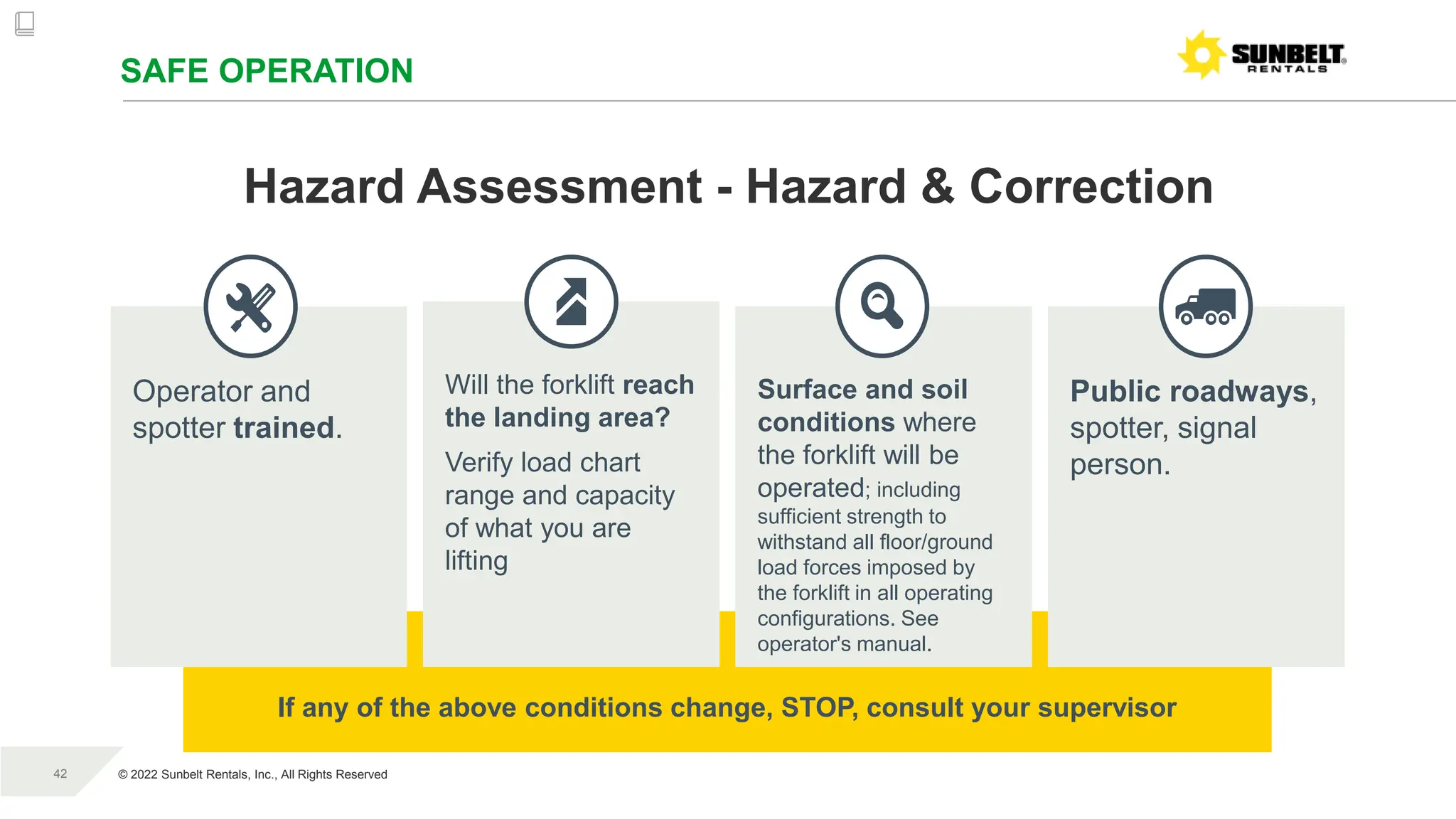

Some potential hazards to be aware of when operating a forklift include:

