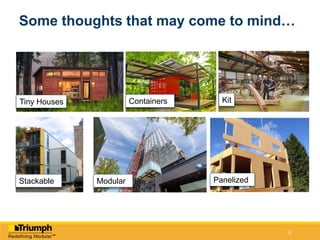

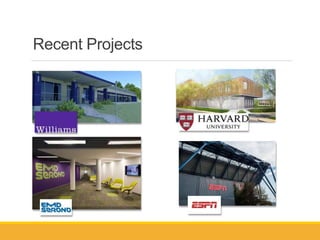

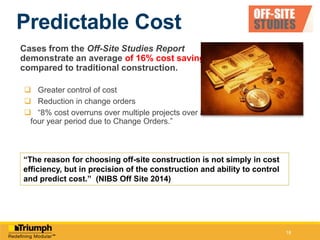

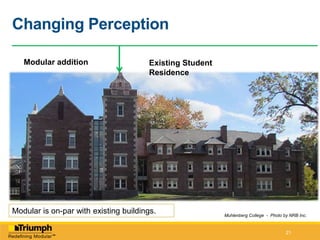

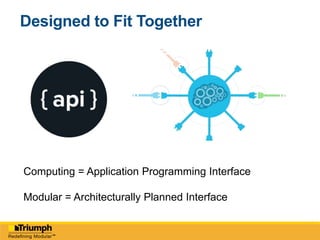

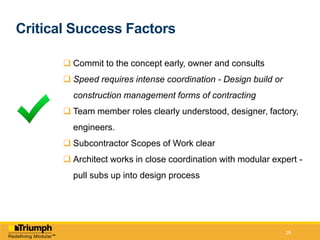

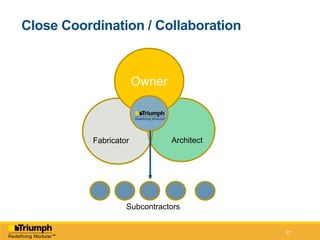

The document discusses the critical success factors for modular construction, highlighting its advantages such as accelerated timelines, cost savings, and increased safety. Modular construction is defined as off-site, factory-built structures that can be designed with flexibility in mind, suitable for modern buildings. Key considerations for adopting modular practices include early commitment, clear roles for team members, and careful coordination among all stakeholders.