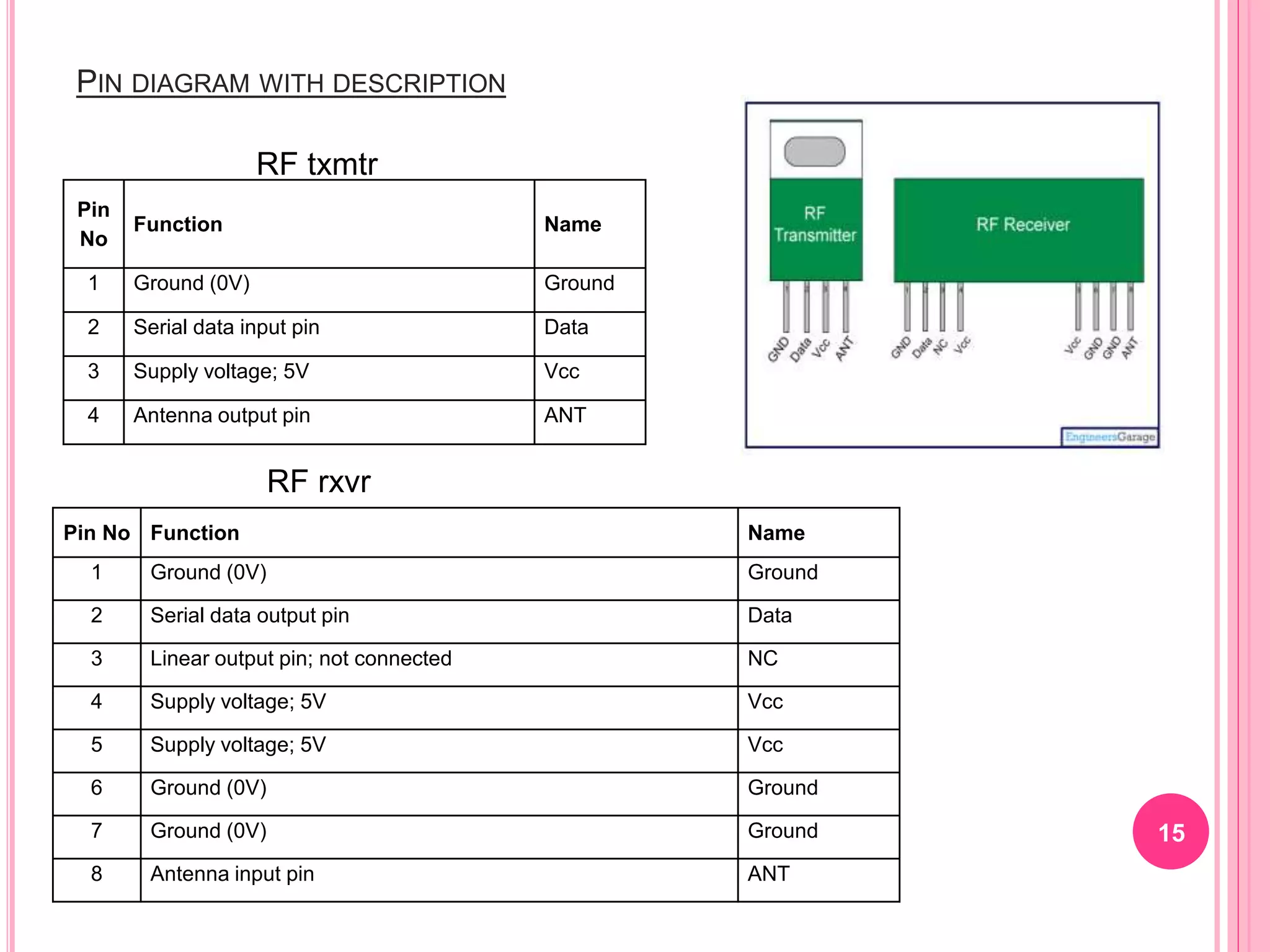

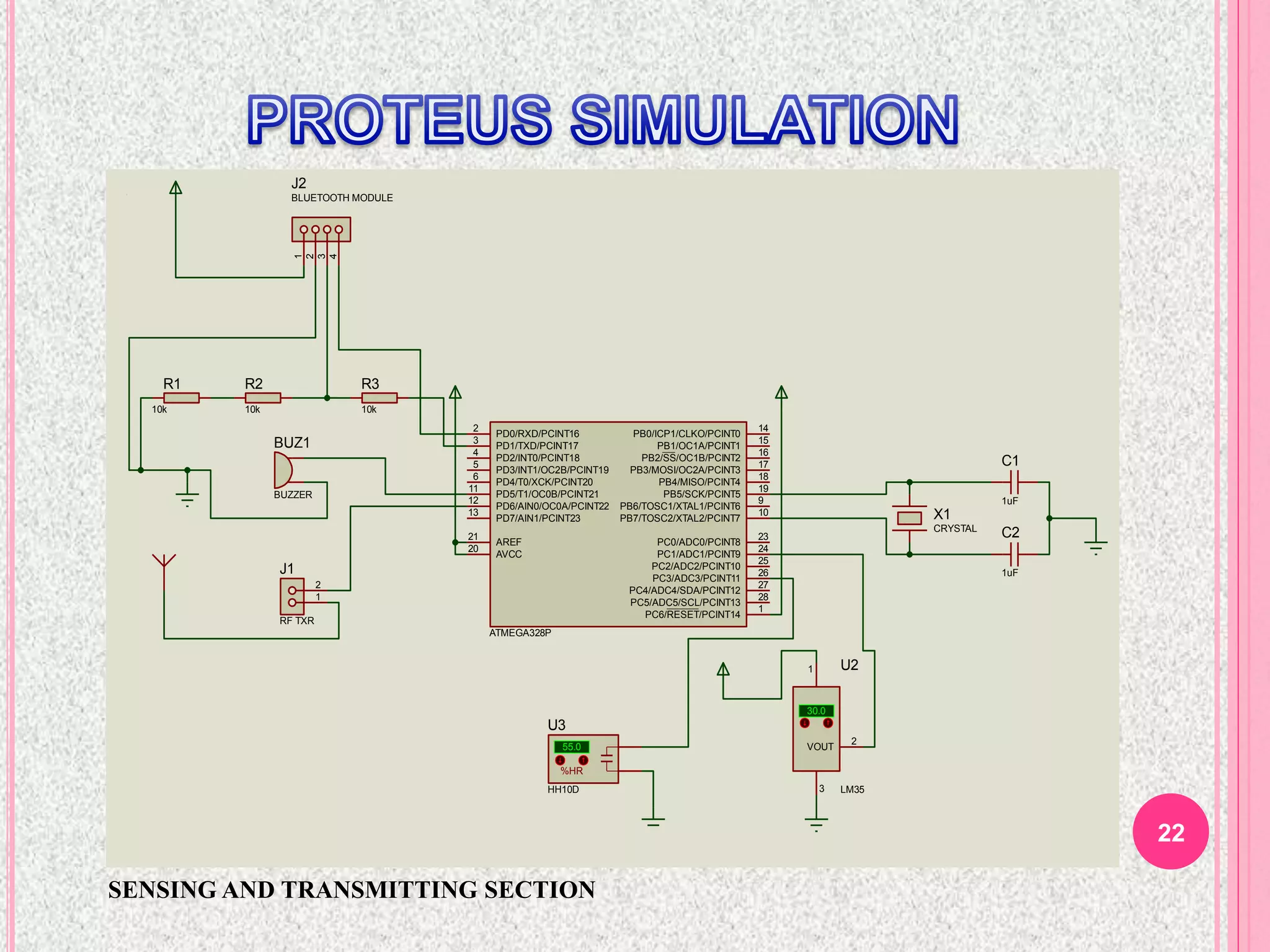

This document describes a mine-worker protection system that uses sensors to continuously monitor temperature, pressure, gases, and the location of underground miners in real-time. It collects sensor data using a microcontroller and can activate safety measures like exhaust fans, coolers, or sprayers if dangerous conditions are detected. The system aims to provide economical and reliable monitoring to improve safety in mining industries where accidents remain common.