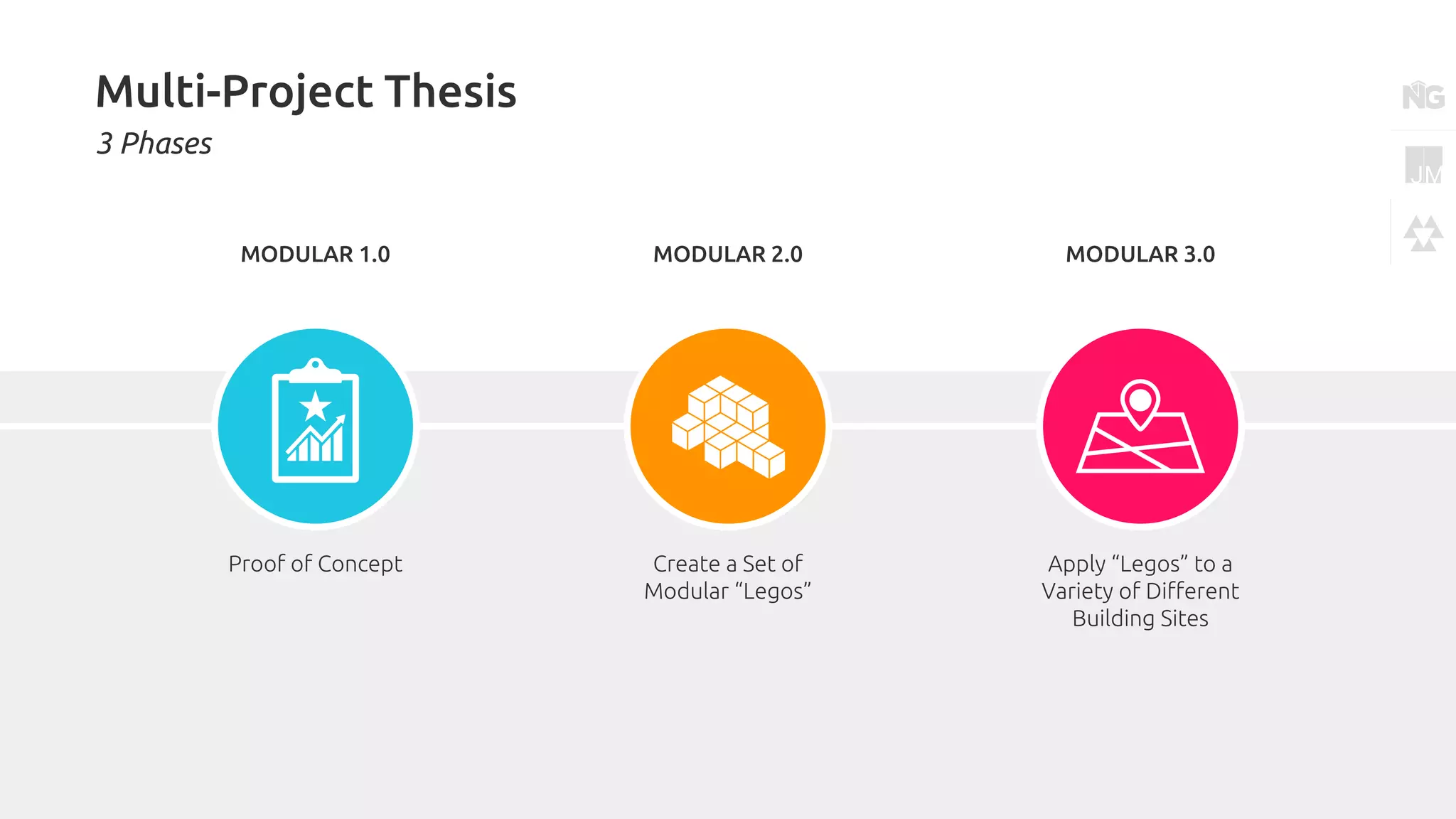

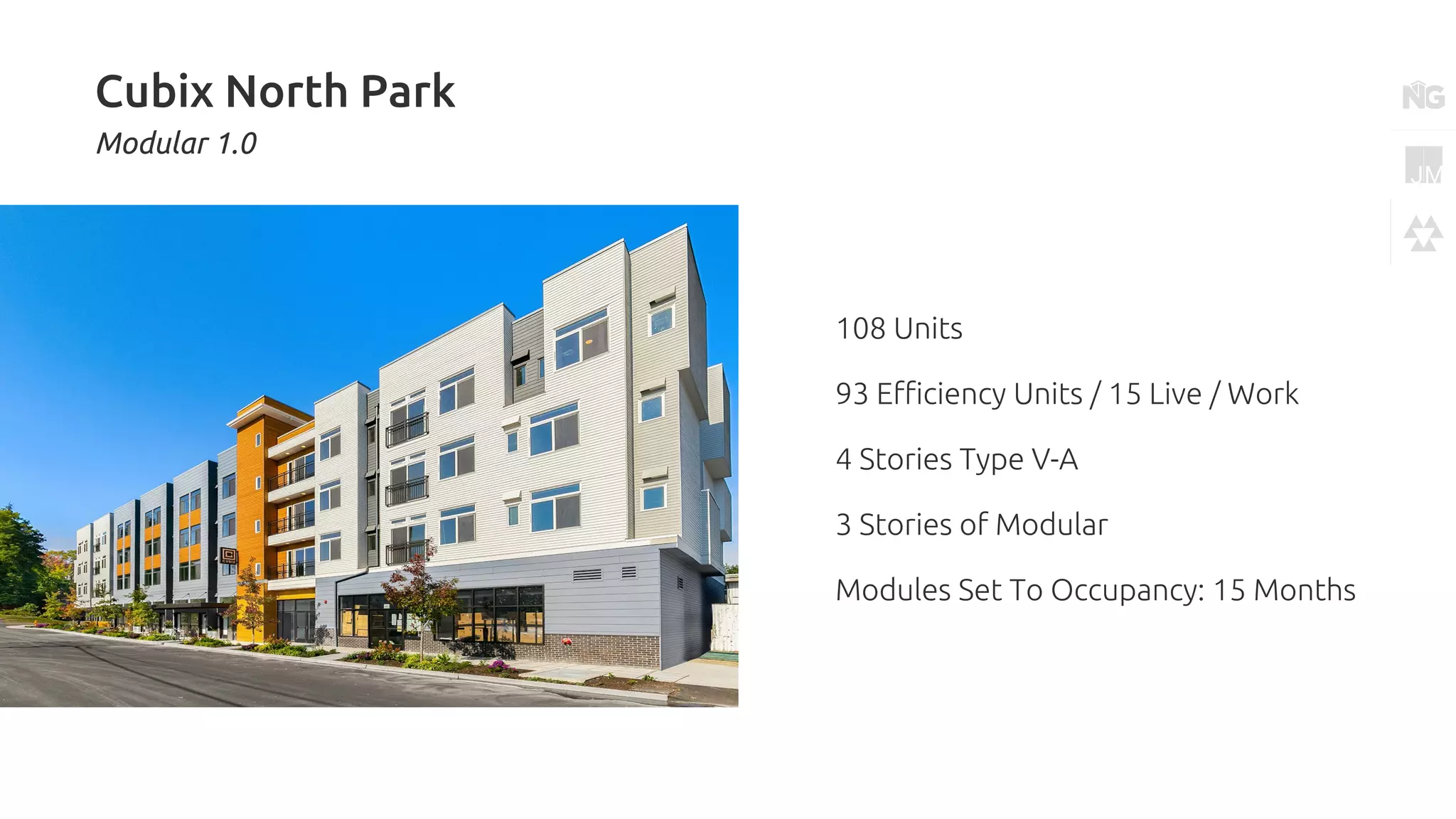

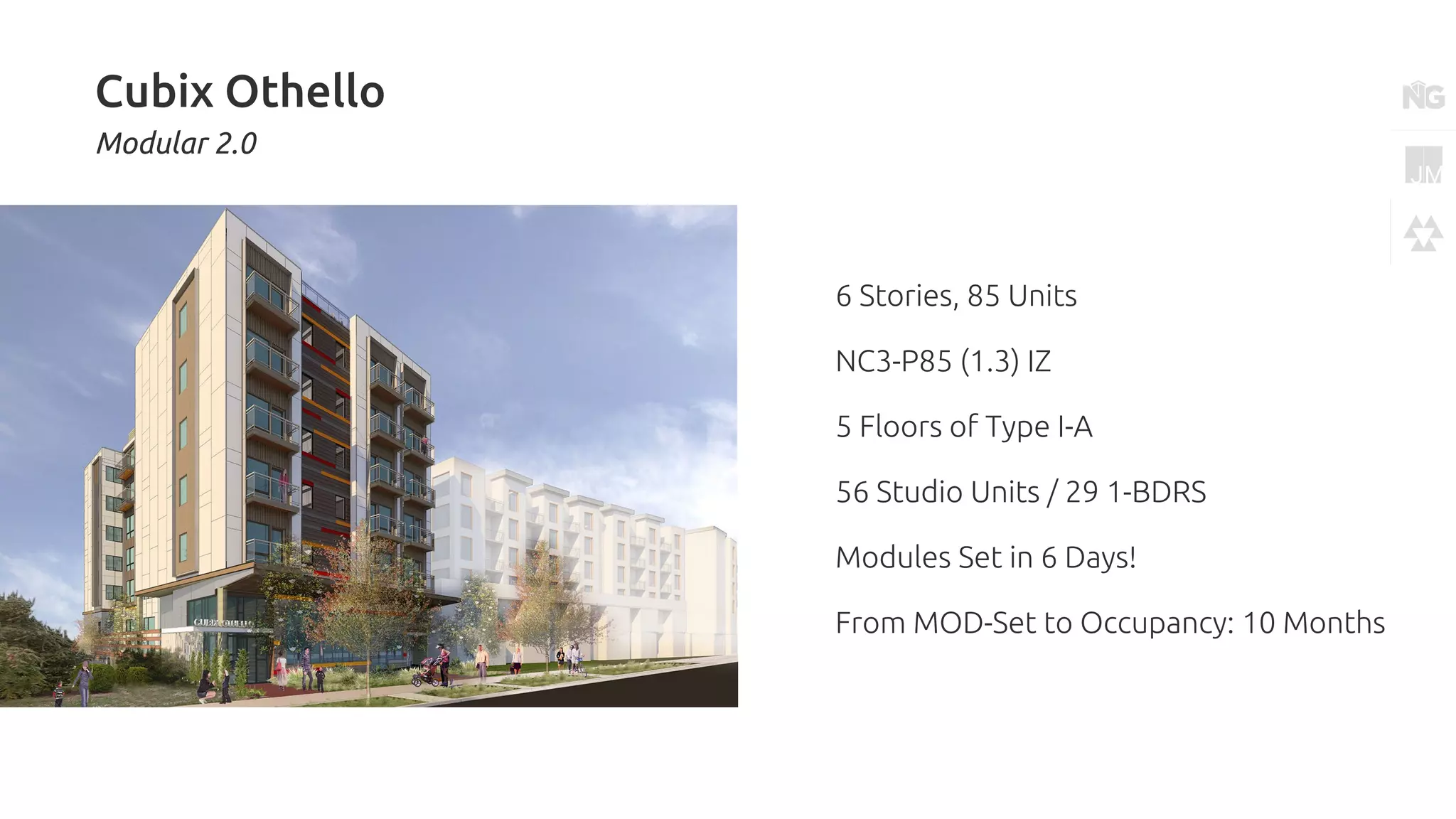

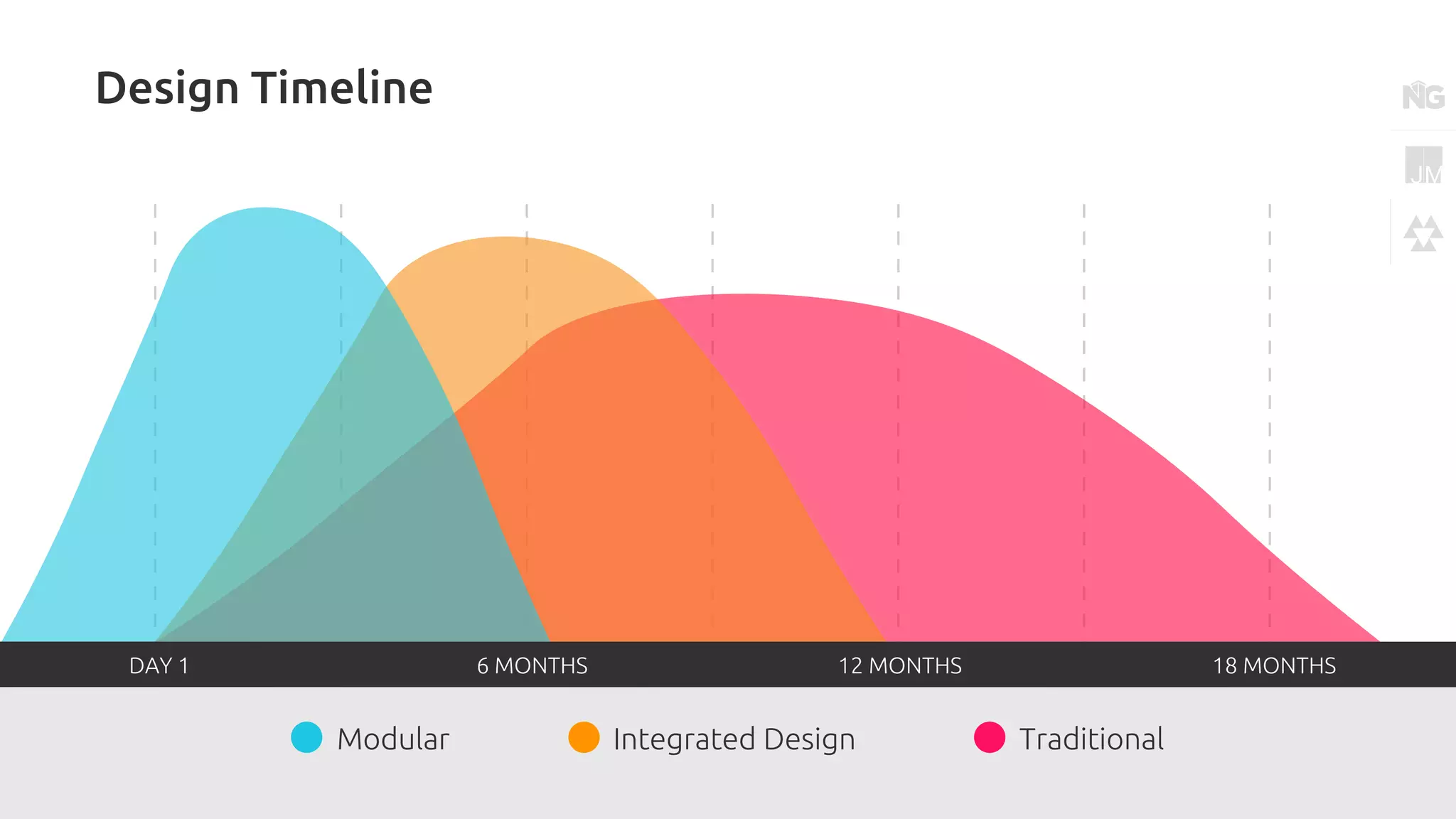

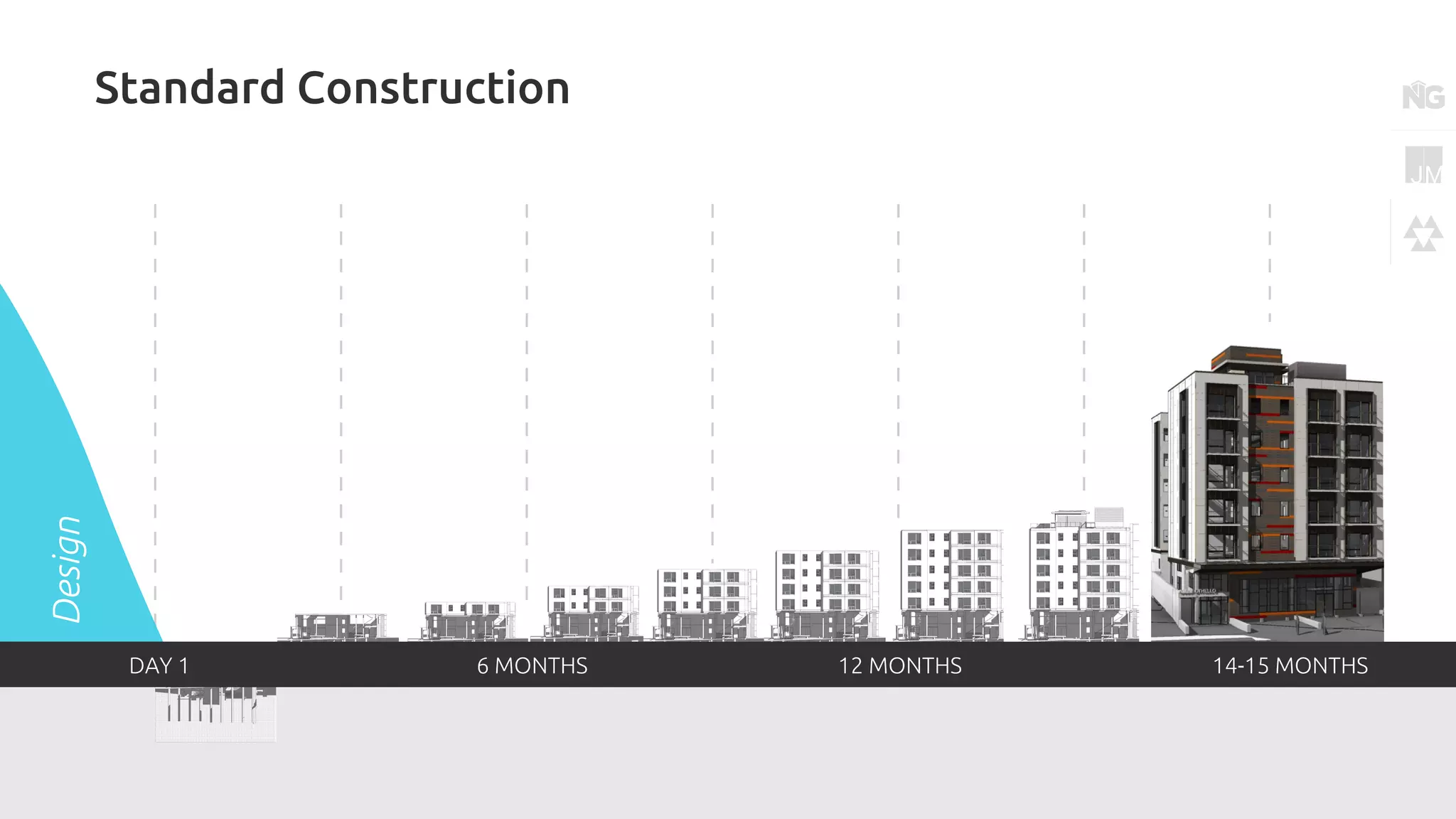