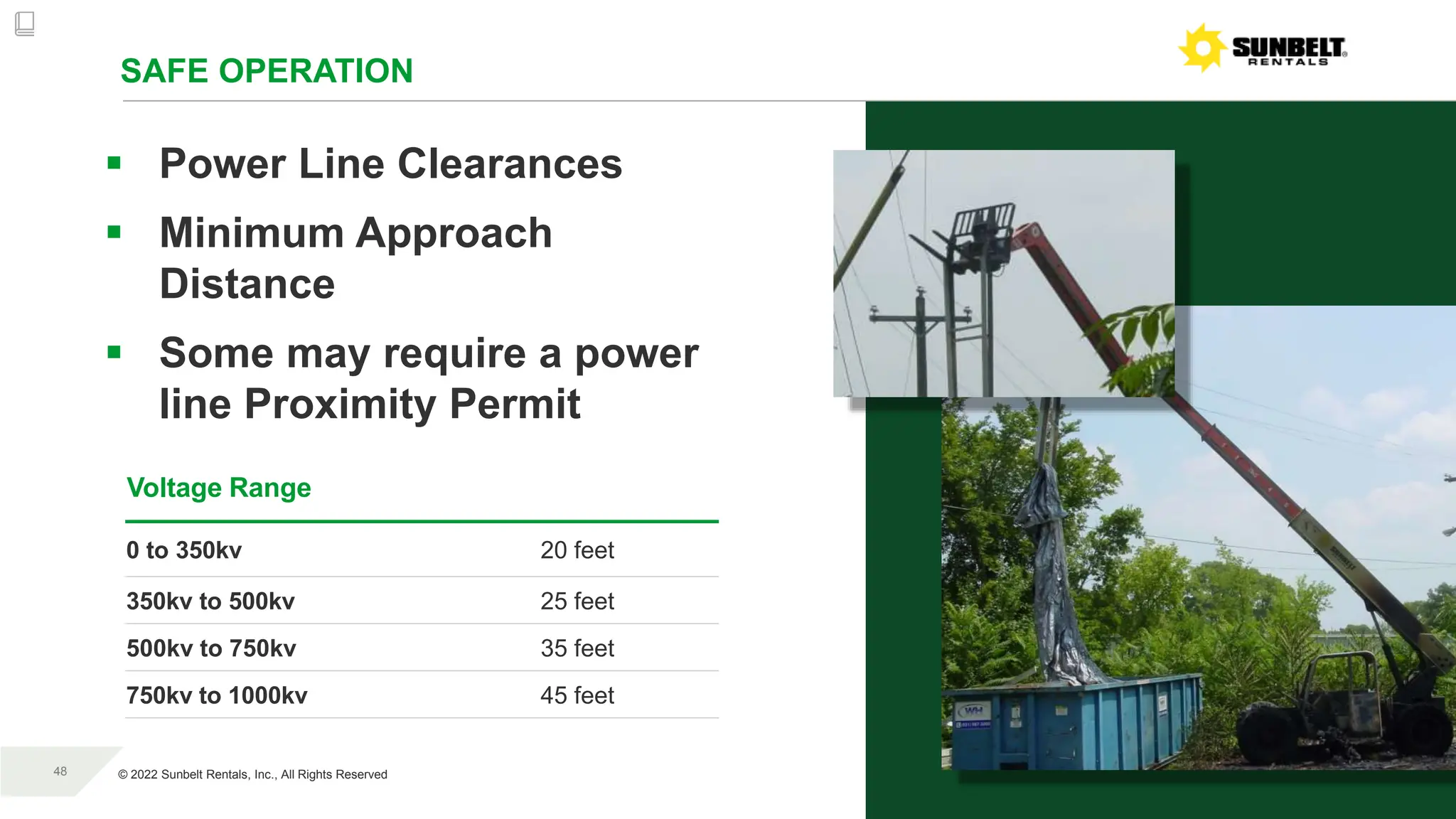

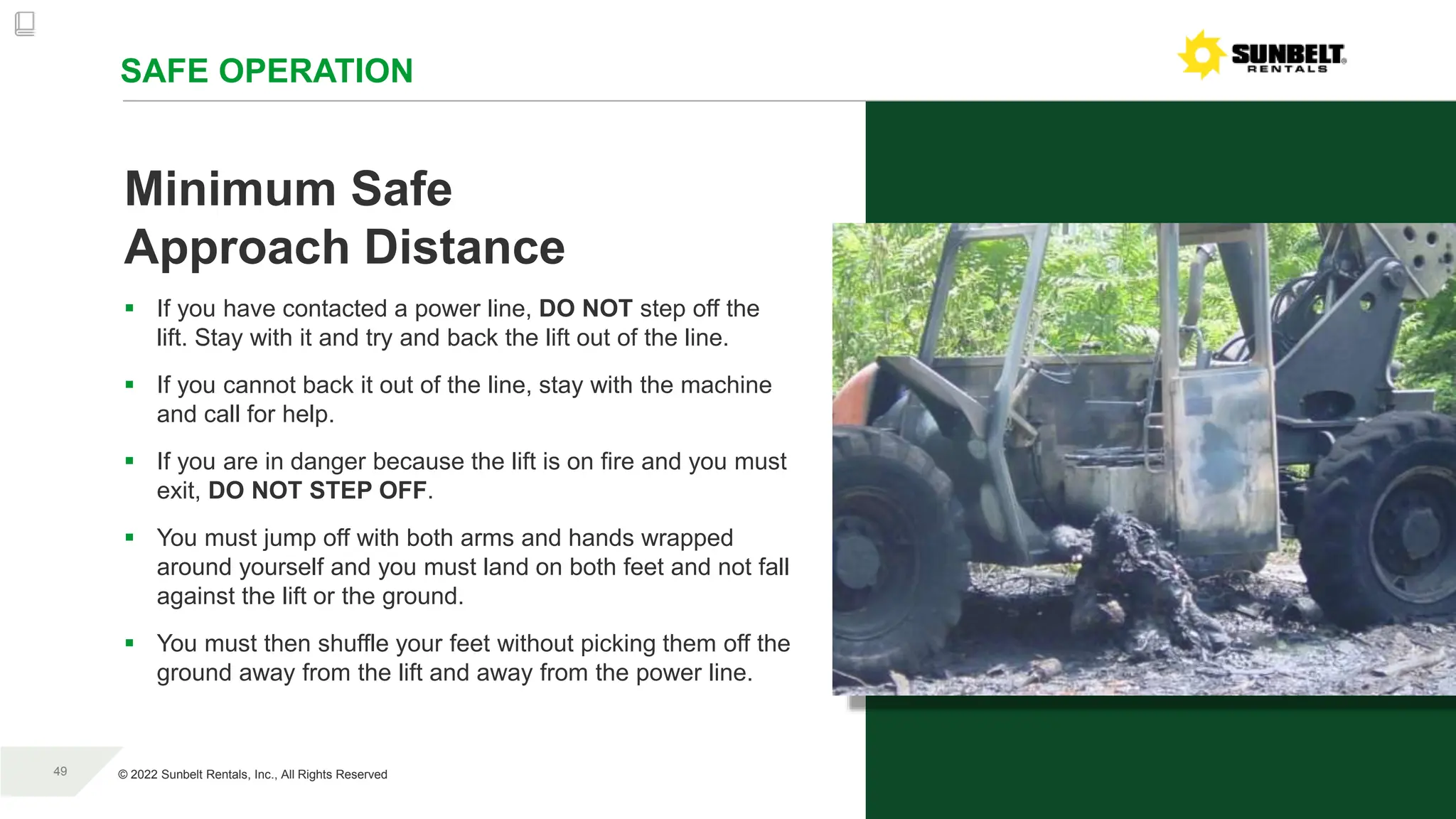

- Overhead hazards like power lines

