Embed presentation

Download to read offline

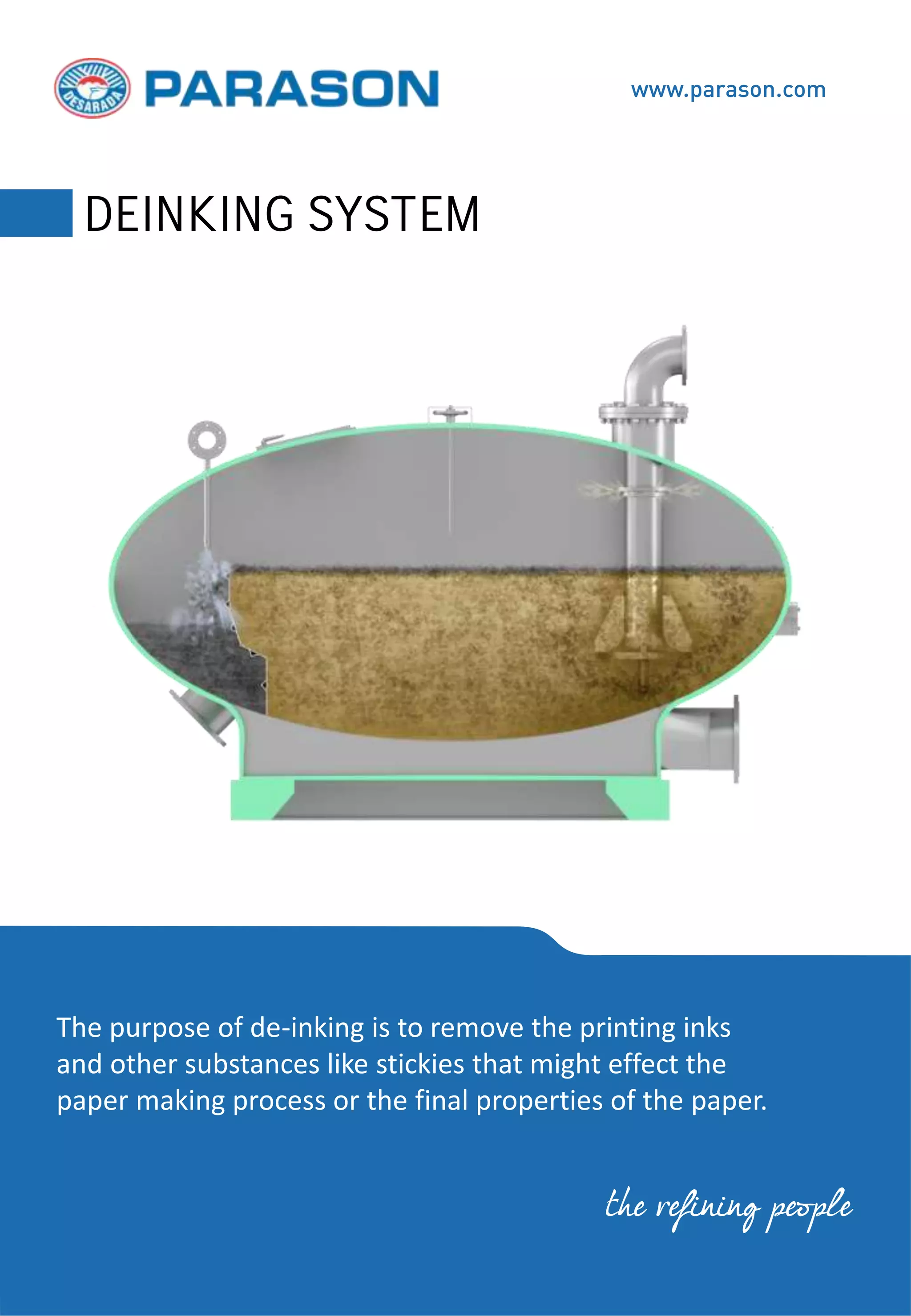

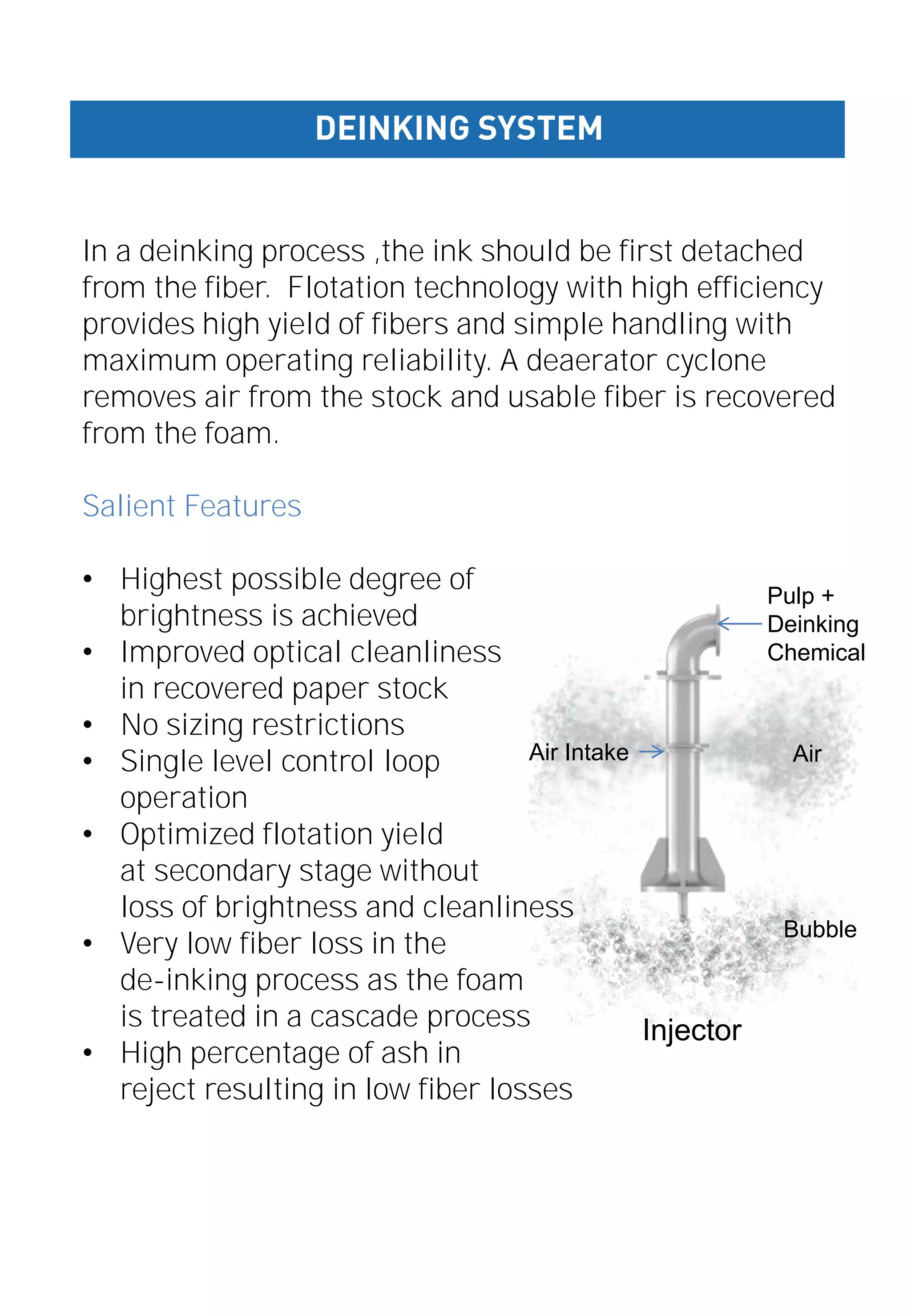