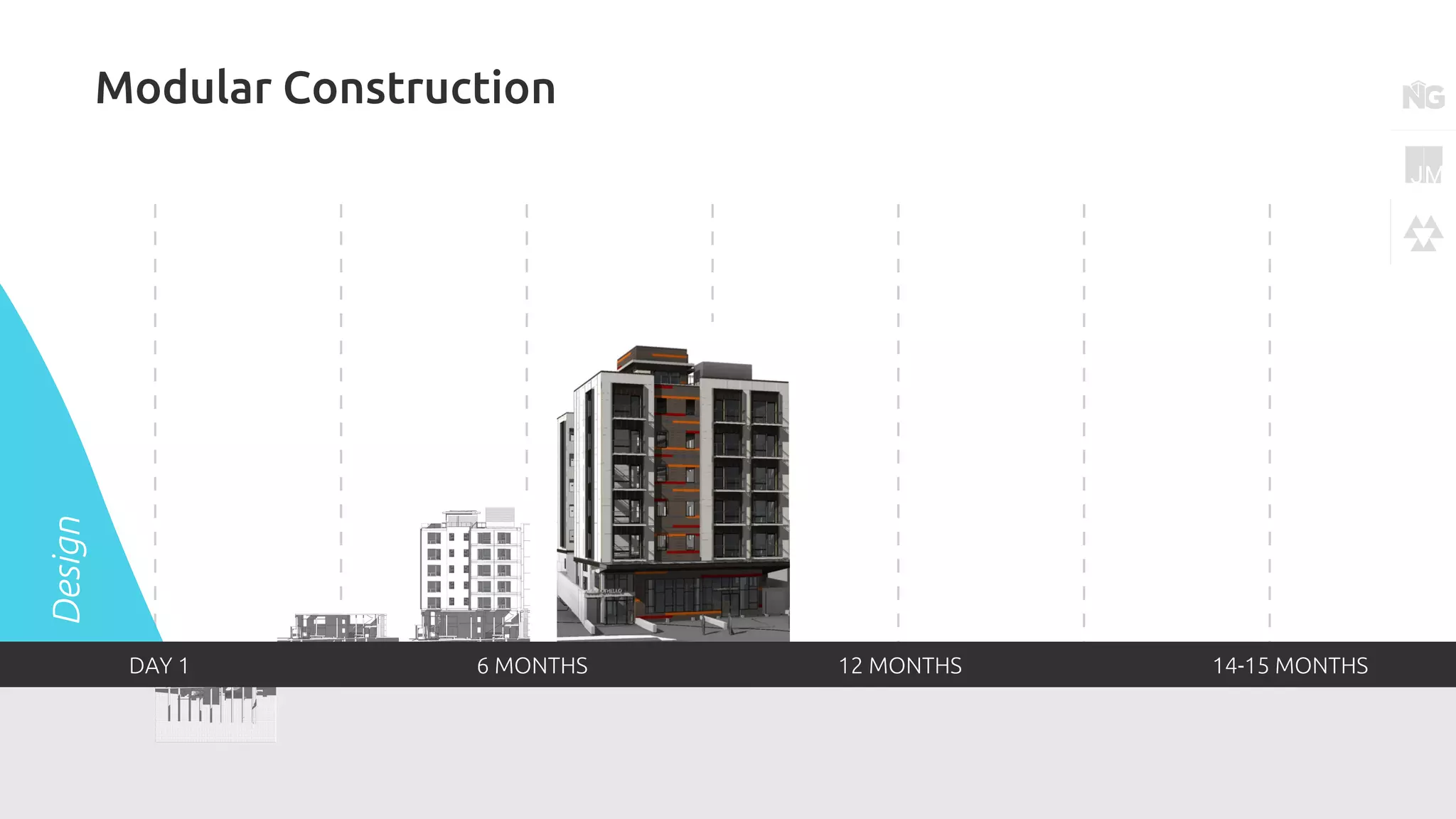

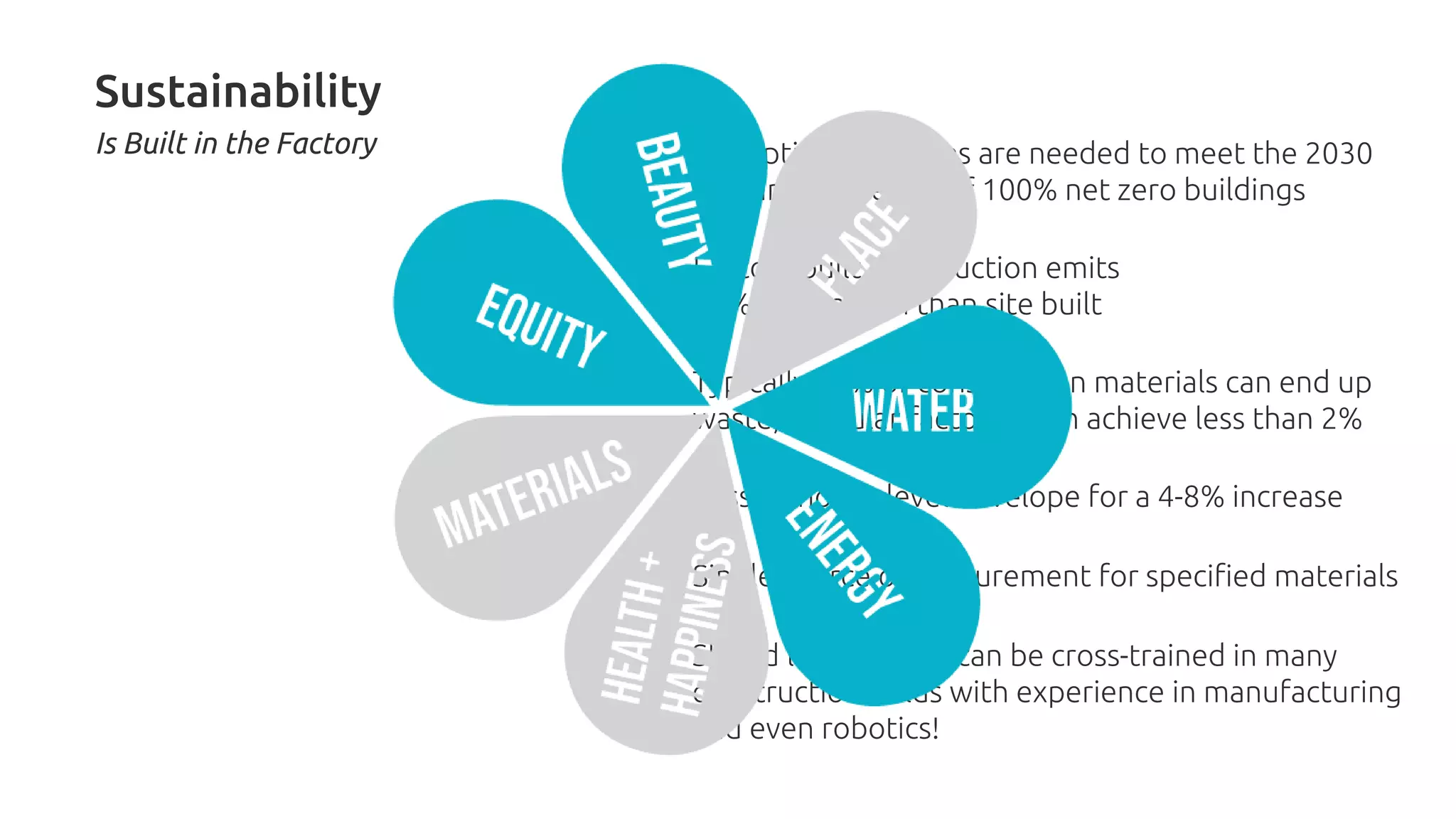

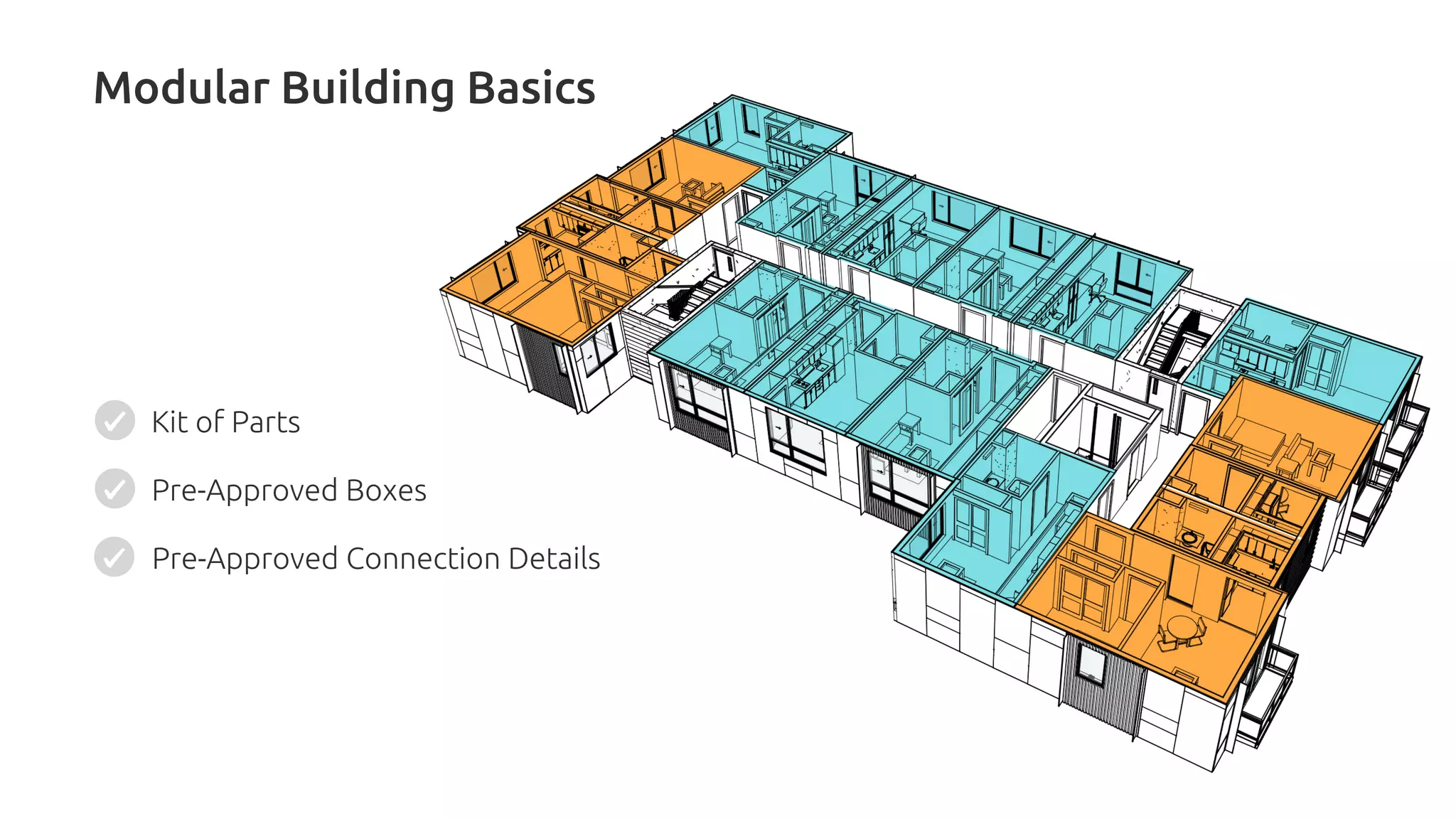

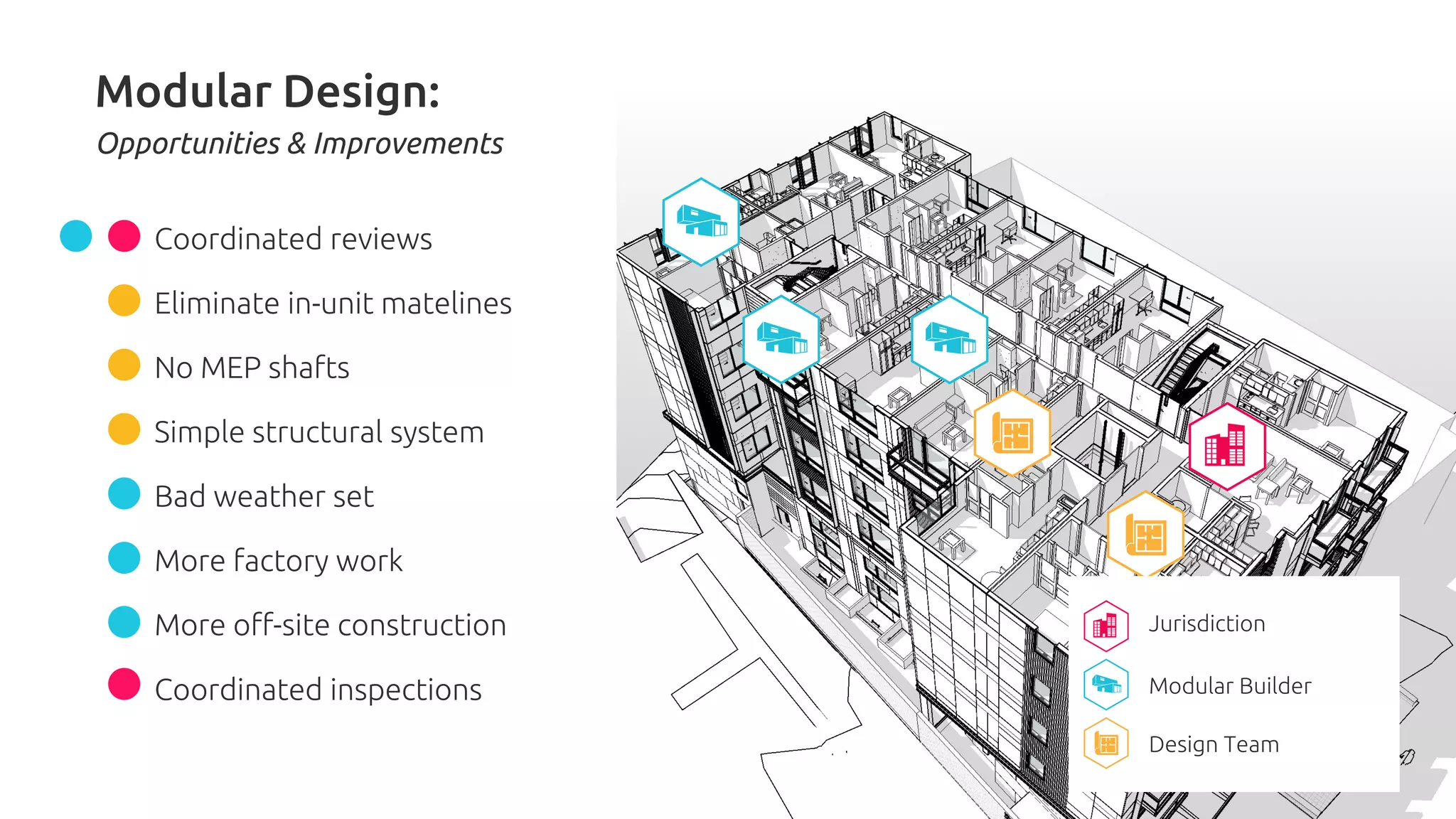

