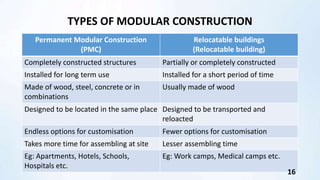

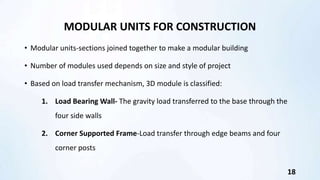

The document provides an extensive overview of modular high-rise construction, highlighting the differences between modular and prefabricated construction, the modular building process, and various construction techniques. It discusses types of modular units, inter-module joining techniques, and presents case studies showcasing successful applications of modular technology in high-rise buildings. The advantages and limitations of modular high-rise construction are addressed, emphasizing its speed, cost-effectiveness, and sustainability in meeting the demand for urban housing.