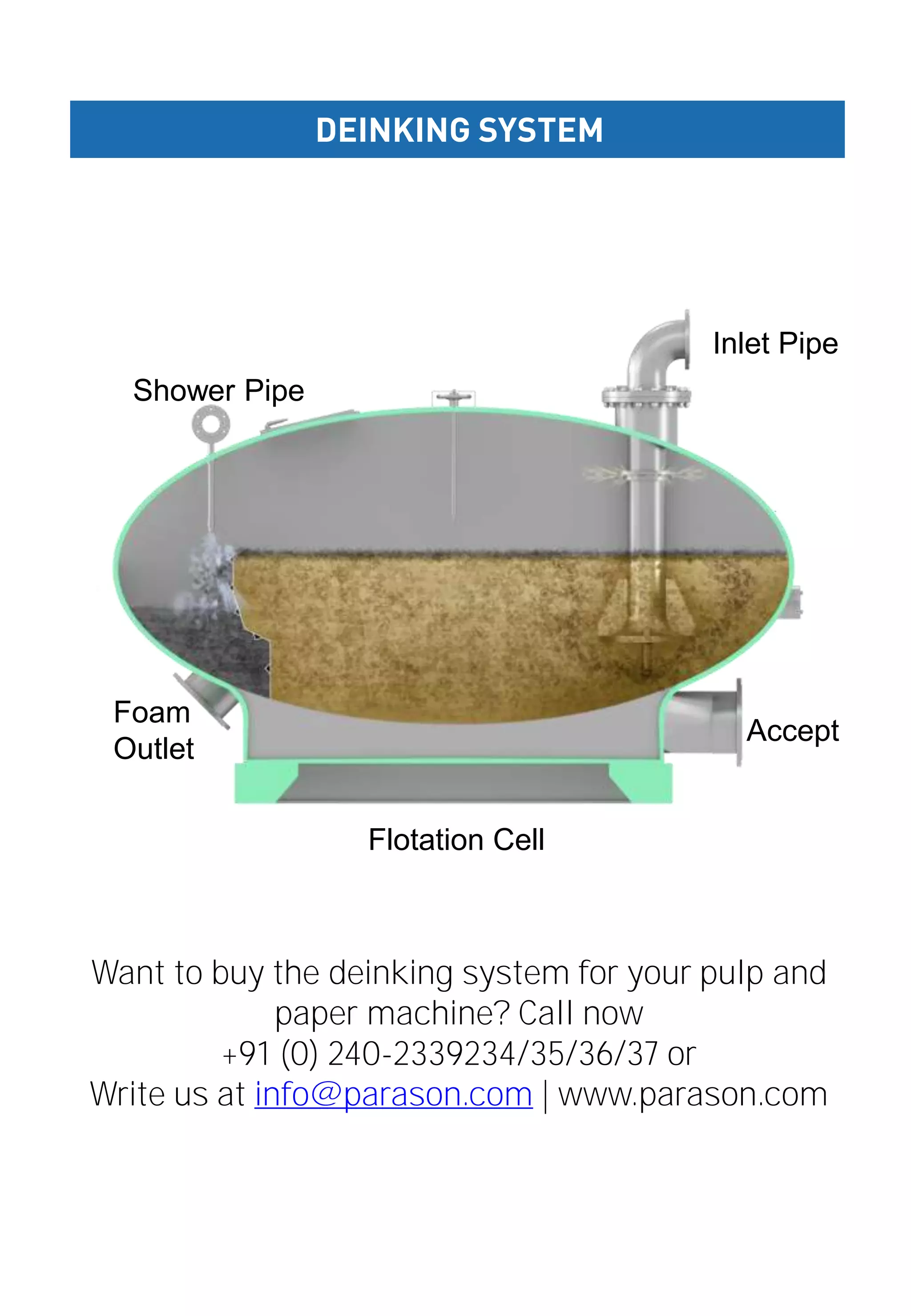

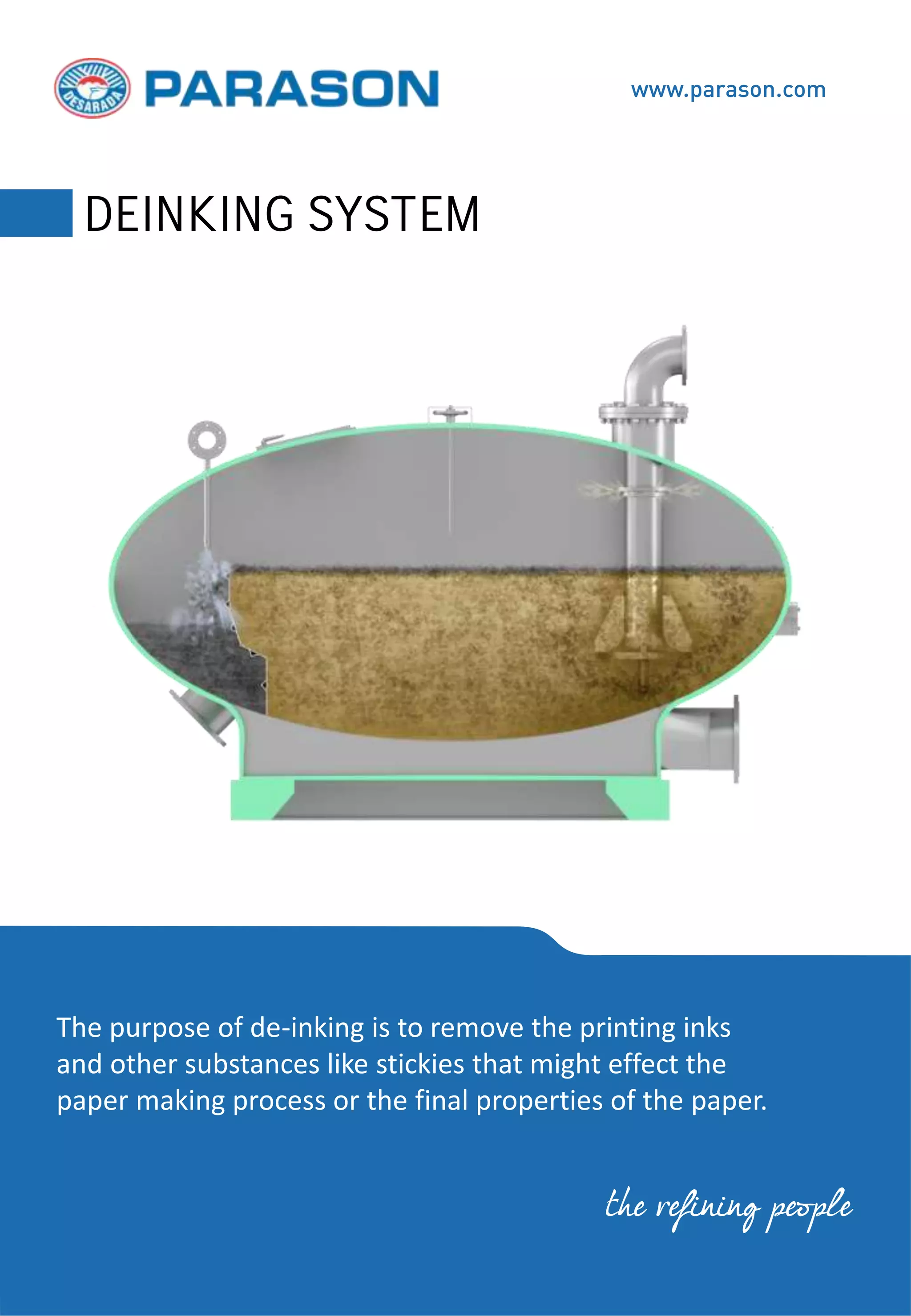

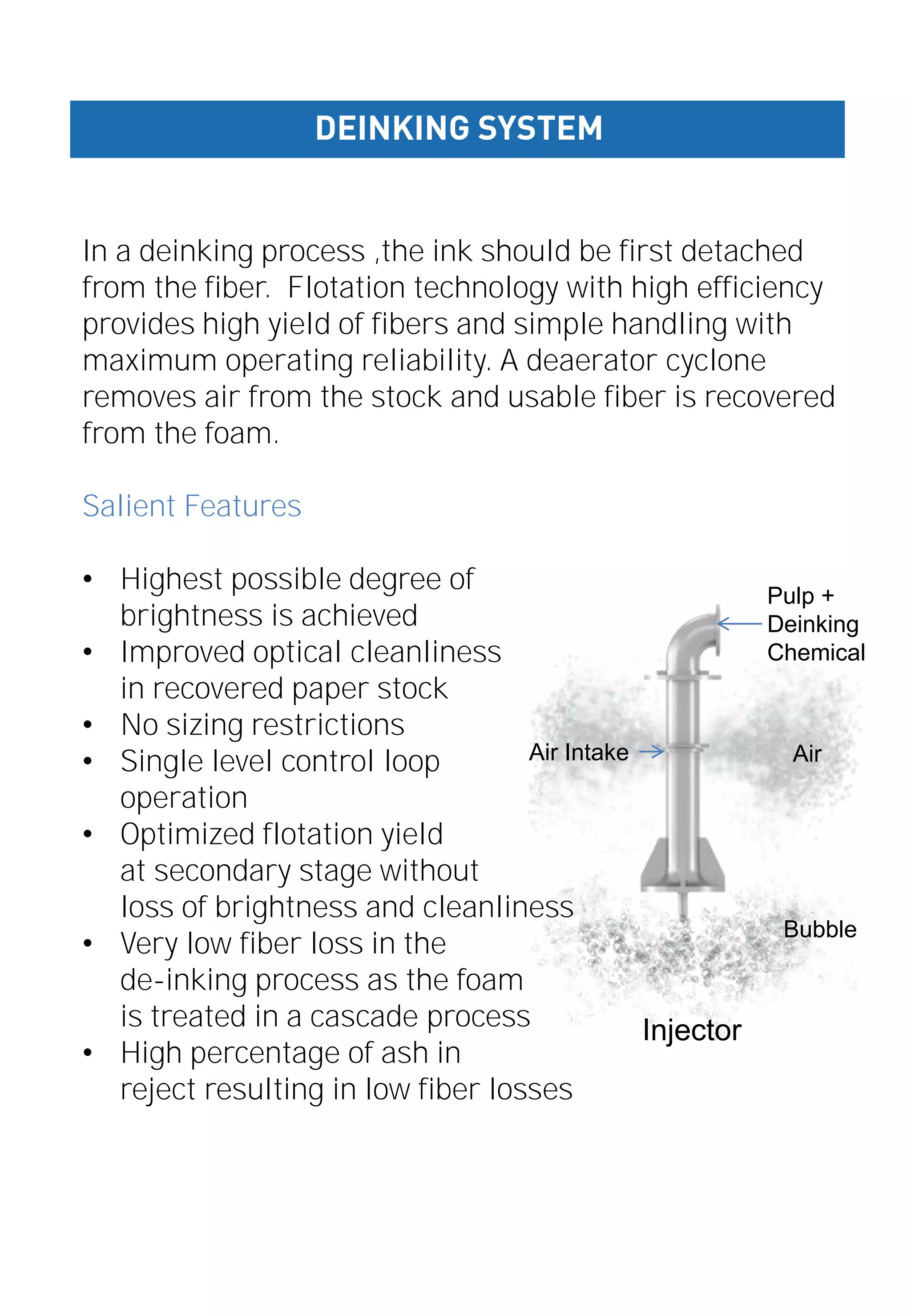