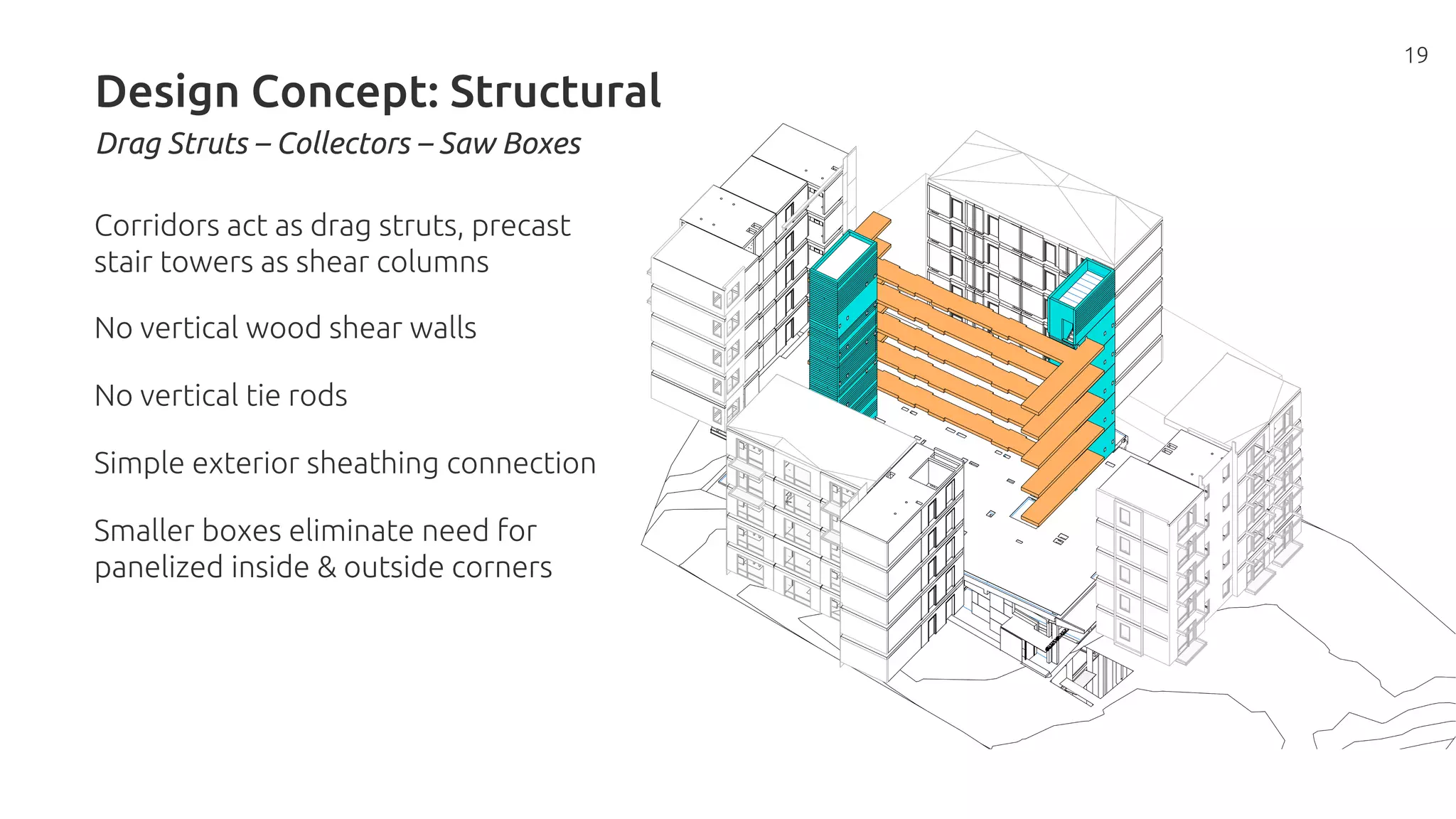

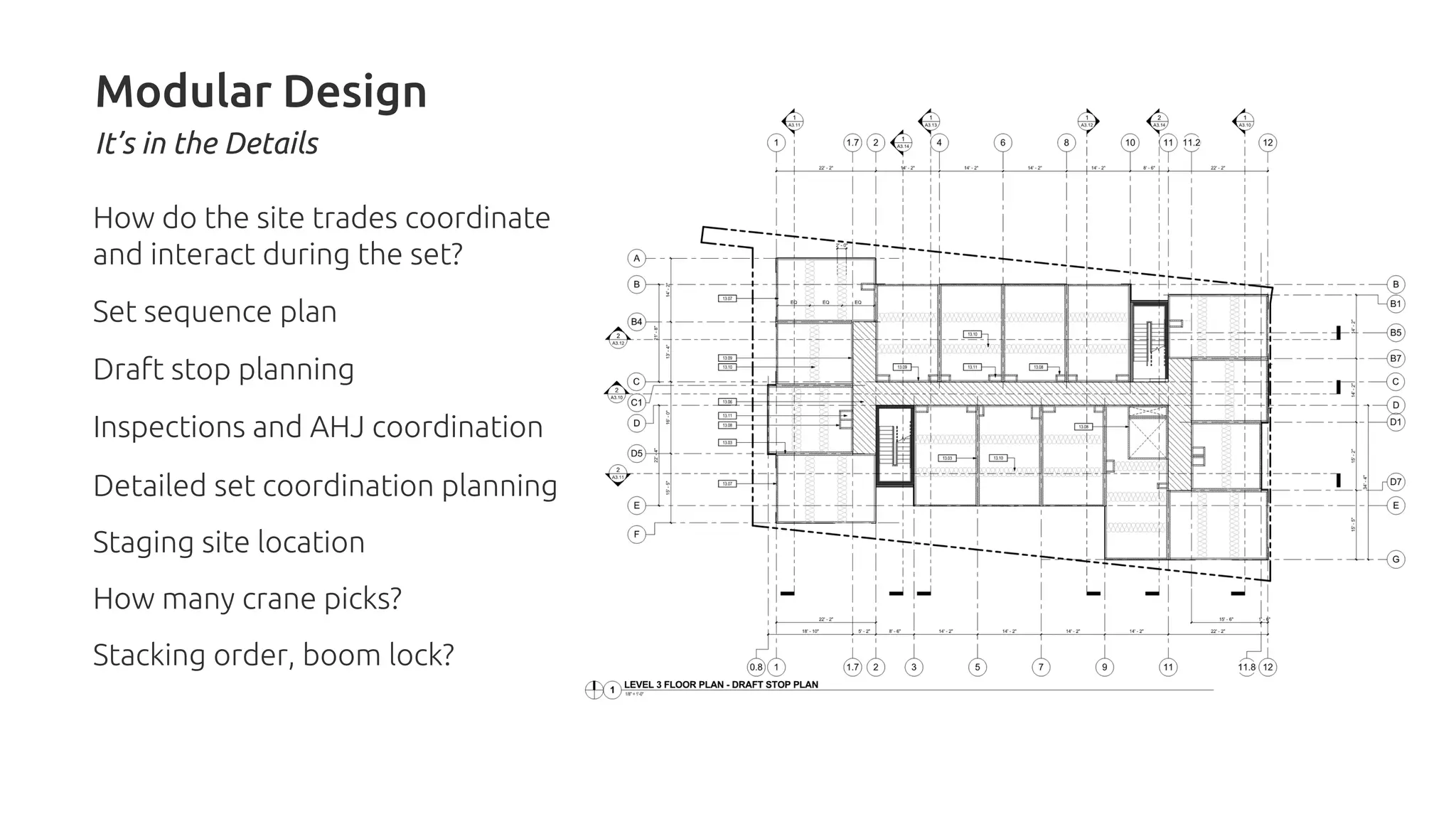

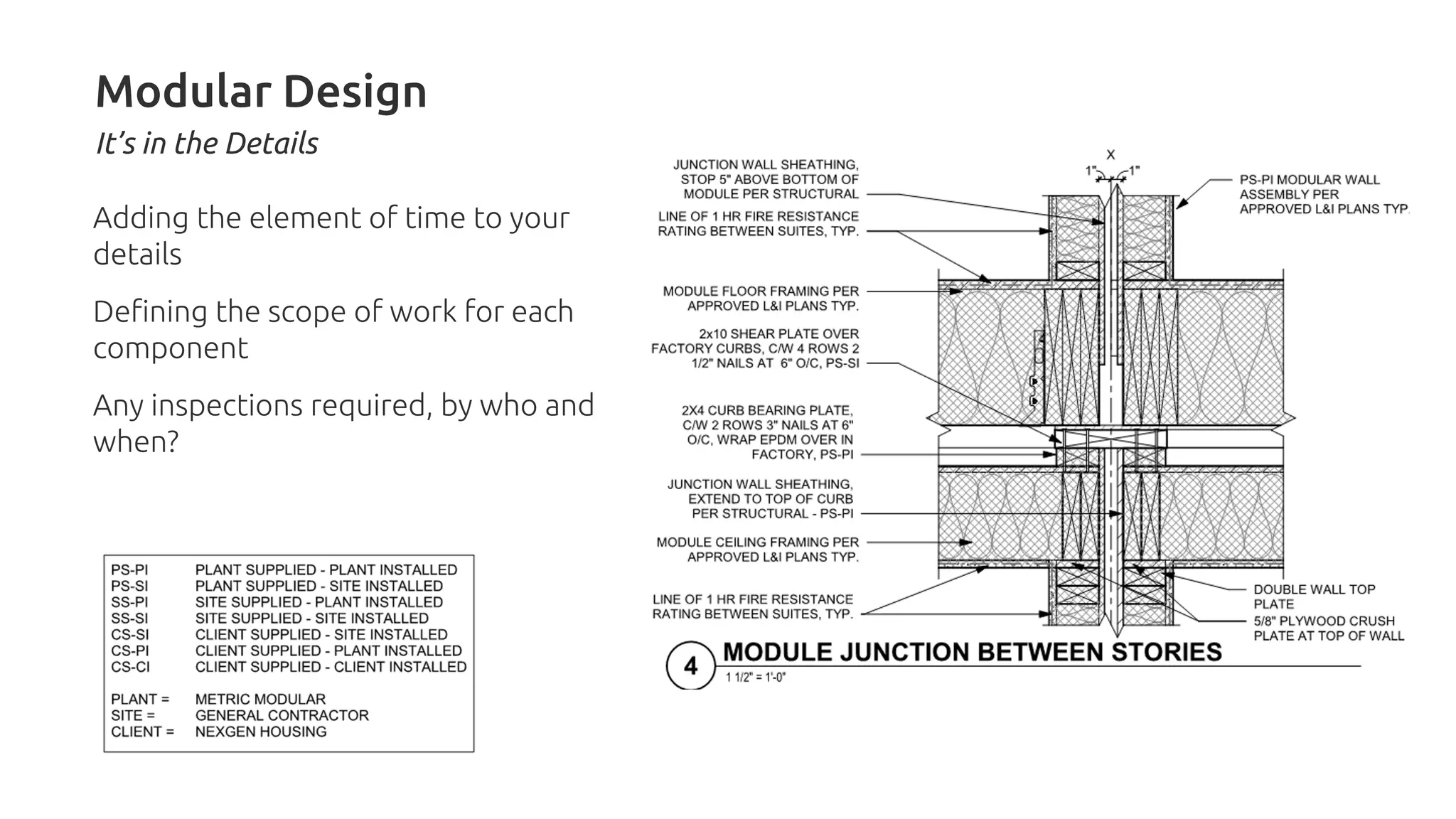

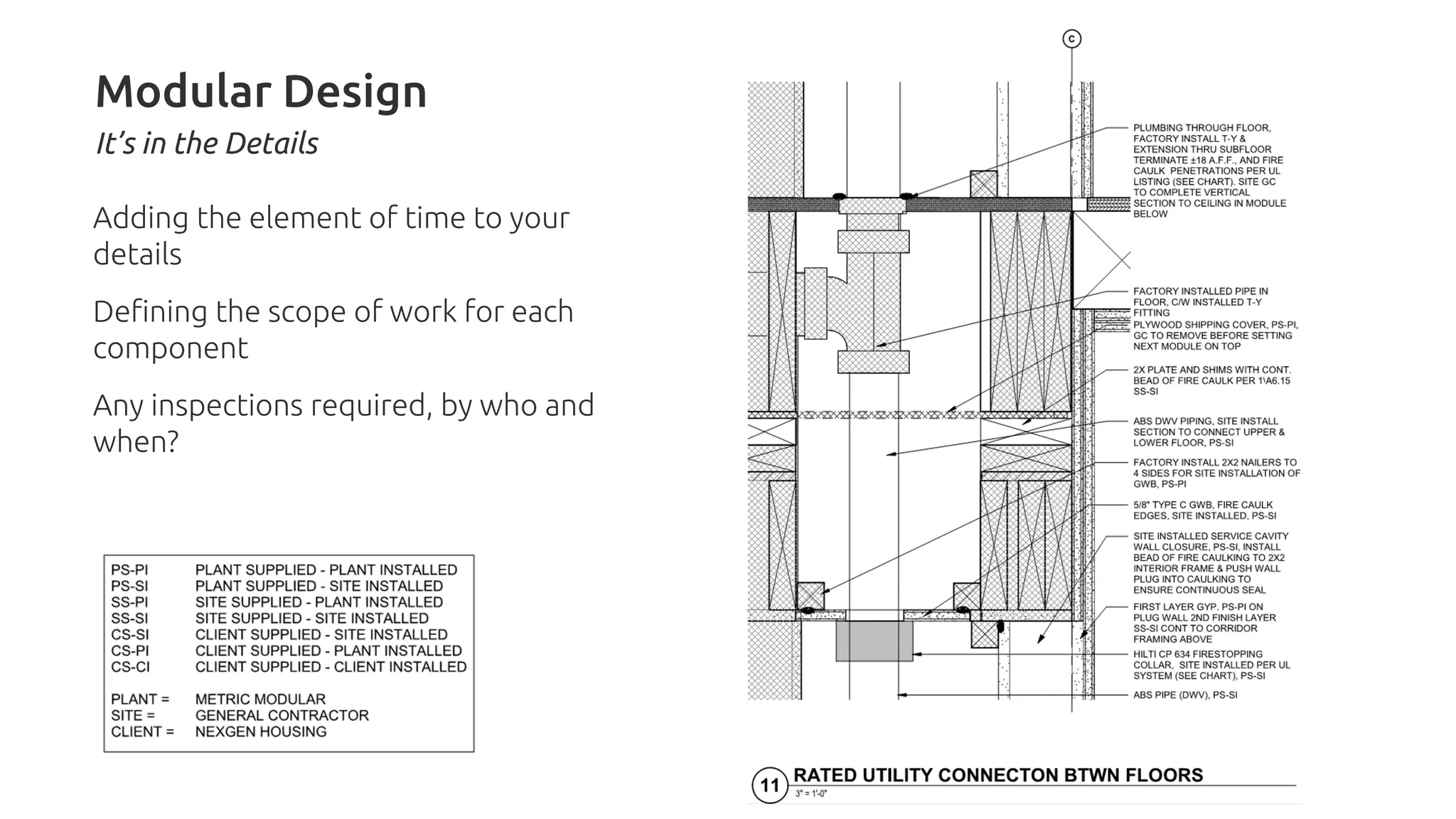

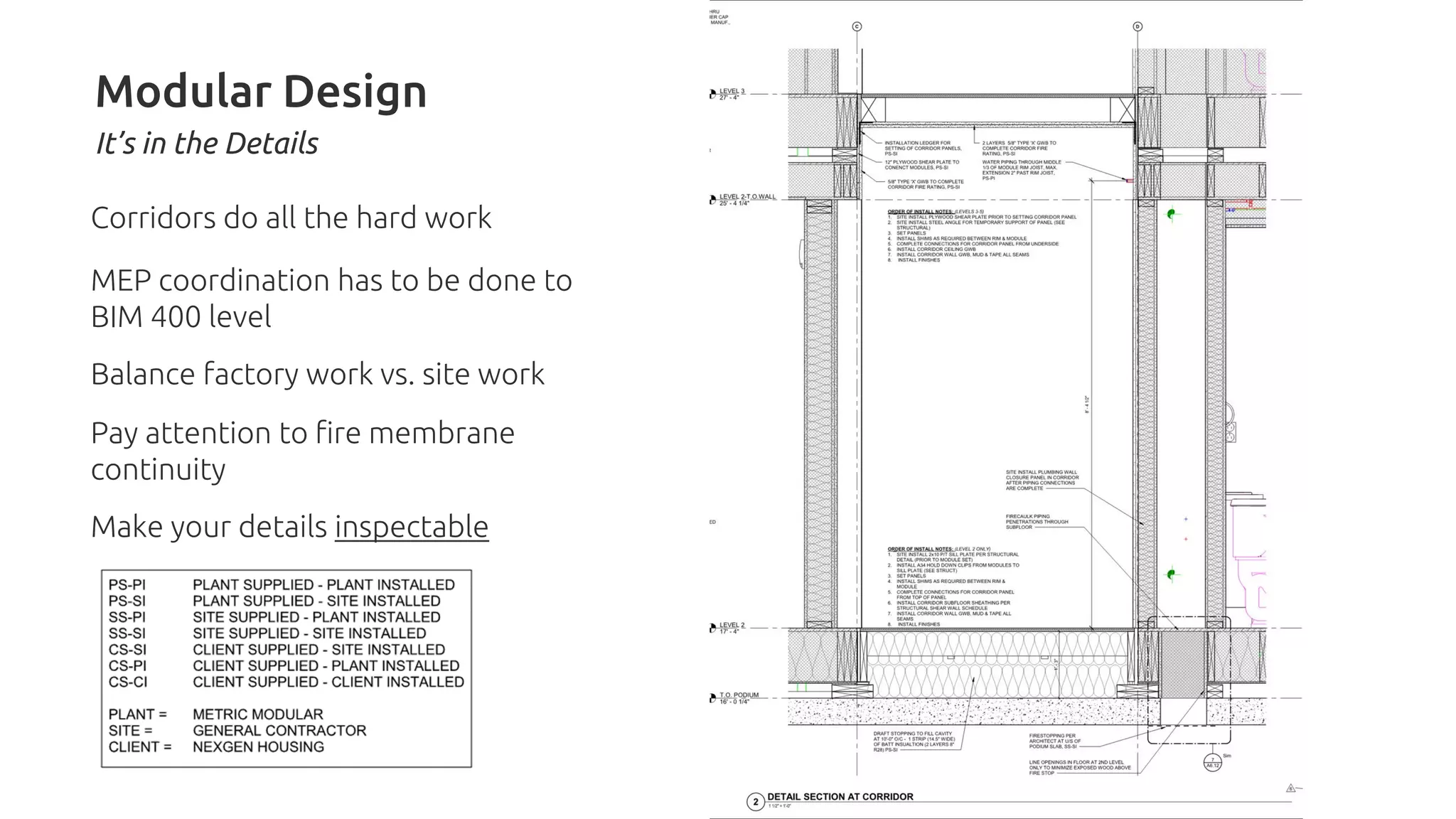

