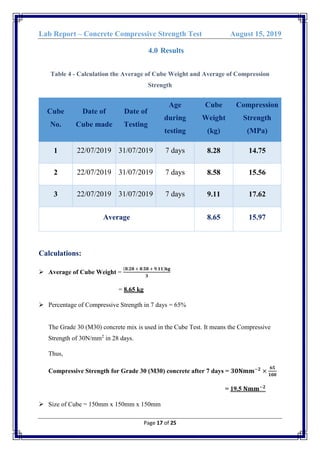

The document describes a laboratory experiment to determine the compressive strength of concrete cubes at 7 days. Three 150mm concrete cubes were cast and tested after 7 days of curing. The average weight of the cubes was 8.65kg. When tested, the cubes failed at an average maximum load of 15.97 MPa. This shows the 7 day compressive strength of the concrete mix met the target strength of 19.5 MPa specified for M30 grade concrete. The results were analyzed to calculate compressive strength and standard deviation according to standard formulas.

![Lab Report – Concrete Compressive Strength Test August 15, 2019

Page 23 of 25

7.0 References

Anon., 2014. The Constructor - Civil Engineering Home. [Online]

Available at: https://theconstructor.org/concrete/compressive-strength-concrete-cube-

test/1561/

[Accessed 02 04 2014].

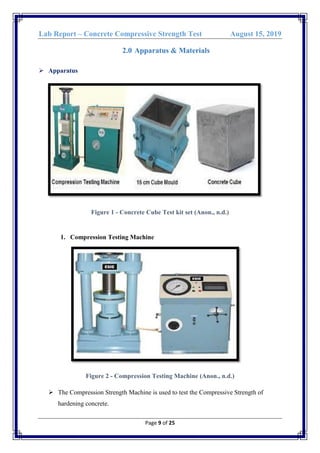

Anon., n.d. Compression Testing Machine. [Online]

Available at: https://theconstructor.org/wp-content/uploads/2011/11/digital-compression-

testing-machine.jpg

Anon., n.d. Cube test apparatures. [Online]

Available at:

data:image/jpeg;base64,/9j/4AAQSkZJRgABAQAAAQABAAD/2wCEAAkGBxISEhU

TExMVFhUXFRgXFRgXGBcXGBcYFxUWFxgXGBgYHSggGBolHRcWITEhJSkrLi4

vFx8zODMtNygtLisBCgoKDg0OGxAQGy0lHyUtLS0tLS0tLS0uLS0tLTUtLS0tLS0tLS

0tLS0tLS0tLS0tLSstLS0tLS0rLS0tLS0tLf/AABEIAI0BZQMBIgACEQEDEQH/

Anon., n.d. Grease. [Online]

Available at:

data:image/jpeg;base64,/9j/4AAQSkZJRgABAQAAAQABAAD/2wCEAAkGBxITEhU

TExIVFRUXFhUVFRUYFRUVFxYWFxUWFhUVFRcYHSggGBolGxUWITEhJikrLi4

uFx8zODMtNygtLisBCgoKDg0OGhAQGy0lICUtLS0tLS0tLS0tLS0tLS0tLS0tLS0tLS0

tLS0tLS0tLS0tLS0tLS0tLS0tLS0tLS0tLf/AABEIAOEA4QMBIgACEQEDEQH/

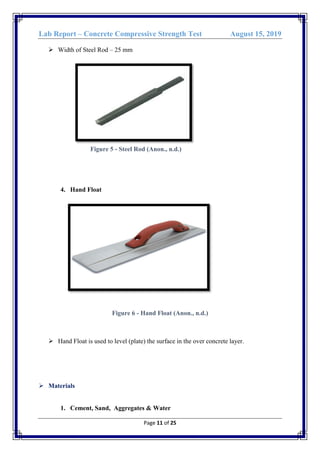

Anon., n.d. Hand Float. [Online]

Available at:

https://www.masterwholesale.com/media/catalog/product/cache/1/image/9df78eab33525d

08d6e5fb8d27136e95/t/-/t-mt_14634.jpg

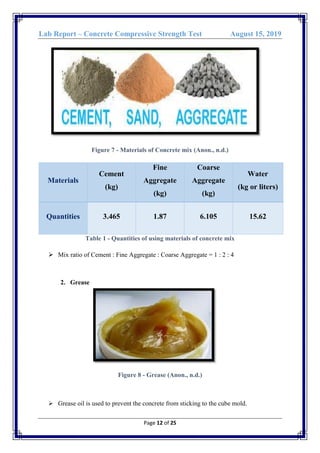

Anon., n.d. Materials of Concrete mix. [Online]

Available at:

data:image/jpeg;base64,/9j/4AAQSkZJRgABAQAAAQABAAD/2wCEAAkGBxMTEh

USEhIWFhUXGB4YFhgXGRogHRoeIR8aGB4dGh4YICkgGh0lHh8gIjEiJikrLi4uGB8z

ODMsNygtLisBCgoKDg0OGxAQGy0mICUtLS0tLy4rLS0vLy0tLS0tLS0tLS8tLi0tLS8t

LS0vLS0tLy8tLS0tLS0tLS8tLS0tLf/AABEIAH8BiwMBEQACEQEDEQH/](https://image.slidesharecdn.com/cubetestreport-190817143533/85/Cube-test-report-23-320.jpg)

![Lab Report – Concrete Compressive Strength Test August 15, 2019

Page 24 of 25

Anon., n.d. Steeel Rod. [Online]

Available at: https://5.imimg.com/data5/VN/KE/MY-720938/tamping-bar-500x500.jpg

Anon., n.d. Steel Cube Mold. [Online]

Available at:

data:image/jpeg;base64,/9j/4AAQSkZJRgABAQAAAQABAAD/2wCEAAkGBxMTEh

UTExMWFhUVFRgVFxgWFRcVFhYXGBUWFhUYGBcYHSggGBolHRUVITEhJSkr

Li4uFx8zODMtNygtLisBCgoKDg0OGhAQGi0lIB0tLS0tLS0tLS0tLS0tLS0tKy0tLS0tL

S0tLS0tLS0tLS0tLS4tLS0tLS0tLy0tLS0tLf/AABEIAOEA4QMBEQACEQEDEQH/

Anon., n.d. Steel Cube Molds. [Online]

Available at:

data:image/jpeg;base64,/9j/4AAQSkZJRgABAQAAAQABAAD/2wCEAAkGBxISEhUS

EhIWFRUXFRYVFRUVFRgWFxgVFRUWFhUXFxYYHSggGBolHRUVITEhJSkrLi4

uFx8zODMtNygtLisBCgoKDg0OFxAQGi0eHx8tLS0tLS0tLS0tLSstLy0tLS0tLS0tLS0t

LS0tKy0tLS0tLS0tLS0tKy0tLS0rLSstLf/AABEIAOEA4QMBIgACEQEDEQH/](https://image.slidesharecdn.com/cubetestreport-190817143533/85/Cube-test-report-24-320.jpg)