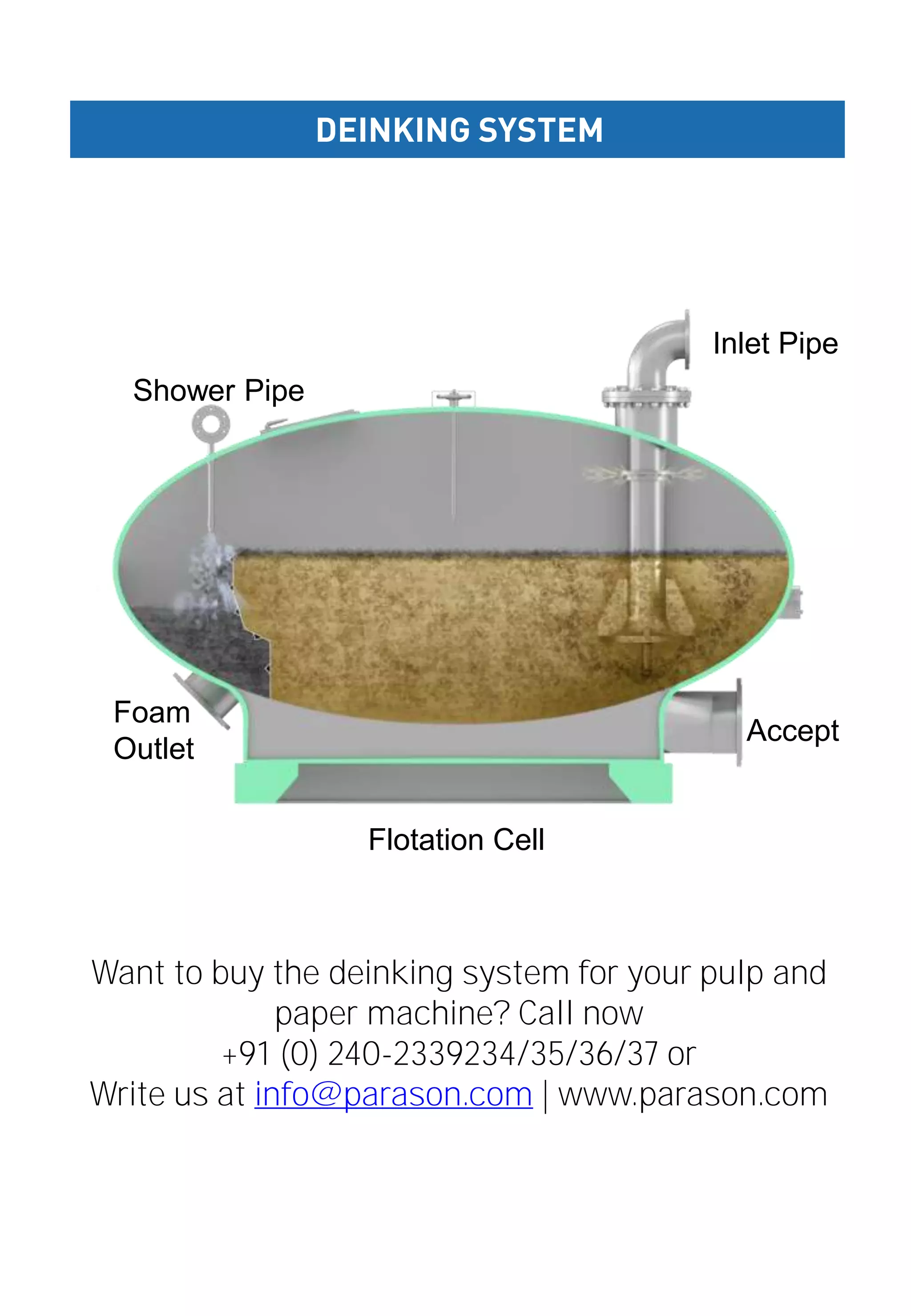

The document discusses de-inking processes used in papermaking. De-inking removes inks and other substances from recycled fibers so they do not interfere with papermaking or the final paper properties. The process first detaches inks from fibers using flotation technology for high fiber yield and simple handling. A deaerator cyclone then removes air and recovers usable fibers from the foam while achieving high brightness and cleanliness in the recovered paper stock.