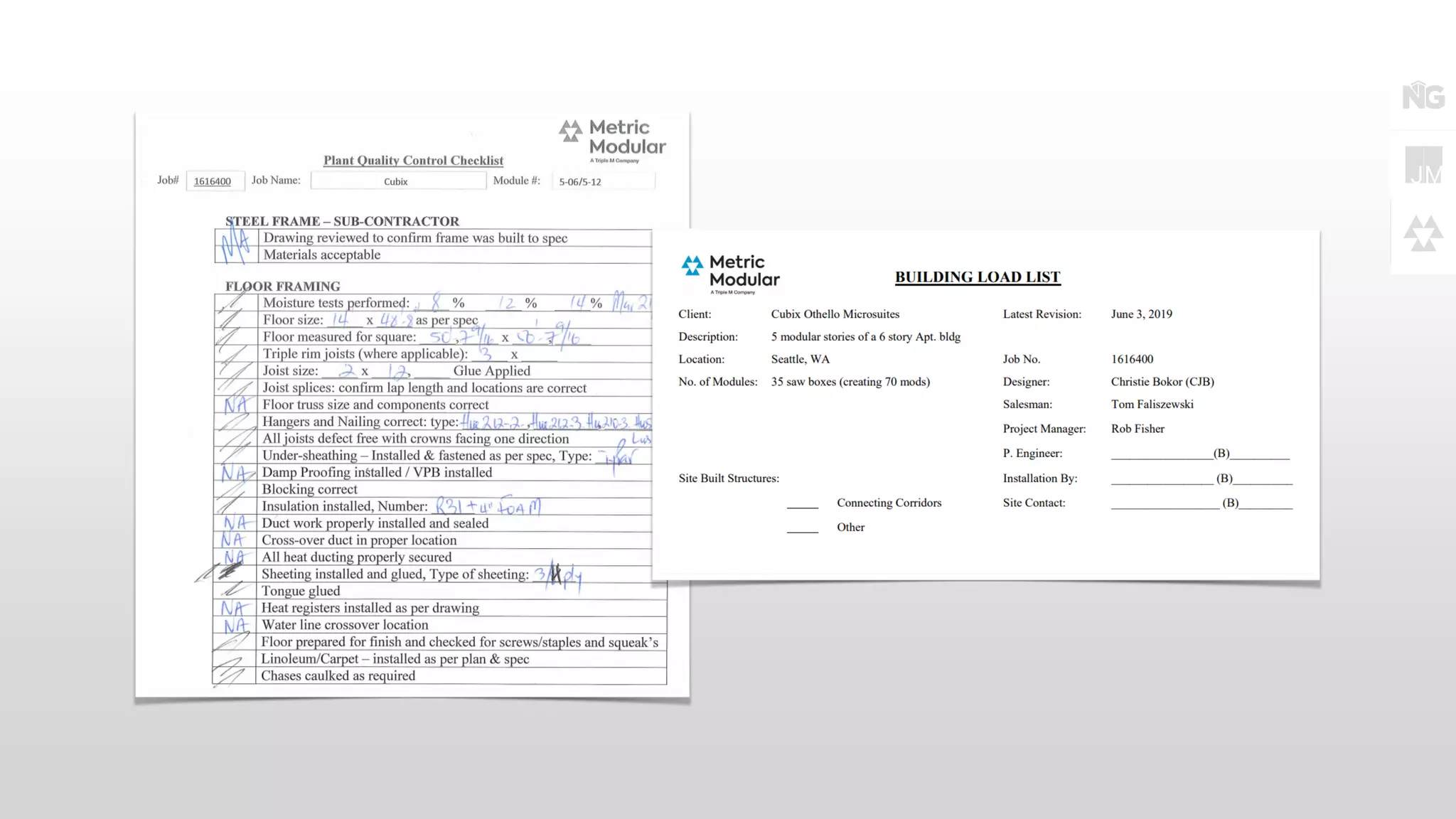

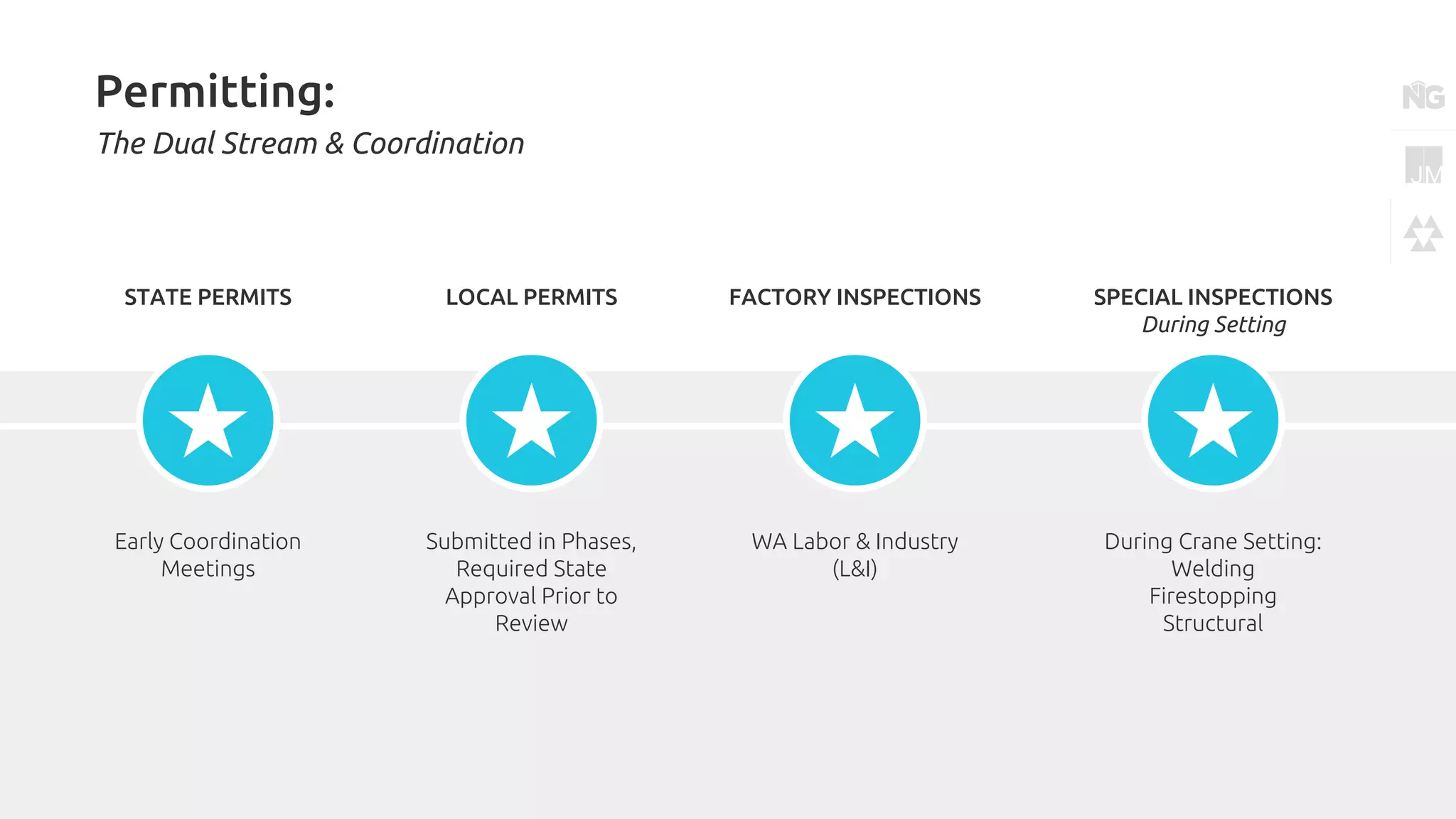

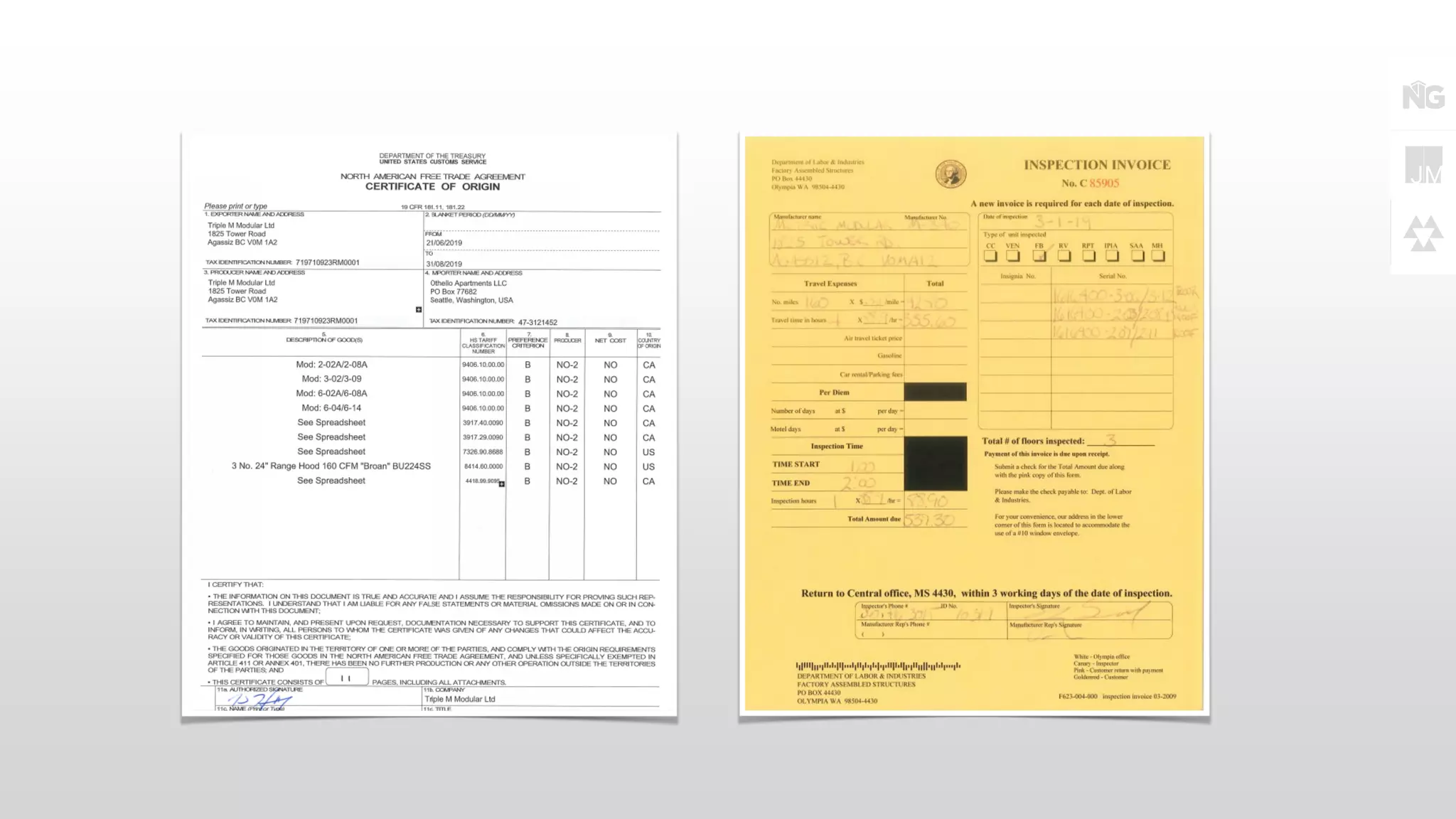

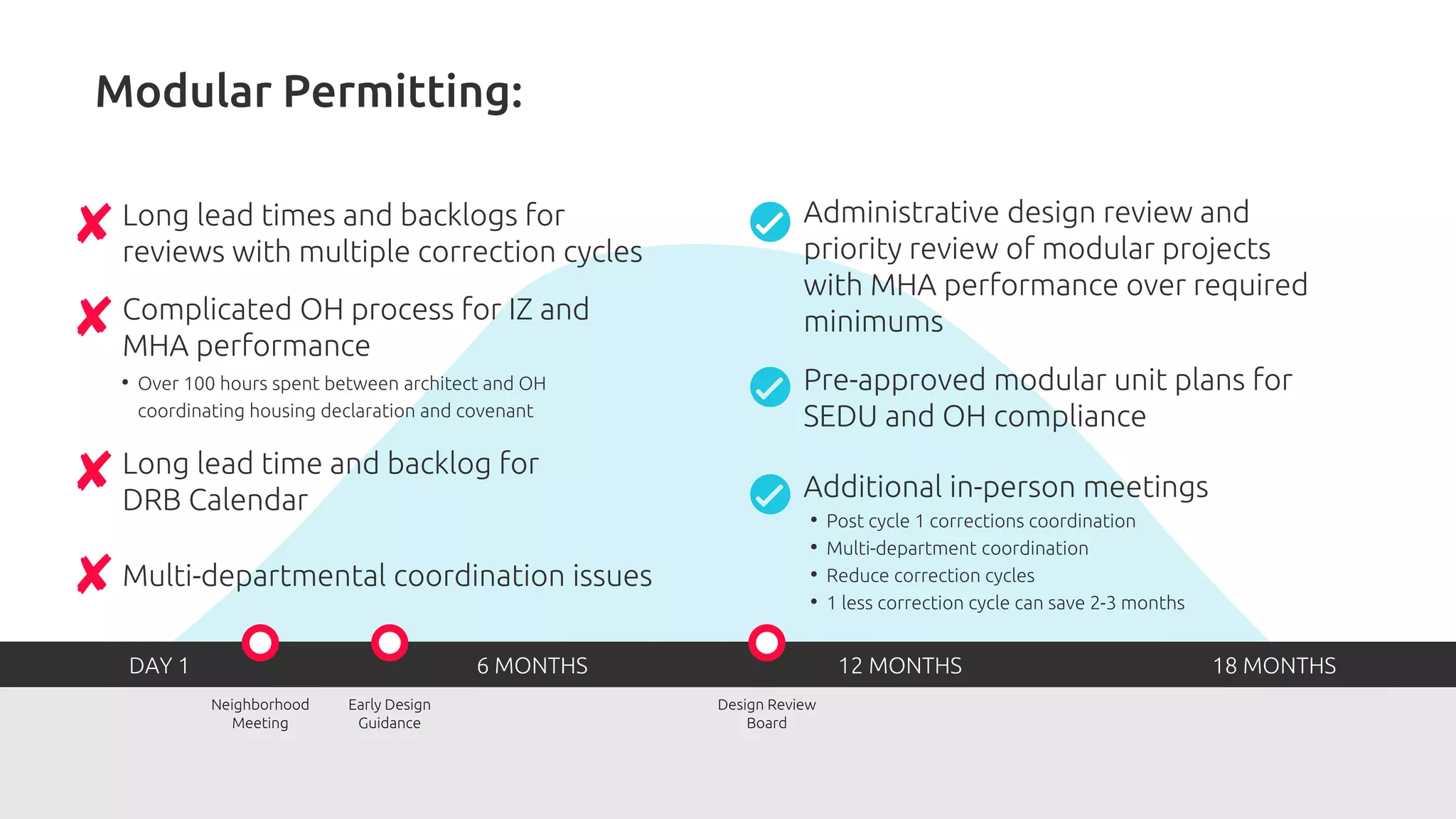

