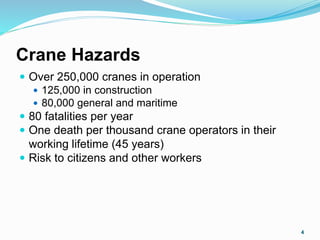

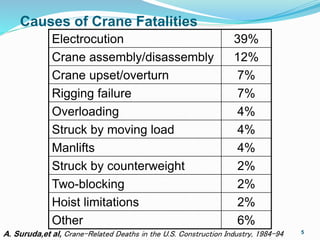

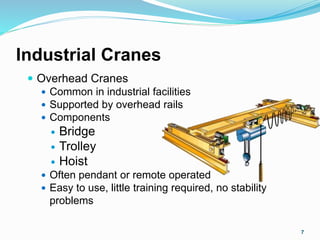

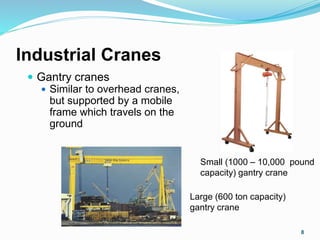

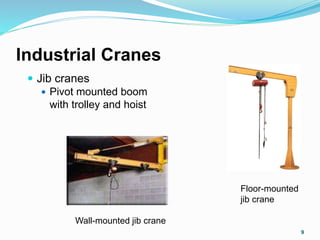

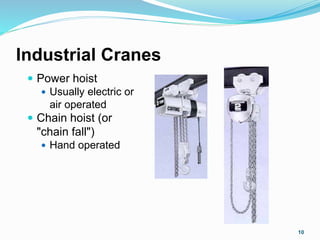

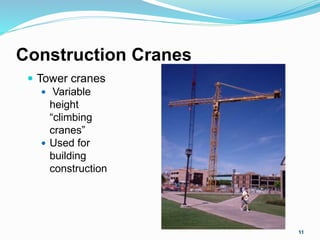

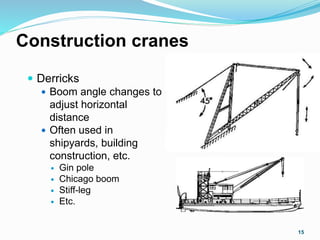

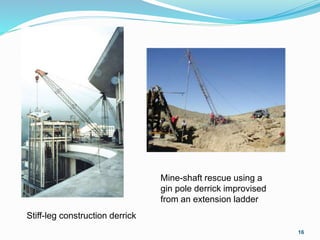

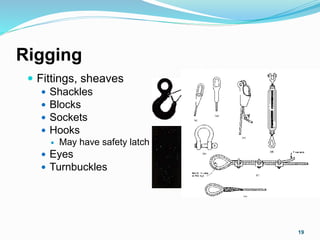

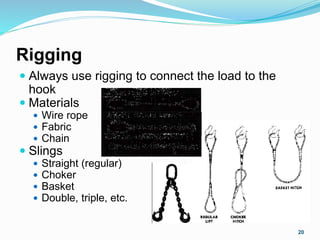

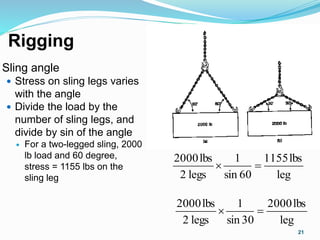

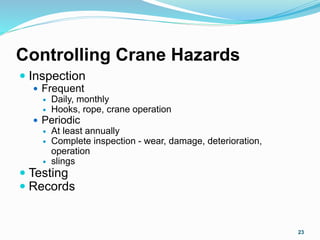

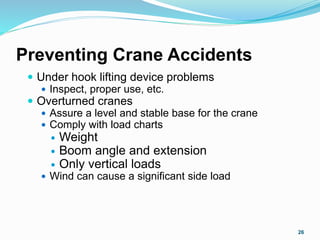

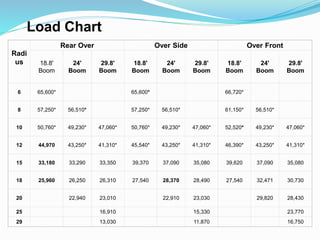

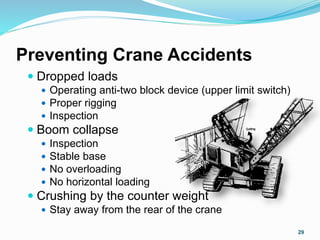

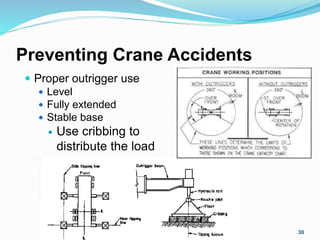

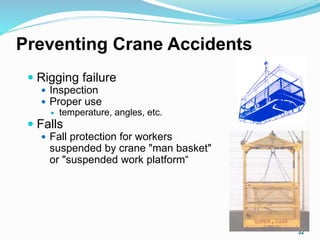

This document provides information on cranes and crane safety. It begins with objectives of becoming familiar with common crane types, rigging, and controlling hazards. It then outlines and describes industrial cranes like overhead, gantry, and jib cranes and construction cranes like mobile, tower, and derrick cranes. It discusses rigging components and the importance of sling angle. The document also covers controlling hazards through inspections, training, preventing power line contact, ensuring crane stability, and following load charts. It provides statistics on crane accidents and their leading causes.