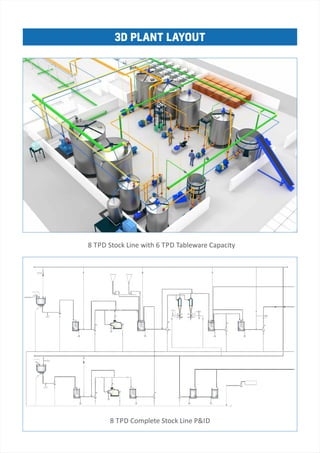

The document outlines the features and specifications of a semi-automatic molded fiber production line designed for various molded fiber products. It includes details about the machinery for forming, trimming, and molding, emphasizing automation, customization options, and safety features. Additionally, it provides a comprehensive list of product sizes and attributes, showcasing the company's capabilities in the molded fiber sector.