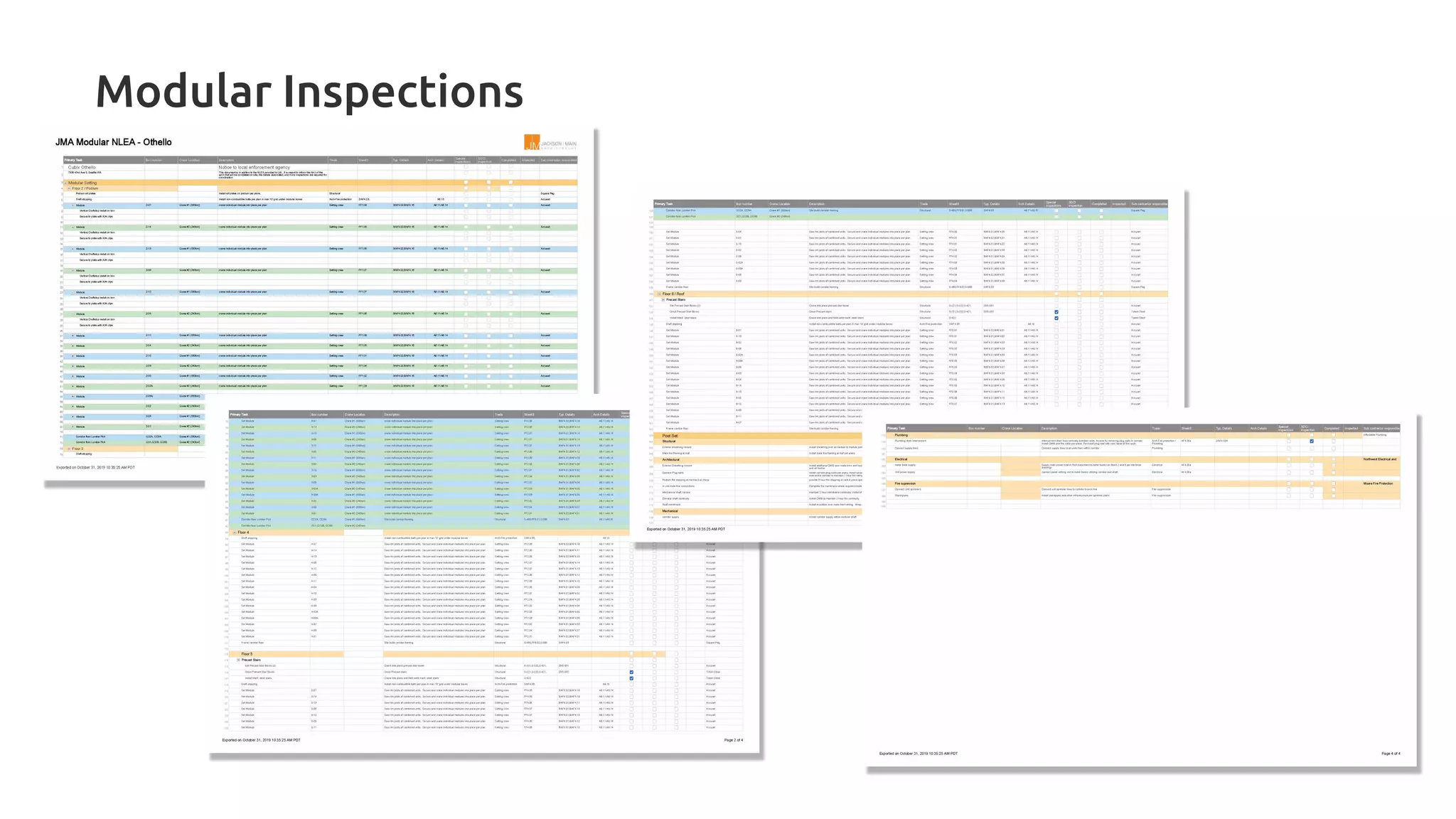

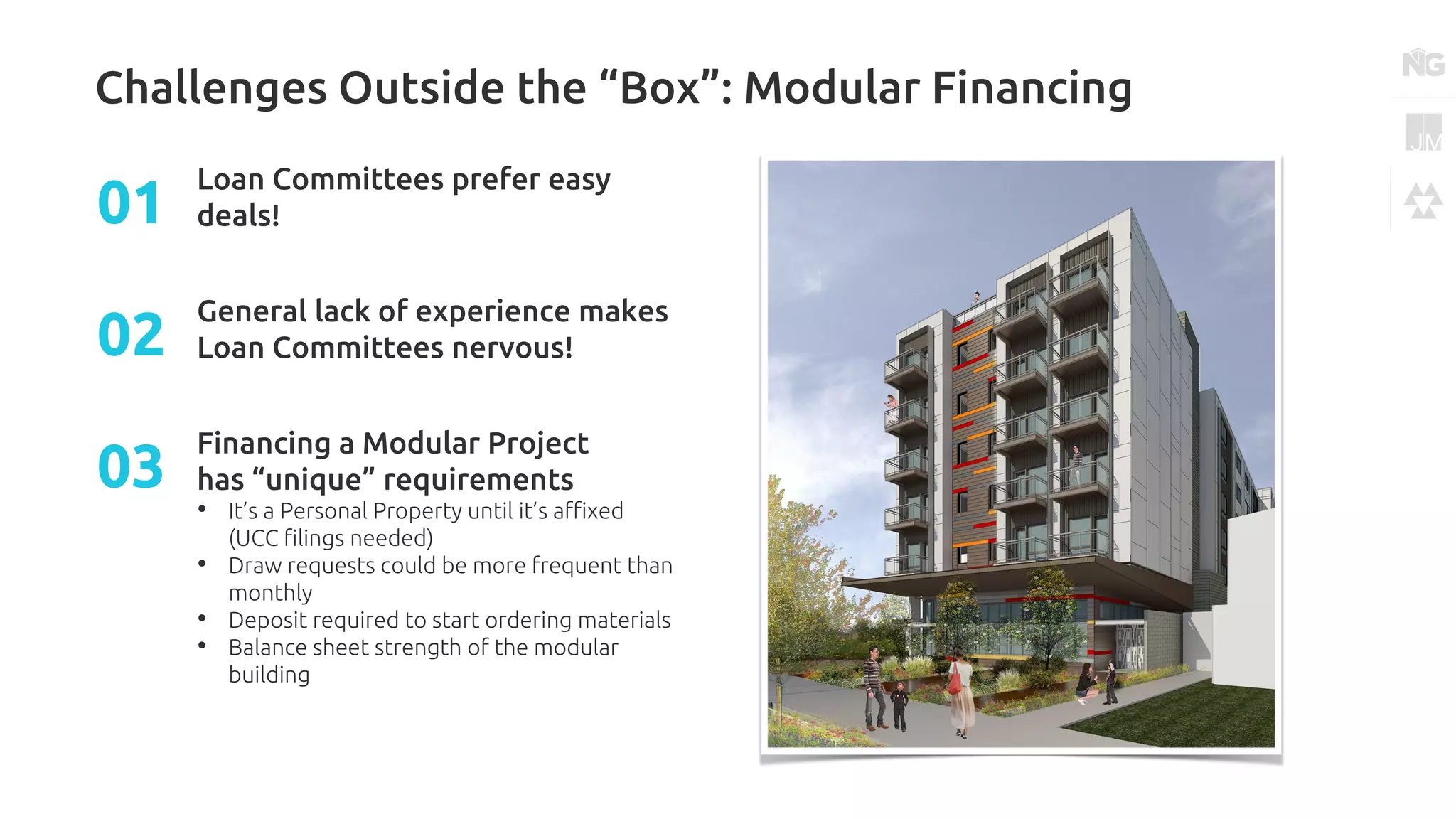

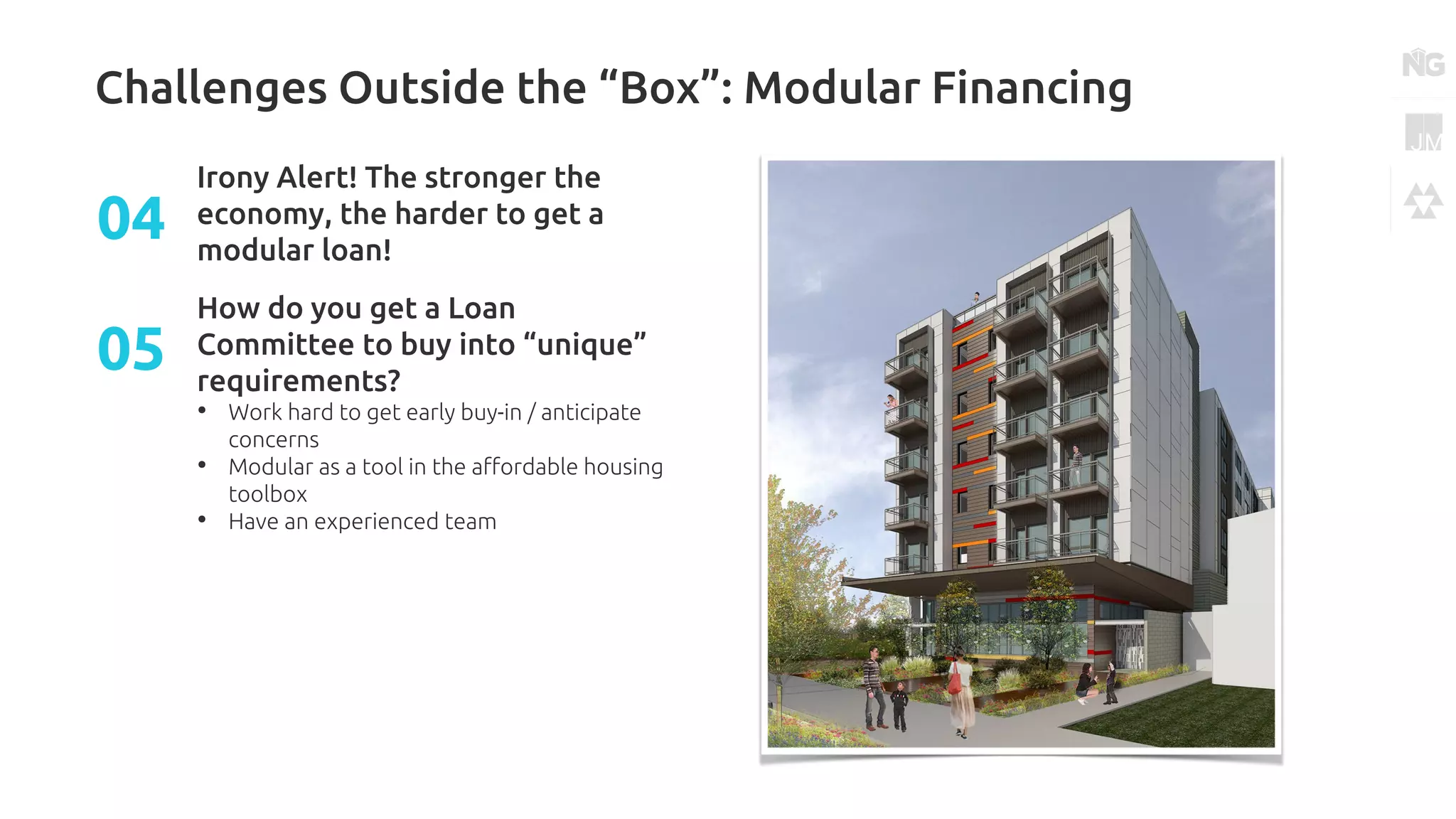

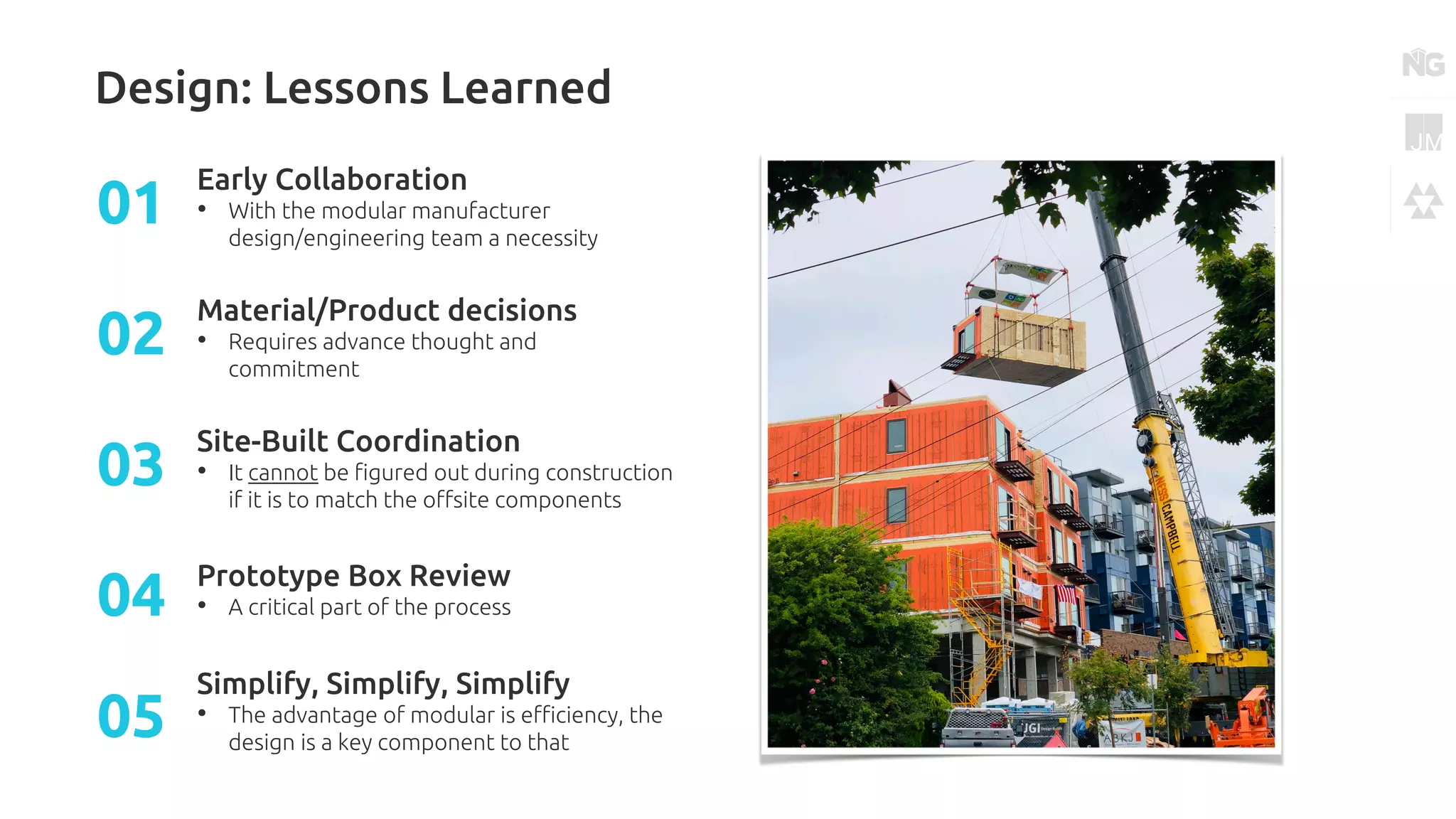

The document is a case study on the modular construction of multi-family housing, specifically the 'Cubix Othello' project, showcasing innovative strategies and benefits of modular building such as cost stability, quality control, and reduced construction waste. It discusses the three phases of a modular project thesis, the benefits of modular technology in meeting sustainability goals, and the importance of early collaboration between teams. The case study also covers challenges in financing and permitting for modular buildings, emphasizing the need for coordinated efforts in design and execution.