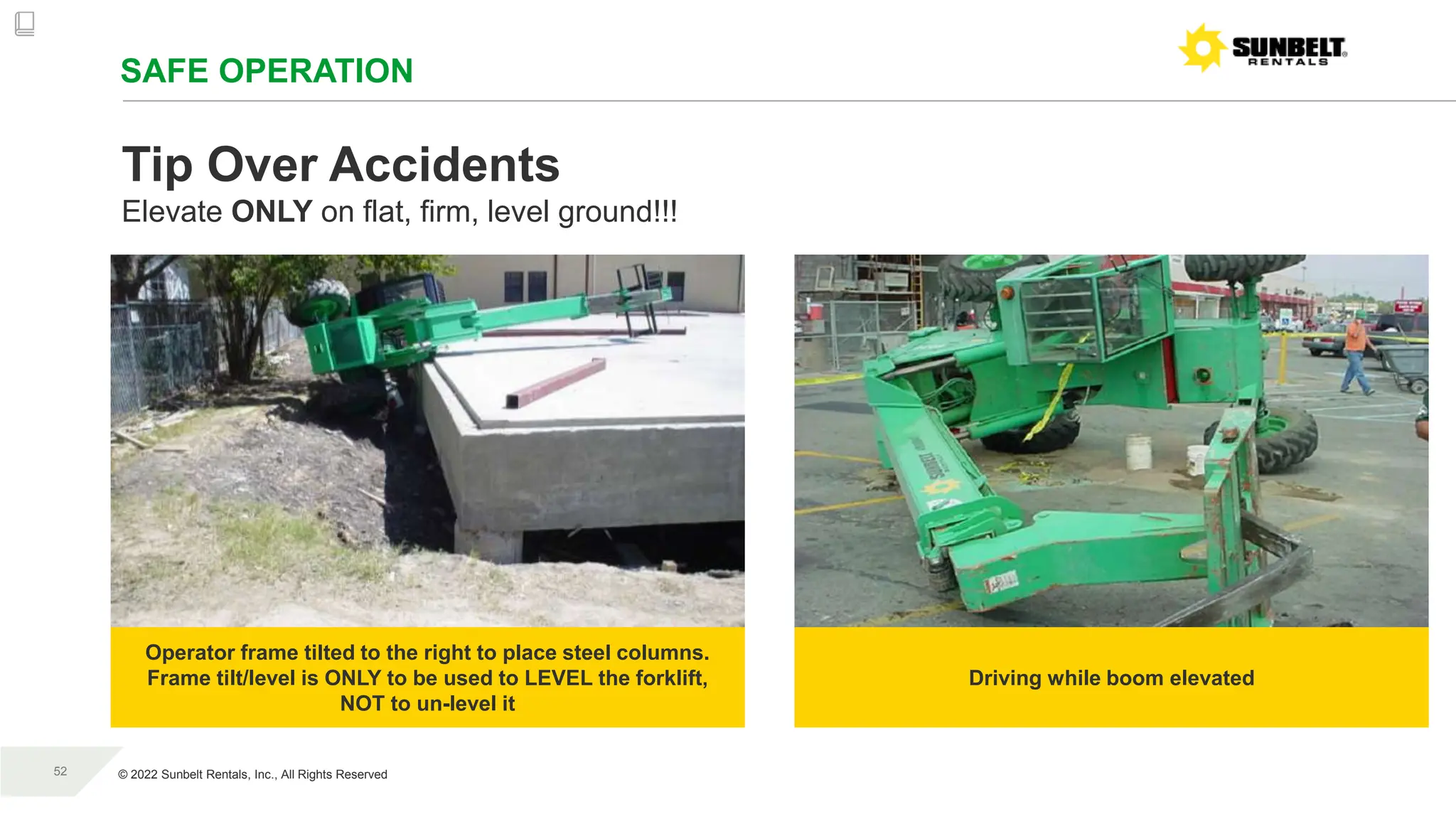

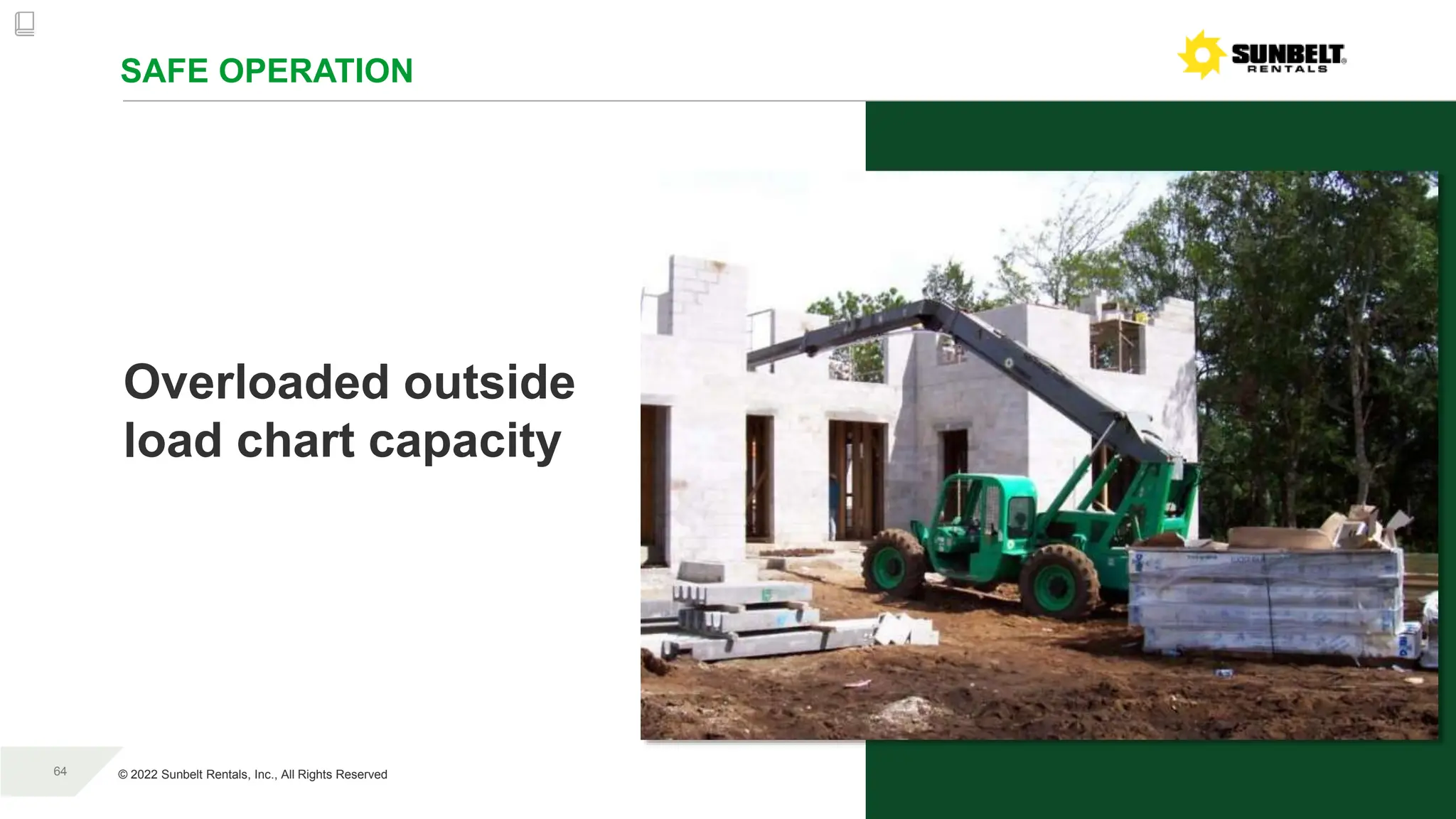

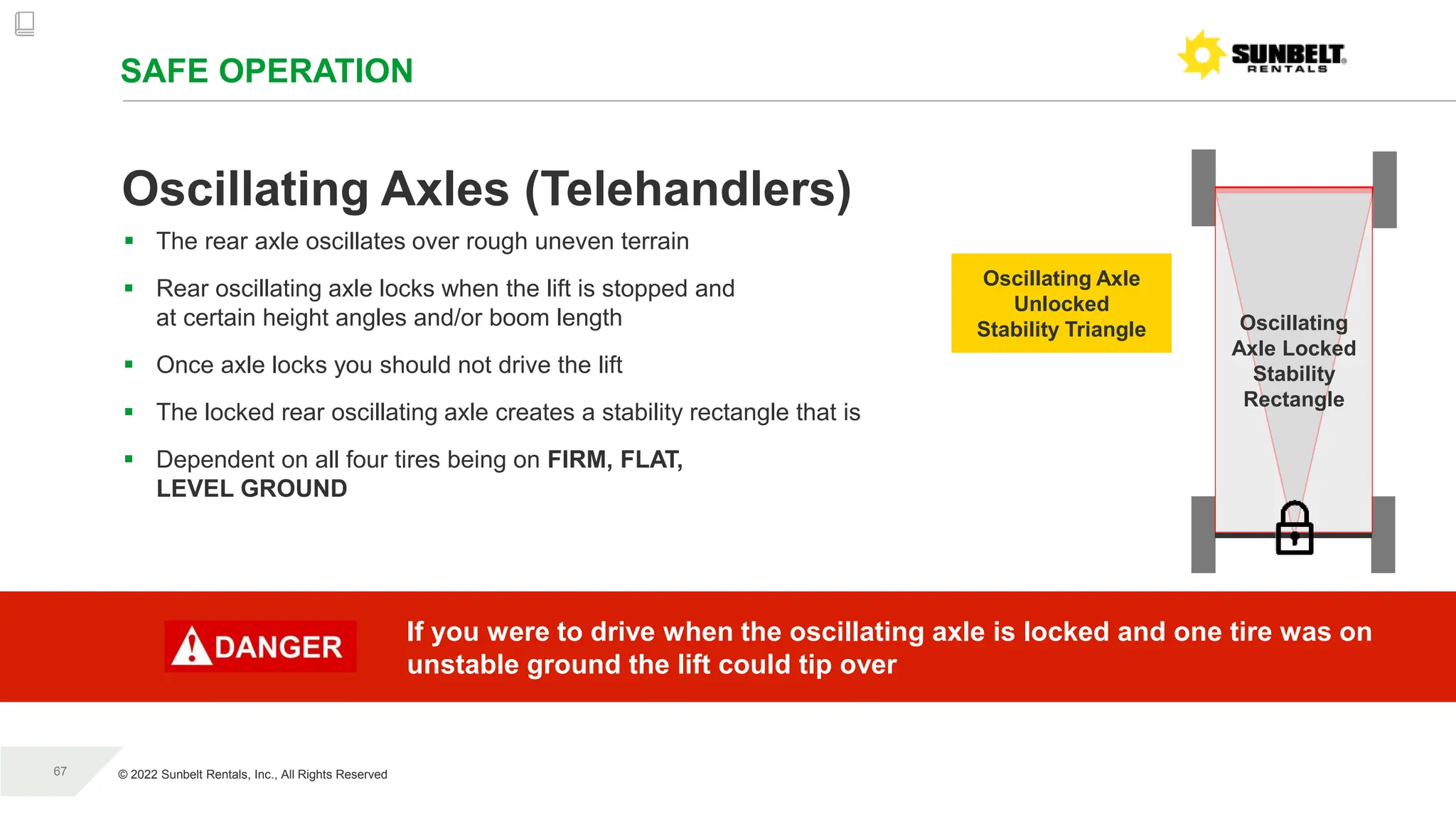

