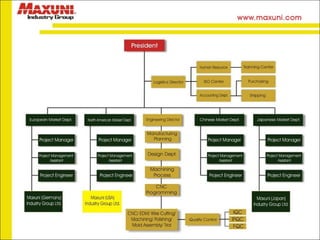

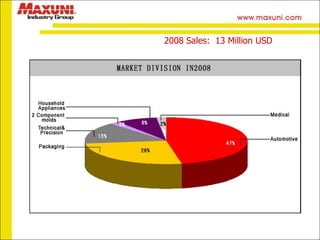

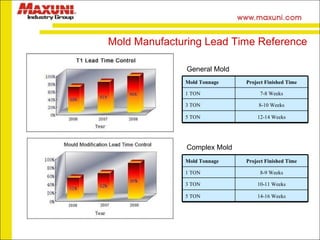

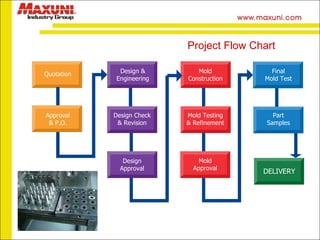

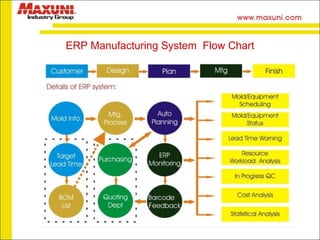

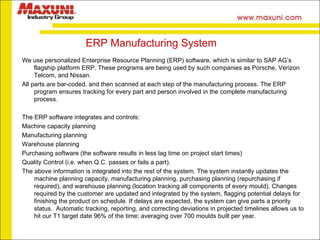

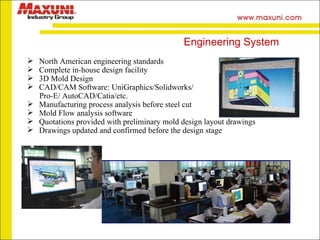

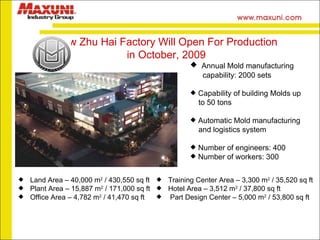

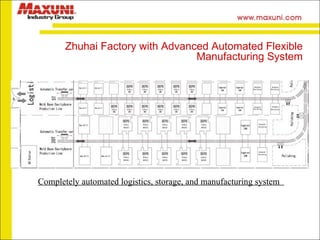

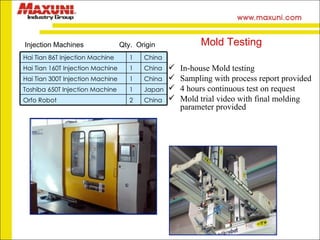

This company presentation provides an overview of Maxuni, a mold manufacturing company with offices in China, Germany, and plans to open an office in North America. It summarizes Maxuni's international team, sales and production figures from 2008, facilities and automated manufacturing capabilities, and customer industries served which include automotive and packaging. Maxuni aims to provide high quality molds on schedule through their engineering, manufacturing, and quality control processes.

![Yang Gang Industrial Area Ren Tian, Fu Yong, Bao An District Shenzhen, 518103 China Phone: +86-755-2996-7108 Fax: +86-755-2996-7708 Email: [email_address] Main Office located in Shenzhen, China German Office serving Europe Emsteker Str. 13A 49661 Cloppenburg Germany Phone: +49-4471-88-271-0 Fax: +49-4471-88-271-17 Email: [email_address] Marketing Design & Confirmation Project Management After-Sale Service North American Office to open in 2010](https://image.slidesharecdn.com/maxunipresentation2009usnew-124840931209-phpapp01/85/Maxuni-Presentation-2009-Us-New-36-320.jpg)