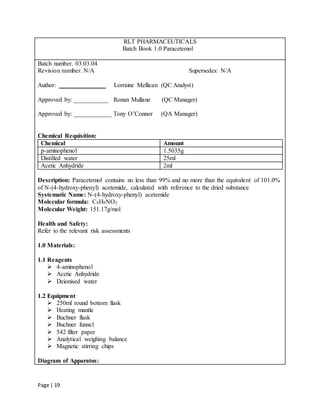

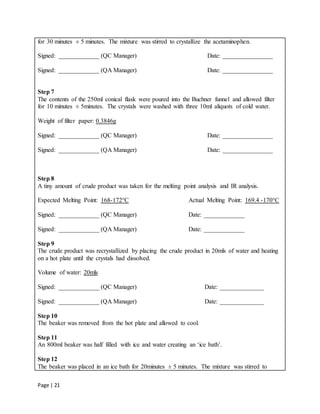

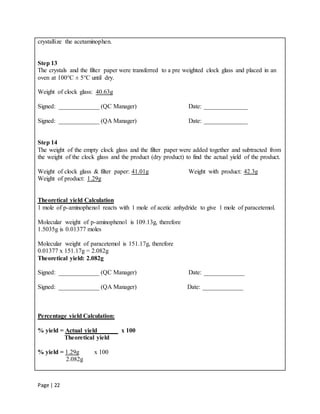

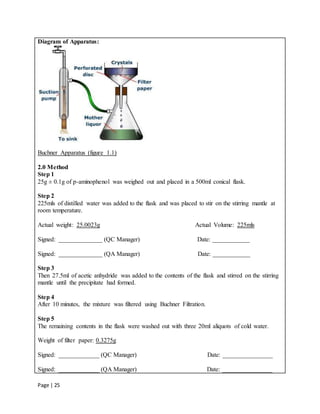

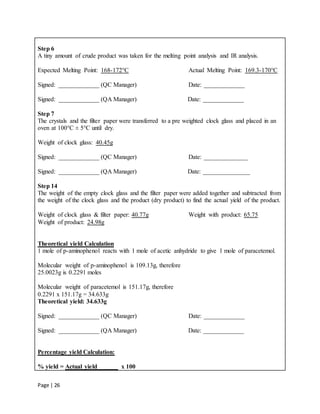

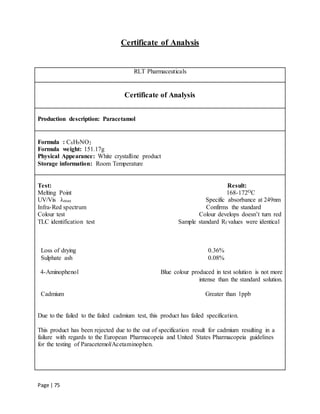

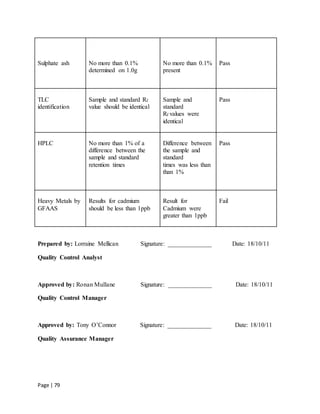

The document discusses the synthesis, history, uses, and metabolism of paracetamol. It aims to synthesize paracetamol from 4-aminophenol and acetic anhydride and test it under various analyses. Paracetamol was discovered in the late 19th century and became popular as a pain reliever and fever reducer. It works by inhibiting prostaglandin production in the brain and has few side effects, making it suitable for both children and adults. The standard adult dosage is 1 gram per dose and no more than 4 grams per day to avoid potential liver damage.