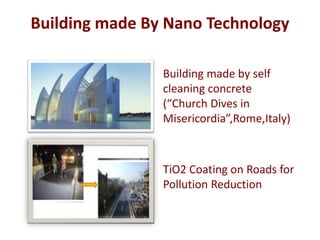

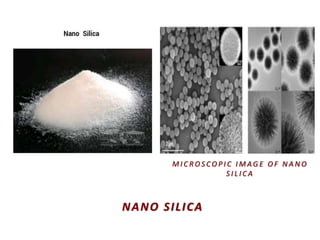

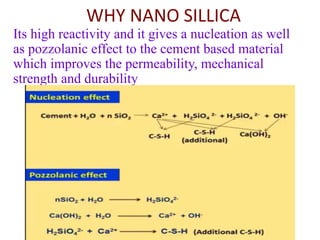

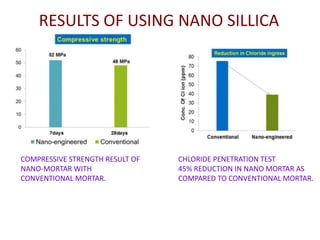

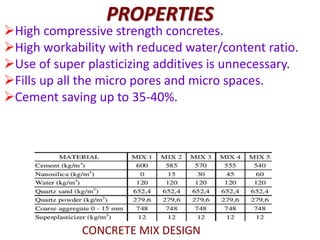

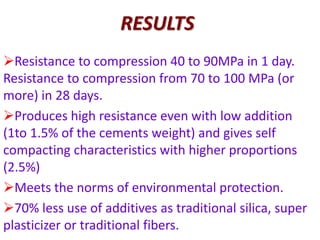

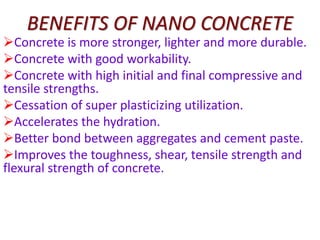

This document discusses nano concrete, which is concrete made with Portland cement particles smaller than 500nm and sometimes additional nano particles. Nano materials like carbon nanotubes and nano-silica are added to improve properties. Carbon nanotubes increase strength by preventing cracks from spreading. Nano-silica improves early hydration and strength. Using nano materials leads to higher strength concrete that uses less cement. Challenges include manufacturing nano cement and controlling heat of hydration.