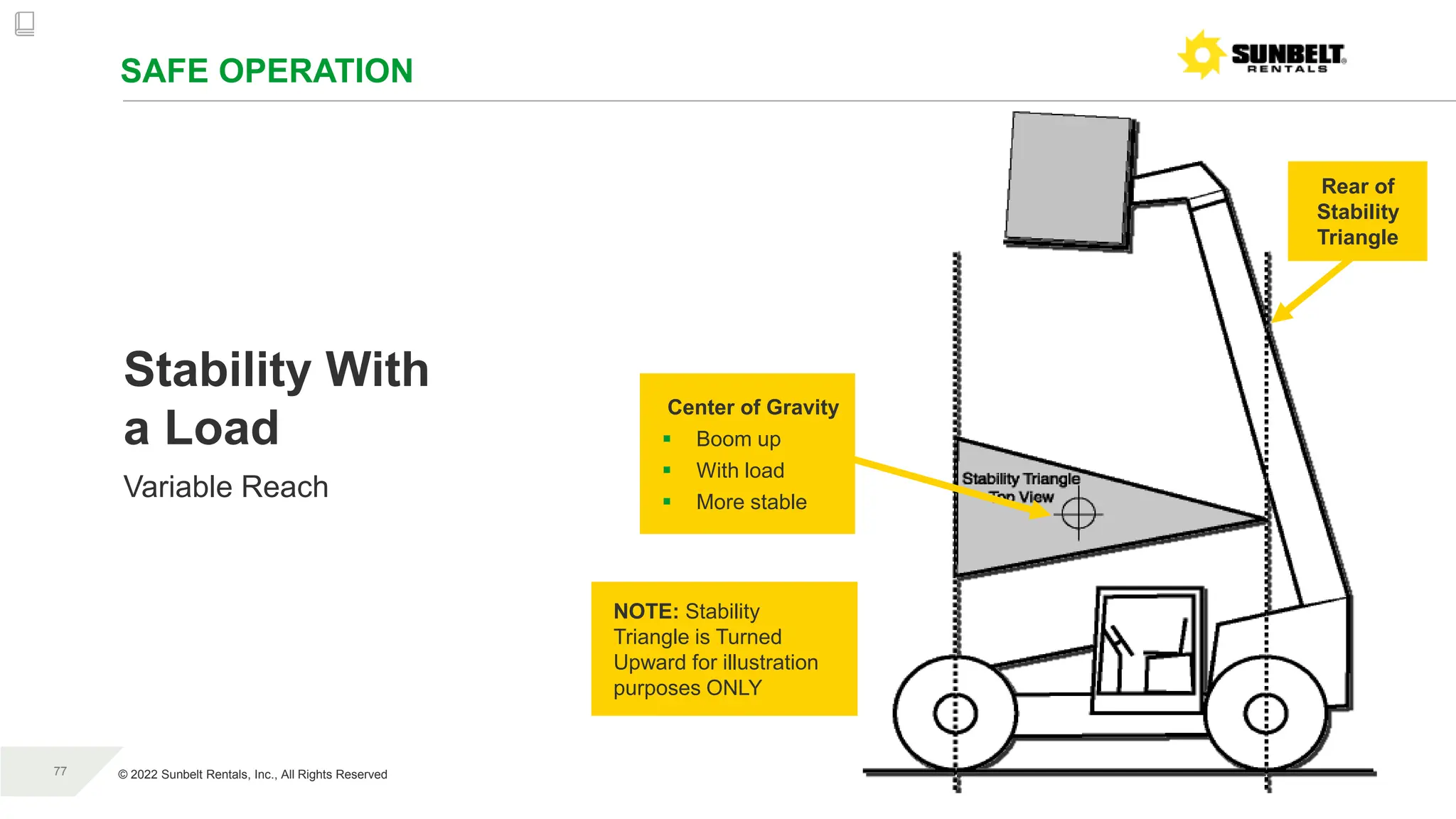

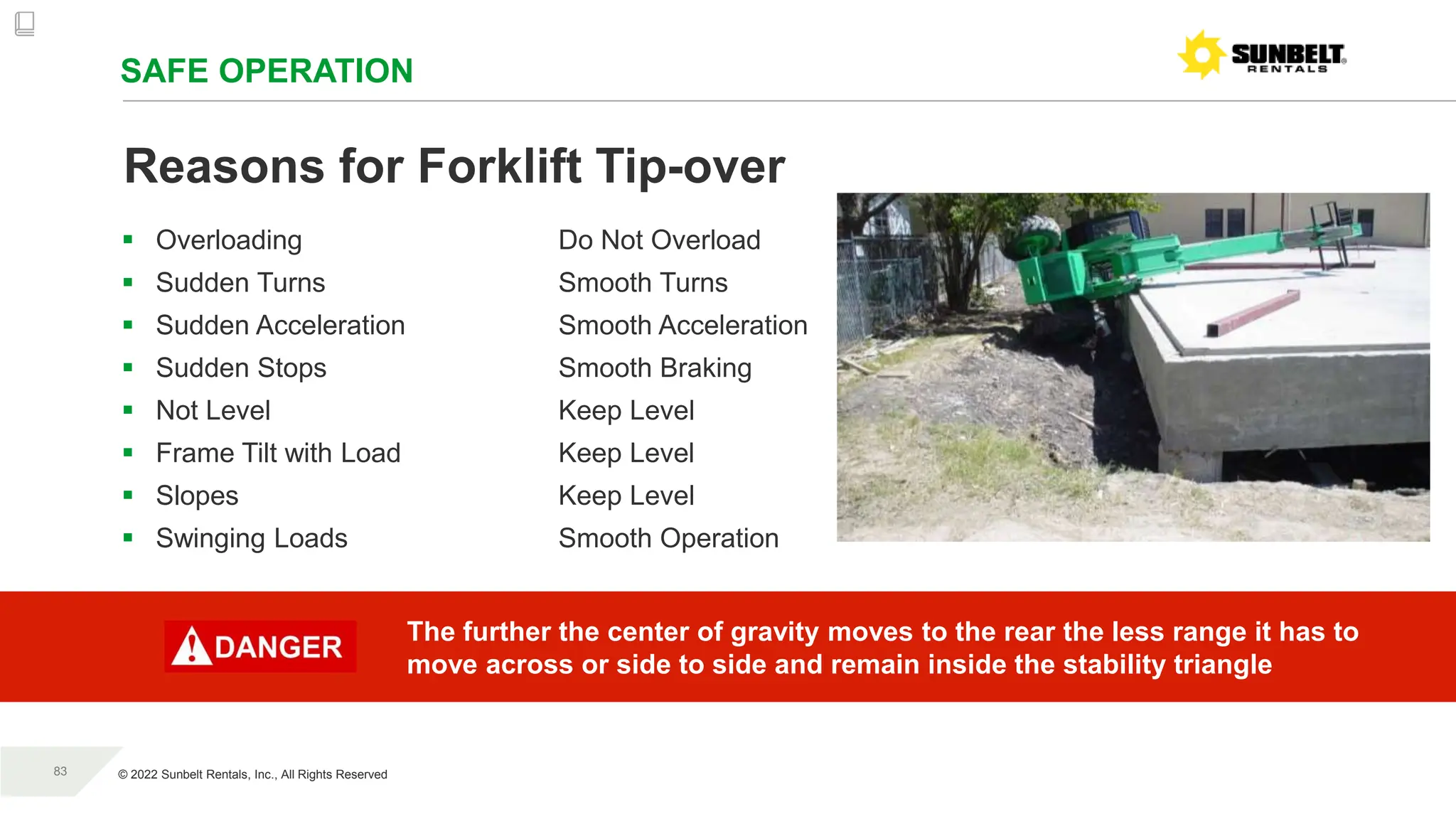

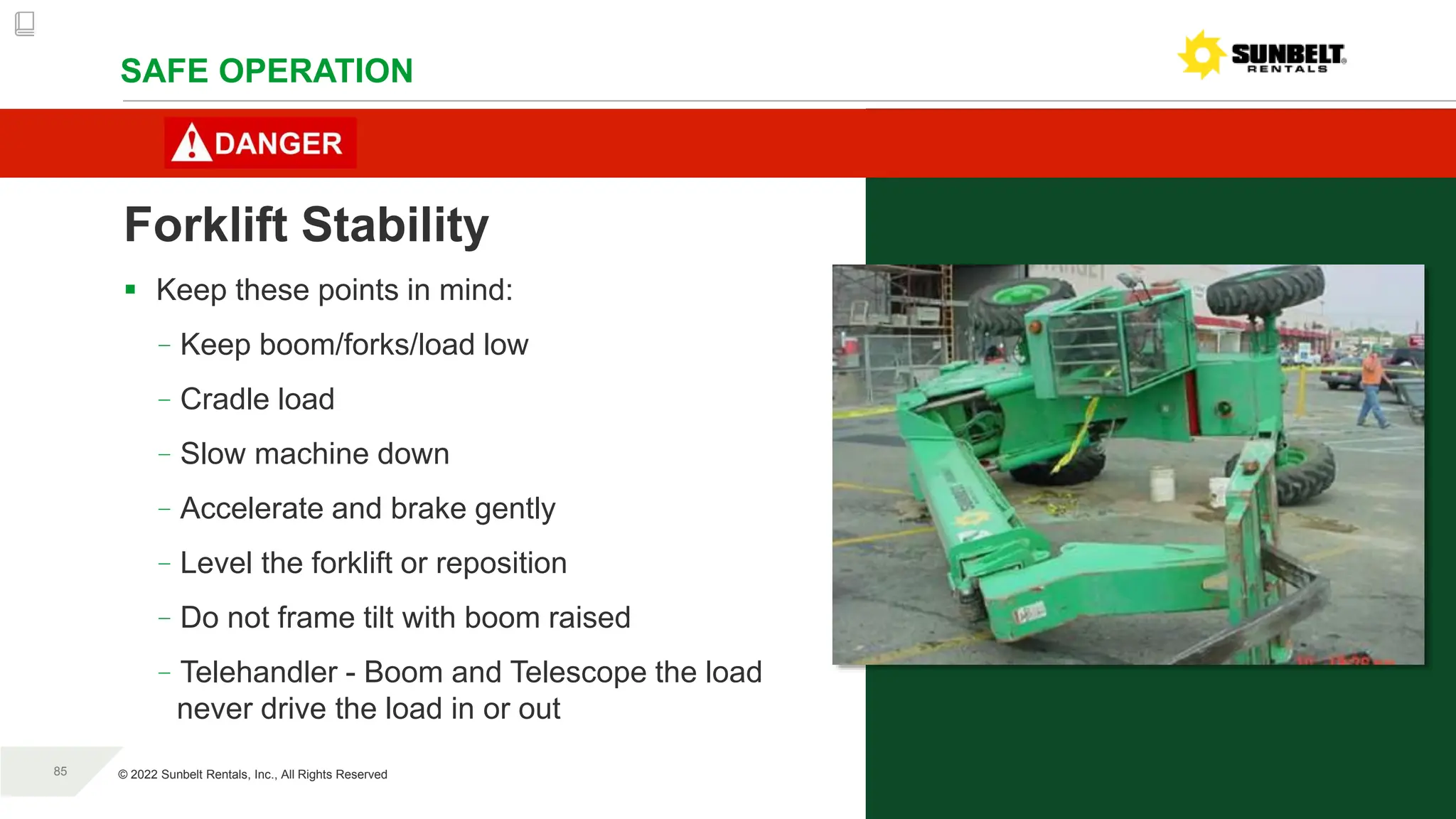

