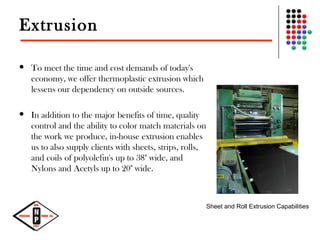

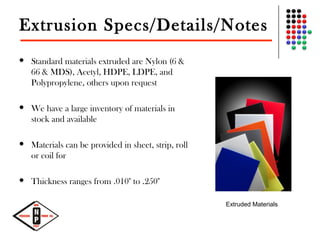

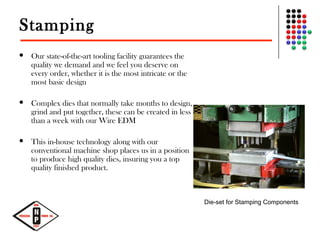

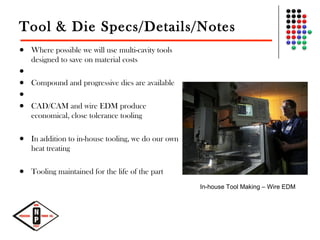

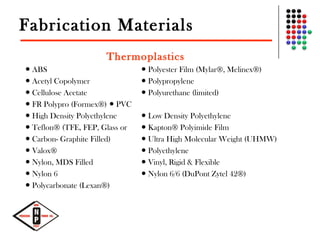

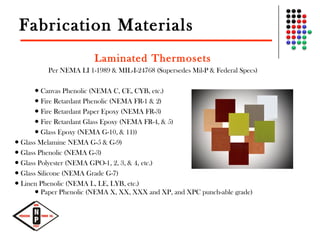

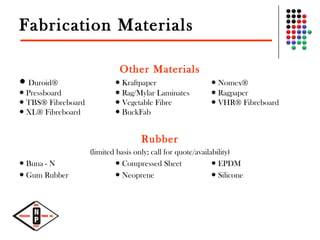

New Process Fibre Company provides custom stamped non-metallic parts and thermoplastic extrusion. They have over 80 years of experience and a 60,000 square foot facility. Their mission is to provide exceptional value, quality, and service as a leading manufacturer. They use various materials and have in-house extrusion, stamping, and toolmaking capabilities. Quality is their top priority and they have ISO certification to support their commitment to continuous improvement and customer satisfaction.