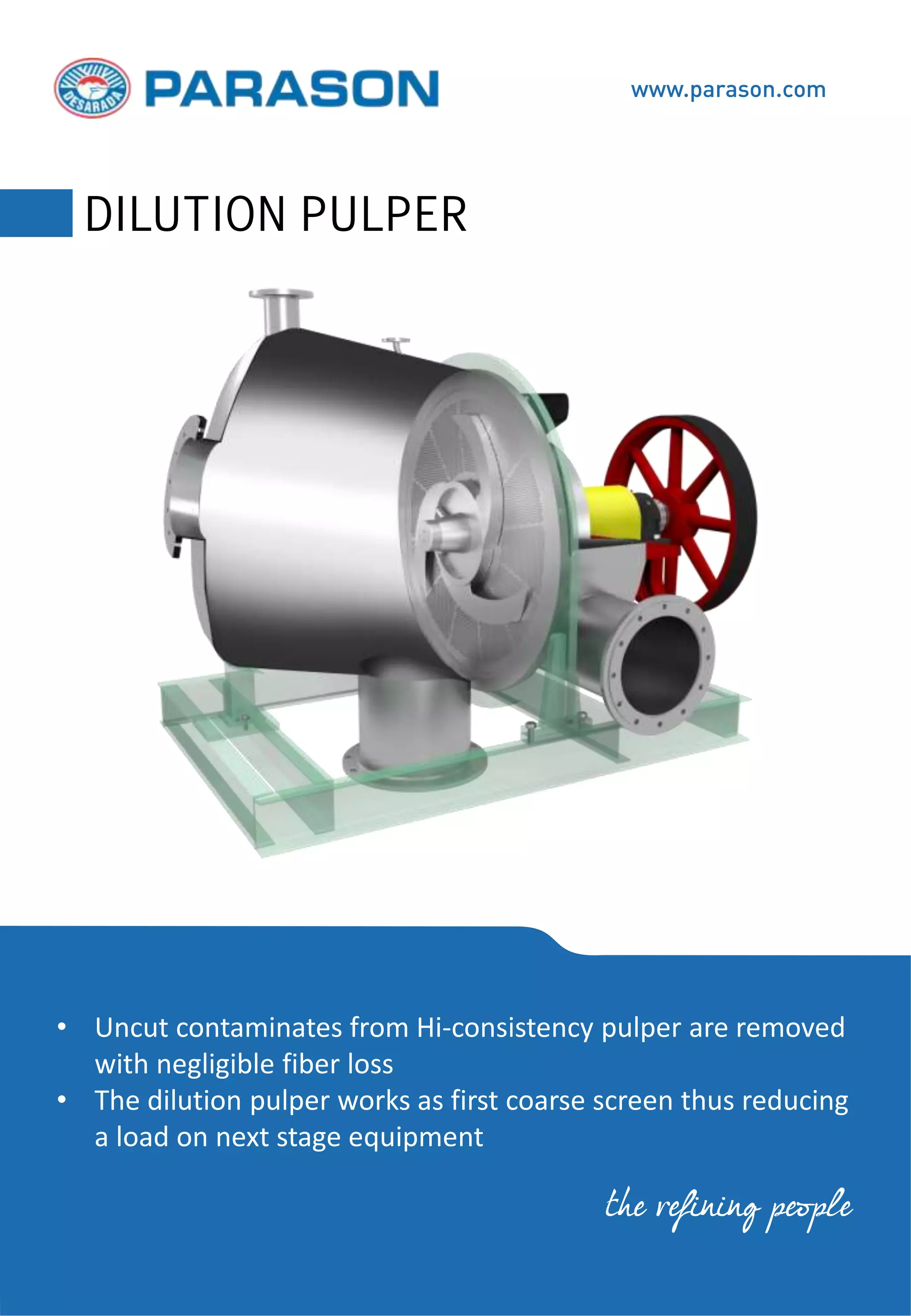

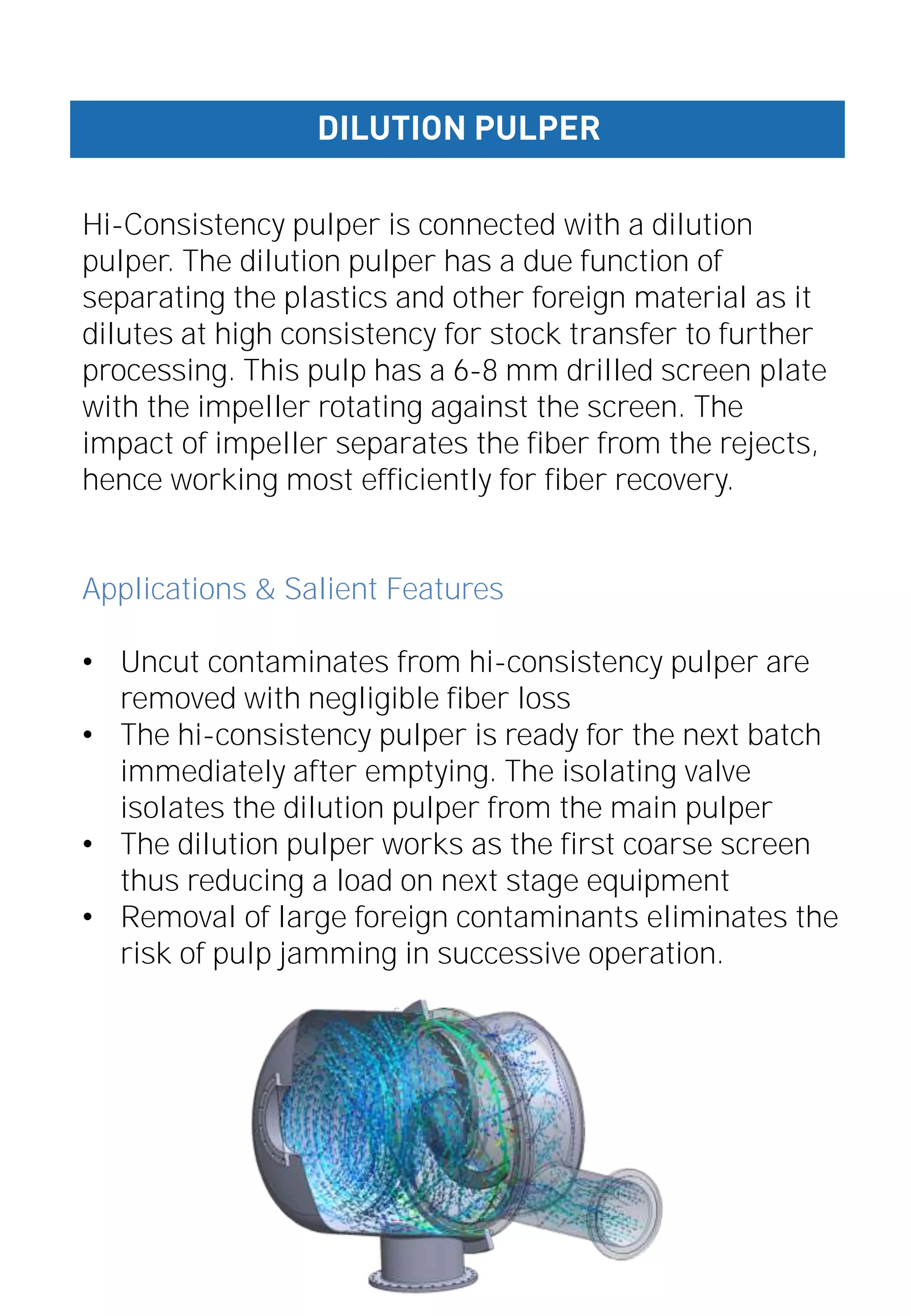

The document discusses the functions and benefits of a dilution pulper, which operates alongside a hi-consistency pulper to remove contaminants while preserving fiber. It highlights the efficiency of the dilution pulper in separating plastics and foreign materials, allowing for smoother processing in subsequent stages. Key features include minimal fiber loss during contaminant removal and immediate readiness for the next batch after operation.