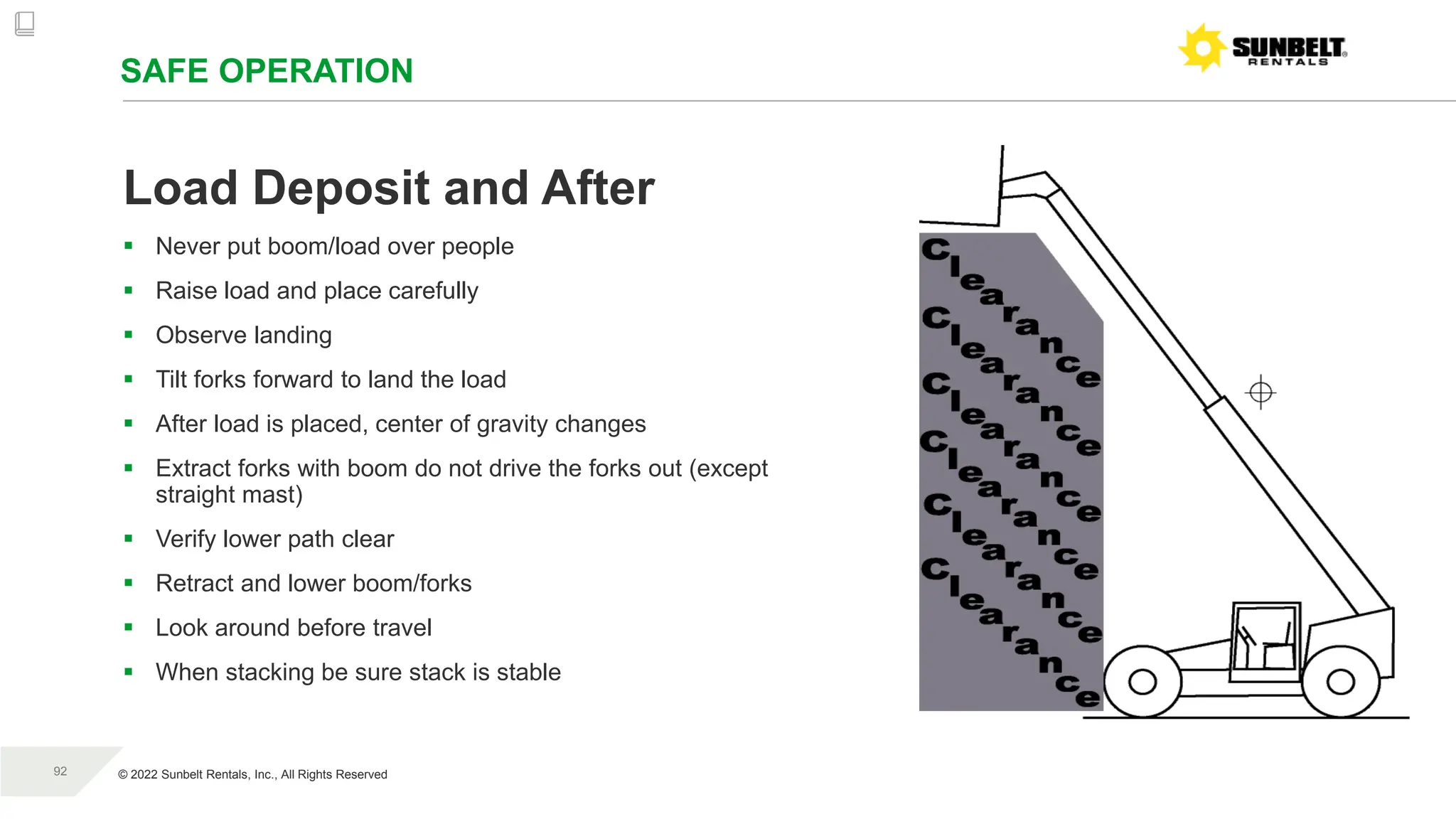

- Uneven or soft surfaces that could cause tipping

- Pedestrians in the operating area

- Other moving equipment in the area

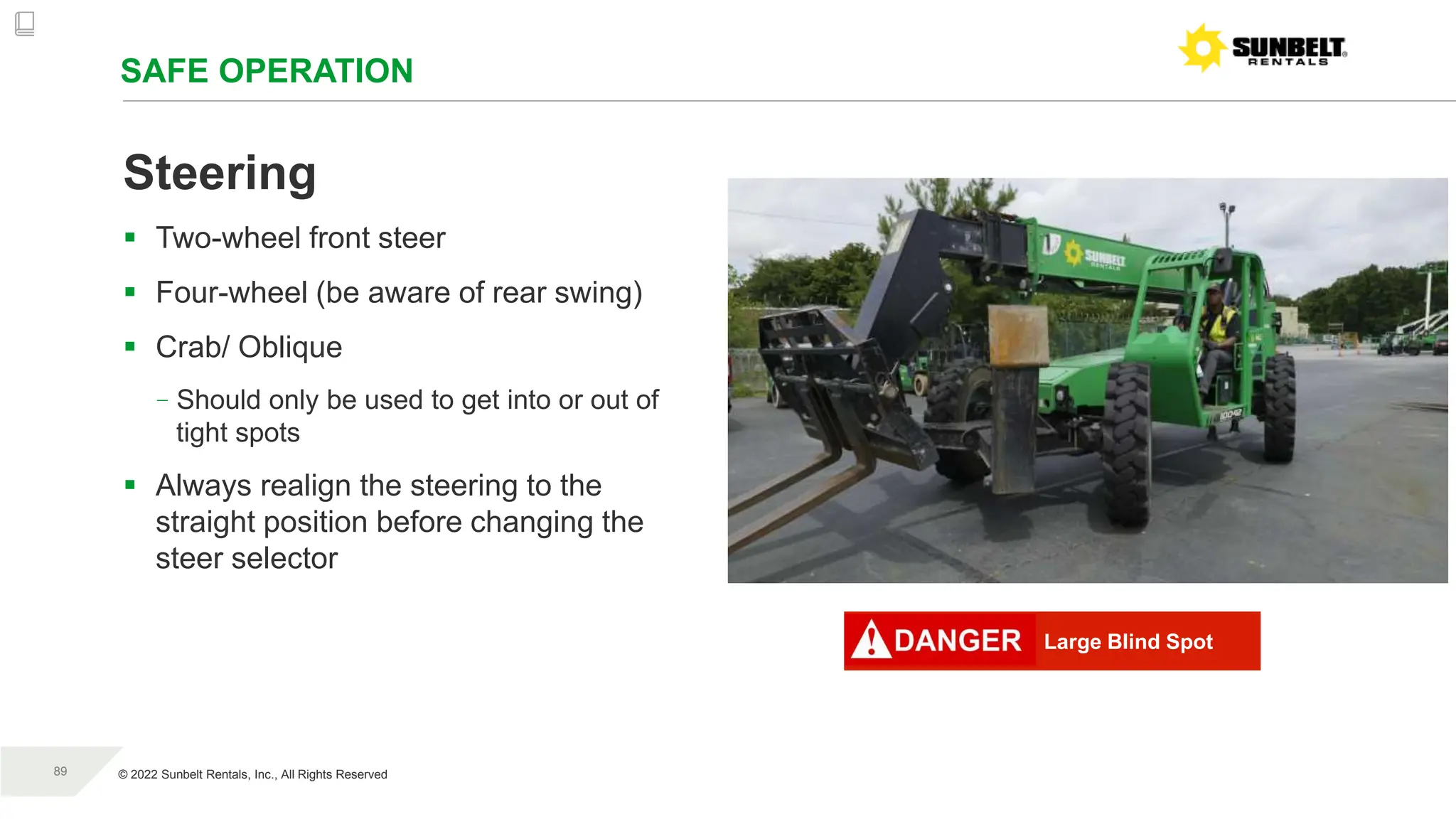

- Inadequate lighting or visibility

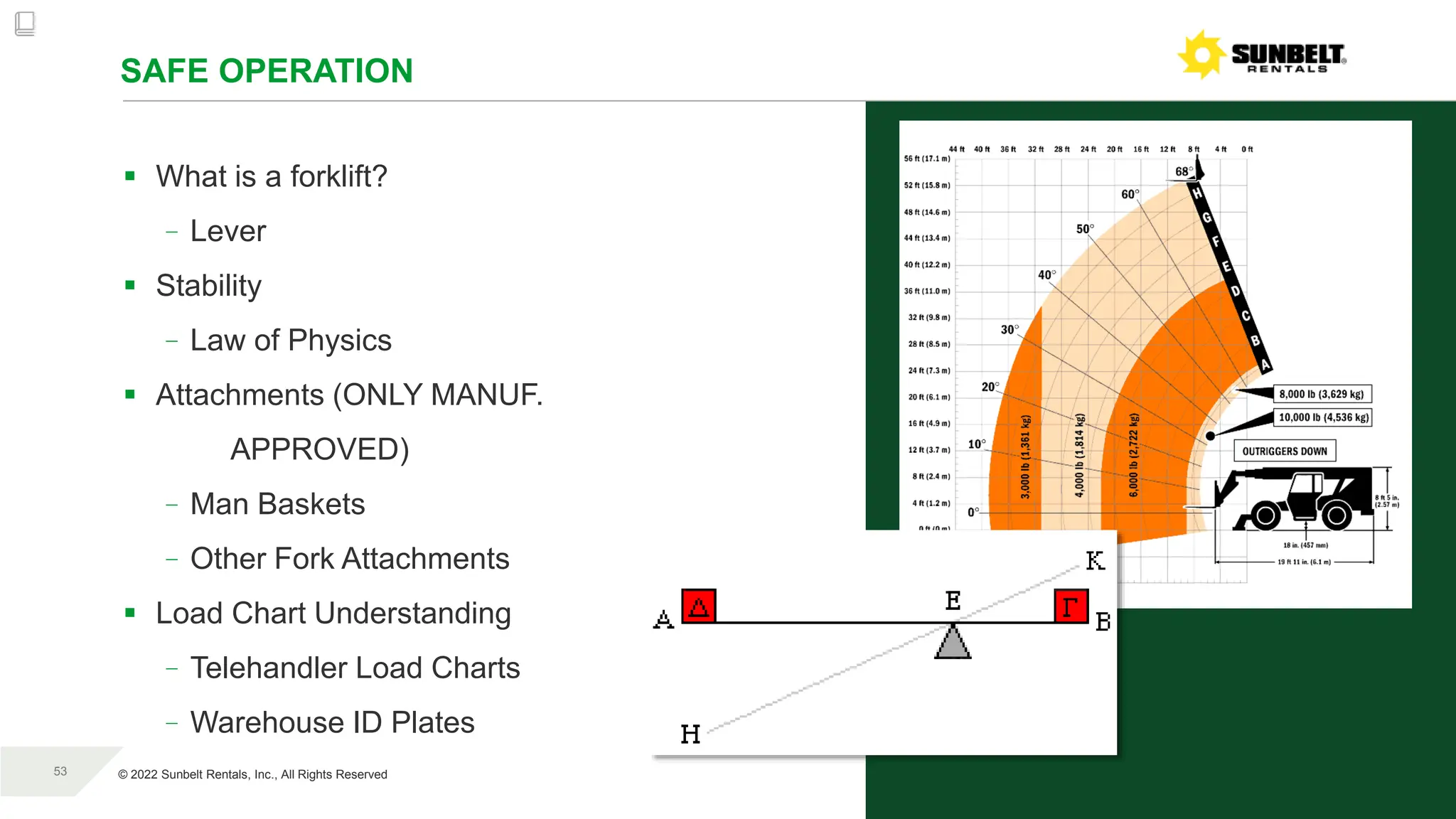

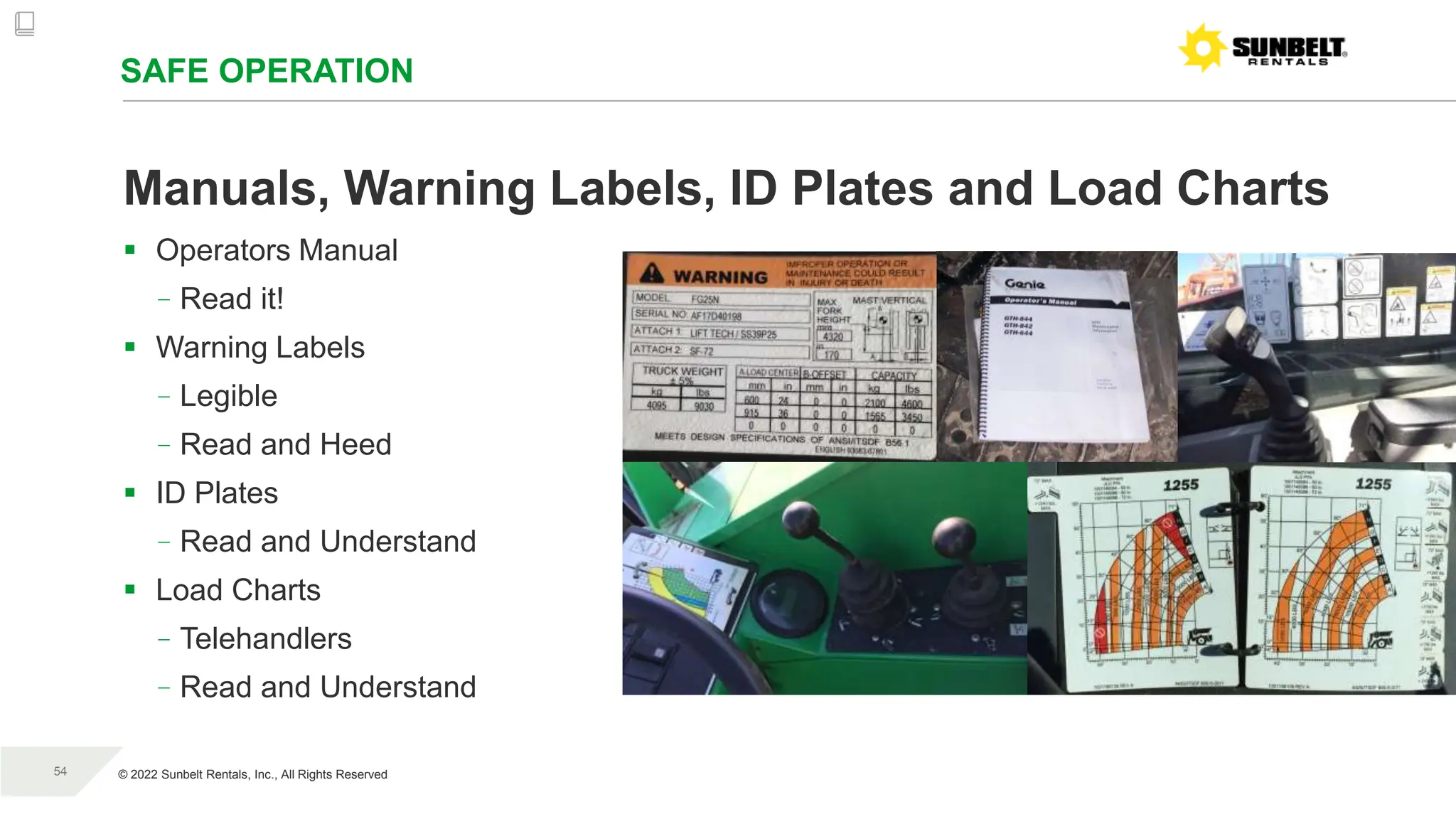

- Unsuitable loads that could become unstable

- Hazardous locations or environments

- Inadequate maintenance of the forklift

- Unsafe driving behaviors like speeding or reckless operation